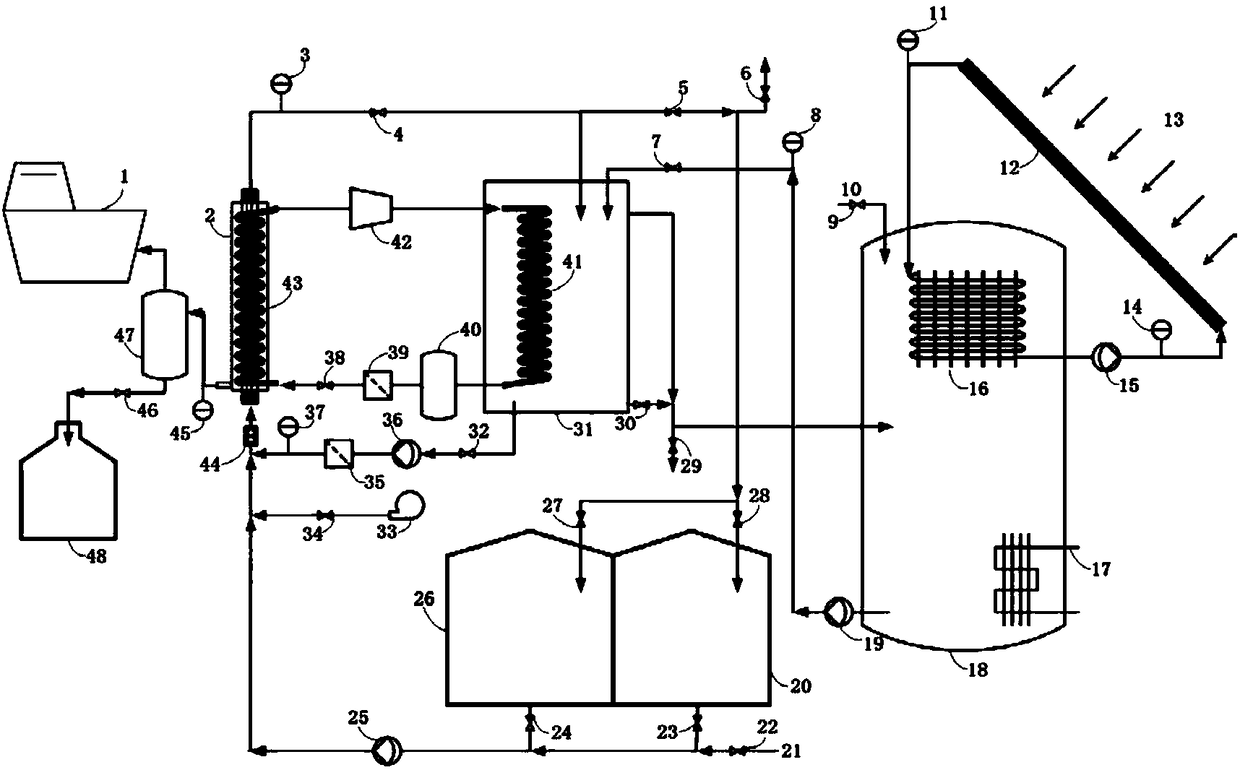

A solar energy film distillation system combining heat pump technology

A technology of solar film and distillation system, applied in heat recovery system, film technology, total evaporation, etc., can solve the problems of high energy consumption and operating cost, high overall energy consumption, improve heat energy utilization efficiency, high system integration, Easy to clean and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

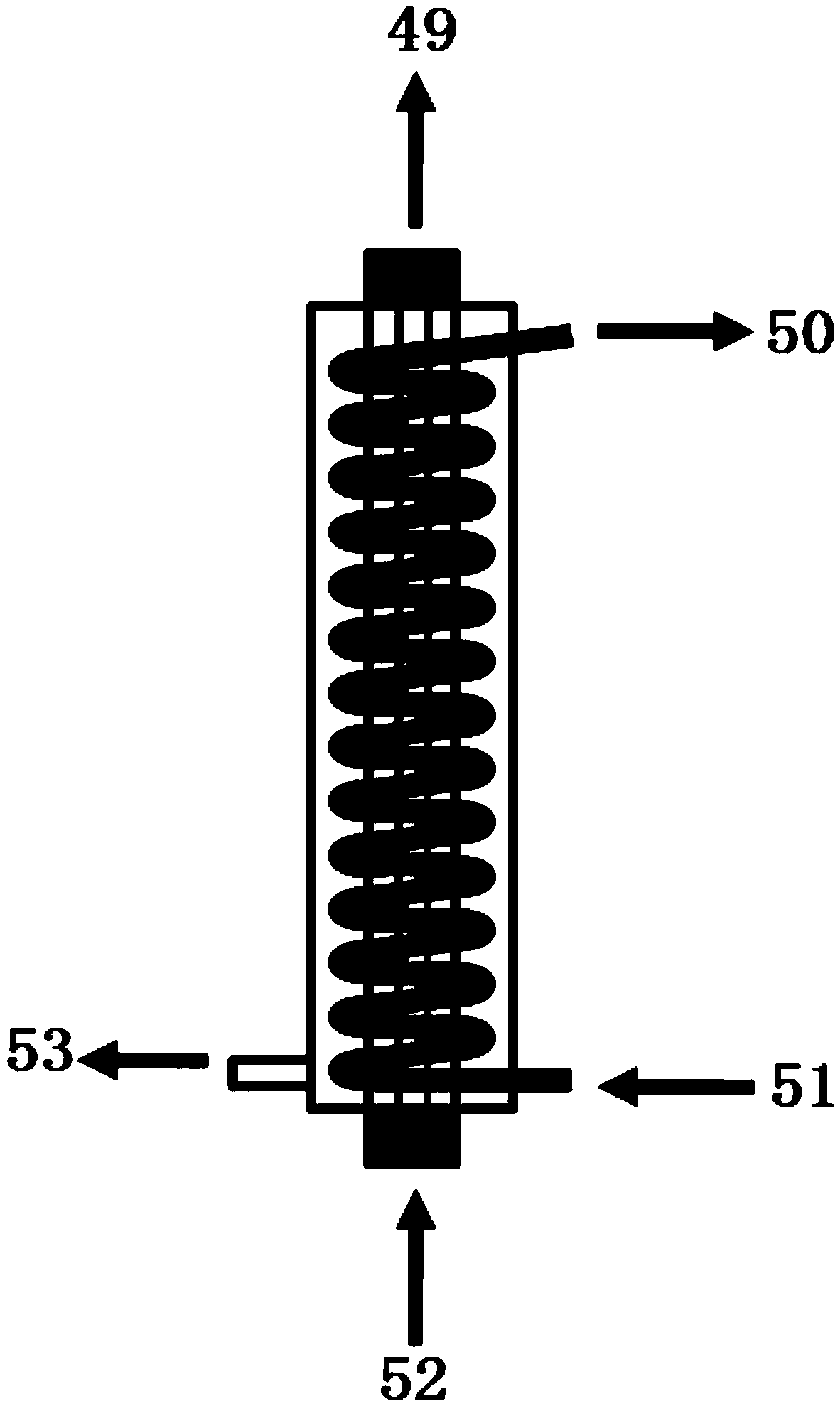

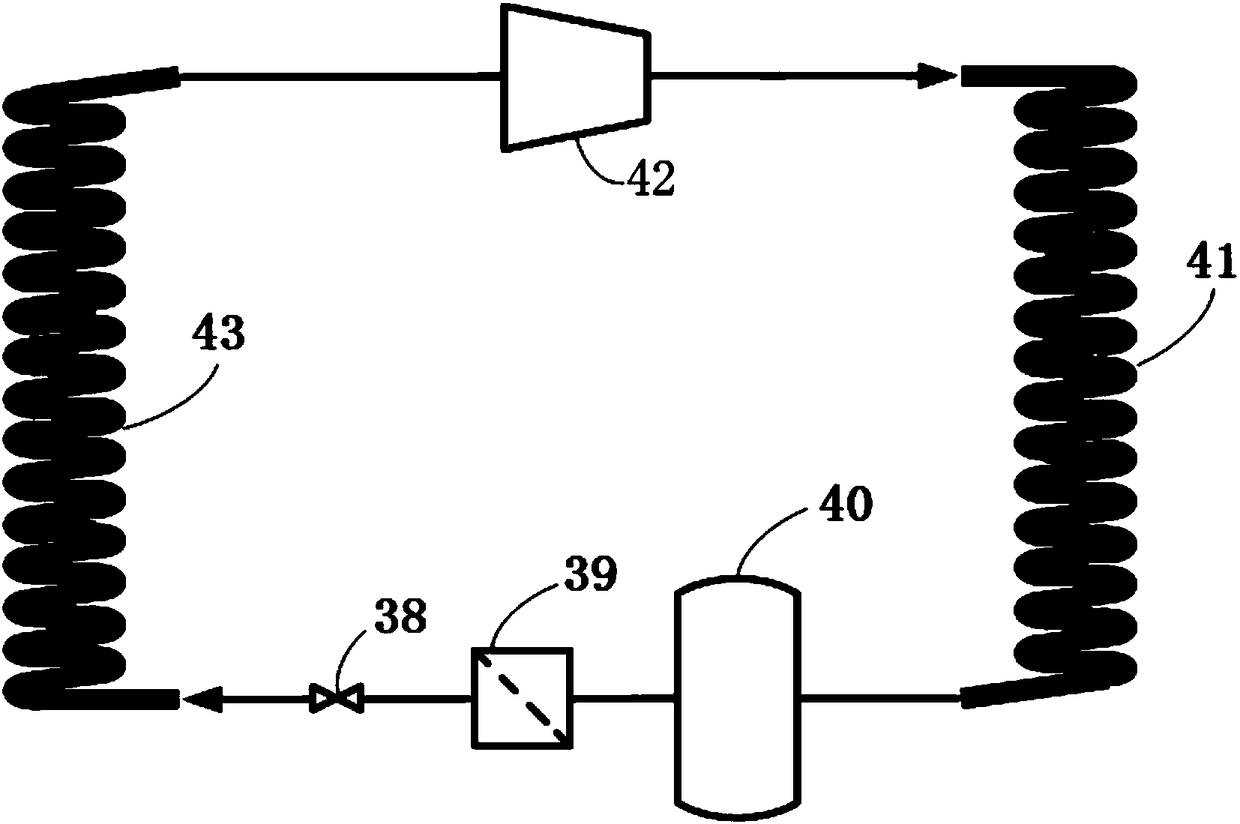

Method used

Image

Examples

Embodiment 1

[0056] Most areas in my country belong to category 3 and above sunshine areas (areas where solar energy can be utilized), and the annual sunshine hours are more than 2,000 hours. Therefore, the heat pump-solar membrane distillation system has broad application prospects, especially in areas where fresh water resources are scarce but brackish water is abundant, and the system can be used to prepare drinking water and domestic water. In addition, the heat pump-solar membrane distillation system is used to treat industrial high-salt wastewater. The produced water can be used as circulating water and industrial water, and the concentrated concentrated water can enter the evaporation and crystallization unit to meet the treatment requirements for near-zero discharge of high-salt wastewater. .

[0057] In a city in my country's Type 3 sunshine area, under typical sunny weather conditions in summer. The intensity of solar radiation gradually increases from 8:00 a.m. to the strongest...

Embodiment 2

[0065] In a city in the third type of sunshine area in my country, under the typical cloudy weather in summer. The solar radiation intensity is very low, and the total daily solar radiation is less than 8MJ m 2 d -1 . The outdoor ambient temperature is between 30-34°C.

[0066] The water temperature in the water tank 18 varies with the intensity of solar radiation, and the temperature range is between 50-60°C. At this time, it is necessary to use the electric heating rod 17 to auxiliary heat the raw water. Use reverse osmosis concentrated water with a conductance of 80000μs / cm as the raw water, and when the temperature of the raw water rises to 80°C, the flow rate of the raw water in the raw water tank 31 is controlled by the rotameter 44 to be 250L·h -1 , the temperature of the raw material liquid before entering the evaporation zone is between 70 and 80 °C, and the continuous operation is 12 hours a day, and the maximum membrane flux obtained is 32L m -2 h -1 , with an...

Embodiment 3

[0071] In a city in the third type of sunshine area in my country, it is a typical summer night. The outdoor ambient temperature is between 26-29°C.

[0072] It is necessary to use the electric heating rod 17 to heat the raw water at night. Use reverse osmosis concentrated water with a conductance of 80000μs / cm as the raw water, and when the temperature of the raw water rises to 80°C, the flow rate of the raw water in the raw water tank 31 is controlled by the rotameter 44 to be 250L·h -1 , the temperature of the raw material liquid before entering the evaporation zone is between 75 and 80°C, and the maximum membrane flux obtained is 32L m after continuous operation for 10 hours -2 h -1 , with an average membrane flux of 30.1L m -2 h -1 ; The conductivity of the product water is maintained at 130-200μS·cm -1 Around, the desalination rate is higher than 99.6%. The use of the heat pump greatly reduces the turn-on frequency of the electric heating rod 17, and the calculated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com