Baking machine for energy-saving tube

A technology for energy-saving lamp tubes and baking machines, which can be used in the manufacture of tubes/lamp screens and the application of luminous paints, etc. It can solve the problems of high production costs, power consumption, labor consumption, etc., and achieve improved heat utilization efficiency and energy saving Energy and the effect of reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

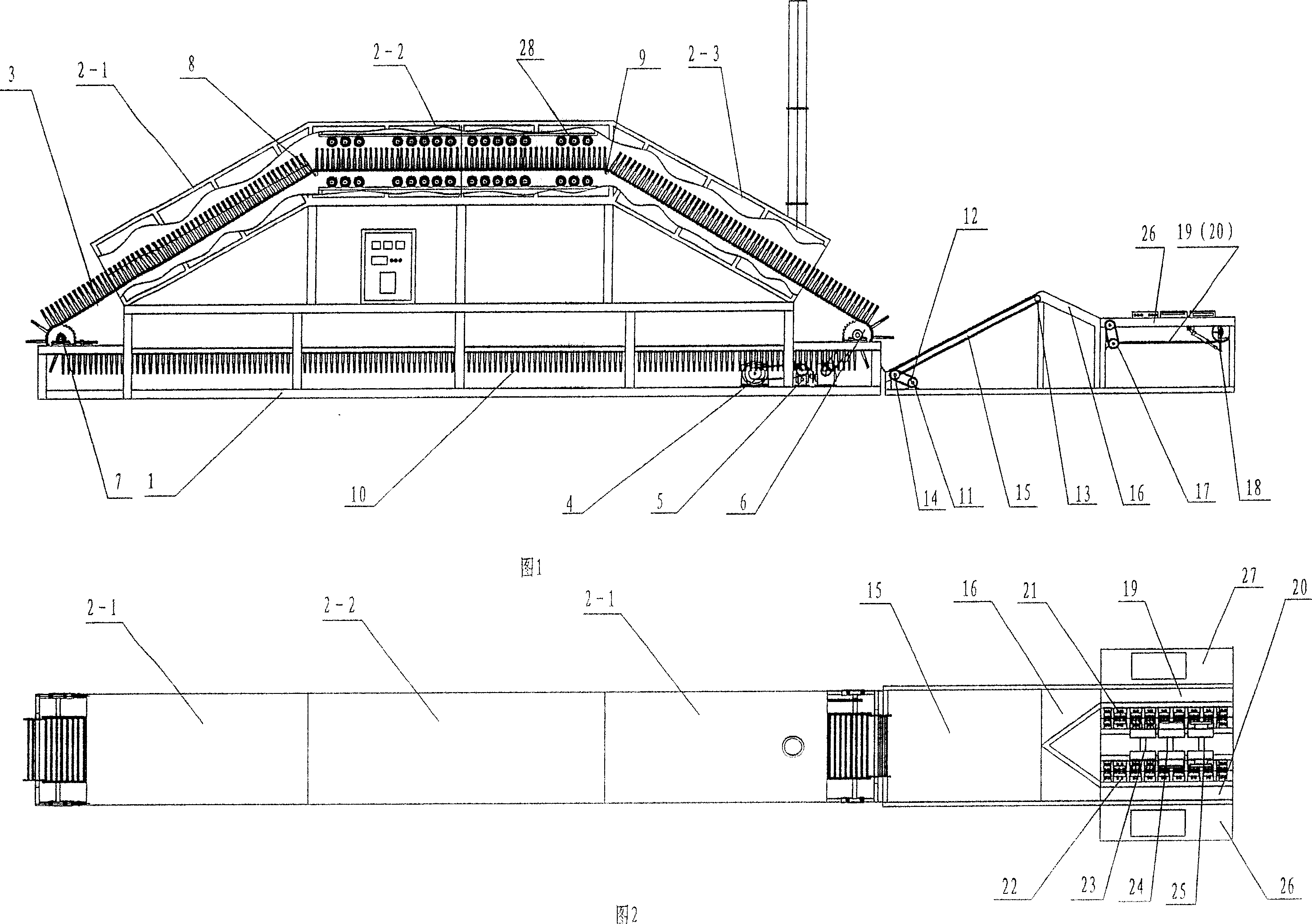

[0012] As shown in Figures 1 and 2, the oven 2 is arranged on the upper end of the frame 1, and the oven 2 is composed of a front section 2-1, a middle section 2-2 and a rear section 2-3, and the front section 2-1 and the rear section 2 -3 are respectively connected to the two ends of the middle section 2-2, the middle section 2-2 of the oven is arranged horizontally, and is located at the highest point of the entire oven 2, the front section 2-1 and the rear section 2- are arranged obliquely, away from Both ends of the middle section 2-2 are gradually approaching the ground respectively.

[0013] In the baking oven 2 and on the frame 1, an endless chain transmission device consisting of an endless chain 3, a main drive motor 4, a two-stage reduction device 5, a transmission gear 6 and three reversing gears 7, 8, and 9 is arranged. Evenly fixedly connect the lamp tube hanger 10 on the ring chain 3 . The upper and lower layers of electric heating tubes 28 are arranged in the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com