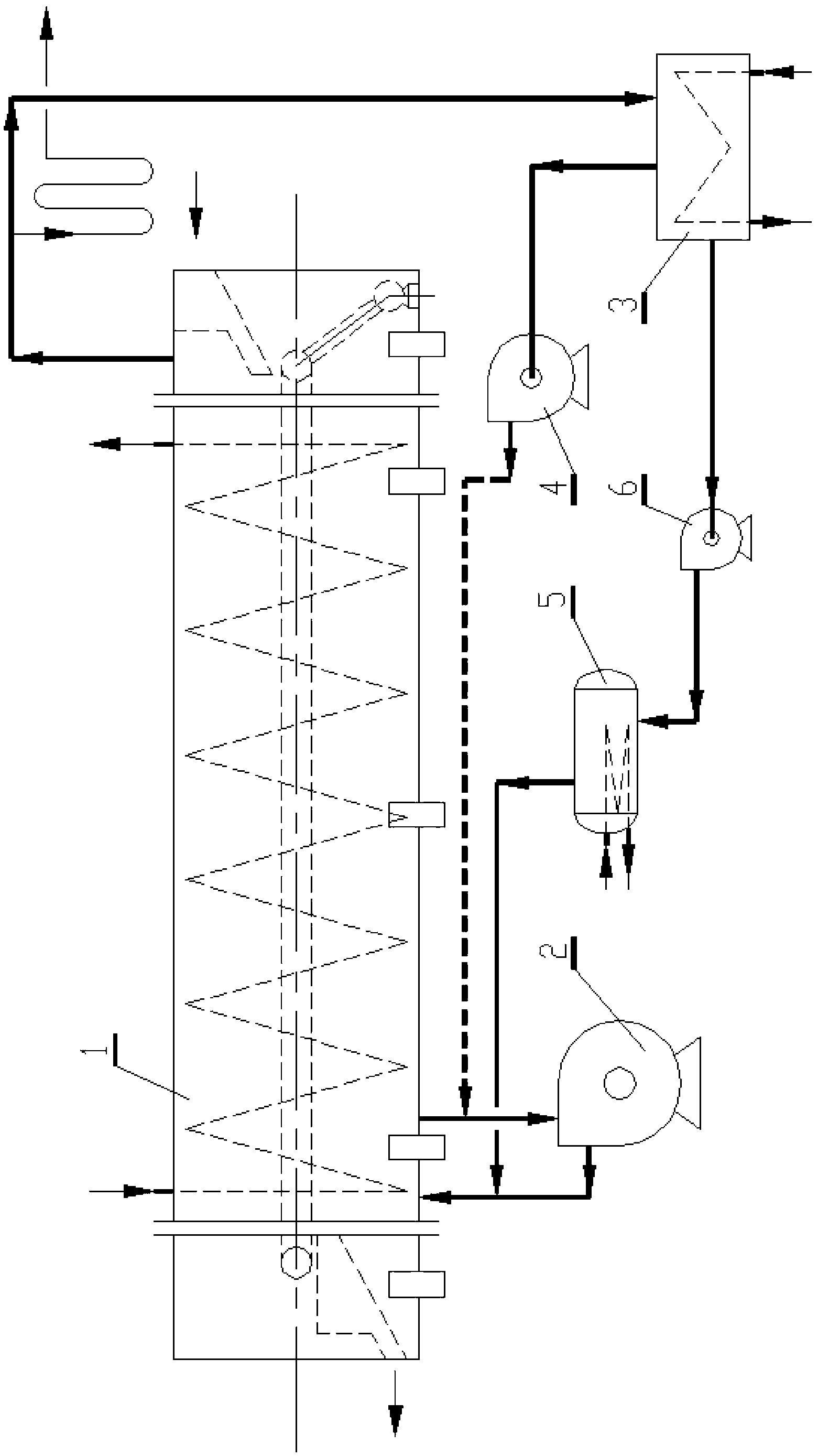

Belt type low-pressure superheat steam drying device

A superheated steam and drying device technology, which is applied in the direction of progressive dryer, drying gas arrangement, drying, etc., can solve the problem of limited internal space of rotary dryer, arranging a large number of heat exchange tubes, drying efficiency of dryer, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

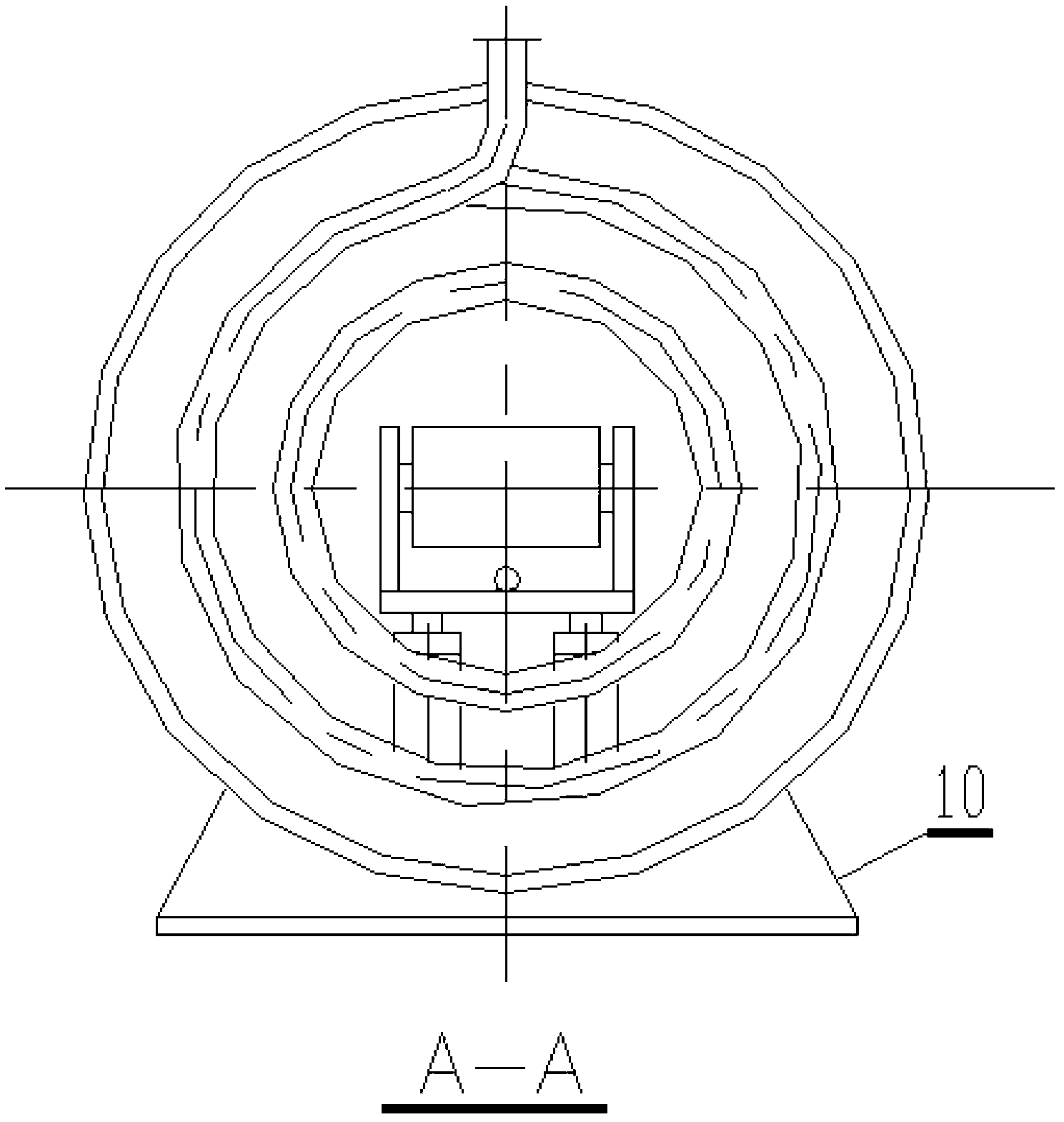

Method used

Image

Examples

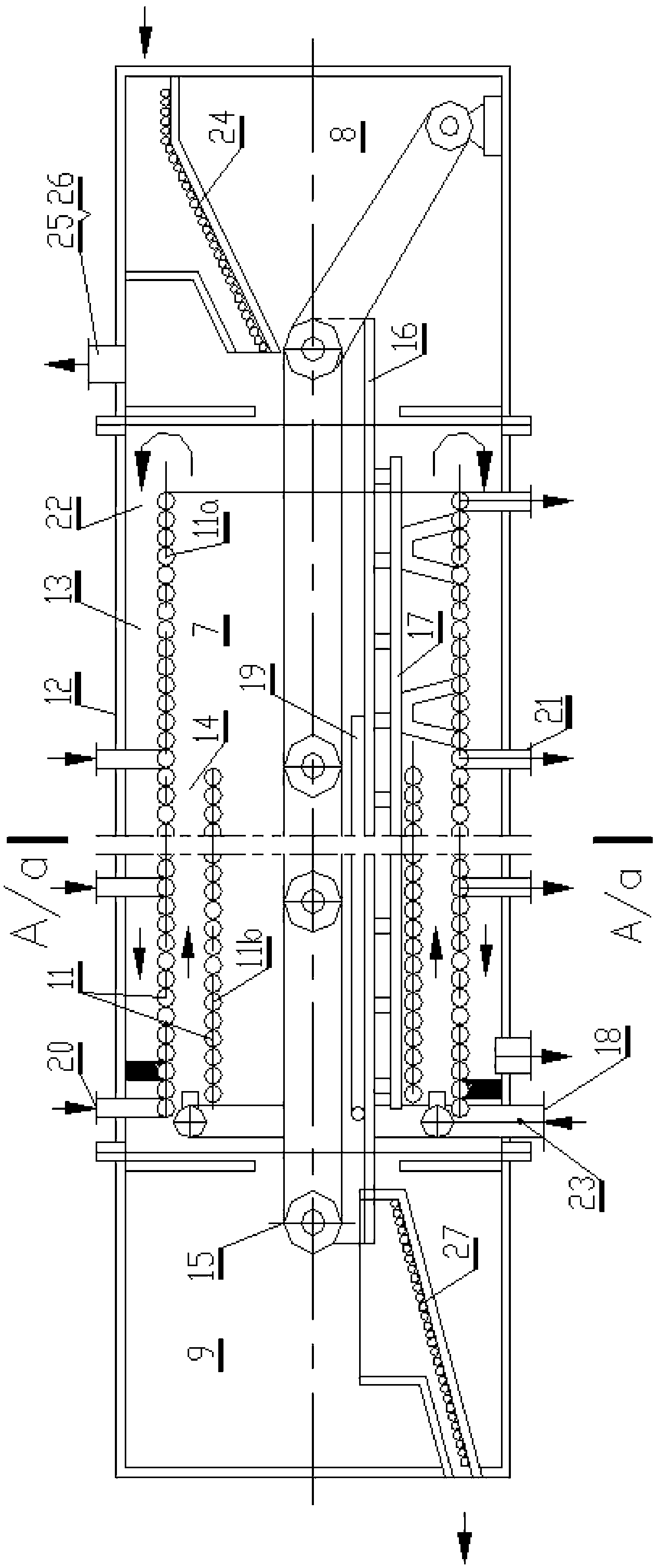

Embodiment 1

[0067] The material to be dried is sludge or peat with a moisture content of 50%, and its particle size is not greater than 2mm. The moisture content of the dried material is required to be less than 15%. A single drying device has a processing capacity of 200 tons / day.

[0068] The characteristics of the material to be dried are: the sludge deposited in the treatment of municipal sewage or the peat deposited in the treatment of coal washing sewage is a mixture of powdery and fine-grained materials and water. The drying is mainly to remove the external moisture. The working temperature of the drying medium is not sensitive, and its chemical properties are stable under 200℃, but the moisture content of the wet material is high and its bulk density is large, resulting in poor thermal conductivity and air permeability of the material, so it needs to be improved in the drying device For the temperature of the drying medium, use a lower flow rate of the drying medium, appropriately red...

Embodiment 2

[0084] The material to be dried is fly ash with a moisture content of 20%, or ore sand such as quartz sand, with a particle size of not more than 3mm, and the moisture content of the dried material is required to be less than 5%. A single set of drying device has a processing capacity of 100 tons / day.

[0085] The characteristics of the material to be dried are: fly ash or ore is a kind of fine particle solid material, and its drying is mainly to remove the external moisture and part of the internal moisture. The chemical properties of fly ash and ore are stable, the density of the material is large and the heat conduction The coefficient is small, and the air permeability of the material in the stacked state is good. During the drying process, the temperature and heating conditions of the drying medium do not need to be restricted. However, if the flow rate of the drying medium is too high, the fine fly ash will be blown up; in addition, due to drying Due to the limited conditi...

Embodiment 3

[0093] The material to be dried is apple pomace or fermented bacteria residue with a moisture content of 43%, and its particle size is not greater than 5mm. The moisture content of the dried material is required to be less than 10%. A single set of drying device has a processing capacity of 30 tons / day.

[0094] The characteristics of the dried material are: the apple pomace after squeezing the juice and the bacteria residue after fermentation are a kind of materials with large moisture content and no fixed form. The drying process is mainly to remove a large amount of external moisture and part of the internal moisture. Due to the loose structure, good air permeability, and stable chemical properties of this kind of material, the moisture content of the dried material is not strict, so the working temperature of the drying medium does not need to be too high, but the surface shape of the wet material is not The regular and low bulk density results in poor fluidity. Therefore, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com