Lignite drying device by aid of low-pressure superheated steam and method

A technology of superheated steam and drying equipment, which is applied in the direction of heating equipment, drying gas arrangement, heating to dry solid materials, etc., and can solve problems such as uncertain temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

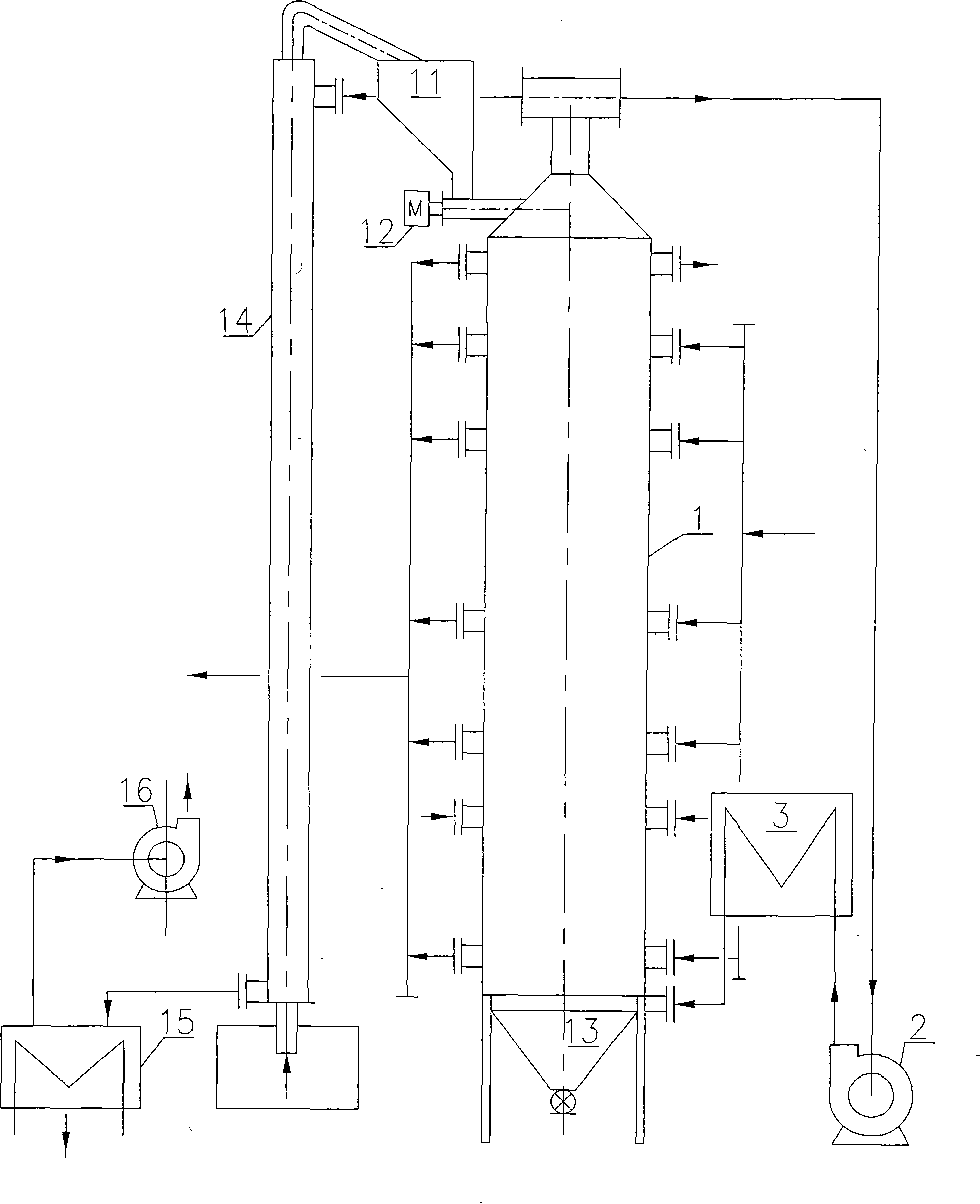

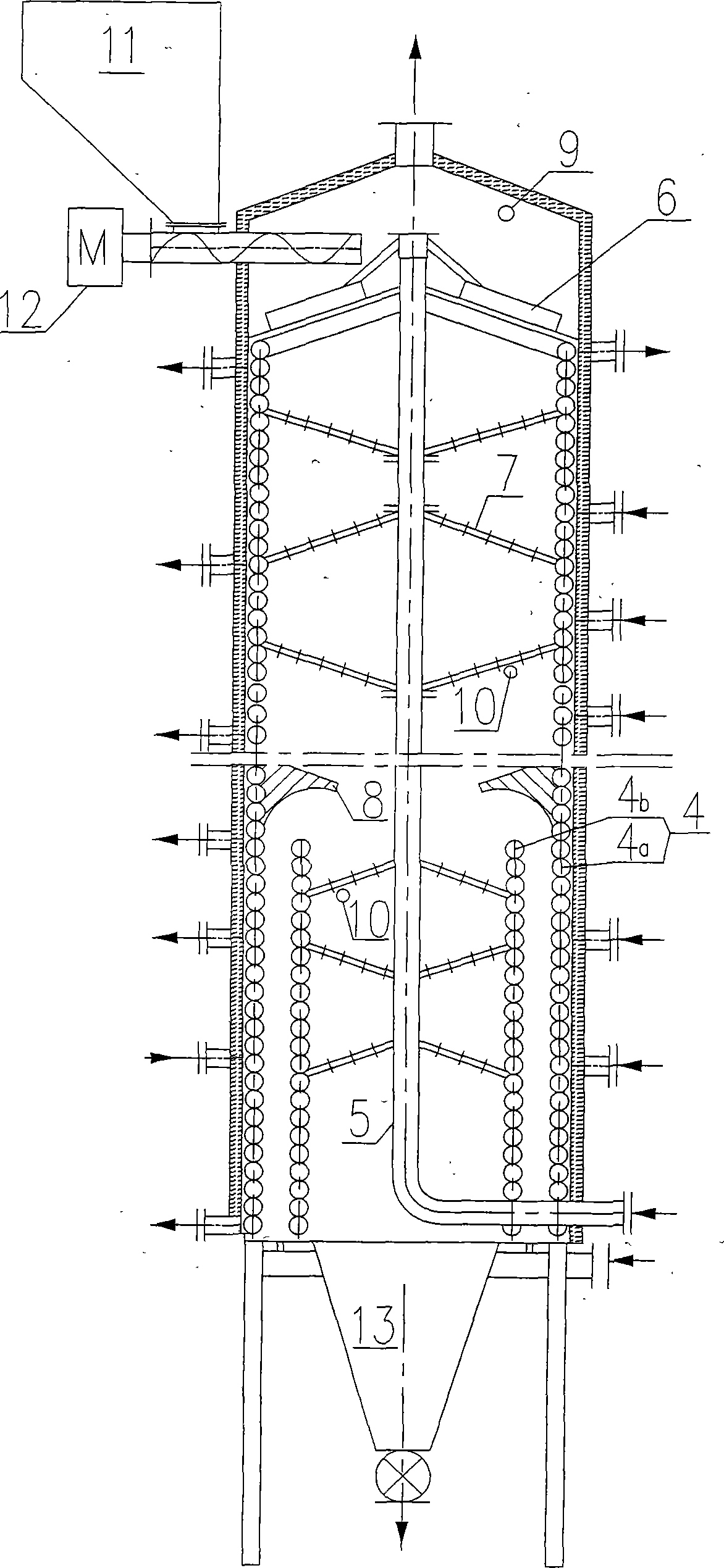

[0054] The technological process and specific implementation of the low-pressure superheated steam drying lignite device related to the present invention are:

[0055] At the beginning of the drying device's work, the heat transfer oil heating system provides high-temperature heat transfer oil to the drying device as its main heat source to preheat the heat transfer oil heater 1 . A small amount of preheated wet lignite is sent down from the top feed hopper 11 of the heat transfer oil heater 1 into the preheated heat transfer oil heater, and the temperature of the lignite is raised until the external water evaporates, and the generated steam continues to be heated And when it is superheated to 120°C, the low-pressure superheated steam is boosted by the circulating superheated steam booster fan 2 and heated by the circulating superheated steam reheater 3, and then used as the drying medium and supplementary heat source of the drying device, it is sent from the lower part of the ...

Embodiment 1

[0068] For lignite with a moisture content of 30%, the particle size is not greater than 10mm, and the minimum distillation temperature of the volatile fraction is 210°C. The moisture content of the dried material is required to be less than 10%, and the processing capacity of a single drying device is 1,000 tons per day.

[0069] The characteristics of the dried lignite are: the moisture content does not exceed 30%, and includes external moisture and internal moisture. During the drying process, it is easy to remove the external moisture, but it is difficult to remove the internal moisture, and the chemical properties of the lignite are unstable, which affects the properties of the drying medium and The operating temperature is more sensitive. The drying process has a large amount of water removal, but the moisture content of the dried lignite is not too high. It is necessary to increase the temperature and flow rate of the drying medium in the constant-rate evaporation sectio...

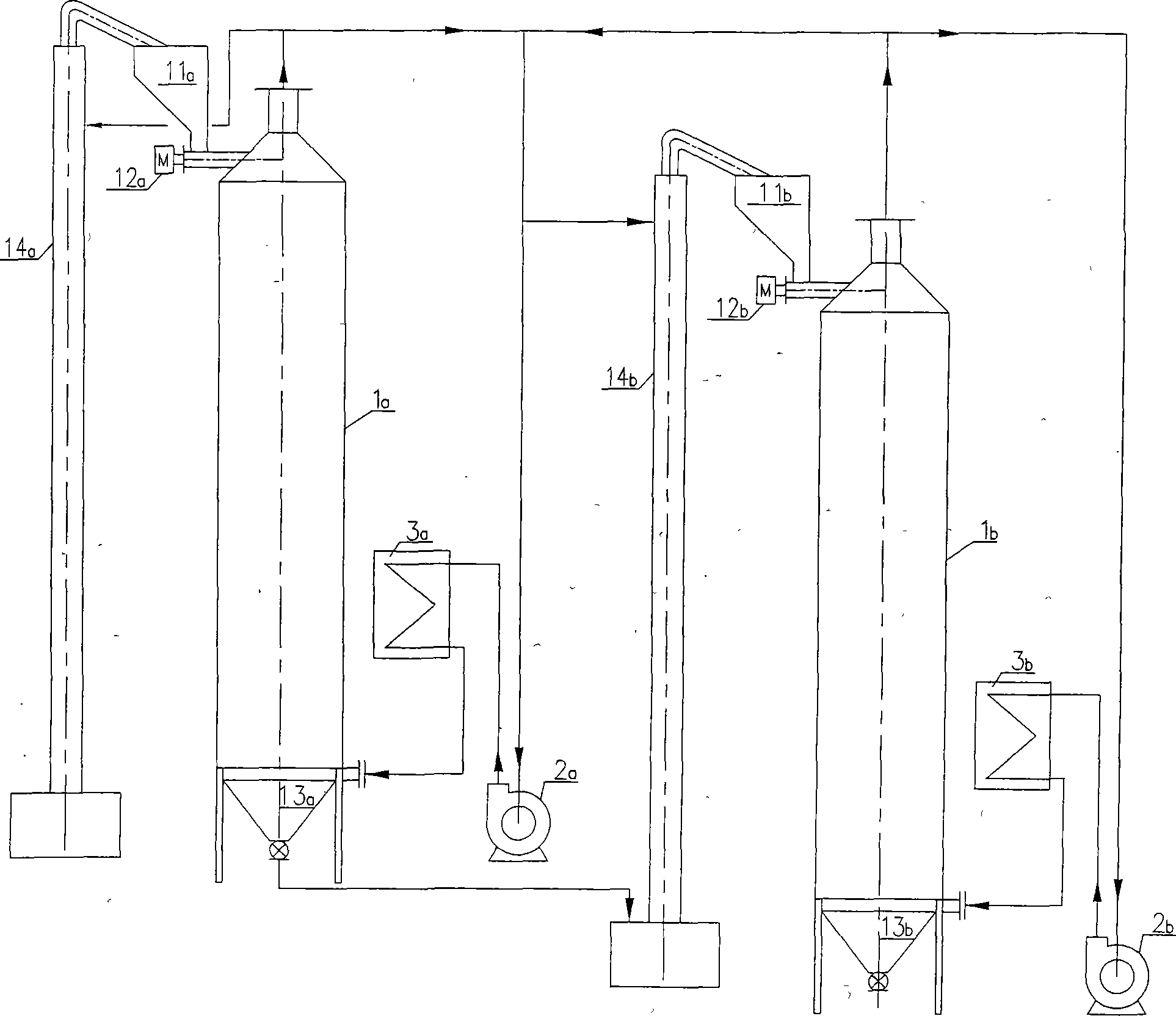

Embodiment 2

[0082] For lignite with a moisture content of 43%, the particle size is not greater than 20mm, and the minimum distillation temperature of the volatile fraction is 220°C. The moisture content of the dried material is required to be less than 10%, and the drying device has a processing capacity of 1,500 tons per day.

[0083] The characteristics of dried lignite are: the moisture content is as high as 43%, and it includes external moisture and internal moisture. During the drying process, it is easy to remove external moisture, but it is difficult to remove internal moisture. Its particle size is uneven, and lignite with larger particle size is more difficult to dry. . In addition, the chemical properties of lignite are unstable and sensitive to the properties of drying medium and working temperature. Due to the large amount of lignite to be processed and the moisture content of the dried lignite is very high, the amount of water removed in the drying process is relatively larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com