Patents

Literature

61results about How to "Surfaces with very little" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

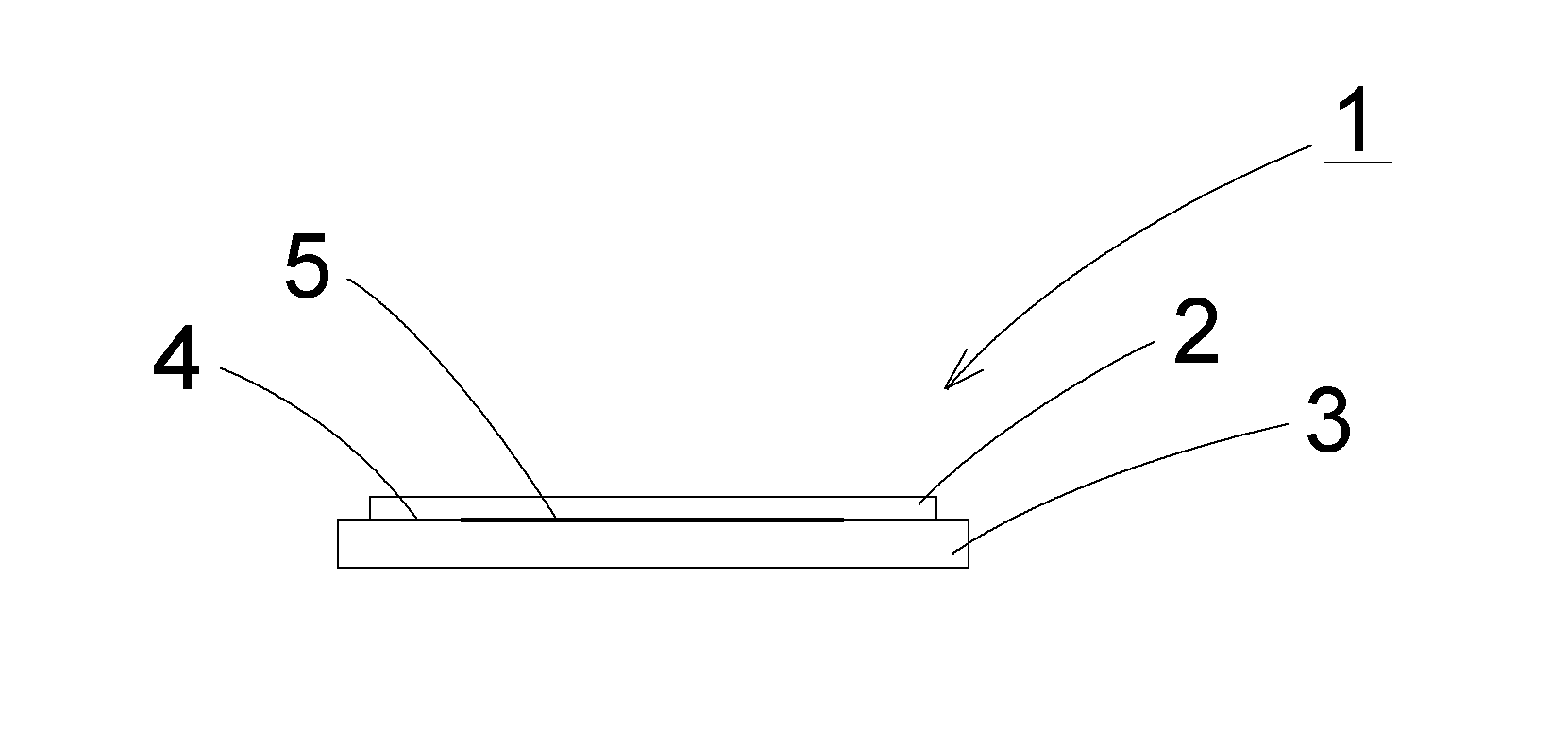

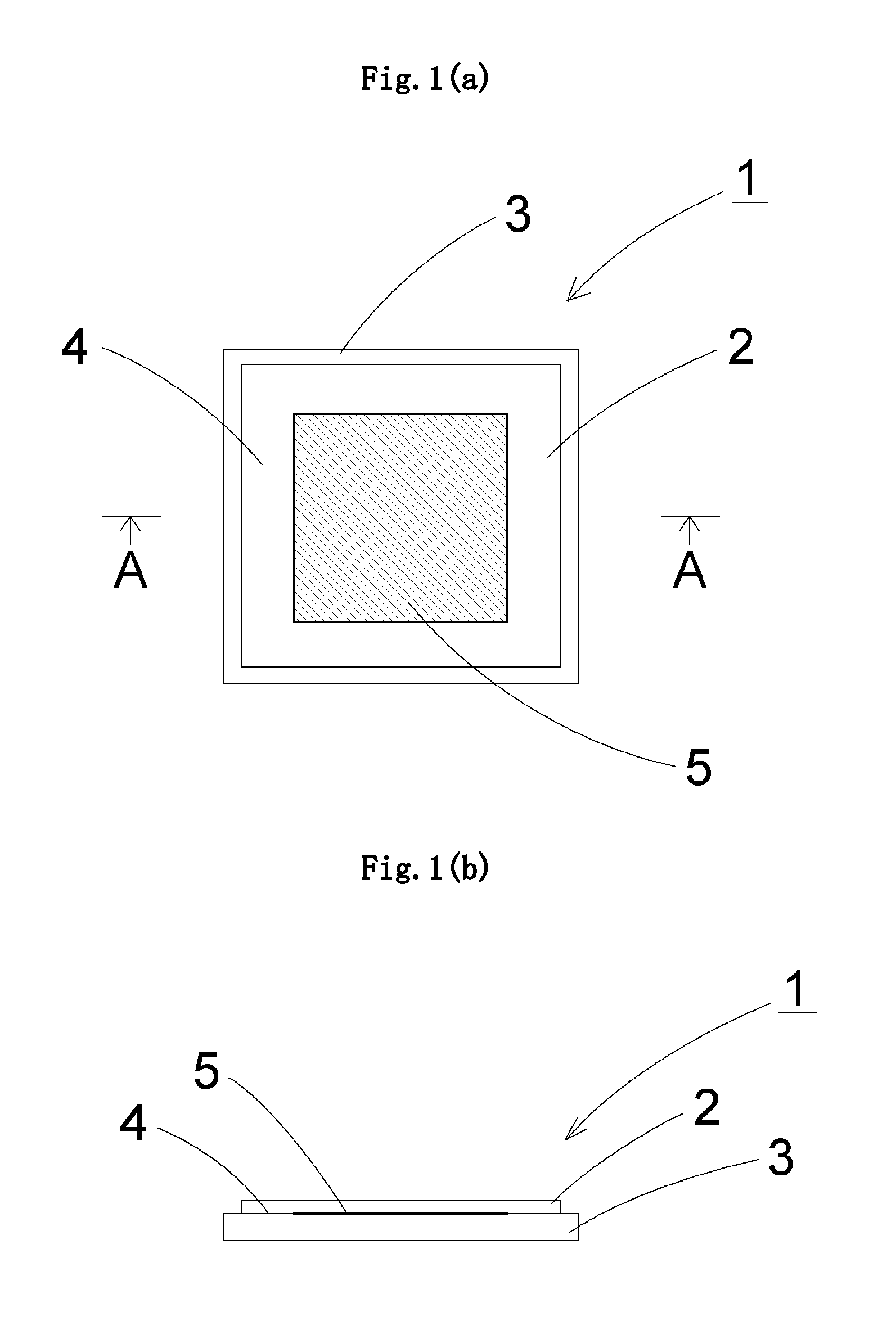

Glass film laminate, method of producing the same, and method of producing glass film

ActiveUS20120080403A1Stably carryEasily peelLamination ancillary operationsDecorative surface effectsGlass filmSurface roughness

A glass film laminate comprises a glass film (2) and a supporting glass (3) laminated to each other. At least one of the contacting surface of the glass film (2) and the contacting surface of the supporting glass (3) comprises a region with a relatively large surface roughness and a region with a relatively small surface roughness.

Owner:NIPPON ELECTRIC GLASS CO LTD

Handling portions

InactiveUS20130341254A1Low costSurfaces with very littleMaterial check-weighingWeighing apparatus for materials with special property/formMechanical engineeringFood products

The invention relates to a method of handling portions comprising a respective at least one slice, wherein the slices have been produced by slicing food products, wherein the portions are conveyed, in particular line-wise, one after the other in a main conveying stream along a conveying direction, wherein incomplete portions, in particular portions low in weight, are automatically recognized and / or classified, wherein incomplete portions are expelled from the main conveying stream and are supplied to a correction station in a correction stream, wherein incomplete portions are respectively completed by at least one single slice which is removed from a slice store with the aid of an automatic transfer unit and wherein completed portions are automatically channeled back into the main conveying stream.

Owner:WEBER MASCHENBAU

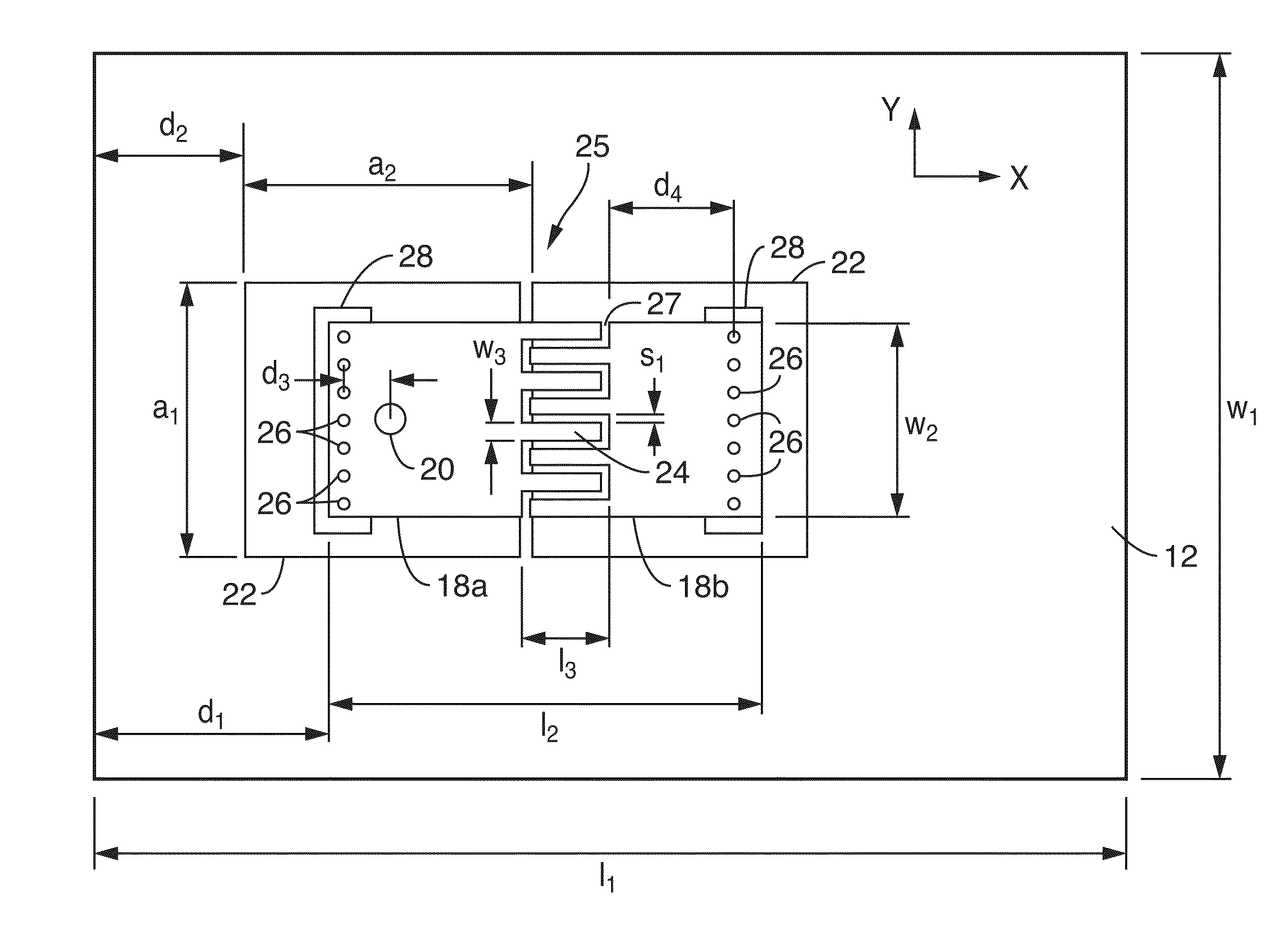

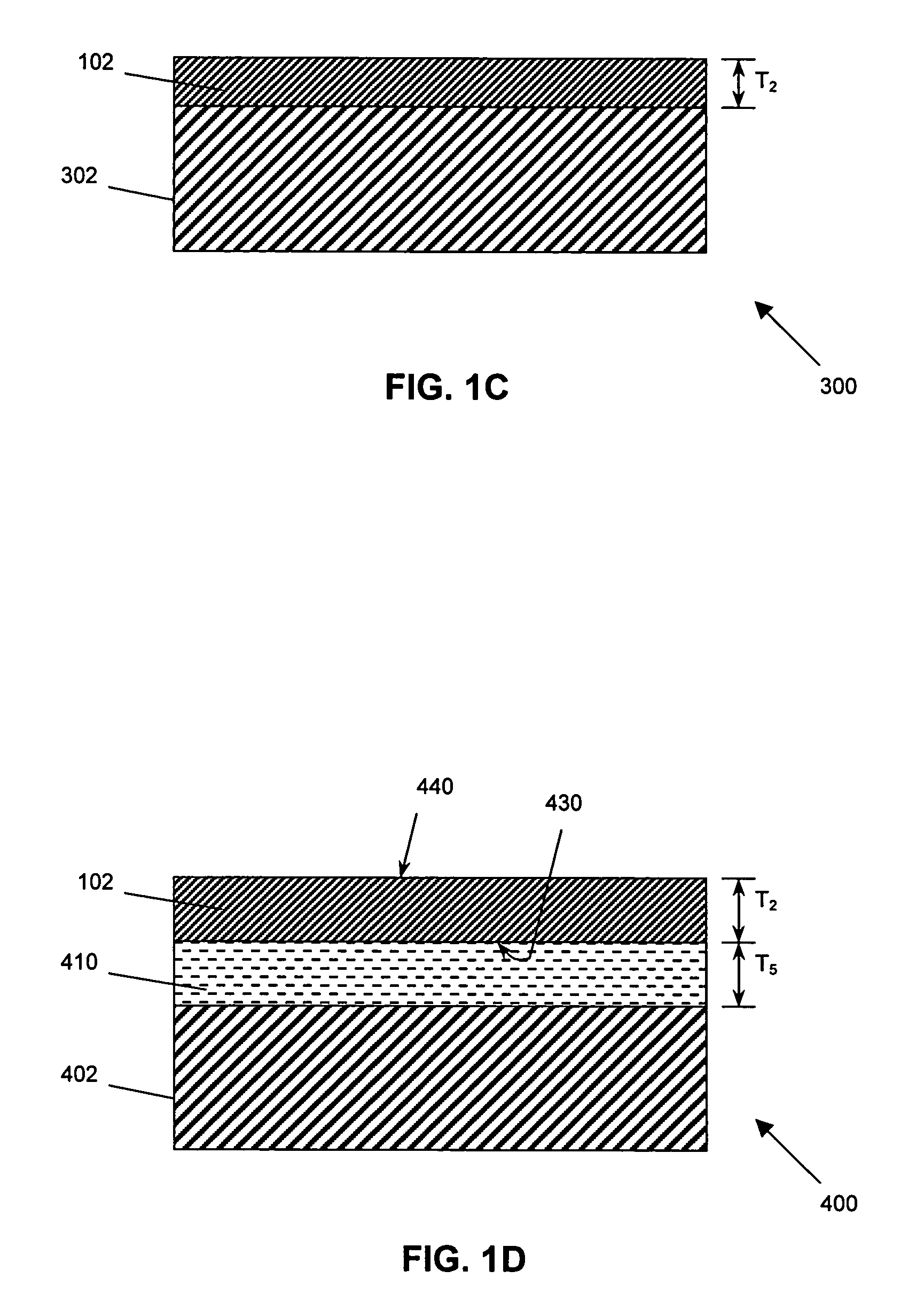

Electrically small vertical split-ring resonator antennas

ActiveUS20140203987A1Miniaturization efficientEffective radiationSimultaneous aerial operationsRadiating elements structural formsEngineeringSplit ring resonators

A vertical split ring resonator antenna is disclosed, comprising a substrate having an upper surface and lower surface, an interdigitated capacitor coupled to the upper surface of the substrate and ground coupled to the lower surface. The interdigitated capacitor includes a first planar segment and a second planar segment, each having interdigitated fingers that are separated by a gap disposed between the first planar segment and second planar segment. The interdigitated capacitor is coupled to the substrate to form a vertical split ring resonator.

Owner:NEC CORP +1

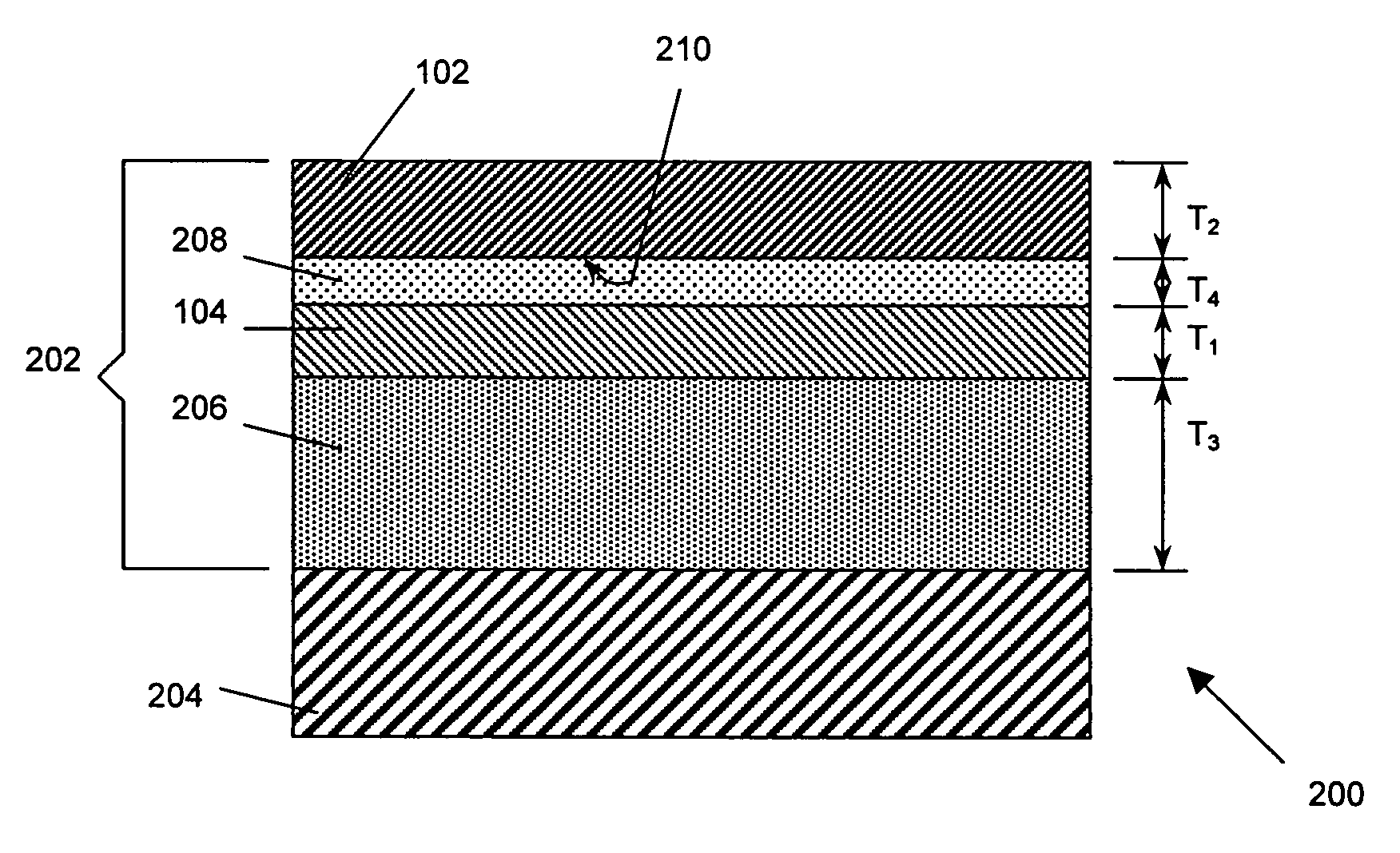

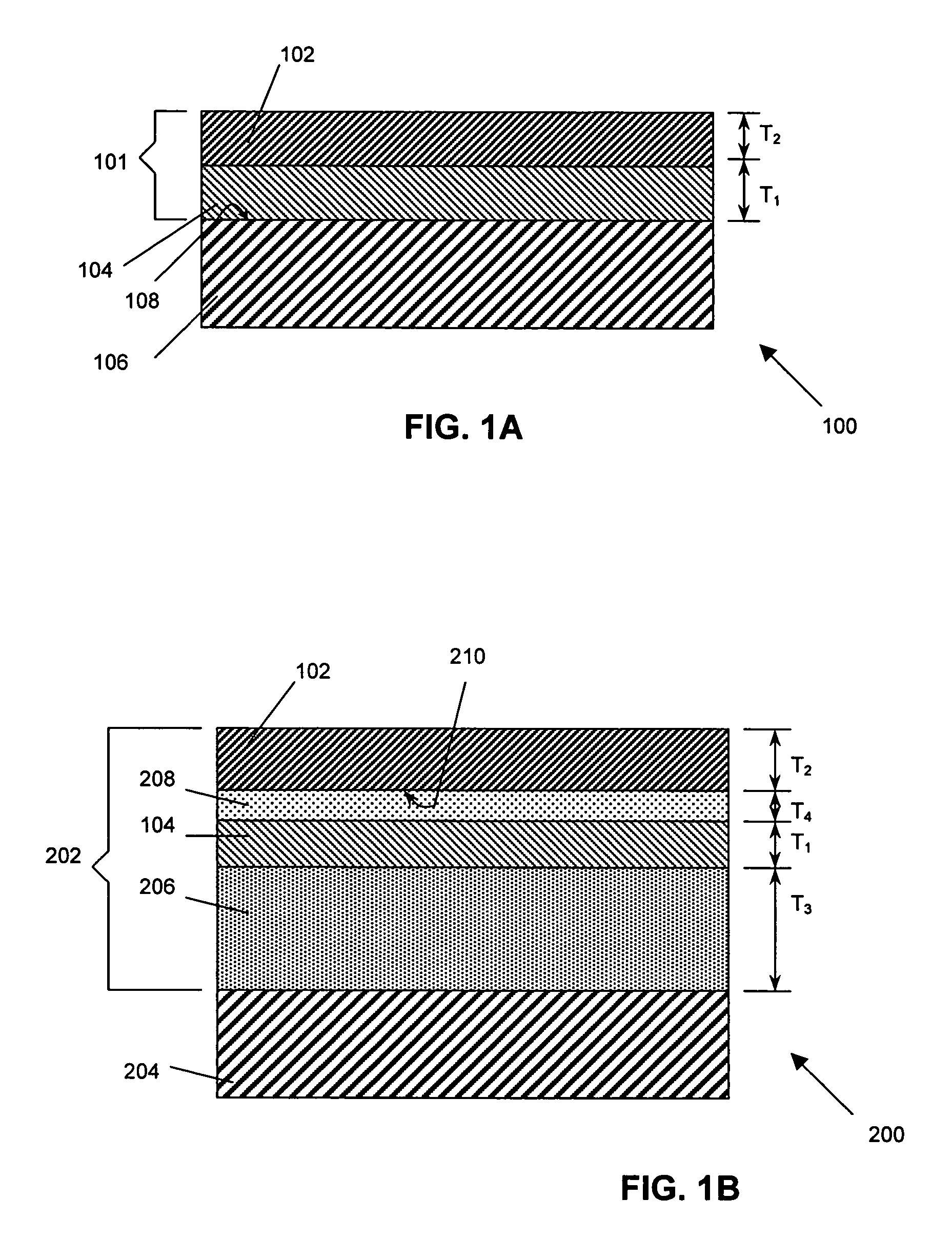

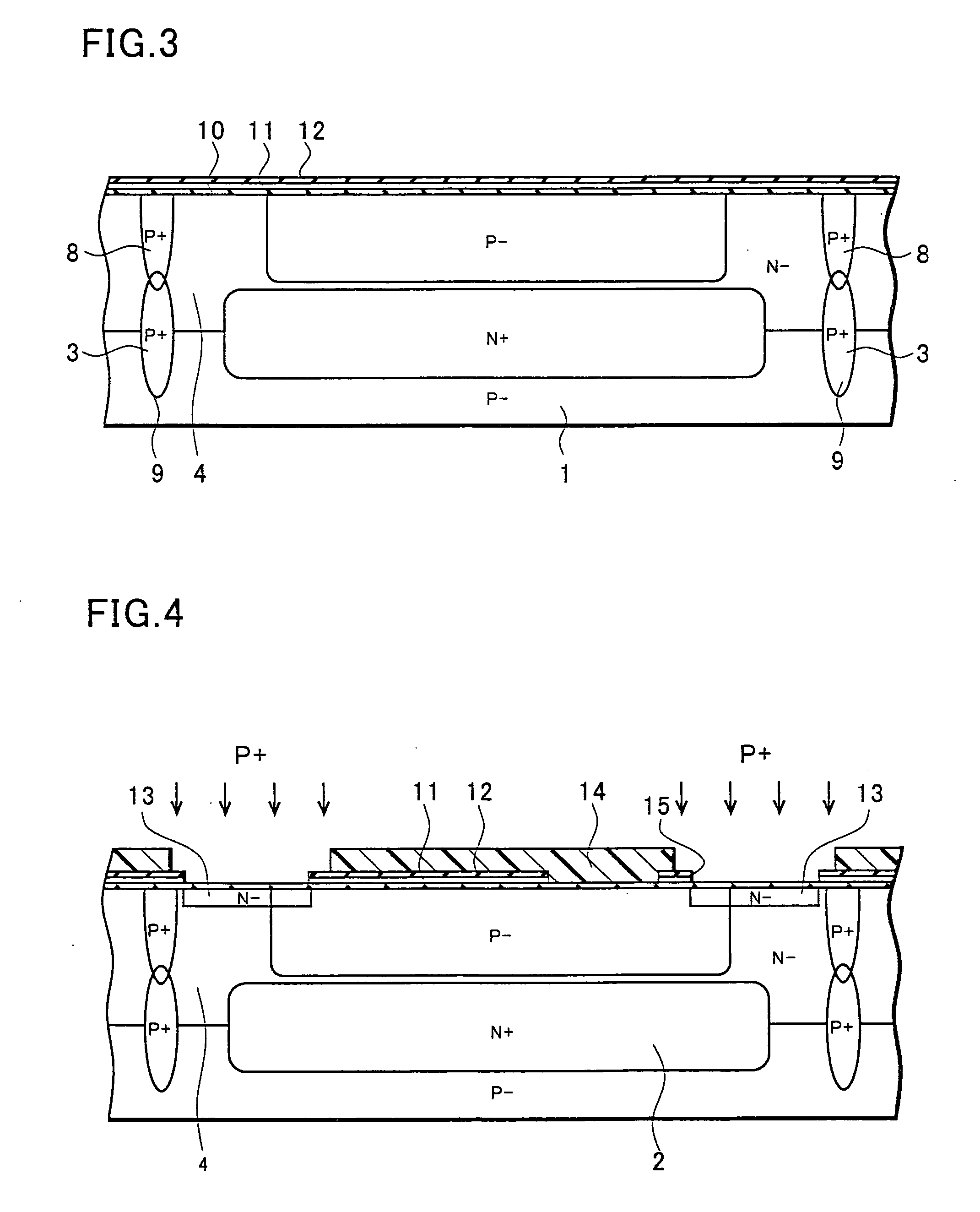

Methods for preserving strained semiconductor substrate layers during CMOS processing

InactiveUS7071014B2Fast oxidationSurfaces with very littleSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSSurface layer

Oxidation methods, which avoid consuming undesirably large amounts of surface material in Si / SiGe heterostructure-based wafers, replace various intermediate CMOS thermal oxidation steps. First, by using oxide deposition methods, arbitrarily thick oxides may be formed with little or no consumption of surface silicon. These oxides, such as screening oxide and pad oxide, are formed by deposition onto, rather than reaction with and consumption of the surface layer. Alternatively, oxide deposition is preceded by a thermal oxidation step of short duration, e.g., rapid thermal oxidation. Here, the short thermal oxidation consumes little surface Si, and the Si / oxide interface is of high quality. The oxide may then be thickened to a desired final thickness by deposition. Furthermore, the thin thermal oxide may act as a barrier layer to prevent contamination associated with subsequent oxide deposition.

Owner:TAIWAN SEMICON MFG CO LTD

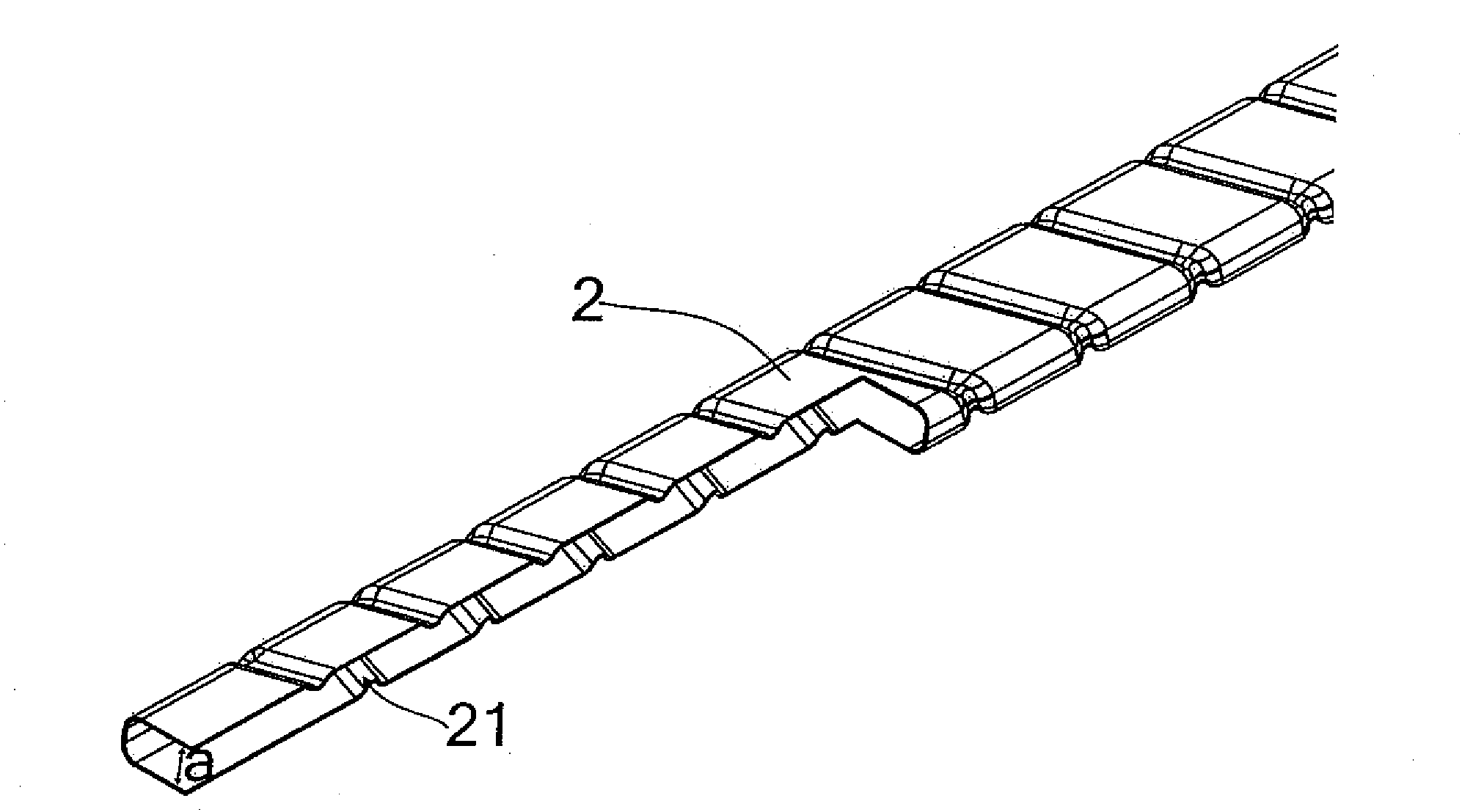

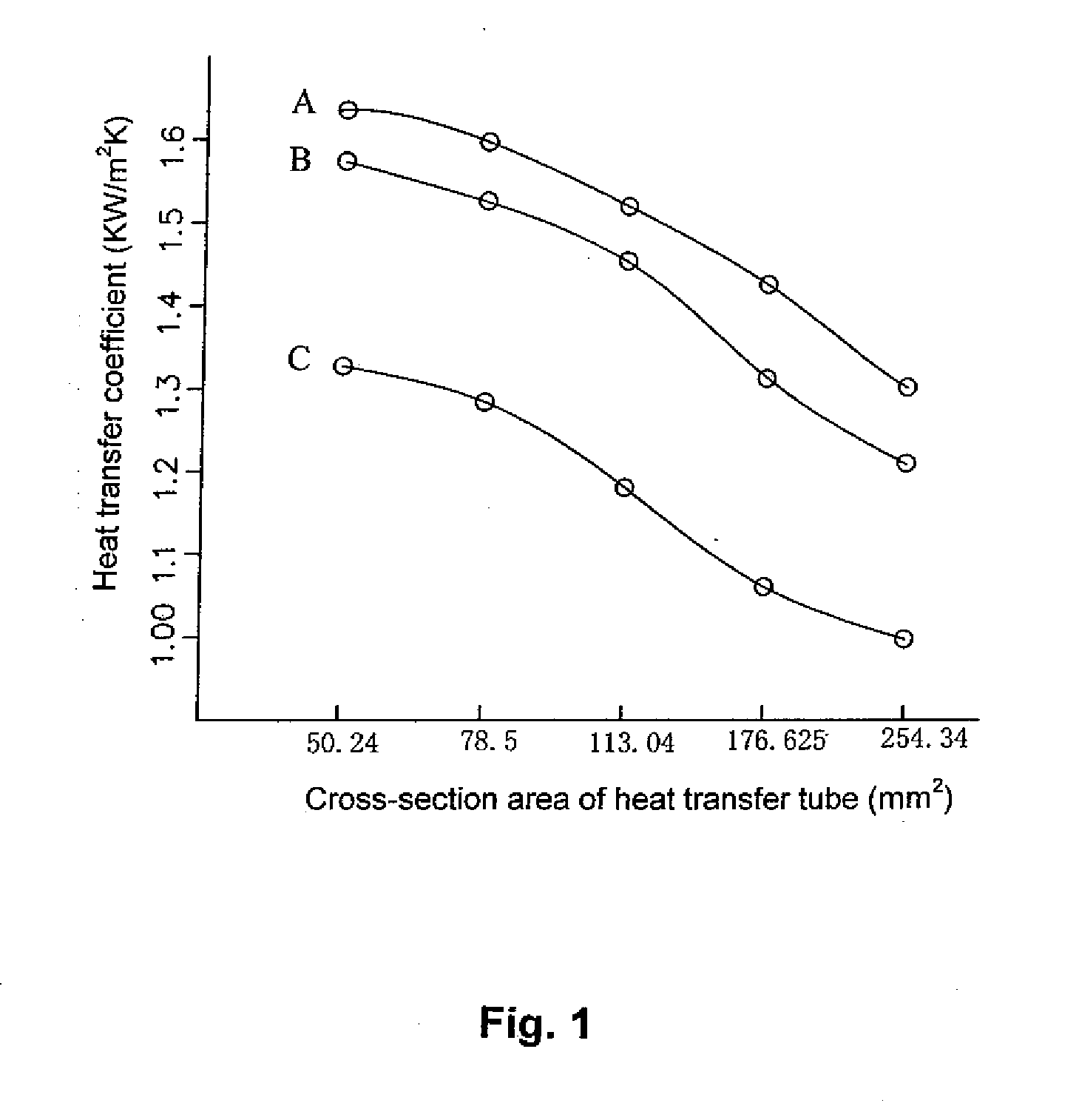

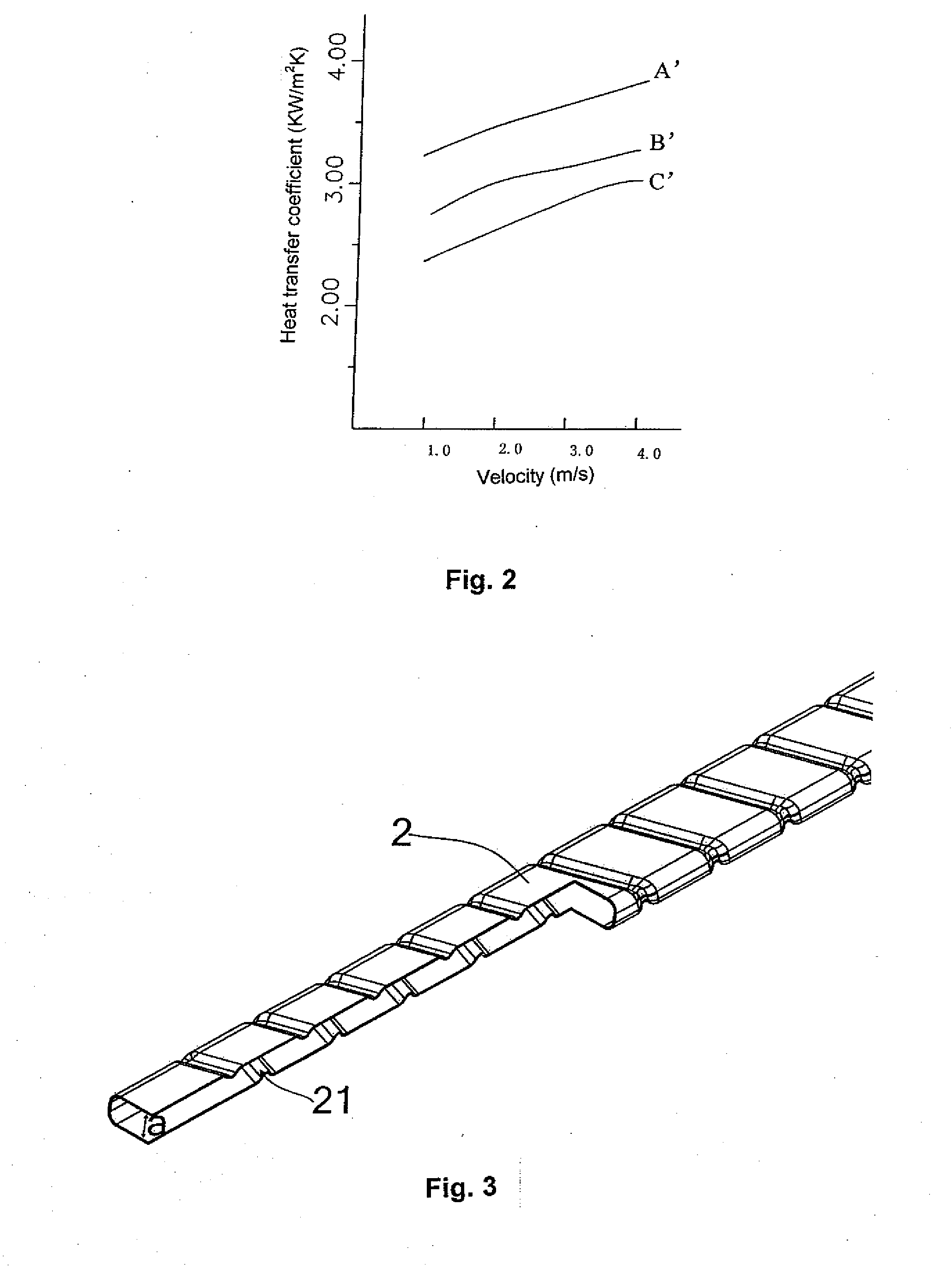

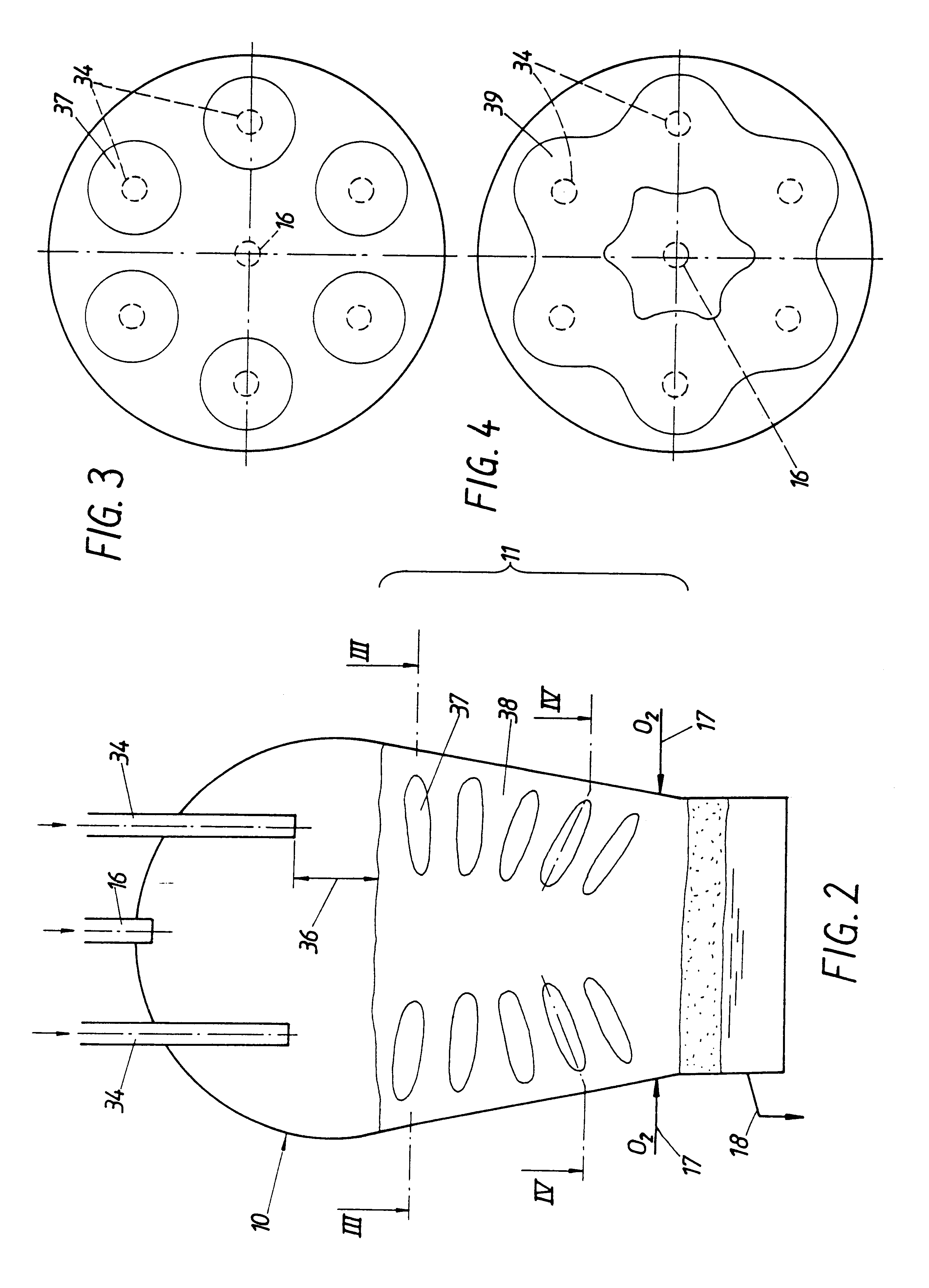

Heat exchanging tube with spiral groove

InactiveUS20070209788A1Improve thermal efficiencyHigh thermal efficiencyNon-fuel substance addition to fuelInternal combustion piston enginesSteel tubeHeat transfer tube

The present invention relates to a heat transfer tube with spiral groove, comprising a stainless steel tube body with inward convex spiral groove on surface, wherein the stainless steel tube body possesses unequal height and width in the cross sectional view. In the EGR (Exhaust Gas Recirculation) cooling system for automotive engine, such kind of spiral groove tube with the unequal height and width in the cross-section acting as the heat transfer tube for the cooler make the cooler gain higher heat transfer effect, and it is hard to make dirt deposited inside or outside the tube, which greatly improves the emissions performance for automotive engine, and satisfies higher requirement of environmental protection.

Owner:BEIJING U BRIDGE CHAOYANG

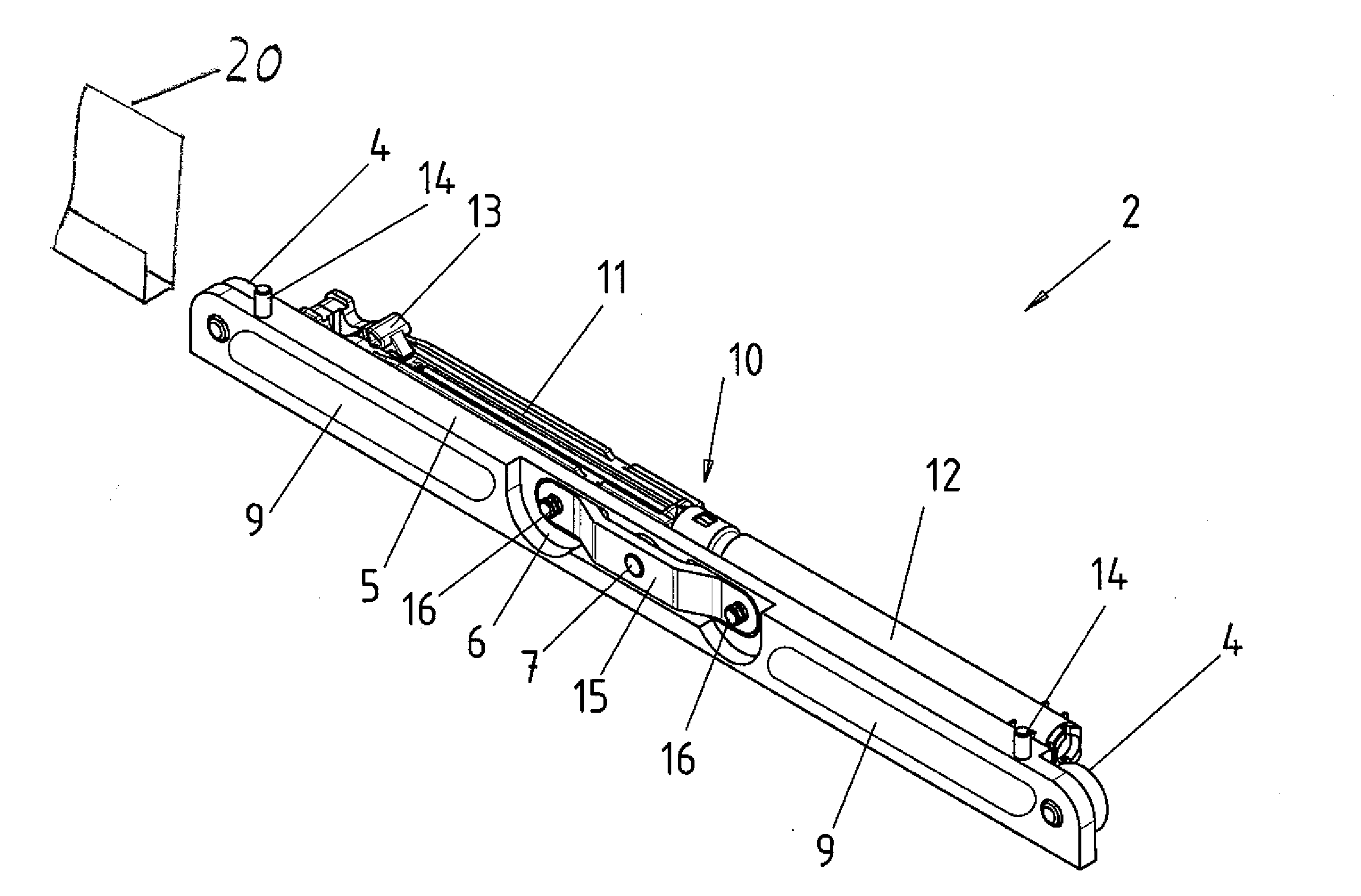

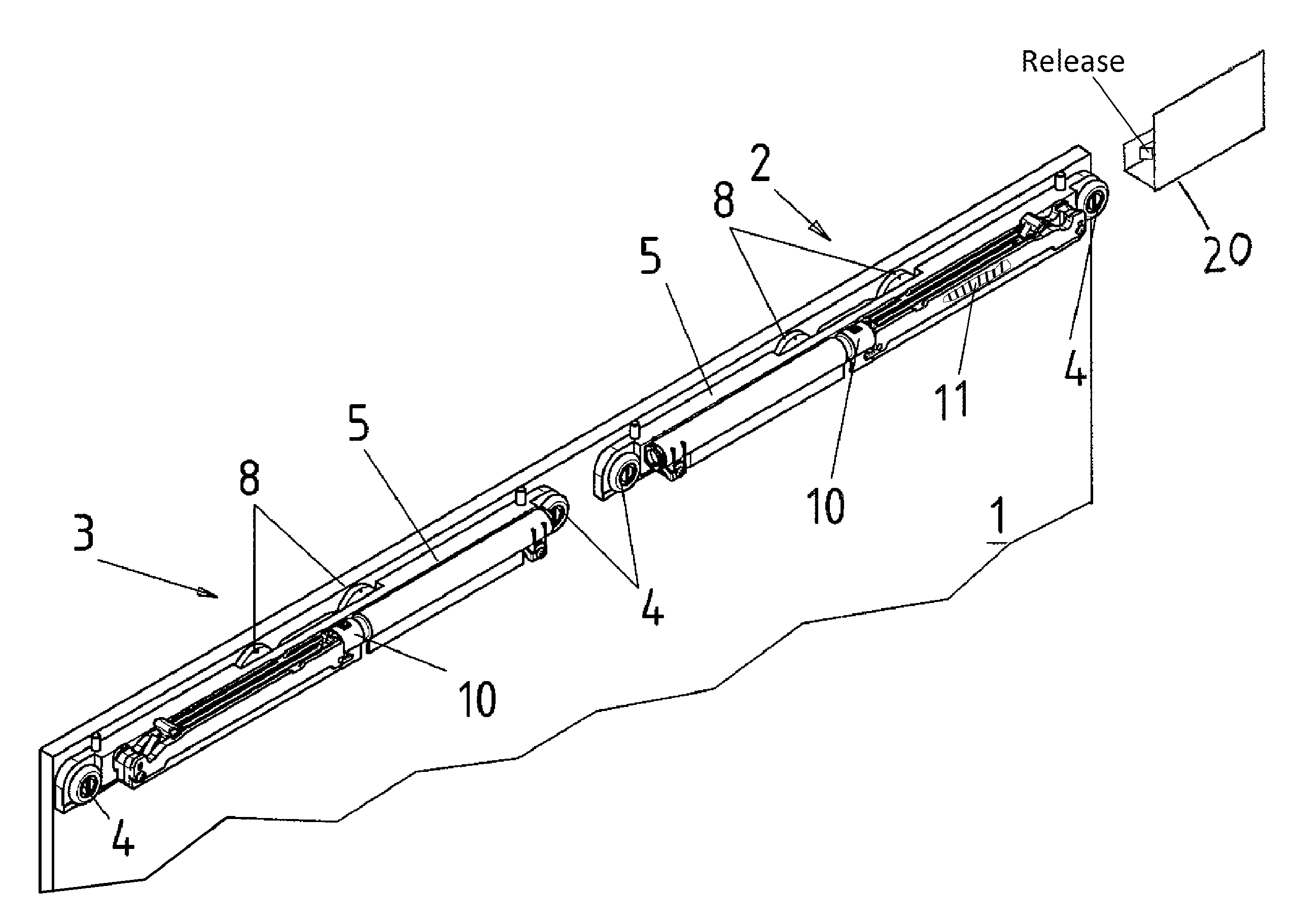

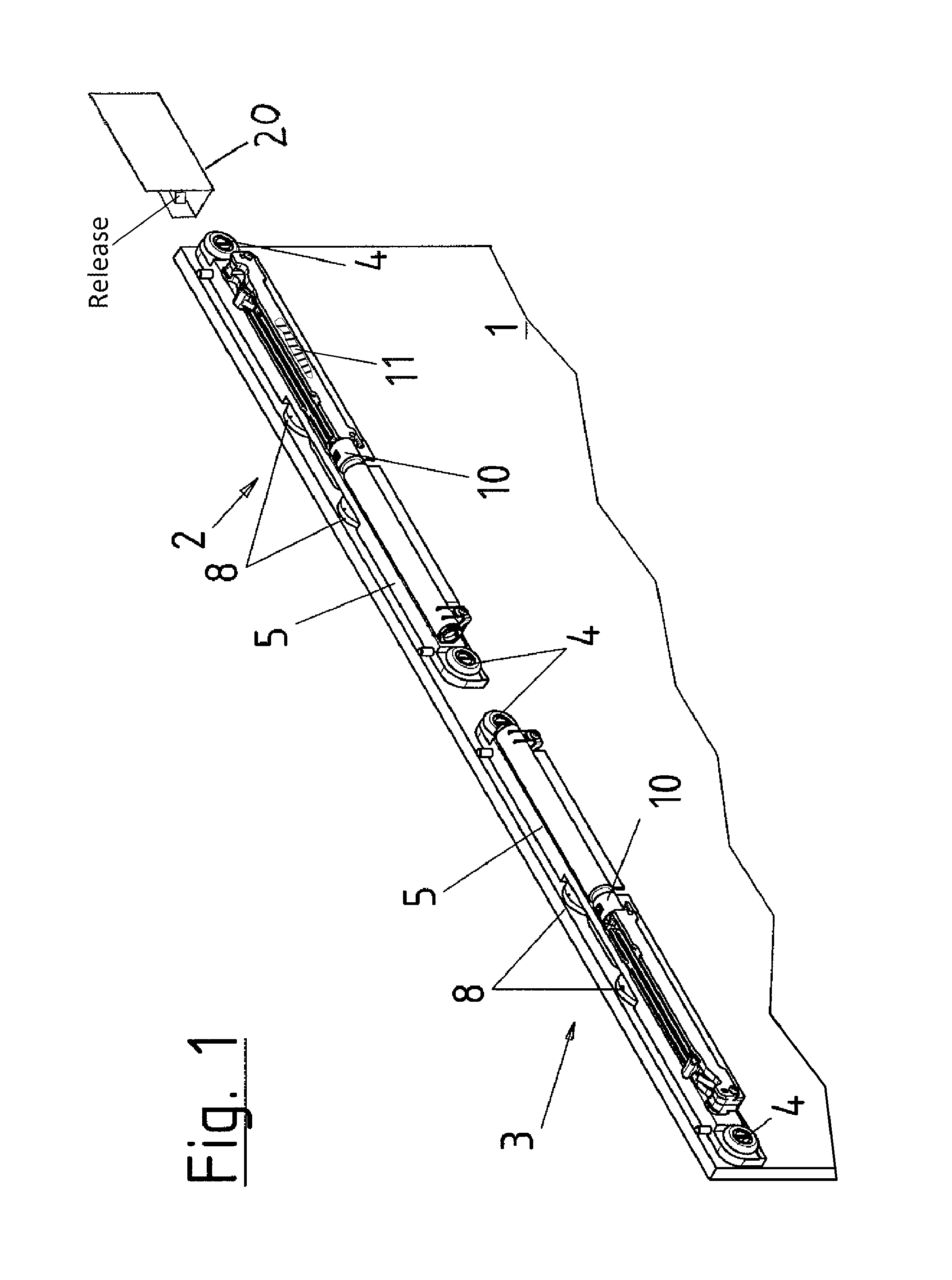

Sliding Door

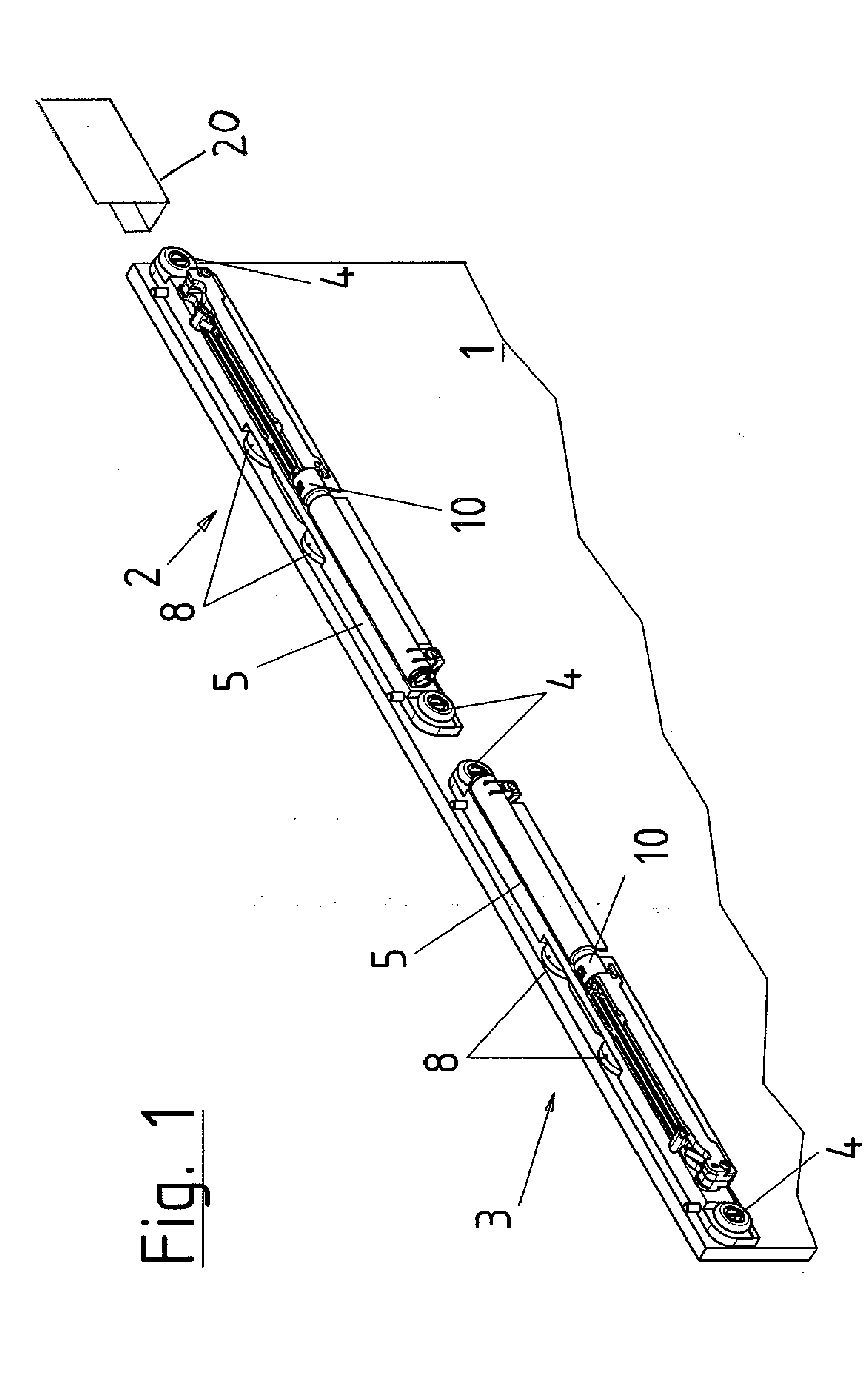

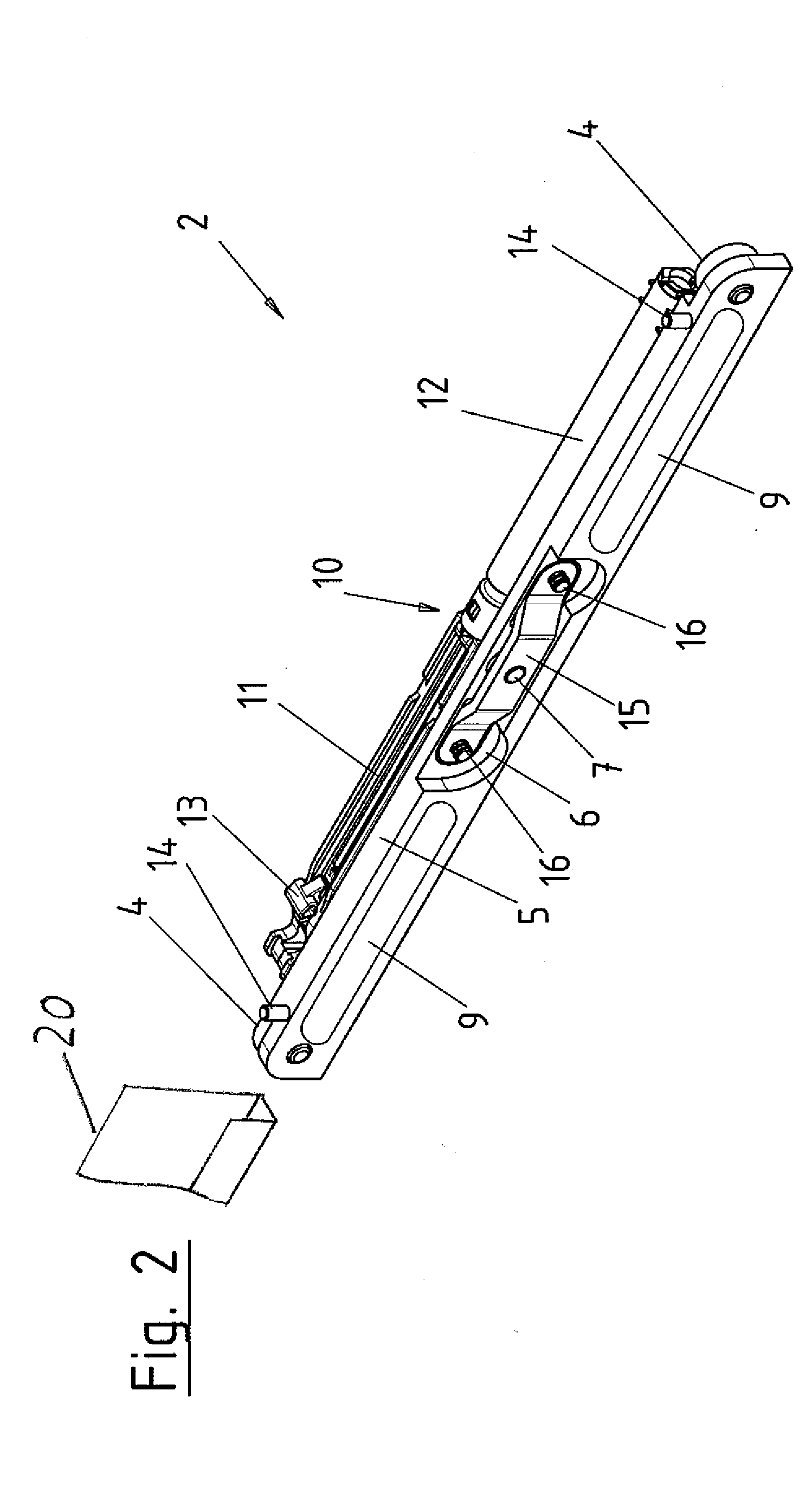

InactiveUS20110067313A1Inexpensive to purchaseMaintain integrityBuilding braking devicesMan-operated mechanismRail profileEngineering

A sliding door with a door leaf, which is suspended from two carriages and displaceably guided along a roller rail profile, which is disposed at a wall or at a ceiling, the sliding door having at least one closing device, which is suitable to displace the decelerated door leaf into a closed position. The at least one carriage has a carrier, at or in which the closing device is disposed.

Owner:DORMAKABA DEUT GMBH

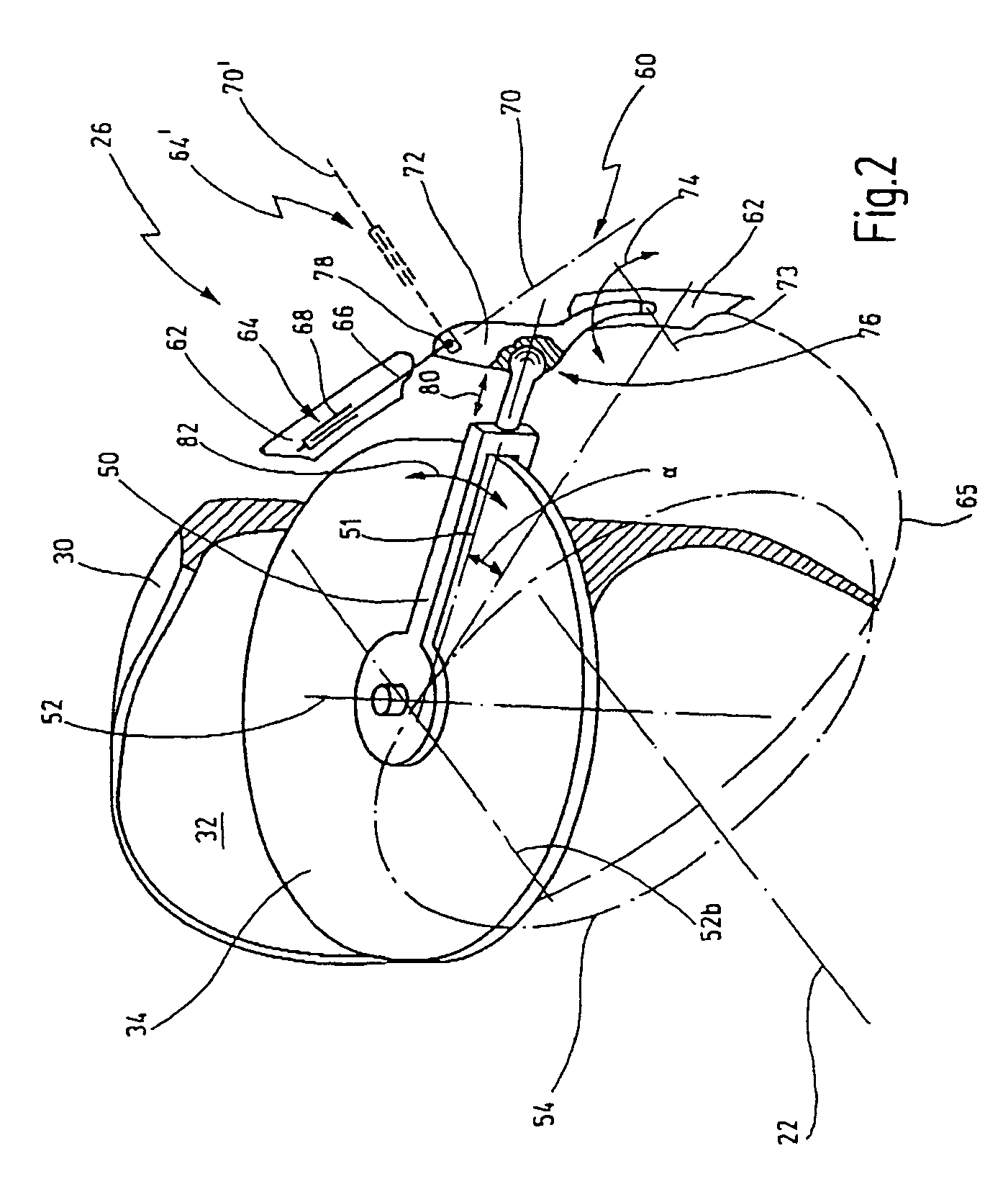

Variator and variator arrangement

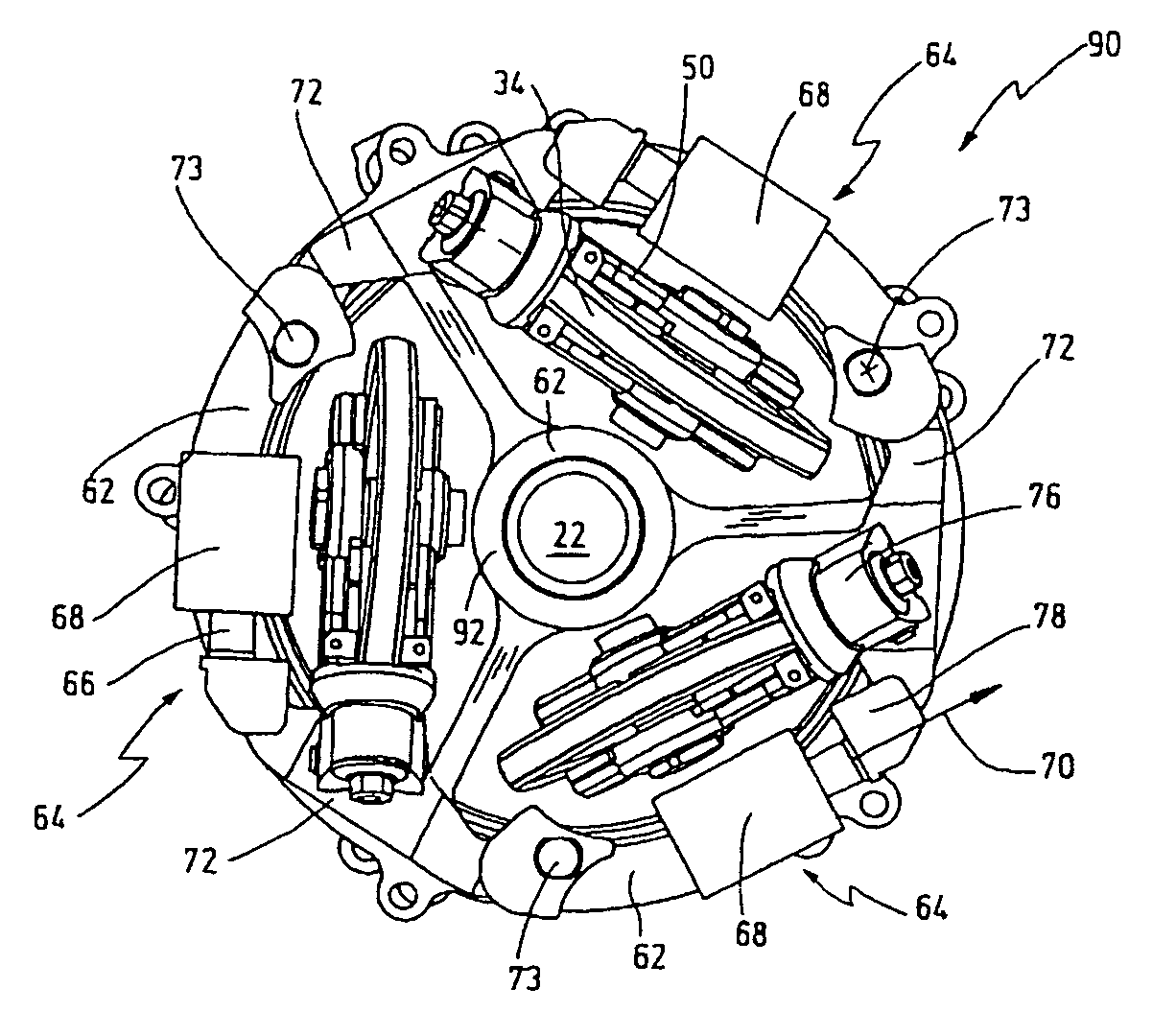

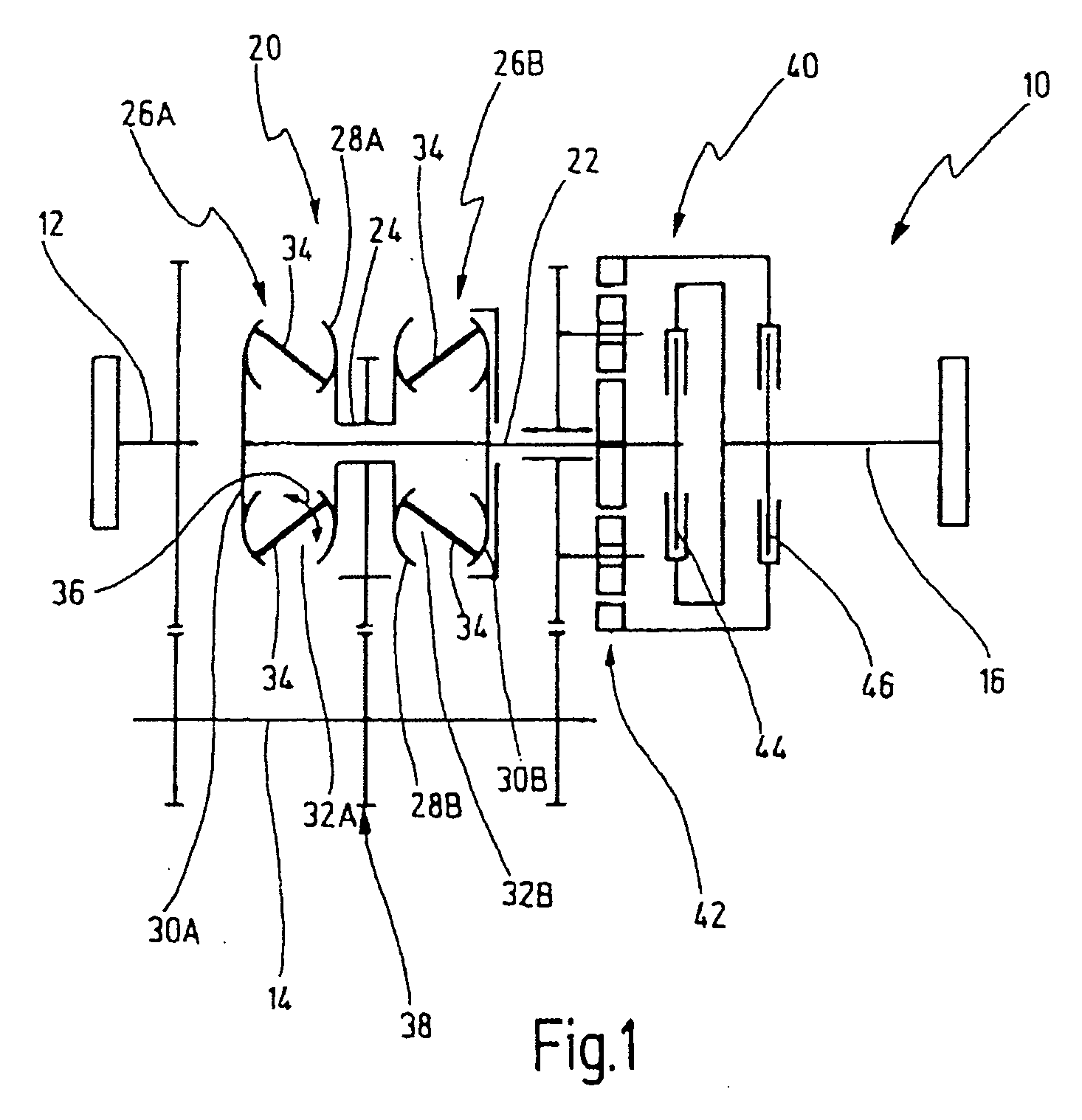

ActiveUS20060189435A1Avoid bendingSuperior in pointGearing controlFriction gearingsMechanical engineeringPiston

A variator for a toroidal transmission, with a driving disk and with a driven disk, between which is set up a toroidal space which defines a toroidal reference circle. The variator, further, comprises at least two rollers which are arranged in the toroidal space for torque transfer between the driving disk and the driven disk. The rollers are in each case mounted rotatably on a roller carrier. The roller carriers are in each case spatially adjustable by means of a piston / cylinder arrangement, in order to adjust the transfer ratio of the variator. The pistons of the piston / cylinder arrangements are in each case adjustable along a stroke axis. Also, the pistons are connected to the roller carriers via respective levers.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

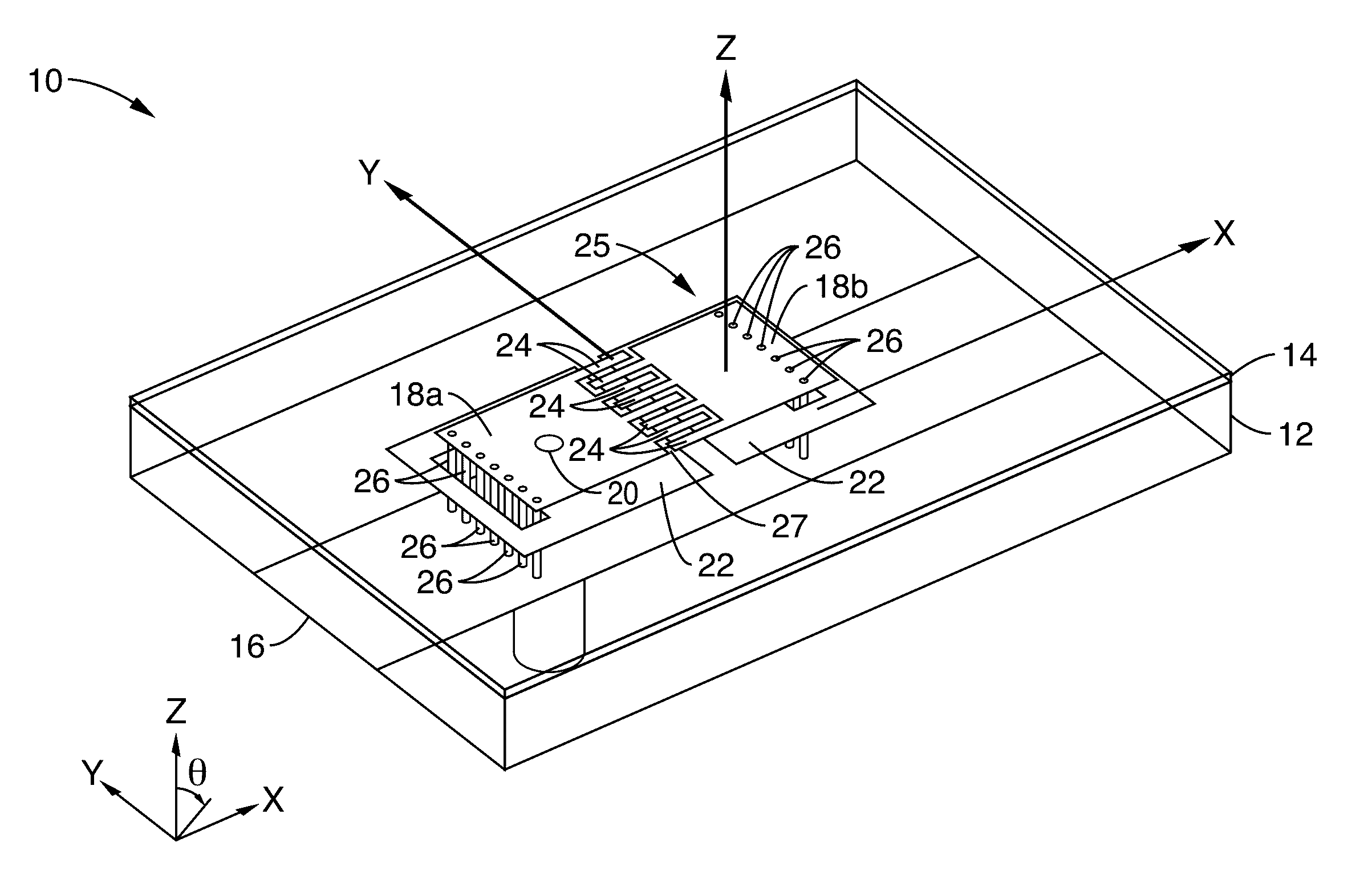

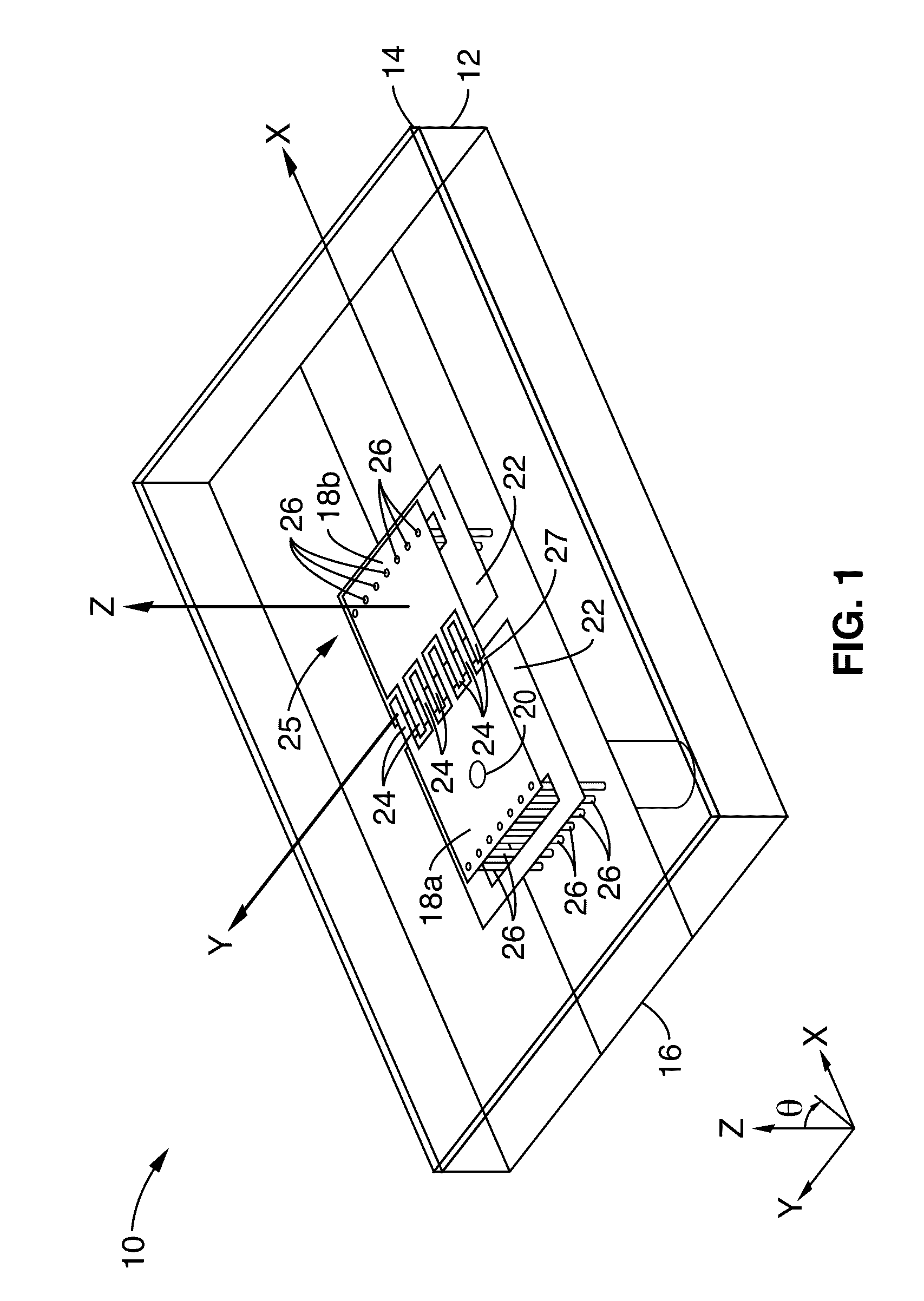

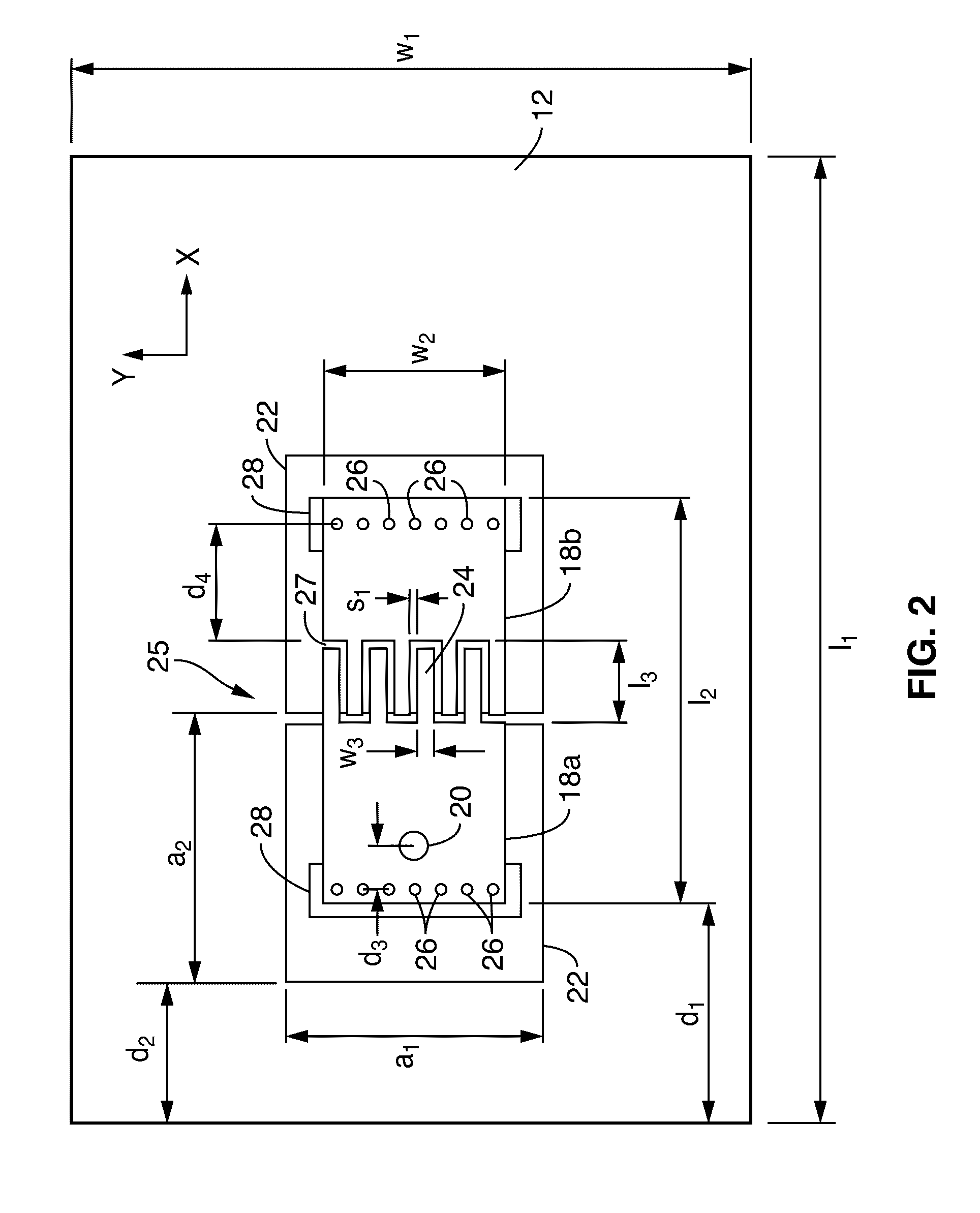

Electrically small vertical split-ring resonator antennas

ActiveUS9502761B2Miniaturization efficientEffective radiationAntenna supports/mountingsLoop antennasDielectric resonator antennaEngineering

A vertical split ring resonator antenna is disclosed, comprising a substrate having an upper surface and lower surface, an interdigitated capacitor coupled to the upper surface of the substrate and ground coupled to the lower surface. The interdigitated capacitor includes a first planar segment and a second planar segment, each having interdigitated fingers that are separated by a gap disposed between the first planar segment and second planar segment. The interdigitated capacitor is coupled to the substrate to form a vertical split ring resonator.

Owner:NEC CORP +1

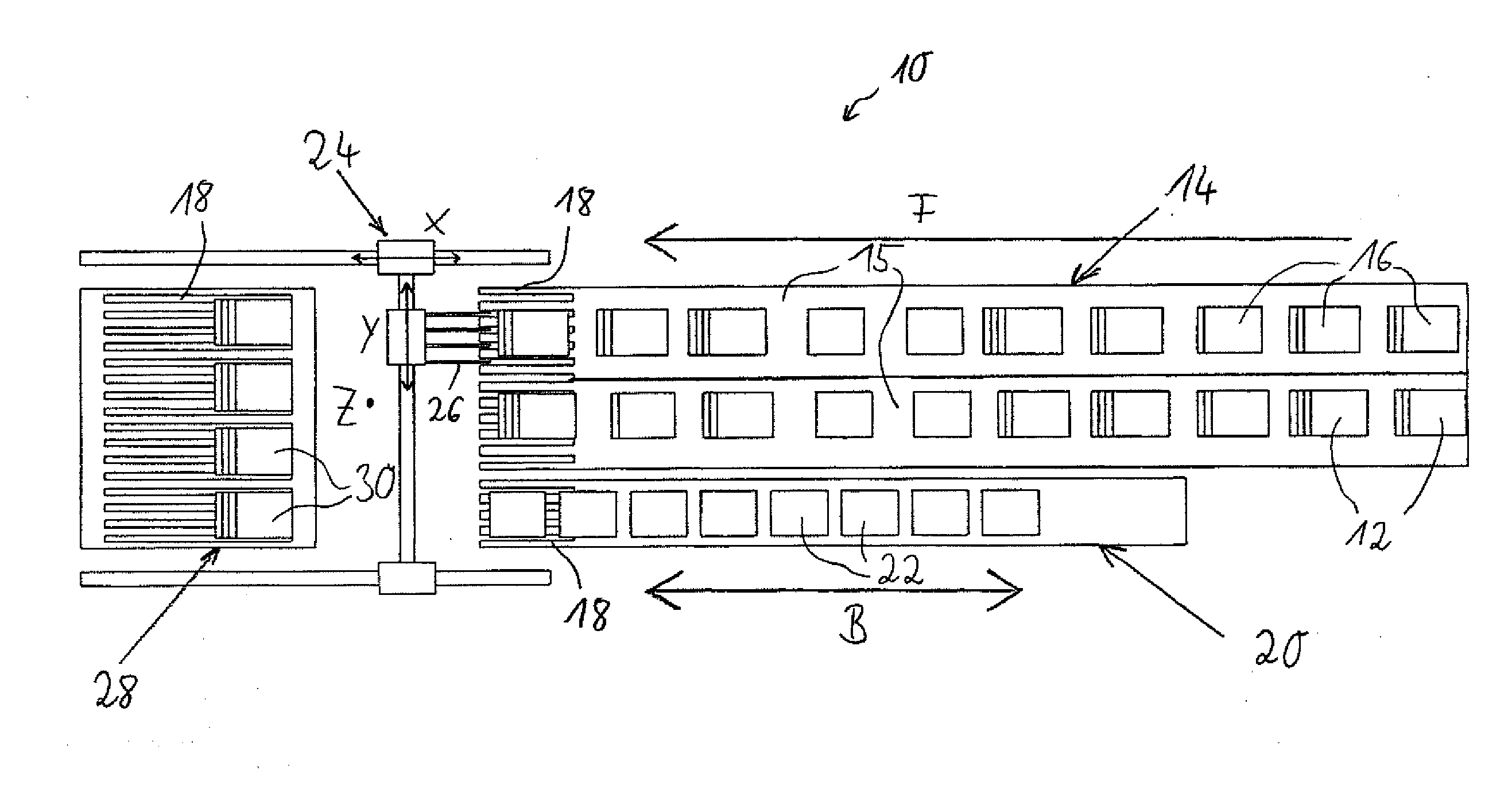

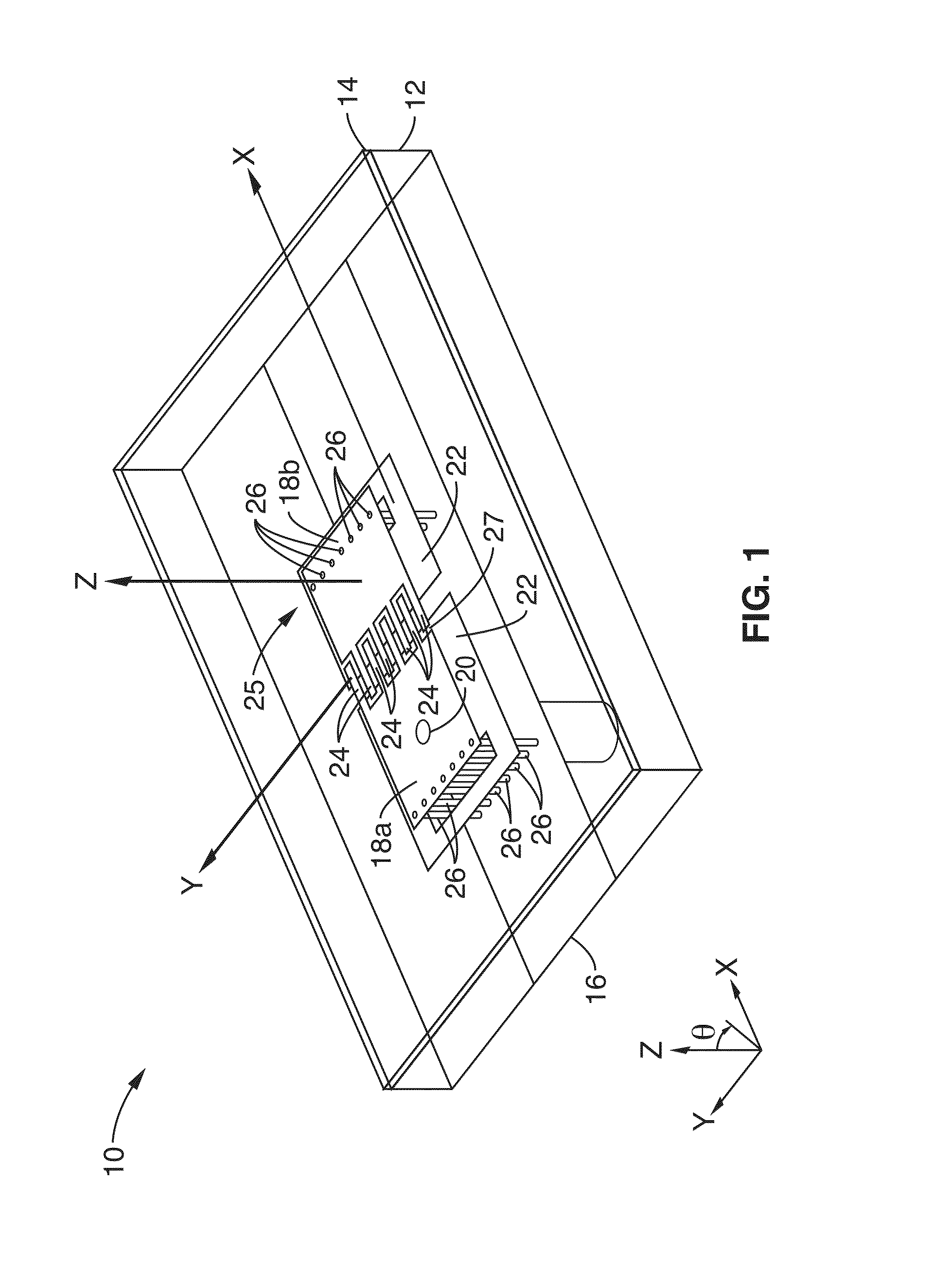

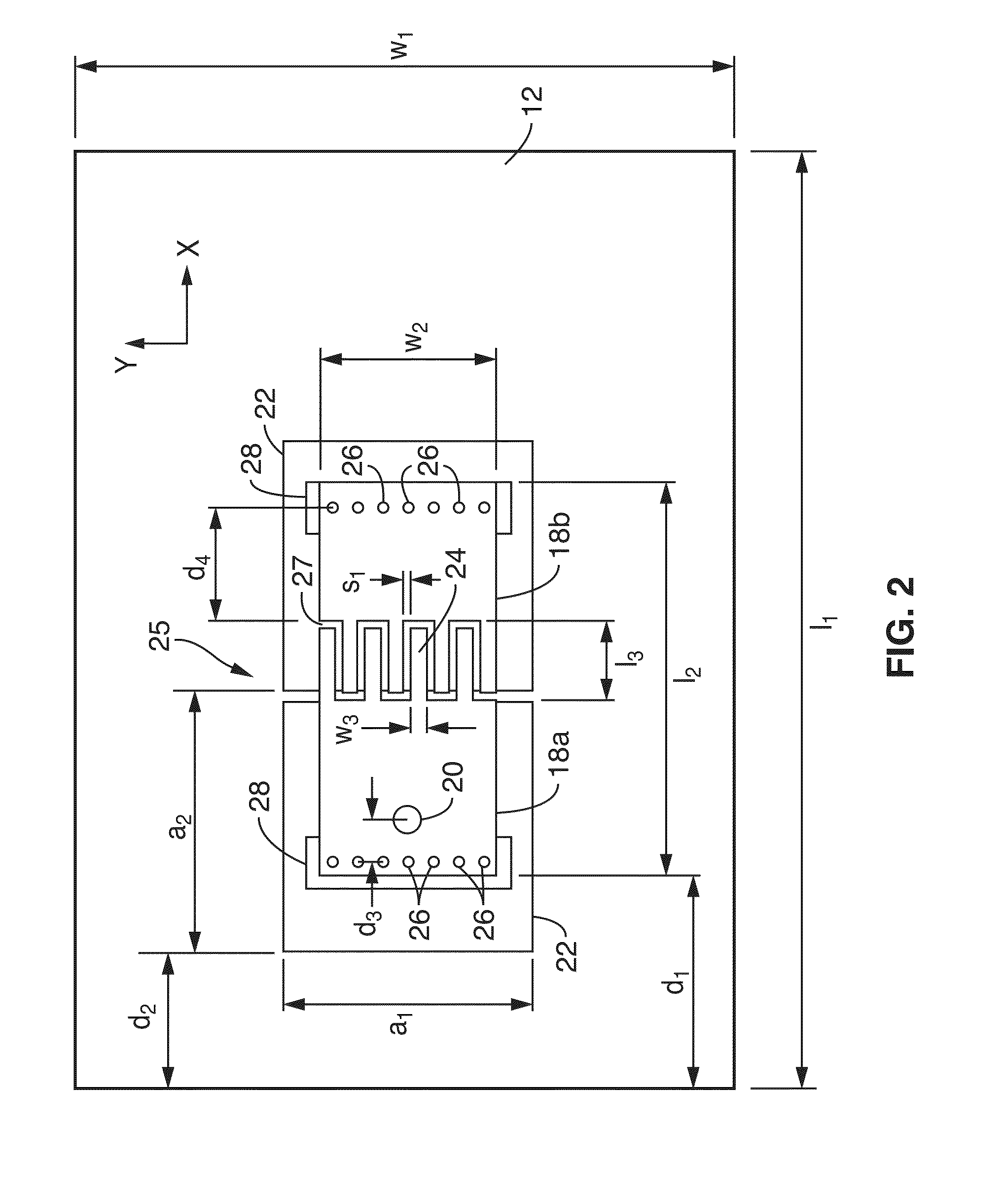

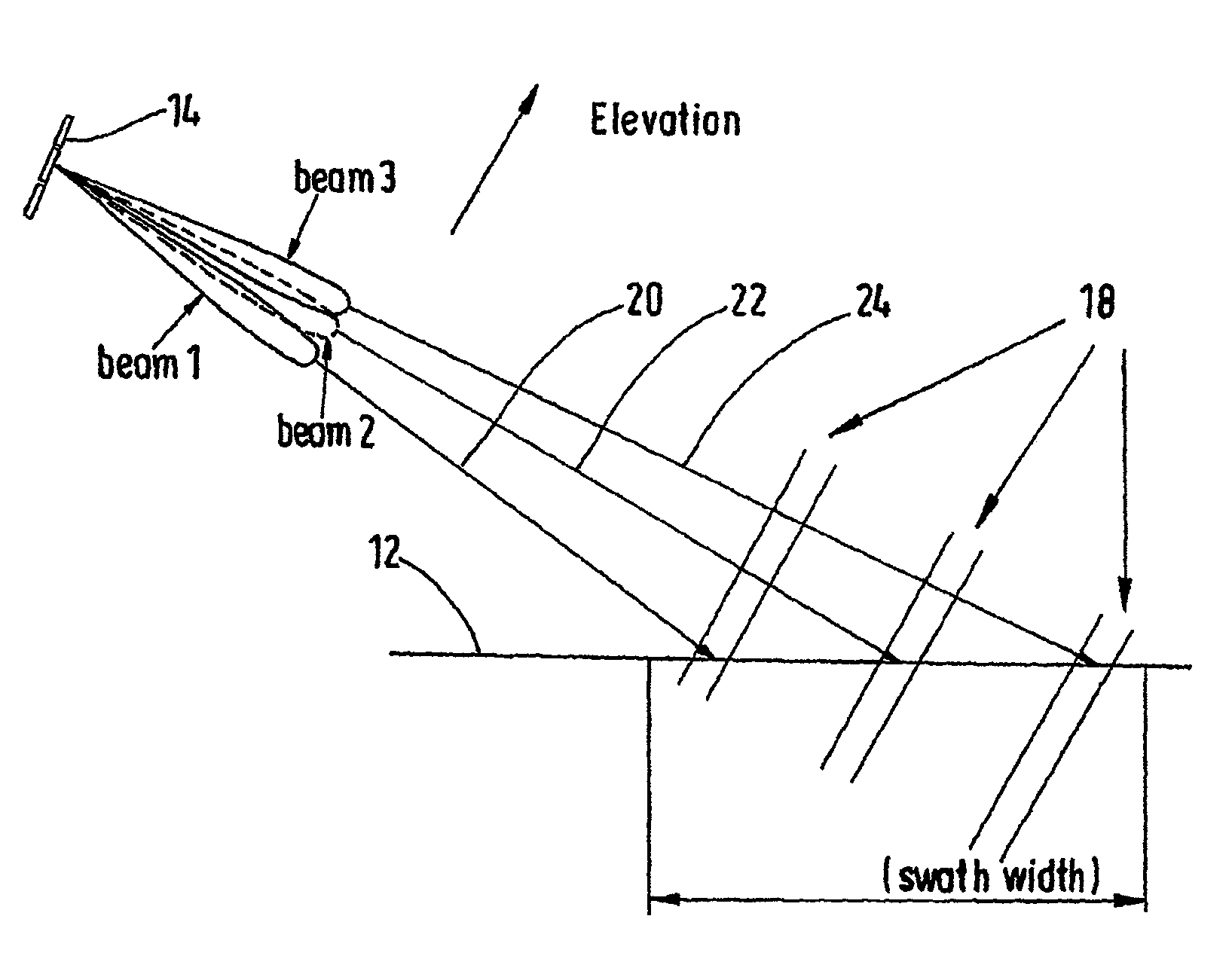

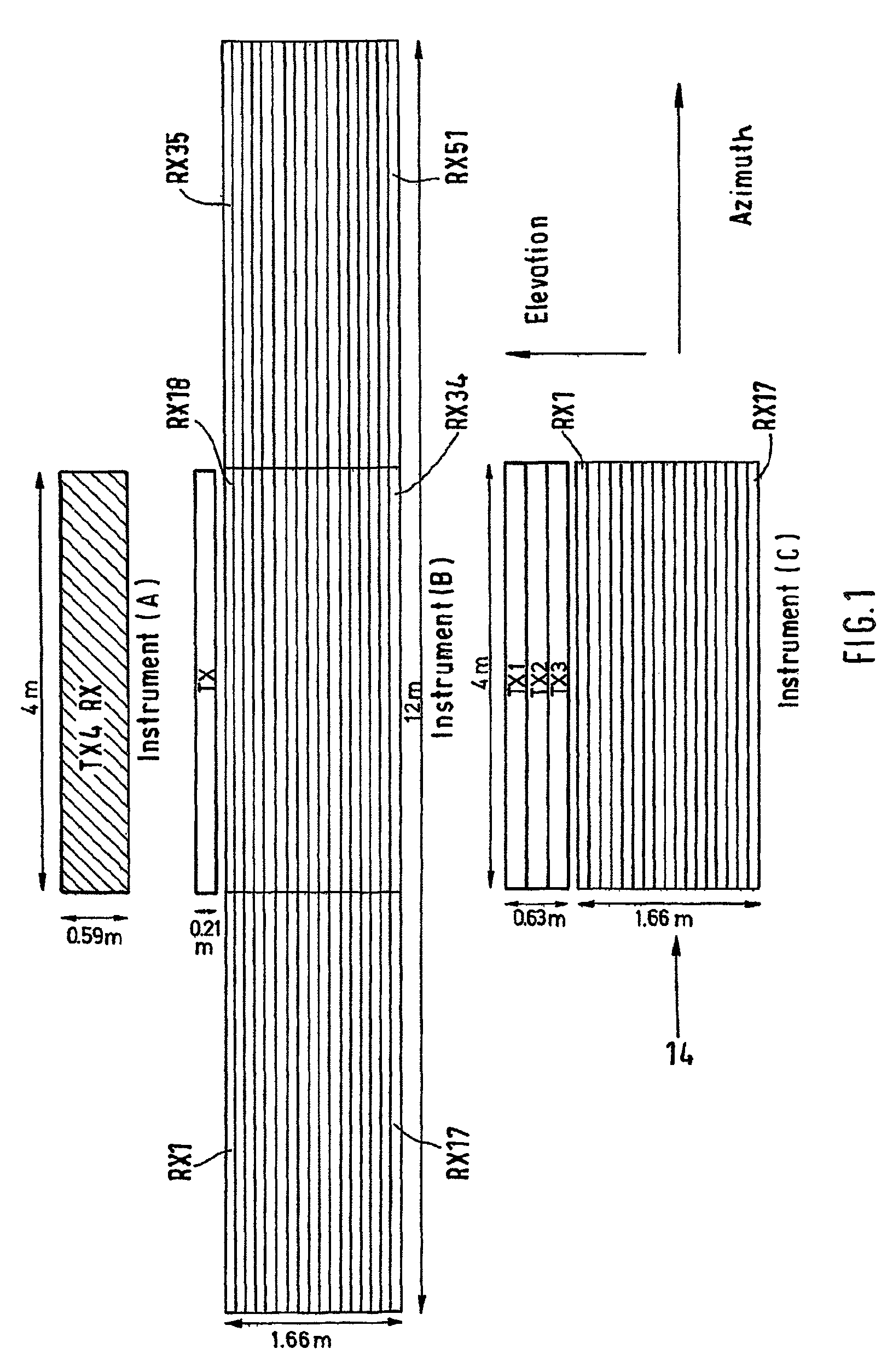

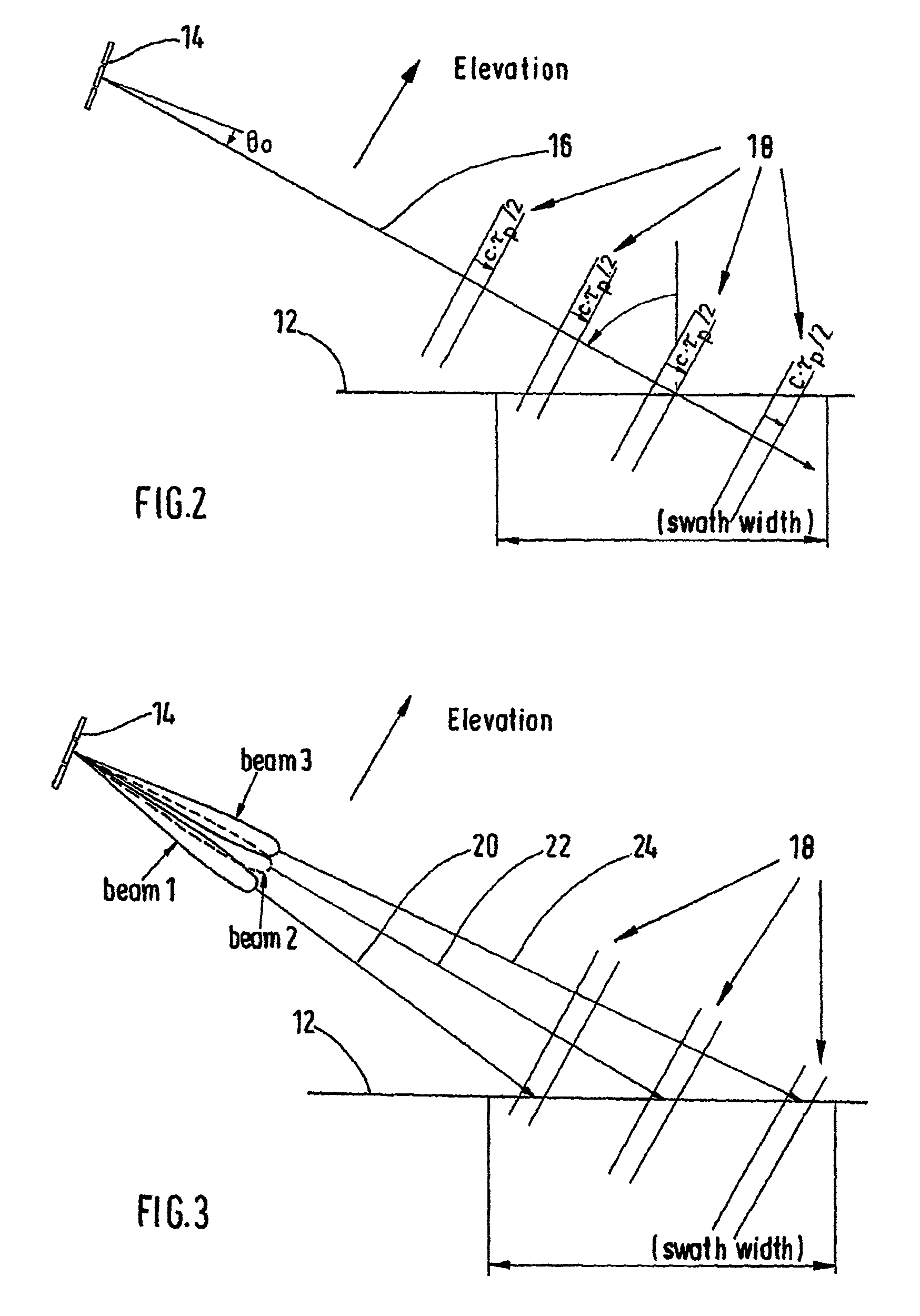

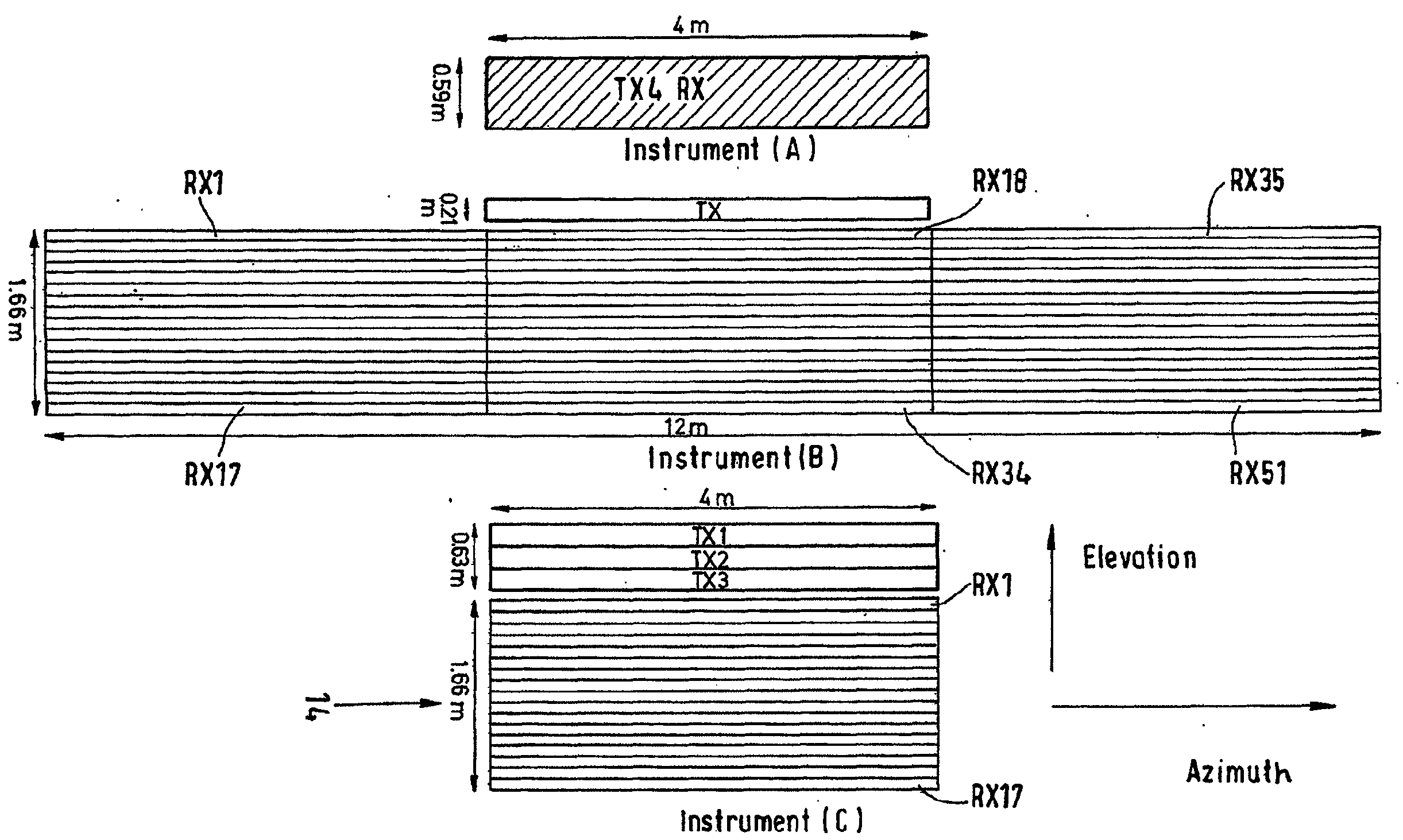

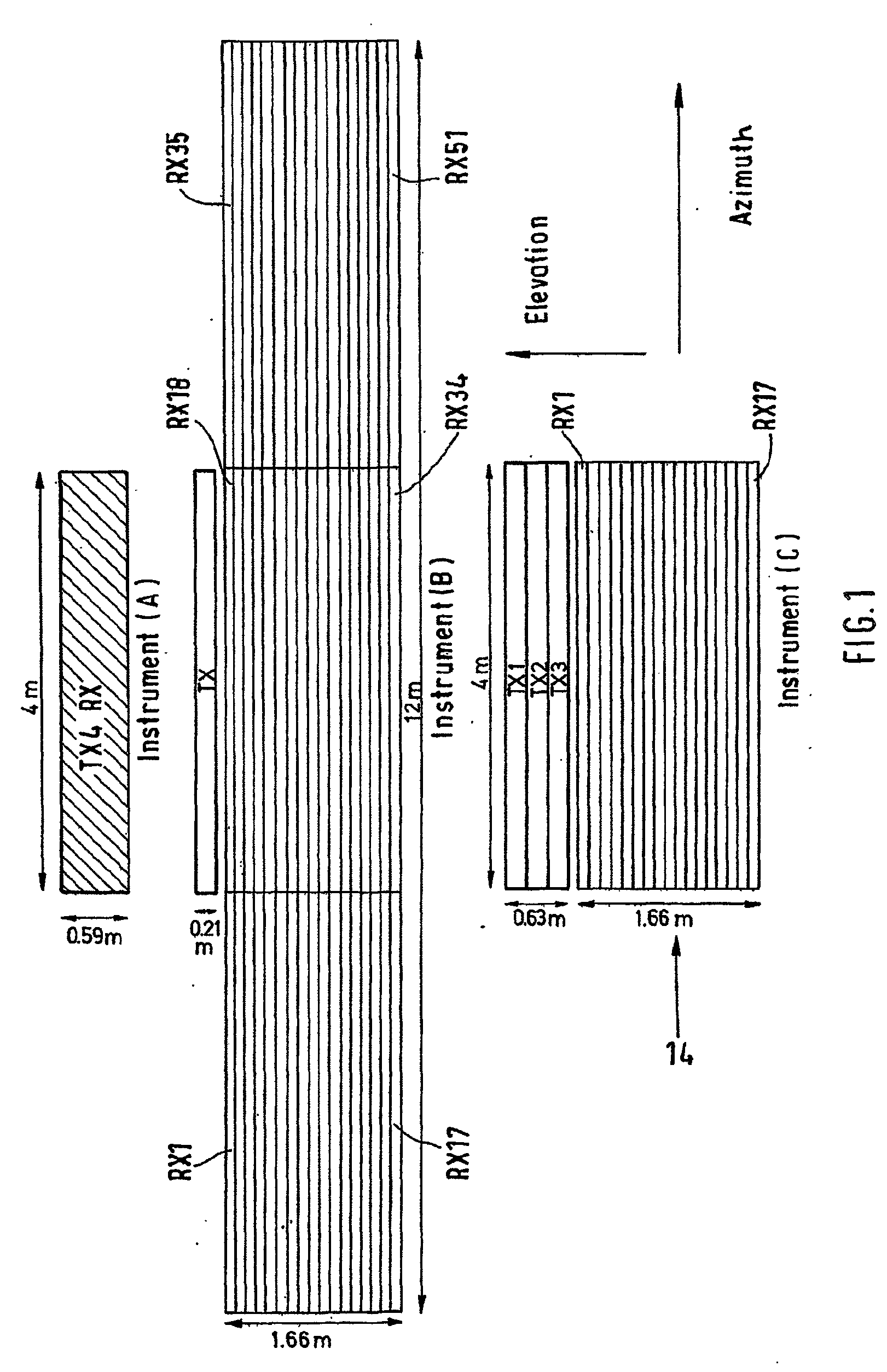

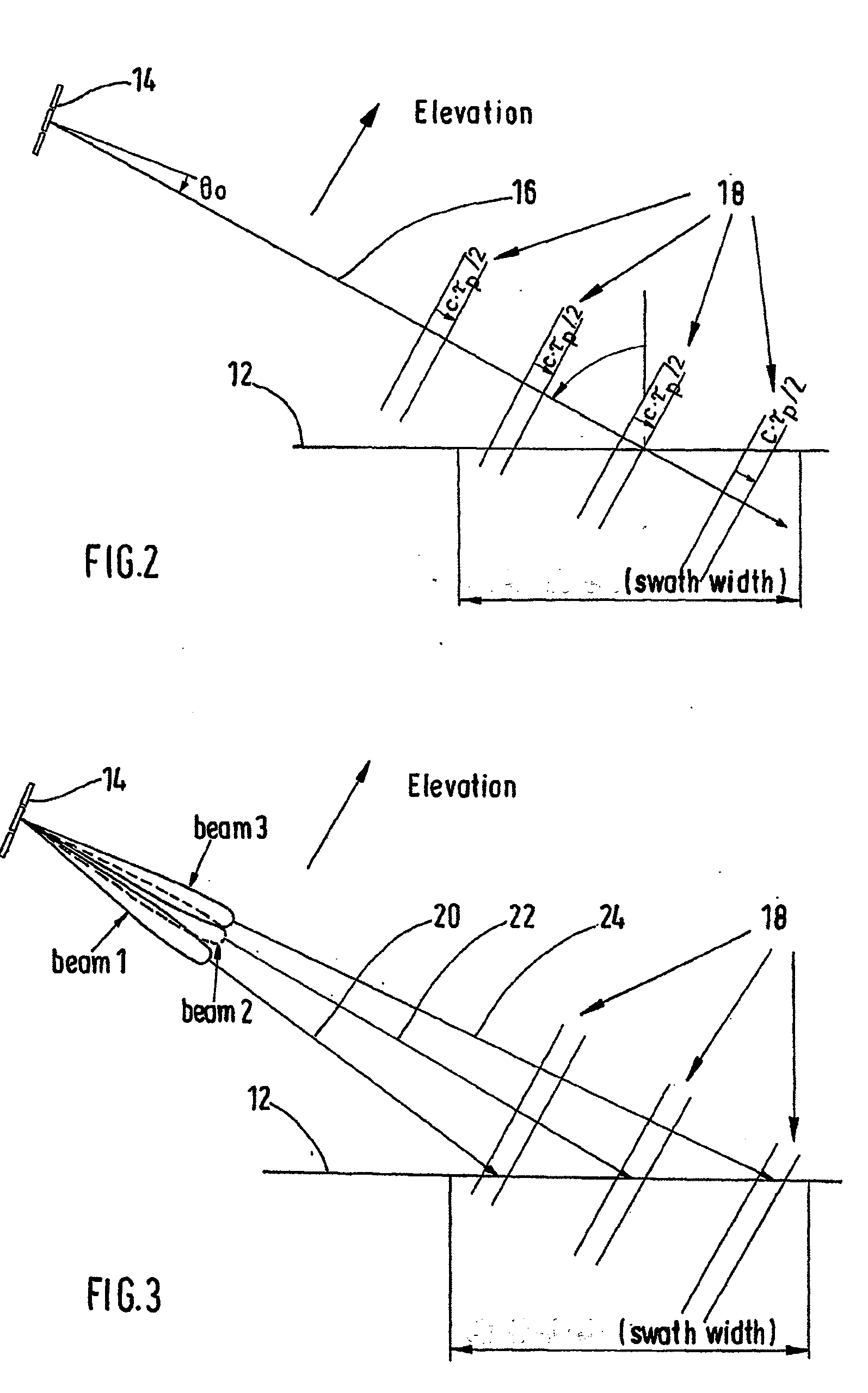

High-resolution synthetic aperture radar device and antenna for one such radar

ActiveUS8013778B2Reduce areaHigh resolutionCommunication jammingRadio wave reradiation/reflectionSynthetic aperture radarLight beam

The invention relates to a high-resolution synthetic aperture radar device (10) comprising at least one transmitting antenna (TX1-TX3) for producing and emitting radar pulses for scanning an object (12), a receiving antenna (14) for receiving the radar beams (20, 22, 24) emitted and reflected by an object, wherein the receiving antenna (14) has several sub-apertures (RX1-RX17) arranged along elevation, which form a minimum of azimuth apertures, wherein the high-resolution synthetic aperture radar device is embodied such that pulse signals (18) are emitted at irregular time intervals.

Owner:AIRBUS DEFENCE & SPACE

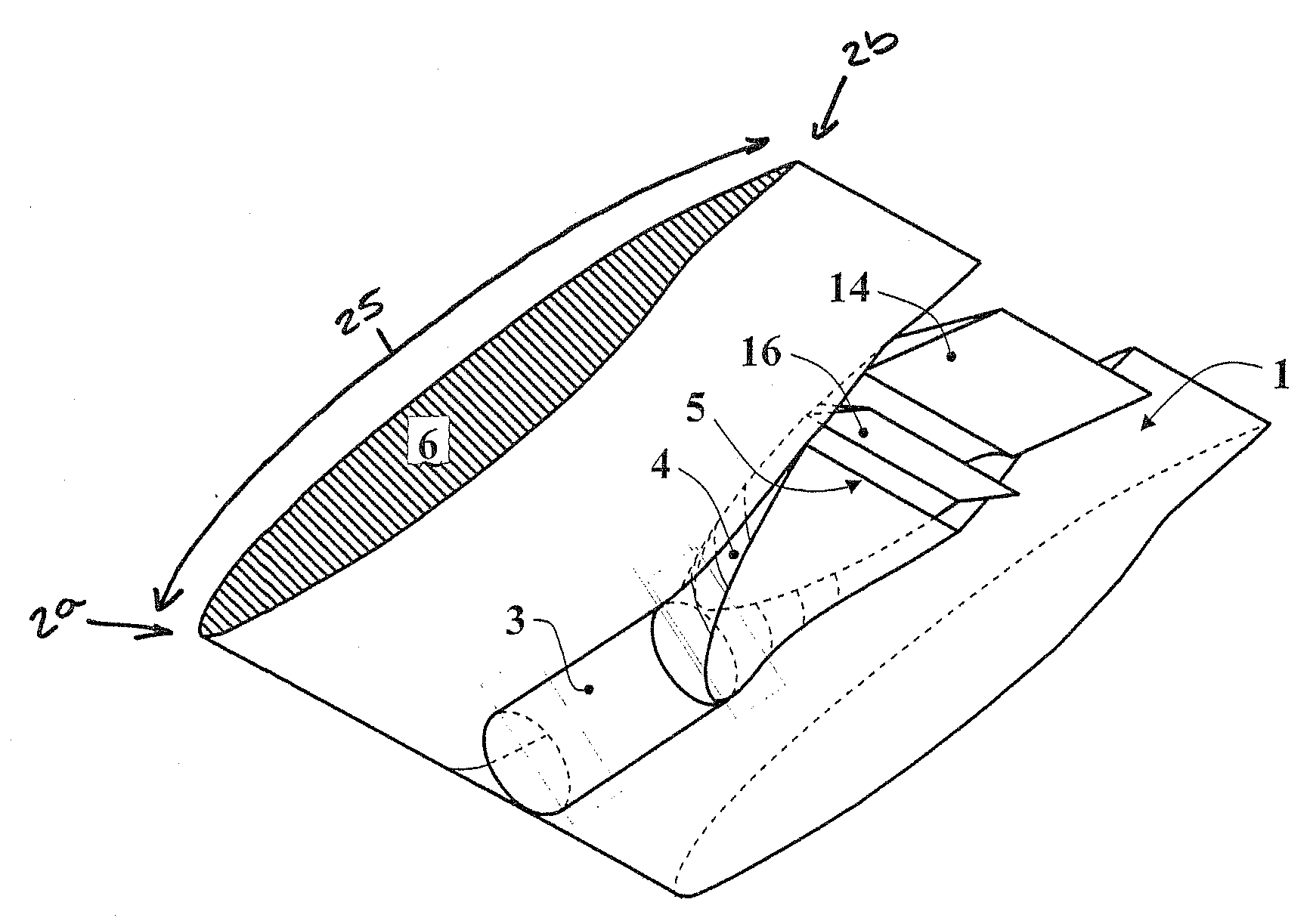

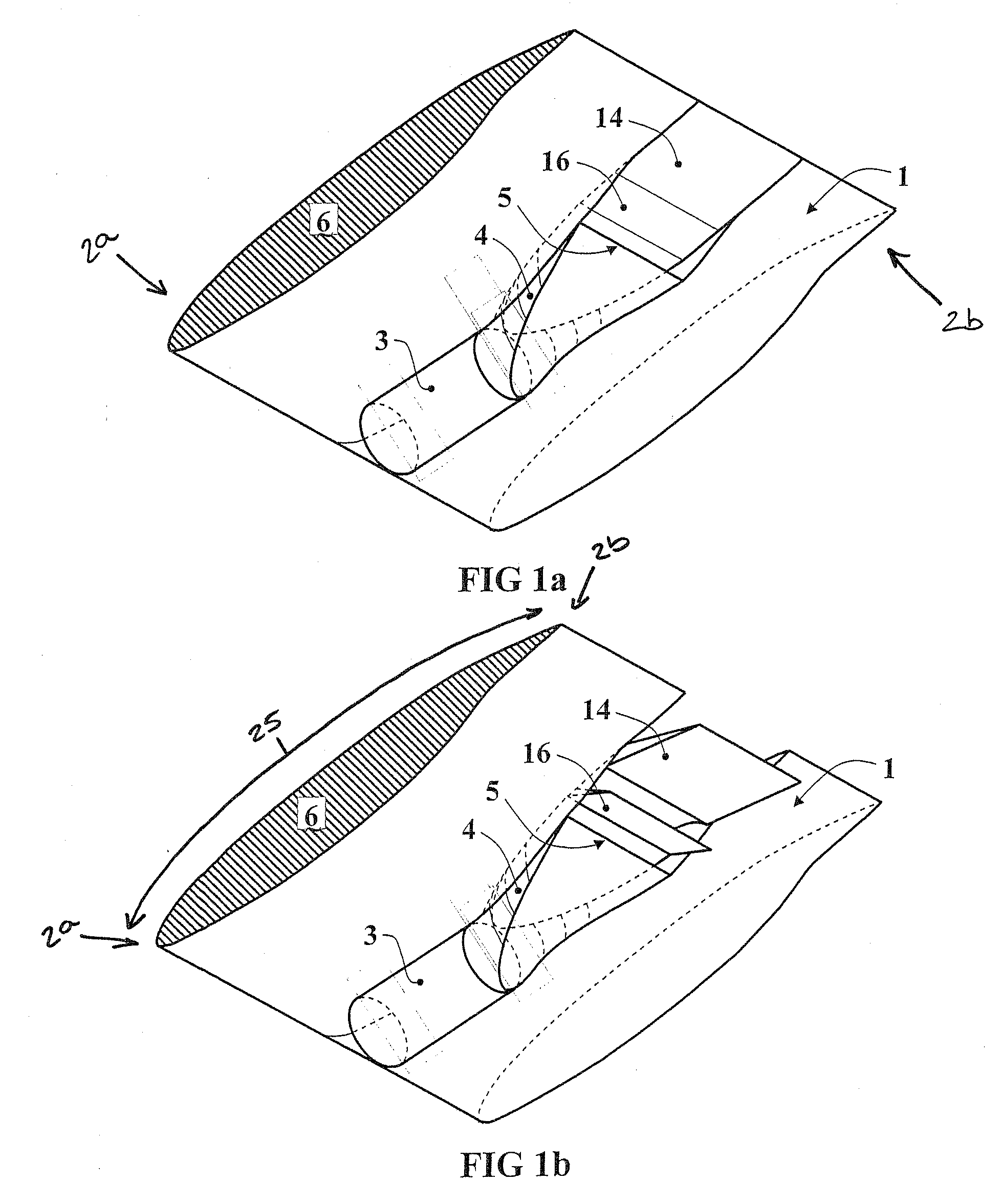

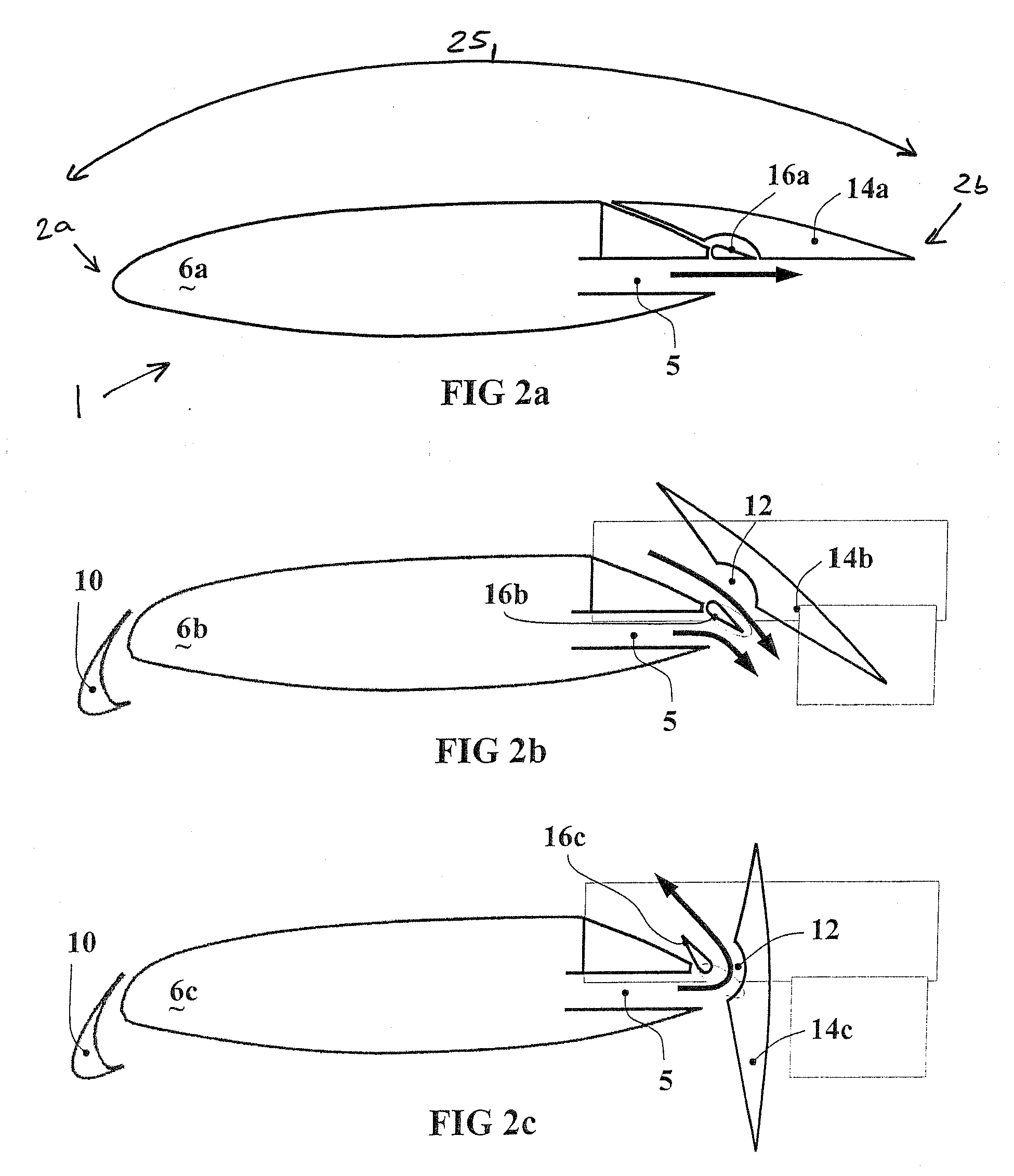

Airfoil having a movable control surface

InactiveUS20070290098A1Large pitching momentImprove abilitiesAircraft navigation controlPower plant exhaust arrangementsLeading edgeTrailing edge

An airfoil for use with an aircraft having an engine positioned such that exhaust from the engine flows under an underside of the airfoil. The airfoil includes an upper surface and a movable control element. The upper surface has a leading edge and a trailing edge. The movable control element is positioned adjacent the trailing edge and is selectively controlled for movement between a first position and a second position. In the first position, the movable control element does not mix fluid flowing over the top of the airfoil with engine exhaust under the airfoil. In the second position, at least some of the fluid flowing over the top of the airfoil mixes under the airfoil with engine exhaust.

Owner:LOCKHEED MARTIN CORP

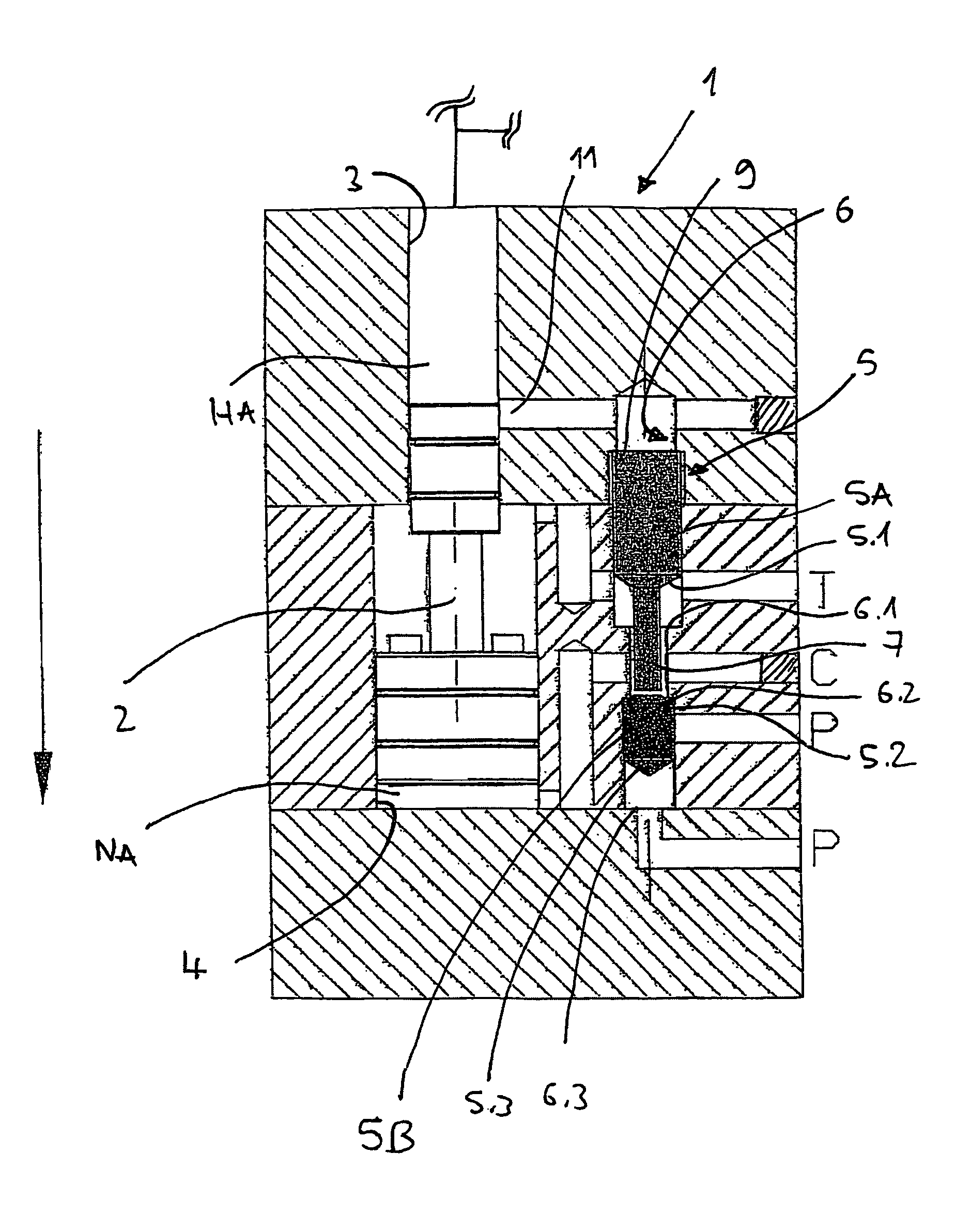

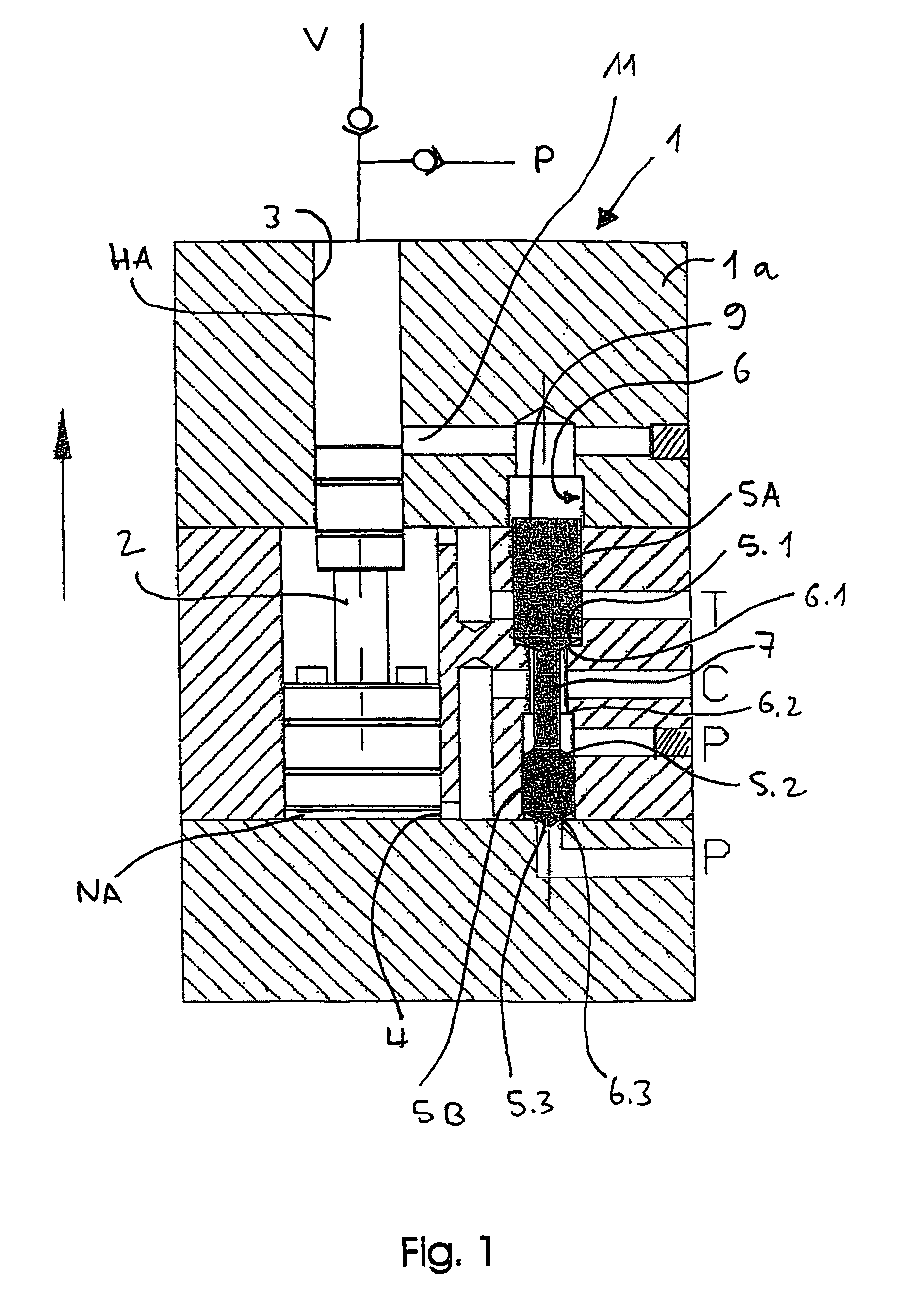

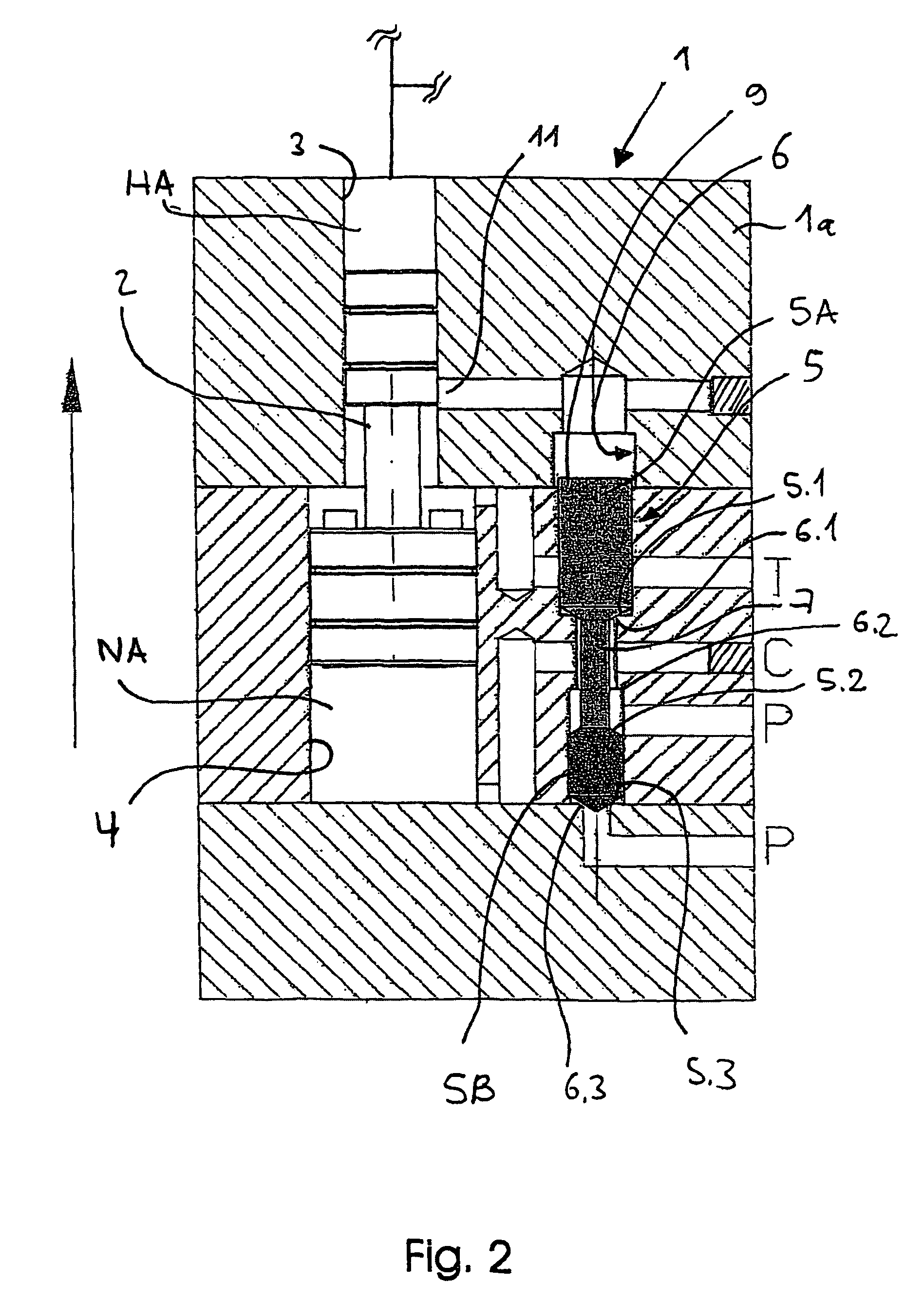

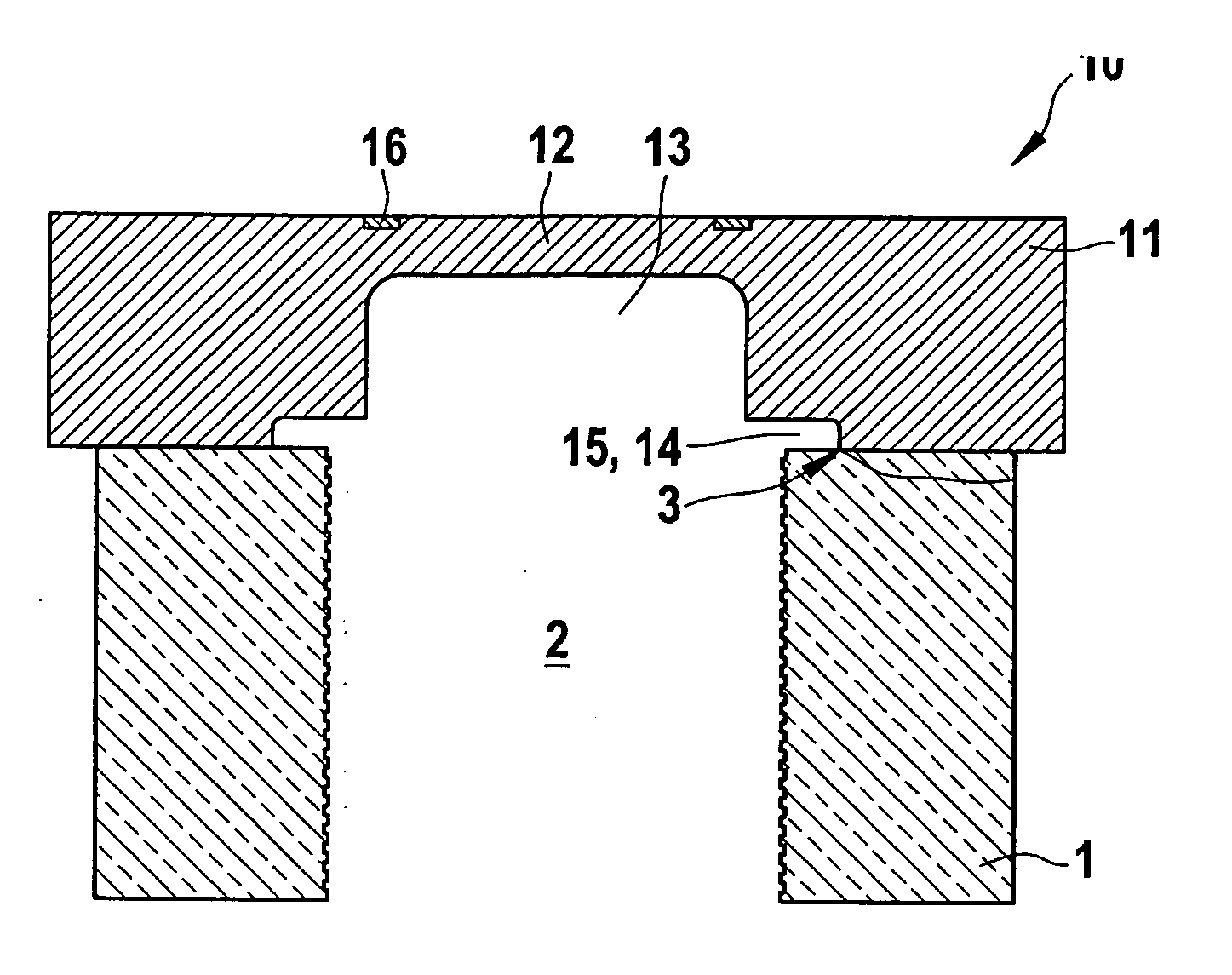

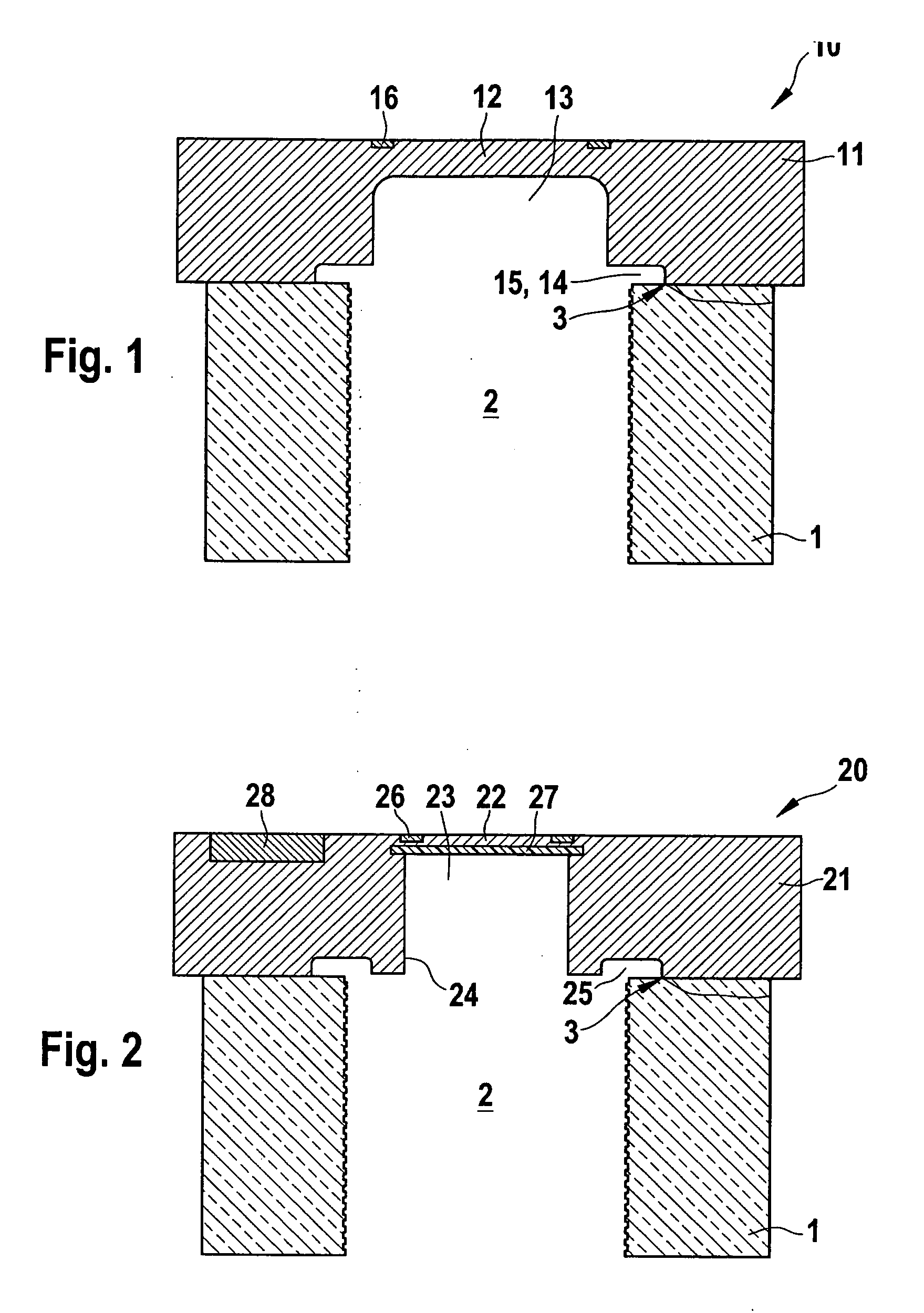

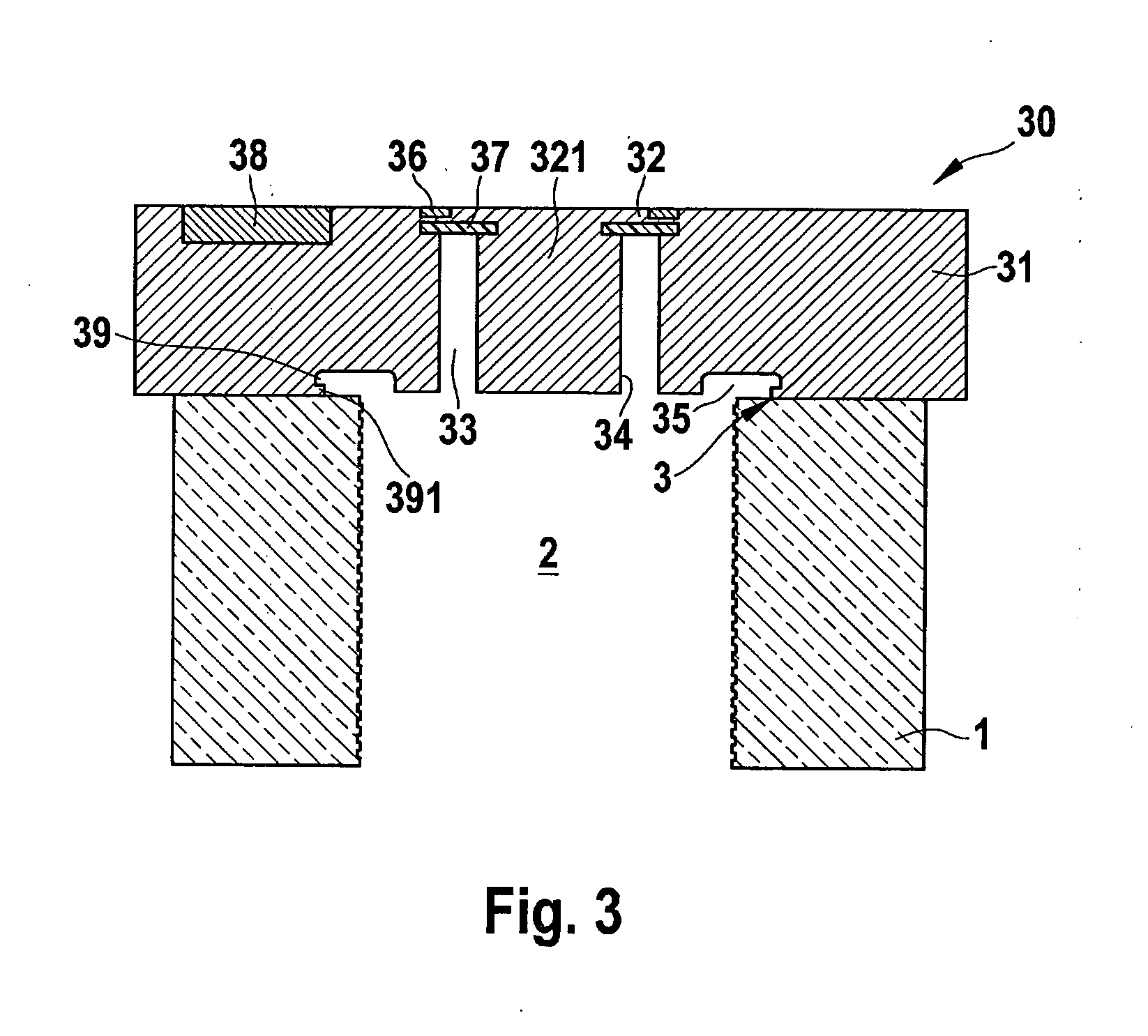

Pressure booster with double-seat valve

ActiveUS8613602B2High roughnessImprove toleranceFluid-pressure convertersMultiple way valvesEngineeringHigh pressure

The invention relates to a pressure boost for fluids, in particular hydraulic fluids, having a booster piston and a control piston unit, wherein a low-pressure side of the booster piston can be alternately connected by the control piston unit via a cylinder line to a low-pressure feed line and a discharge line, and a high-pressure side of the booster piston can be alternately connected to a high-pressure load line and a low-pressure feed line, wherein the control piston unit has two elements which are embodied as seat valves and which each interact with one valve seat and which are designed such that one of the elements intermittently seals off the low-pressure feed line, which can be connected to the low-pressure side of the booster piston, and the other element intermittently seals off the discharge line, which can be connected to the low-pressure side of the booster piston.

Owner:SCANWILL FLUID POWER APS

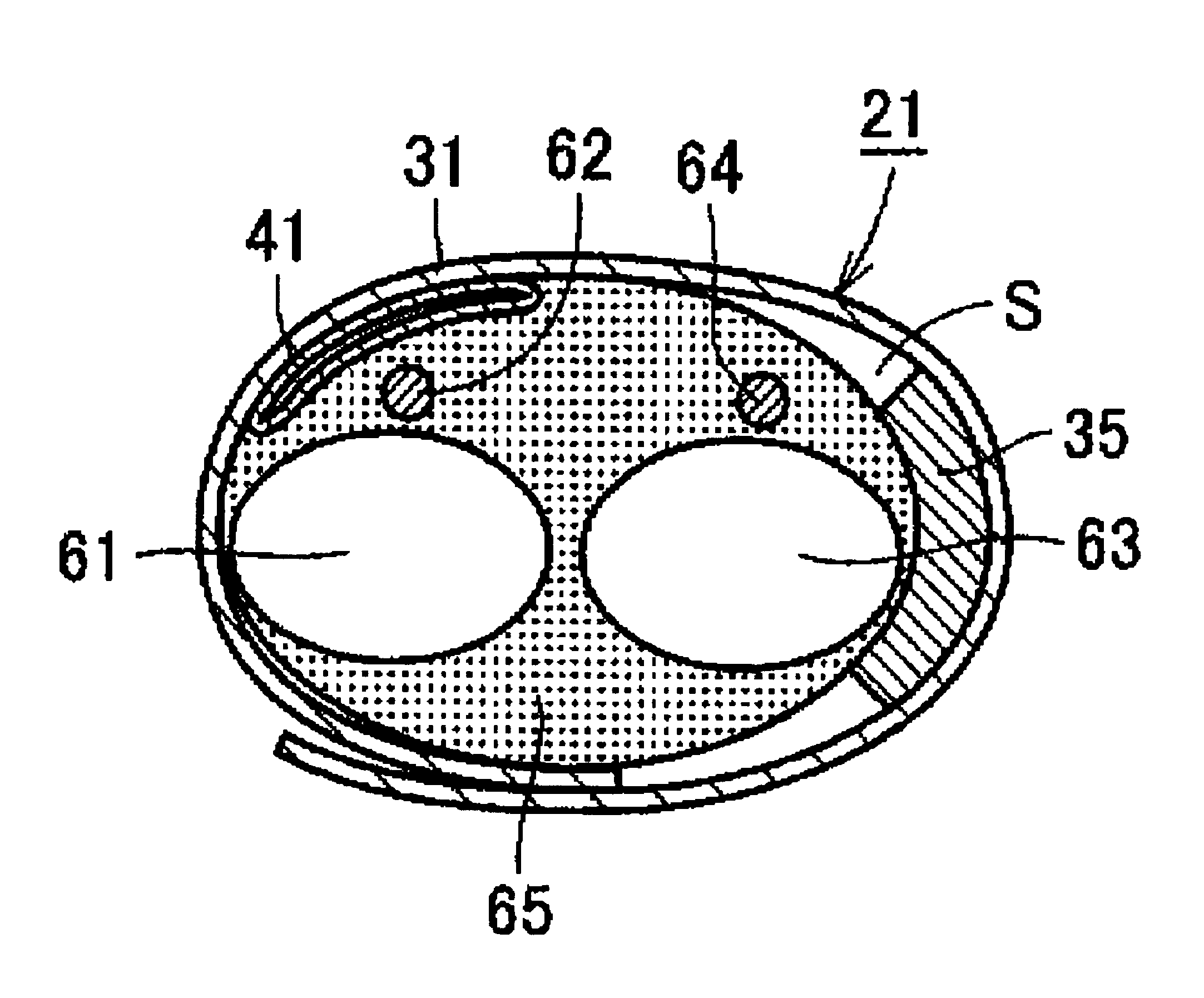

Wrist type blood pressure meter cuff

InactiveUS6932773B2Reduce pressureSmall rateEvaluation of blood vesselsCatheterUlnar arterySphygmomanometer

Provide is a wrist type blood pressure meter cuff not oppressing the non-selected artery so as to prevent its pulse waves from mixing into pulse waves of the selected artery necessary for measurement, in a cuff used in a blood pressure meter for measuring blood pressures by selecting and oppressing one artery of the wrist. A wrist type blood pressure meter cuff comprises a fluid bag for oppressing a selected artery of either radial artery or ulnar artery located at the wrist by feeding fluid inside to inflate, and a fixing member for fixing the fluid bag at the wrist. By forming a gap between the fixing member and the wrist, the oppressing pressure directly applied from the fixing member to the wrist at which the non-selected artery is located is set smaller than the oppressing pressure directly applied from the fixing member to other position of the wrist when oppressing the wrist by inflating the fluid bag. This gap is produced by a swollen part provided in the fixing member.

Owner:OMRON HEALTHCARE CO LTD

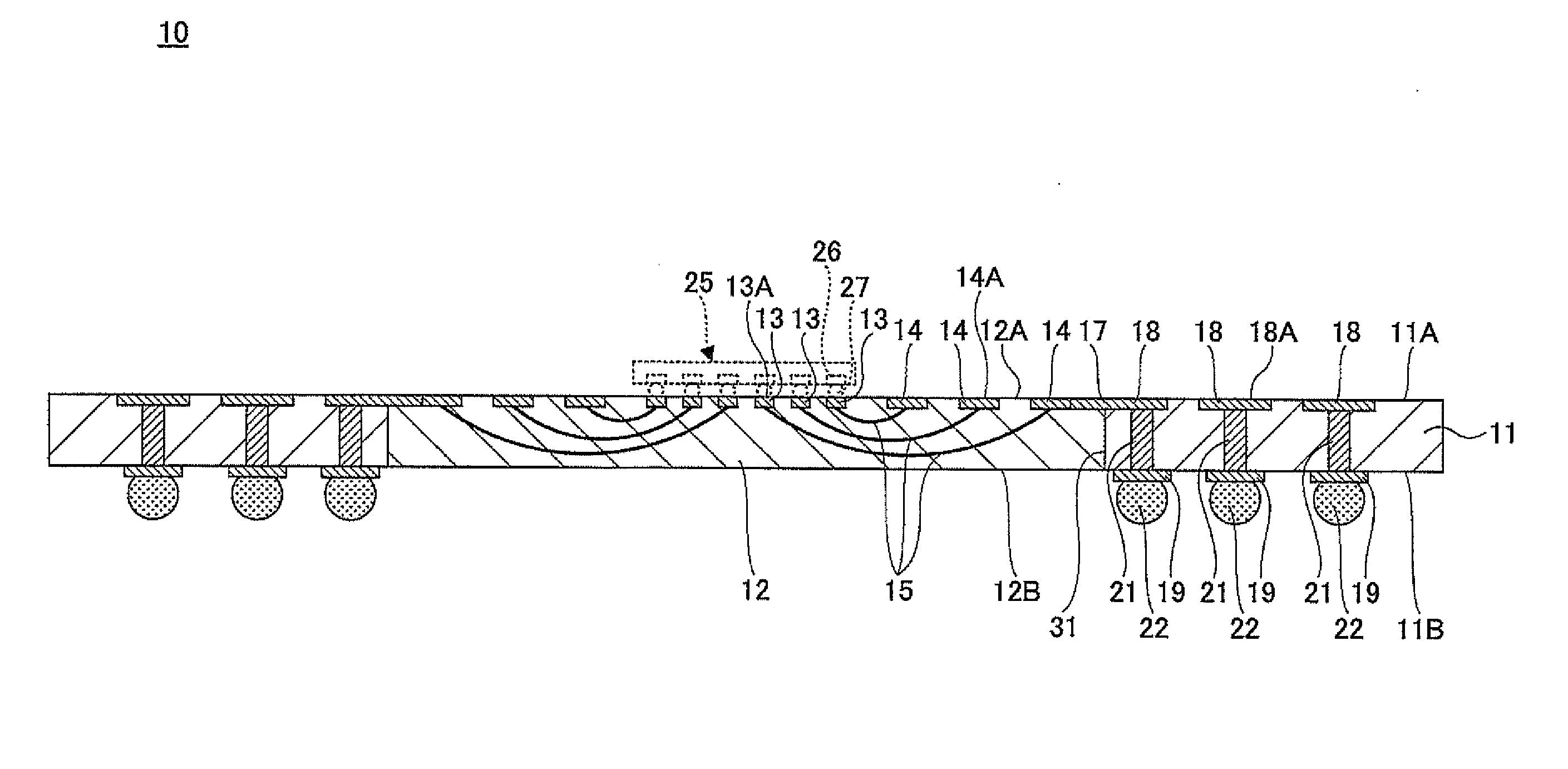

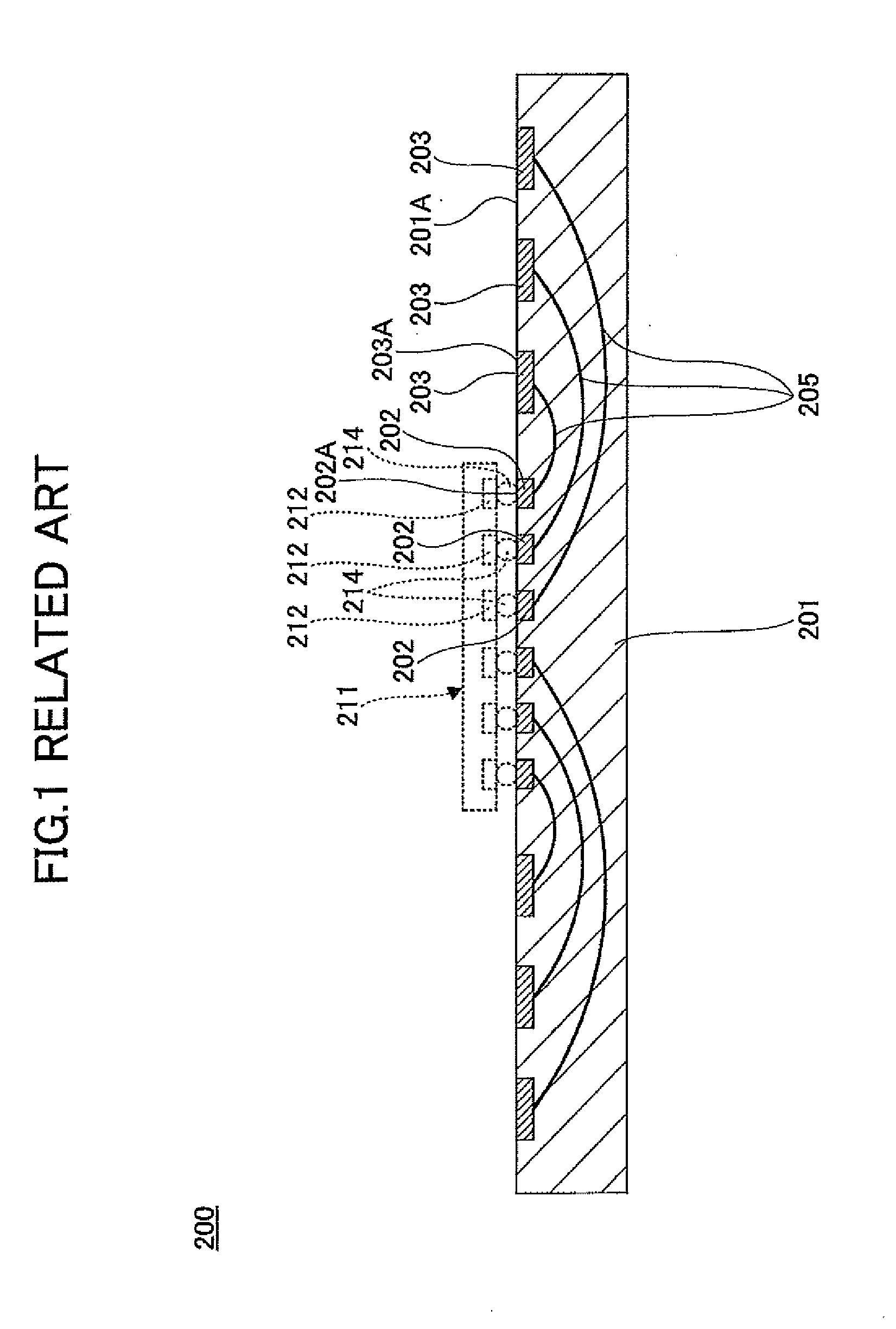

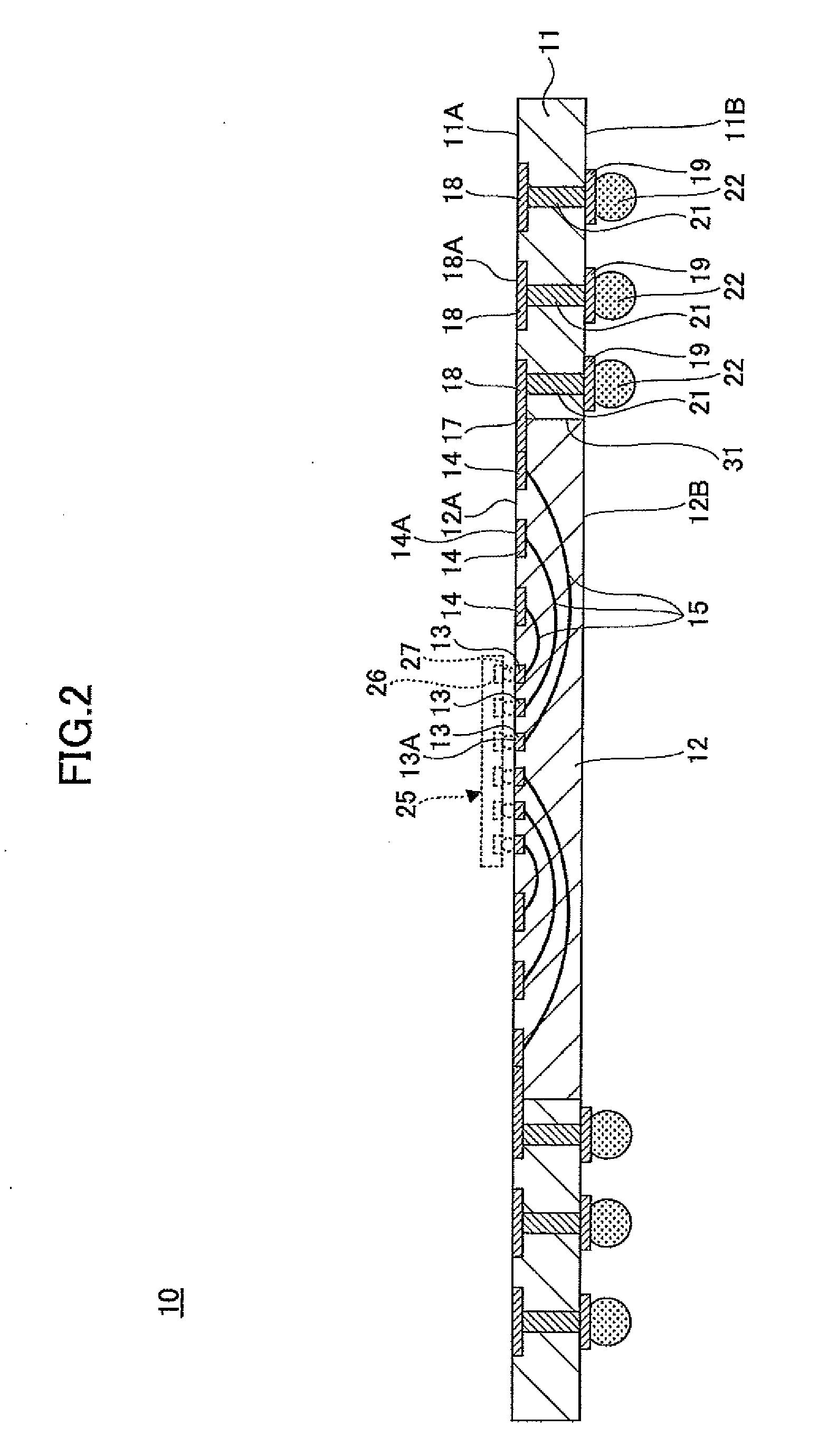

Wiring board

InactiveUS20090266598A1Efficient arrangementSurfaces with very littlePrinted electric component incorporationSemiconductor/solid-state device detailsSemiconductor chipPower strip

A wiring board includes a plate-shaped resin member; chip connection pads provided in the resin member, the chip connection pads having connection surfaces electrically connected to electrode pads provided on a semiconductor chip, the connection surfaces being situated in substantially the same plane as a first surface of the resin member, the first surface being a side where the semiconductor chip is mounted; pads provided in a portion of the resin member, the portion being situated outside an area where the chip connection pads are formed; lead wirings connected to the pads; and conductive wires sealed by the resin member, the conductive wires electrically connecting the chip connection pads and the pads to each other.

Owner:SHINKO ELECTRIC IND CO LTD

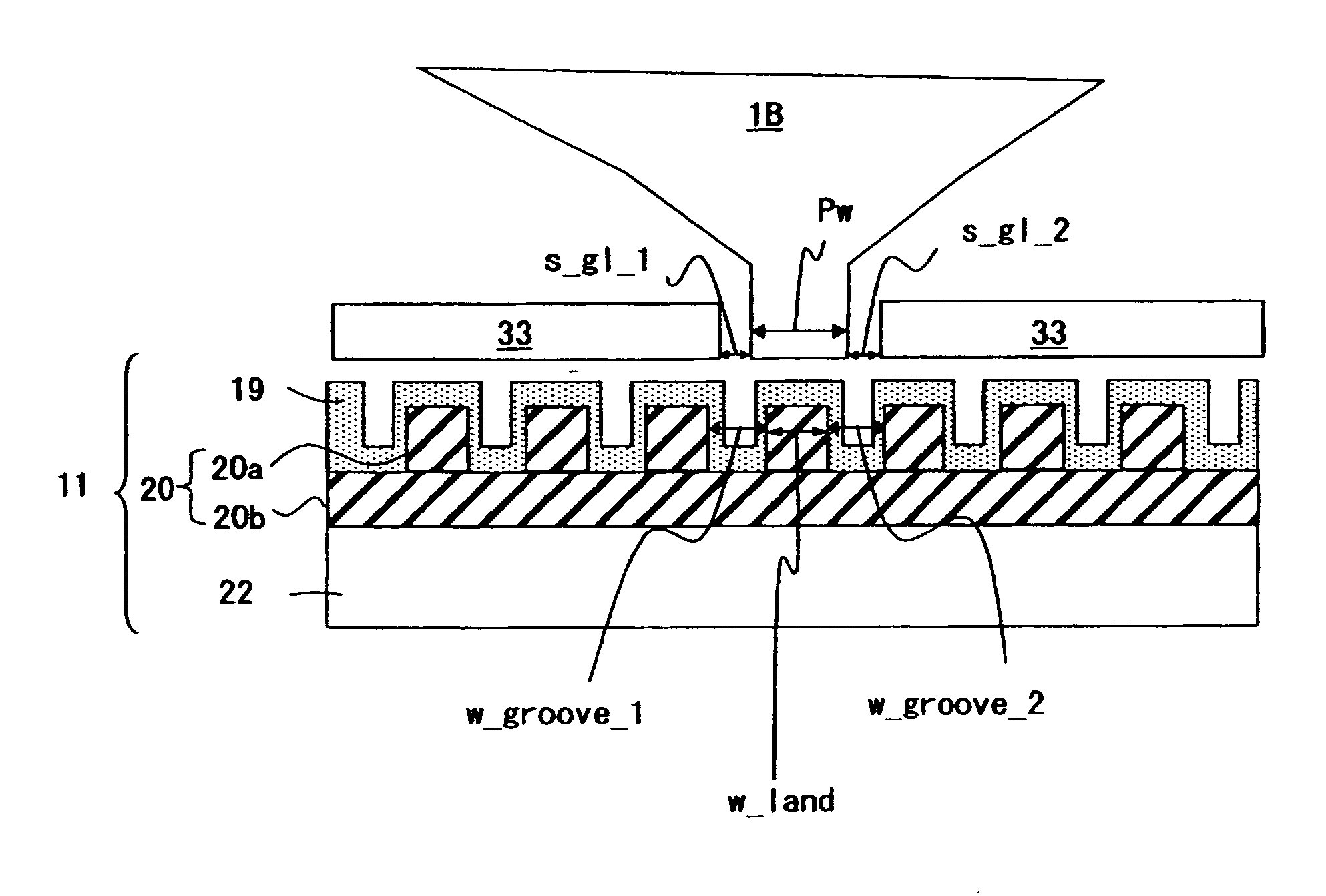

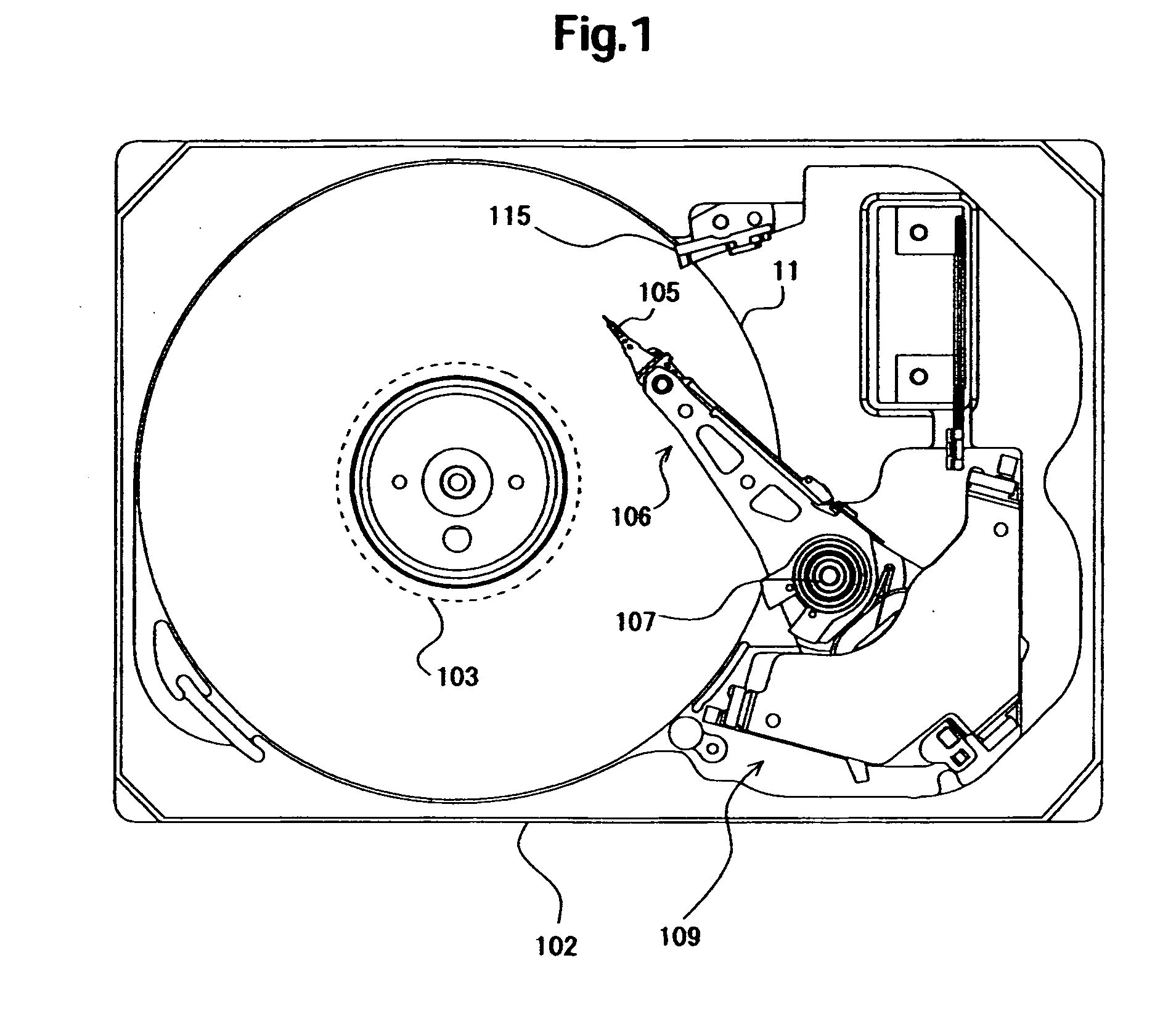

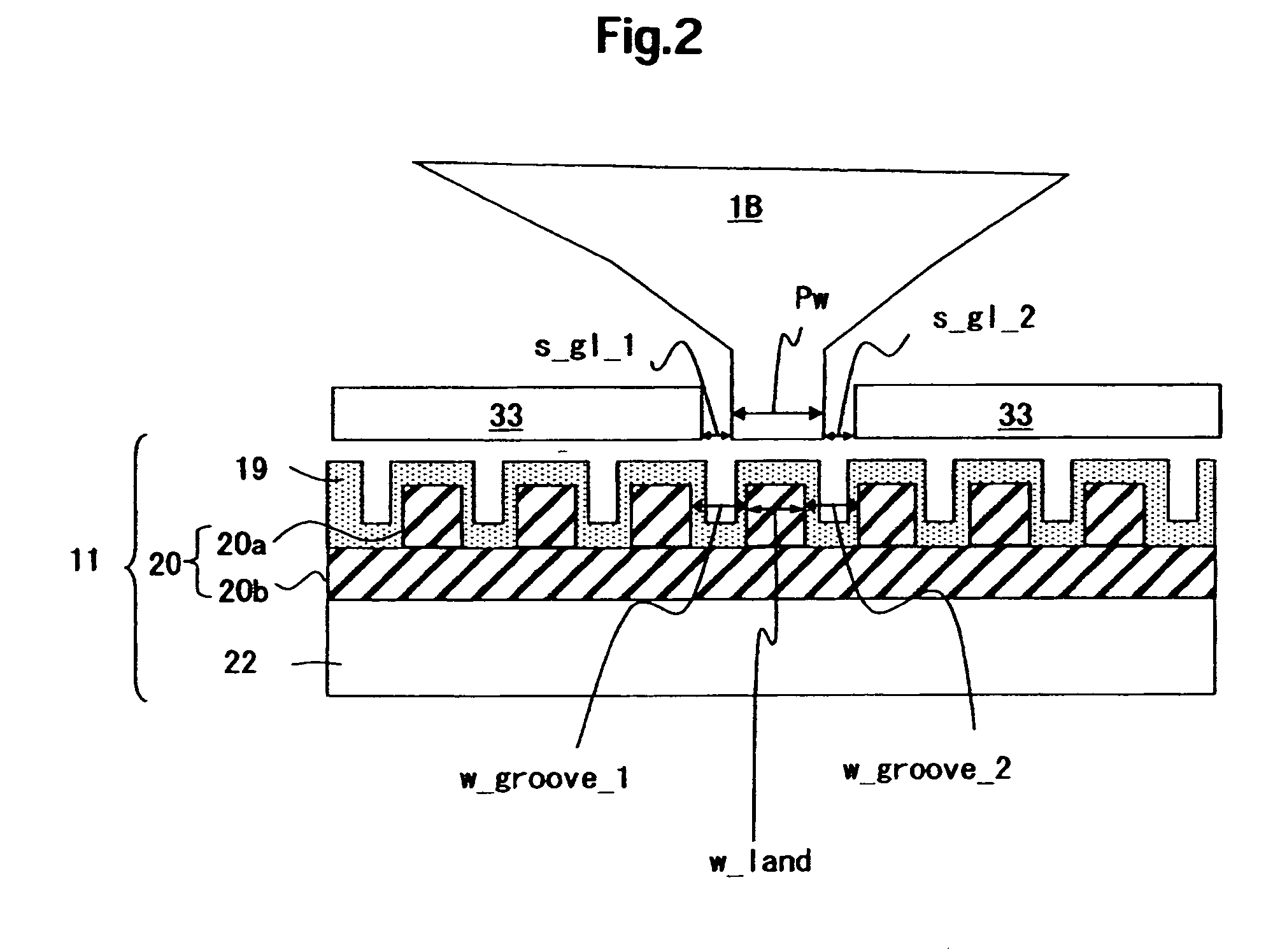

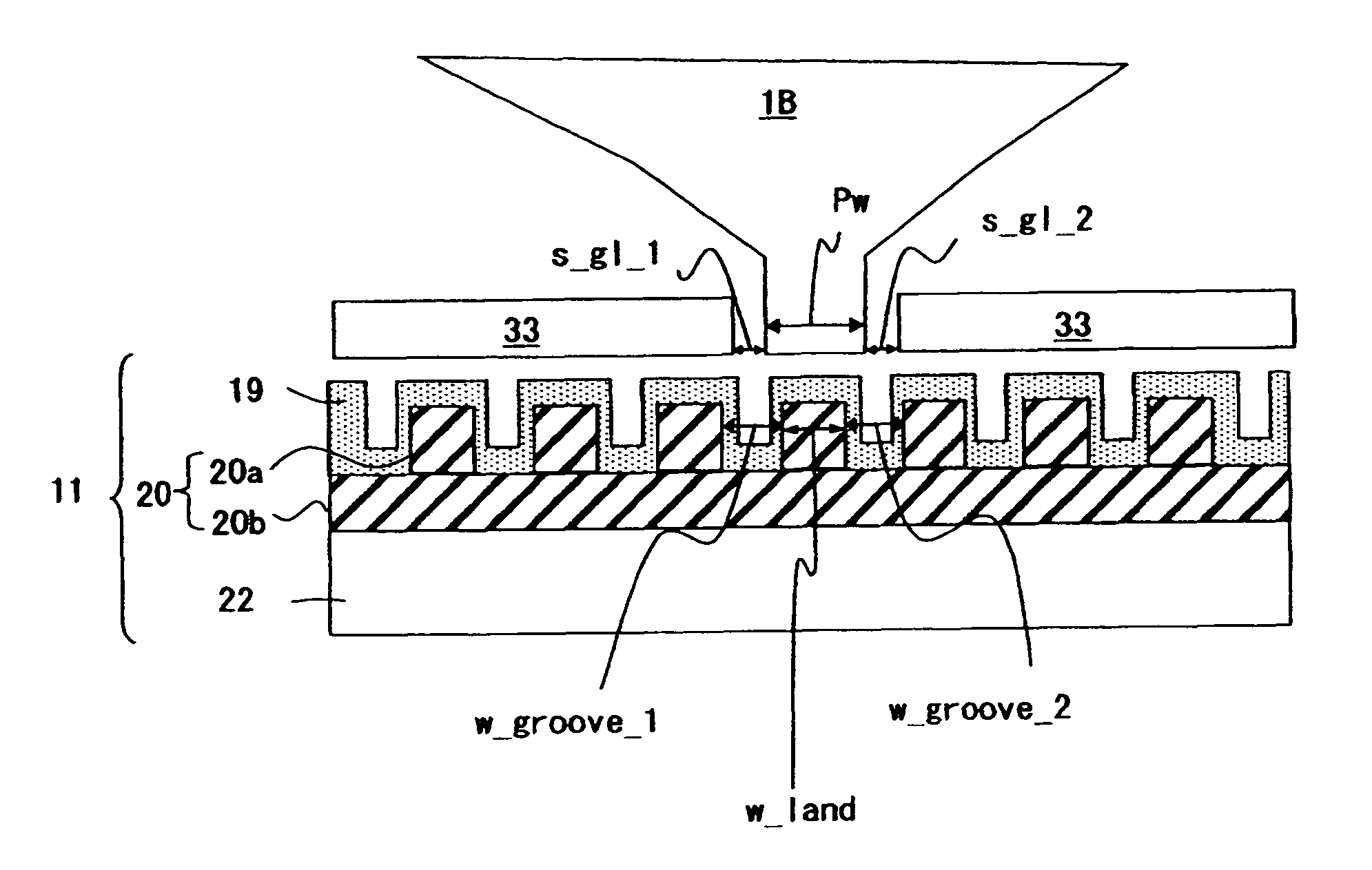

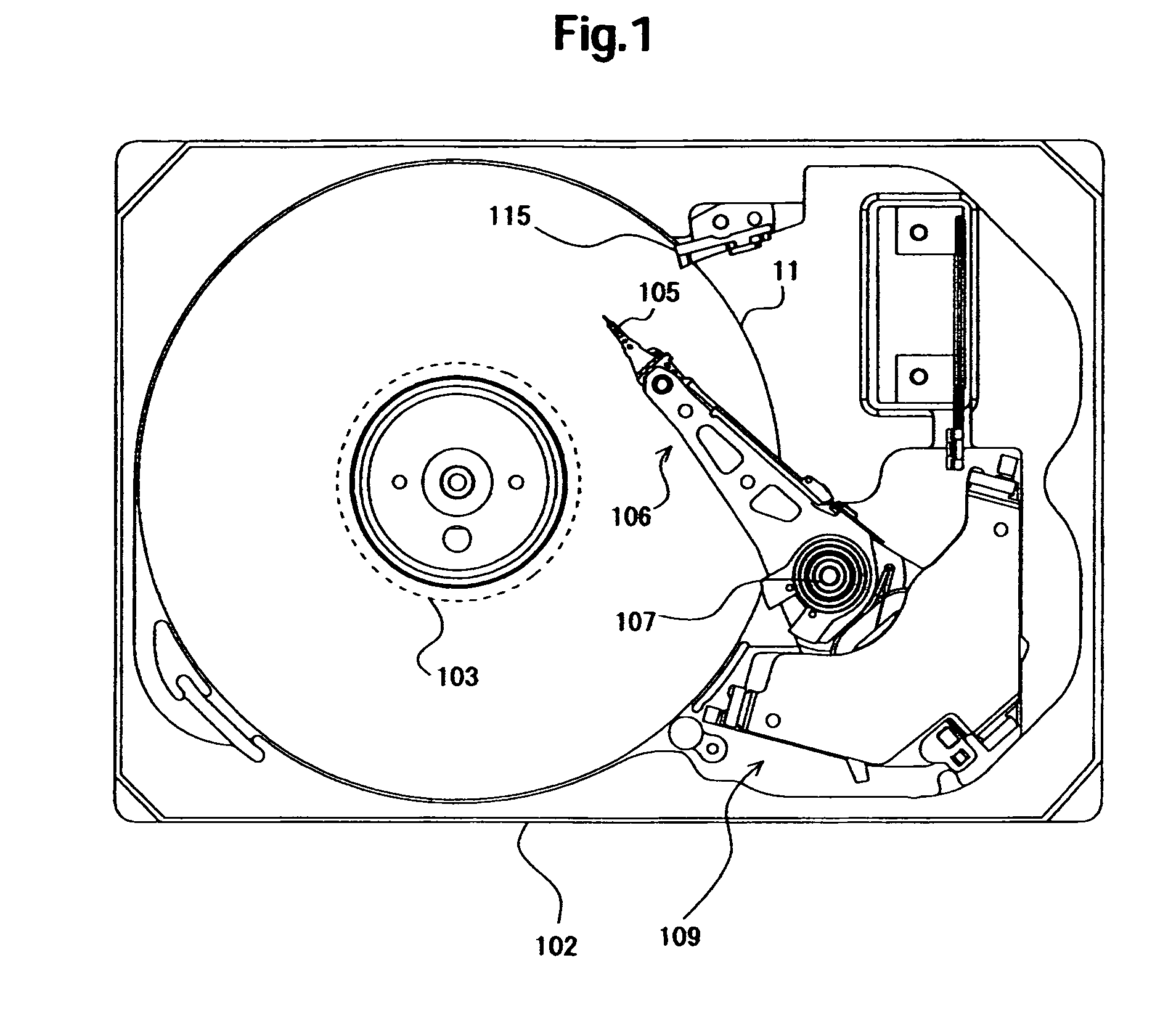

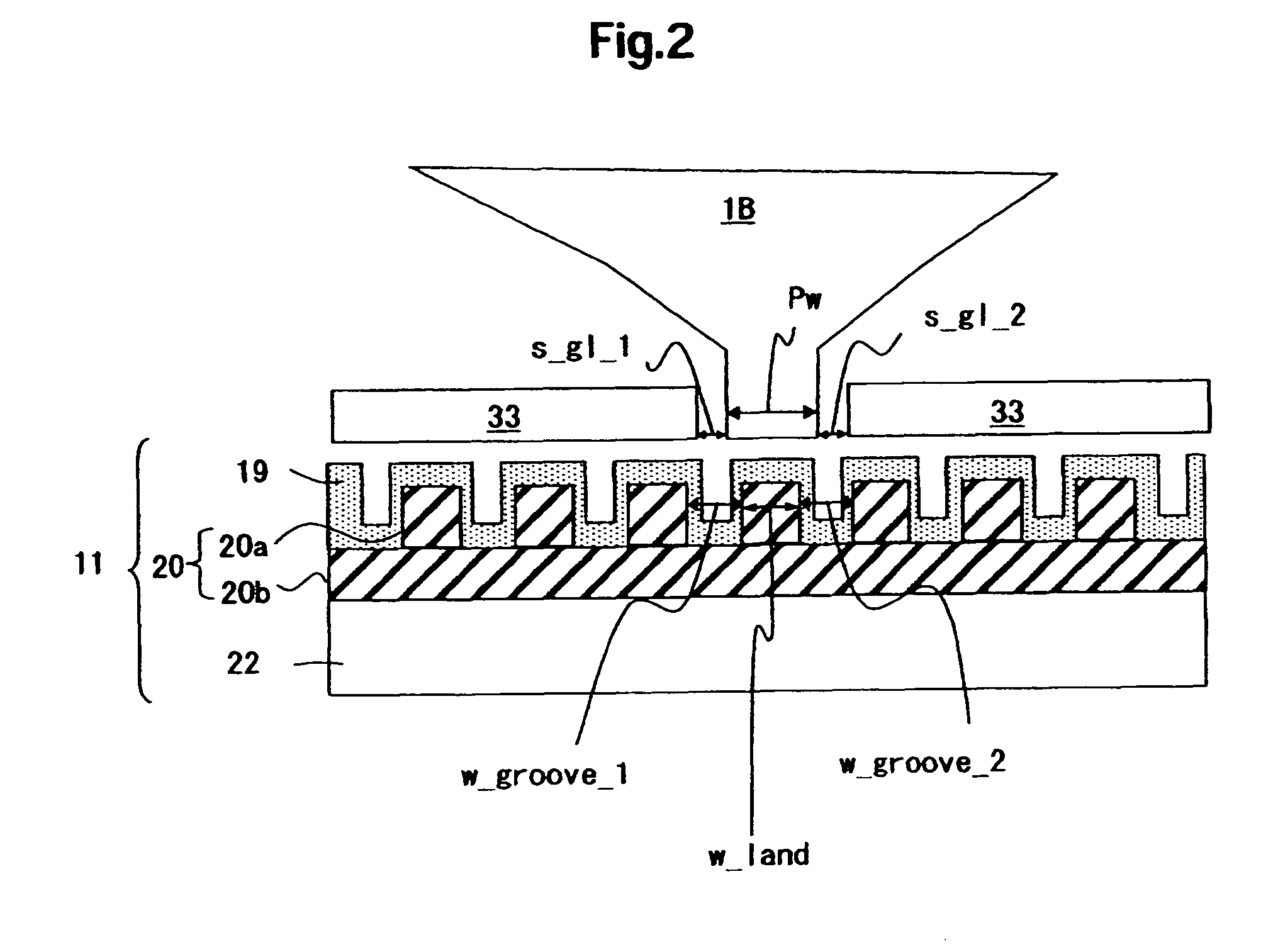

Magnetic disk drive

InactiveUS20080180839A1Strong recording magnetic fieldSurfaces with very littleNanoinformaticsPatterned record carriersMagnetic polesEngineering

In a patterned perpendicular magnetic recording medium, embodiments of the present invention provide a magnetic head in which magnetic field to be applied to adjacent tracks can be suppressed and a recording device equipped with the magnetic head. In one embodiment of the present invention, a sum of a width Pw of a main pole of a magnetic head and distances between right and left magnetic substances on a width-directional side of tracks and the main pole, so-called widths of side gap lengths s_g1—1 and s_g1—2 is, in a magnetic recording medium having a soft-magnetic underlayer, made to be not more than a sum of a width w_land of a convexity or land of the soft-magnetic underlayer and widths w_groove—1 and w_groove—2 of concavities or grooves adjacent to the land on both its sides.

Owner:WESTERN DIGITAL TECH INC

High-resolution synthetic aperture radar device and antenna for one such radar

ActiveUS20090079621A1Small antenna areaReduce areaRadio wave reradiation/reflectionSynthetic aperture radarLight beam

The invention relates to a high-resolution synthetic aperture radar device (10) comprising at least one transmitting antenna (TX1-TX3) for producing and emitting radar pulses for scanning an object (12), a receiving antenna (14) for receiving the radar beams (20, 22, 24) emitted and reflected by an object, wherein the receiving antenna (14) has several sub-apertures (RX1-RX17) arranged along elevation, which form a minimum of azimuth apertures, wherein the high-resolution synthetic aperture radar device is embodied such that pulse signals (18) are emitted at irregular time intervals.

Owner:AIRBUS DEFENCE & SPACE

Sliding door

InactiveUS8443551B2Inexpensive to purchaseMaintain integrityBuilding braking devicesMan-operated mechanismRail profileEngineering

A sliding door with a door leaf, which is suspended from two carriages and displaceably guided along a roller rail profile, which is disposed at a wall or at a ceiling, the sliding door having at least one closing device, which is suitable to displace the decelerated door leaf into a closed position. The at least one carriage has a carrier, at or in which the closing device is disposed.

Owner:DORMAKABA DEUT GMBH

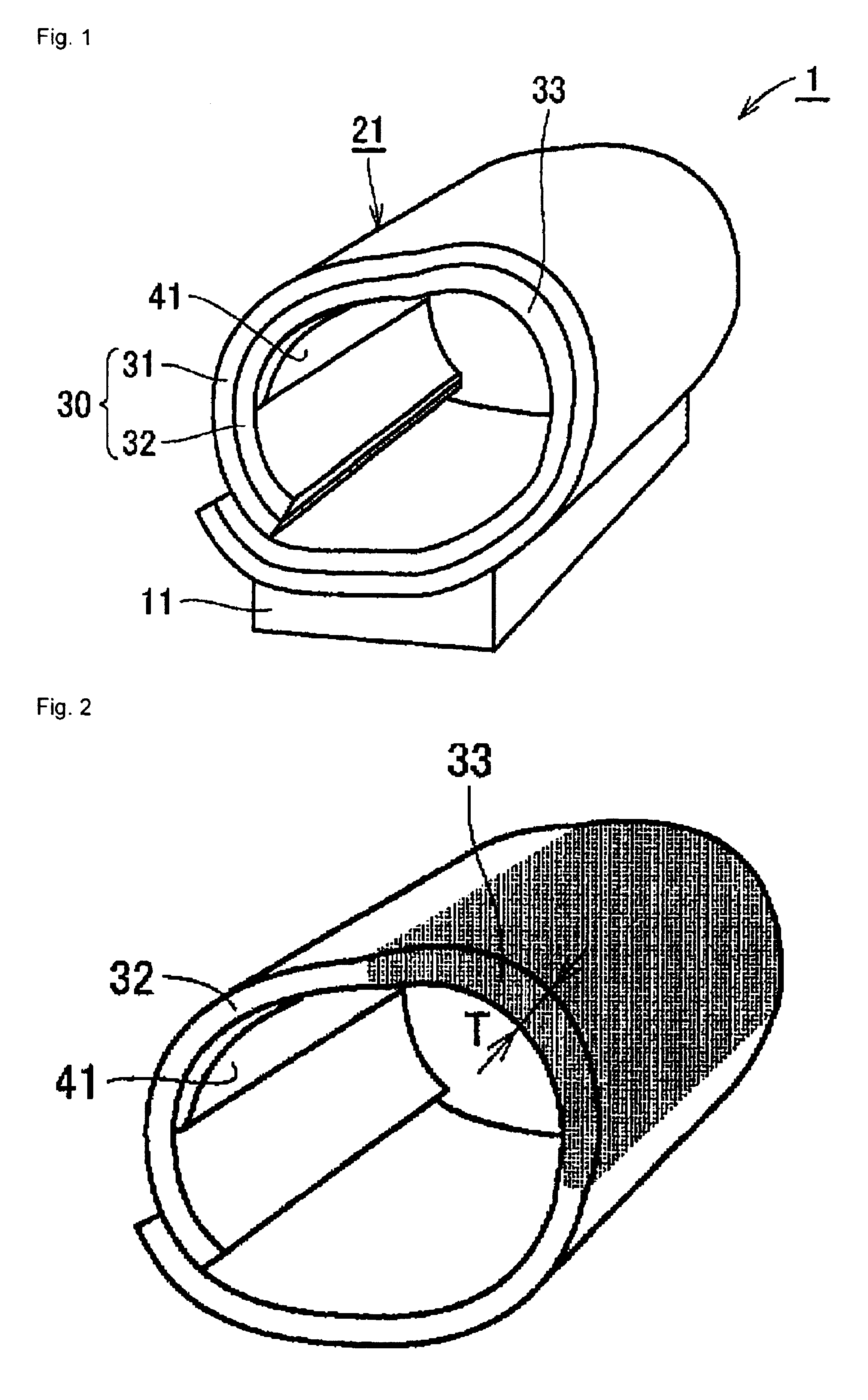

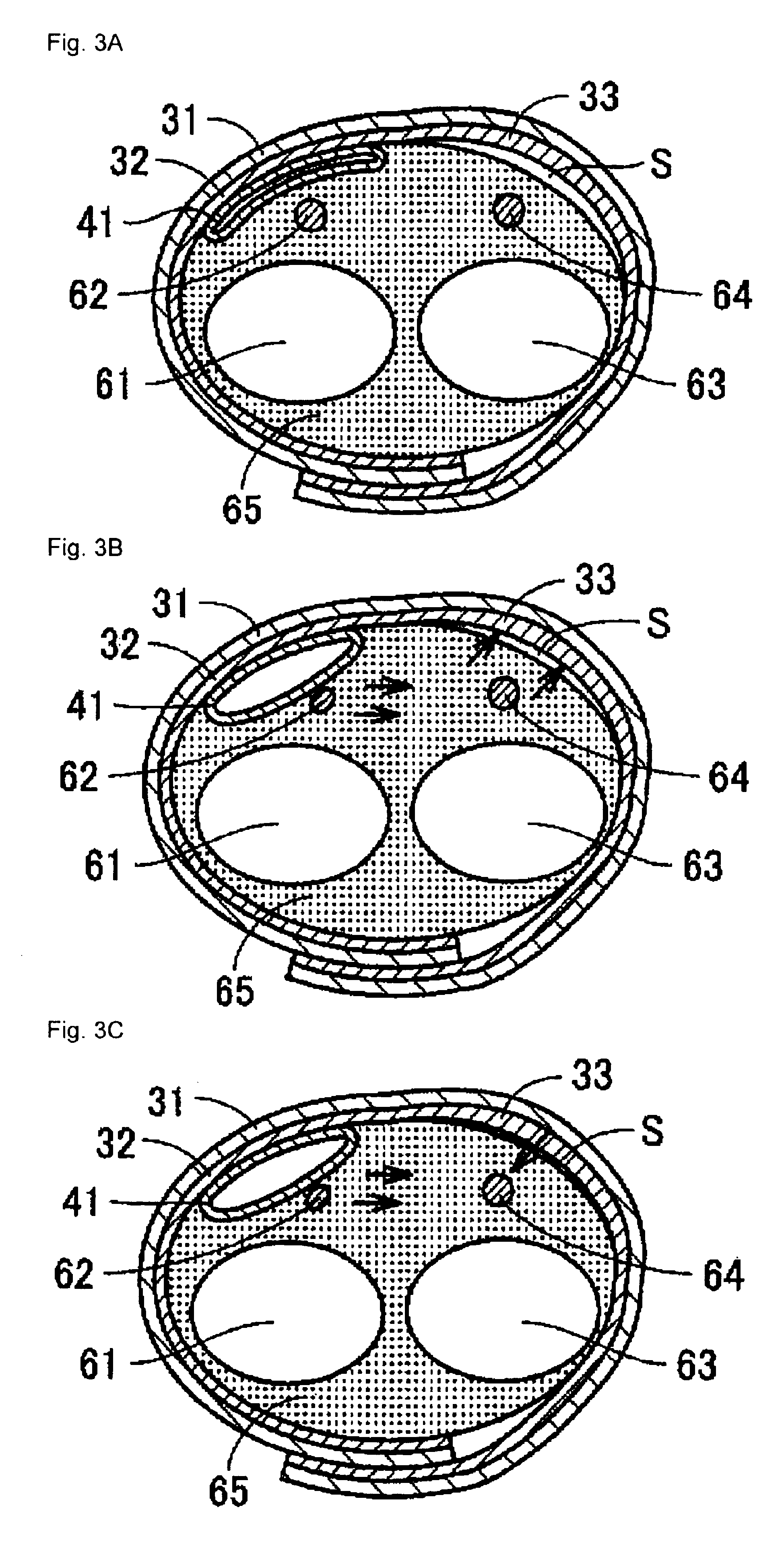

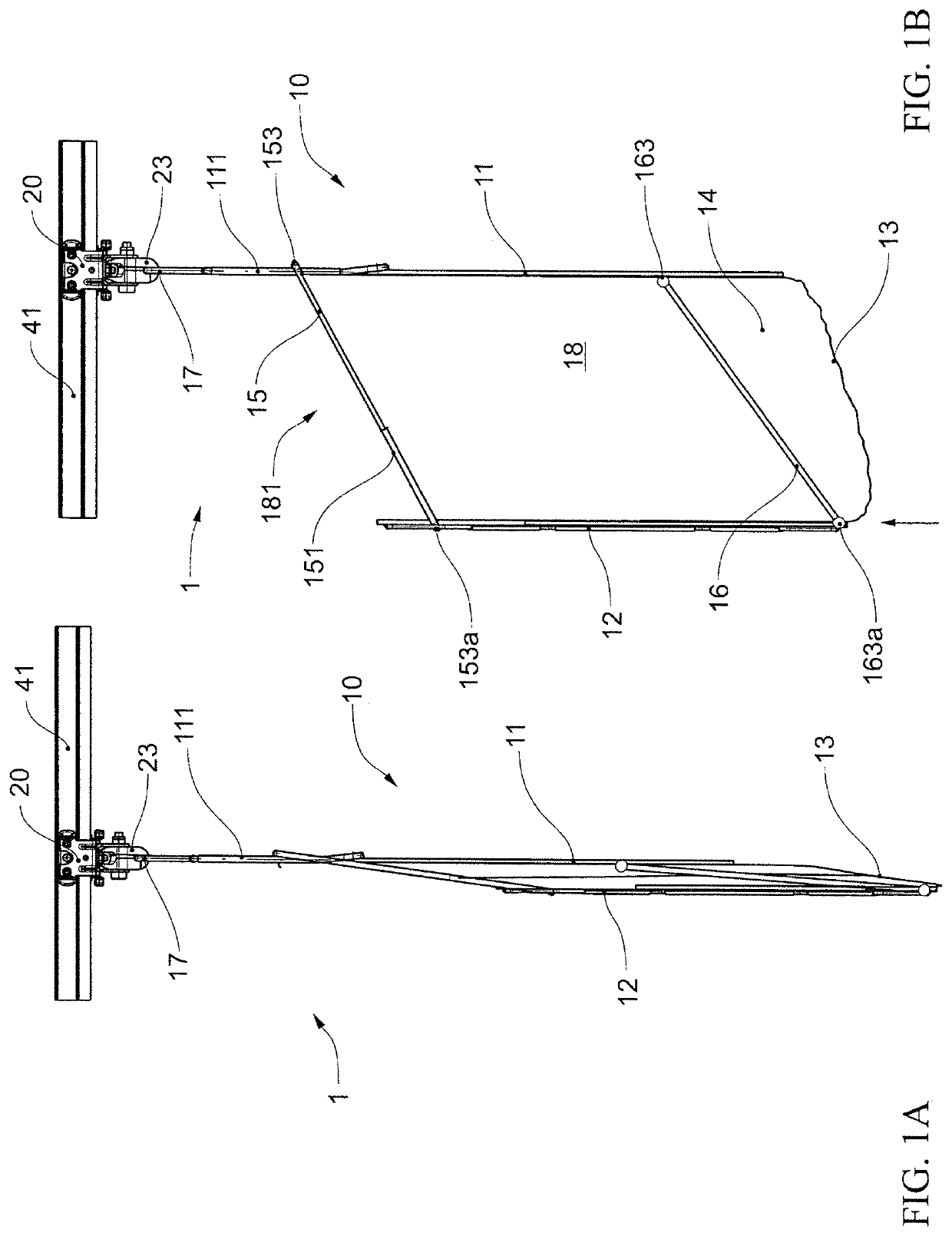

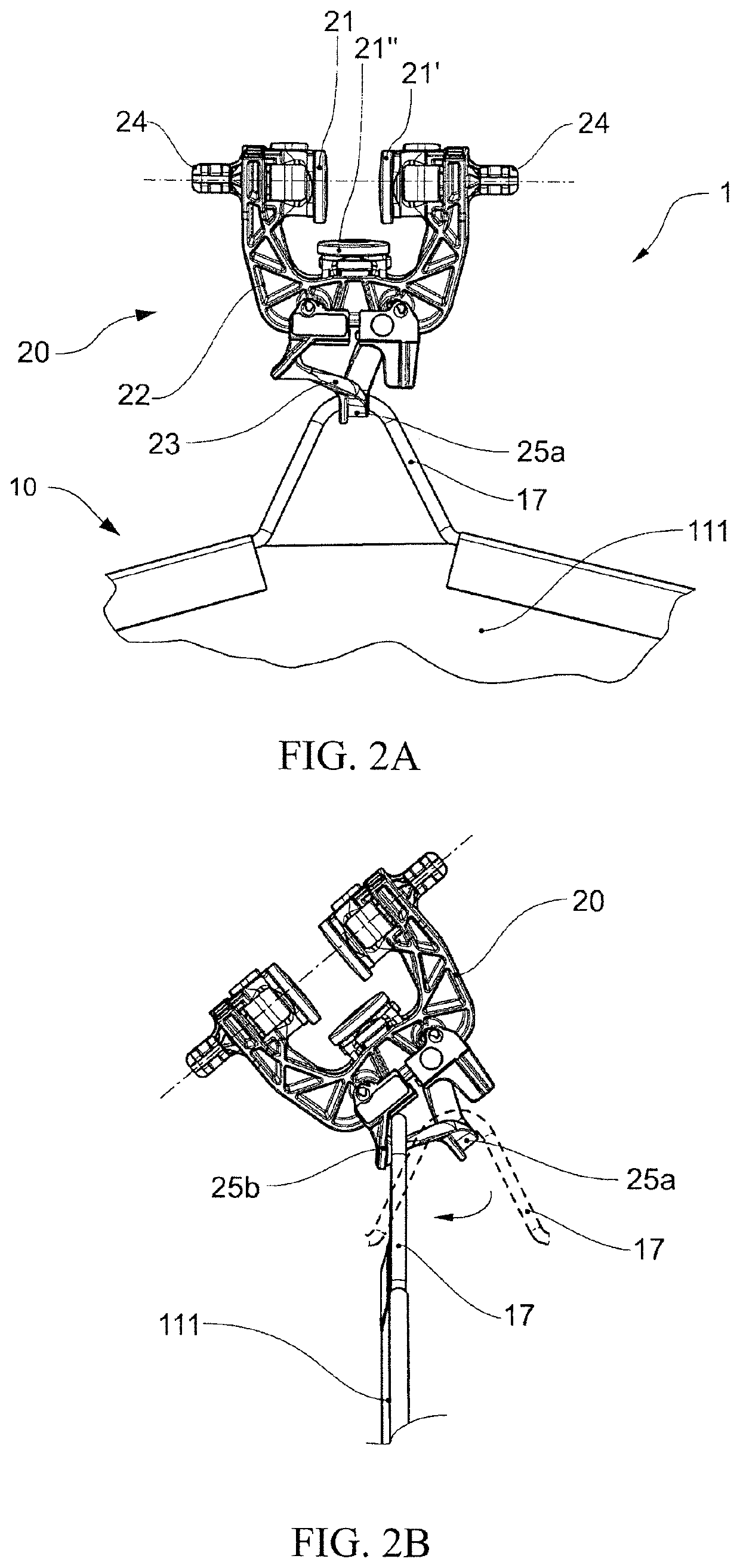

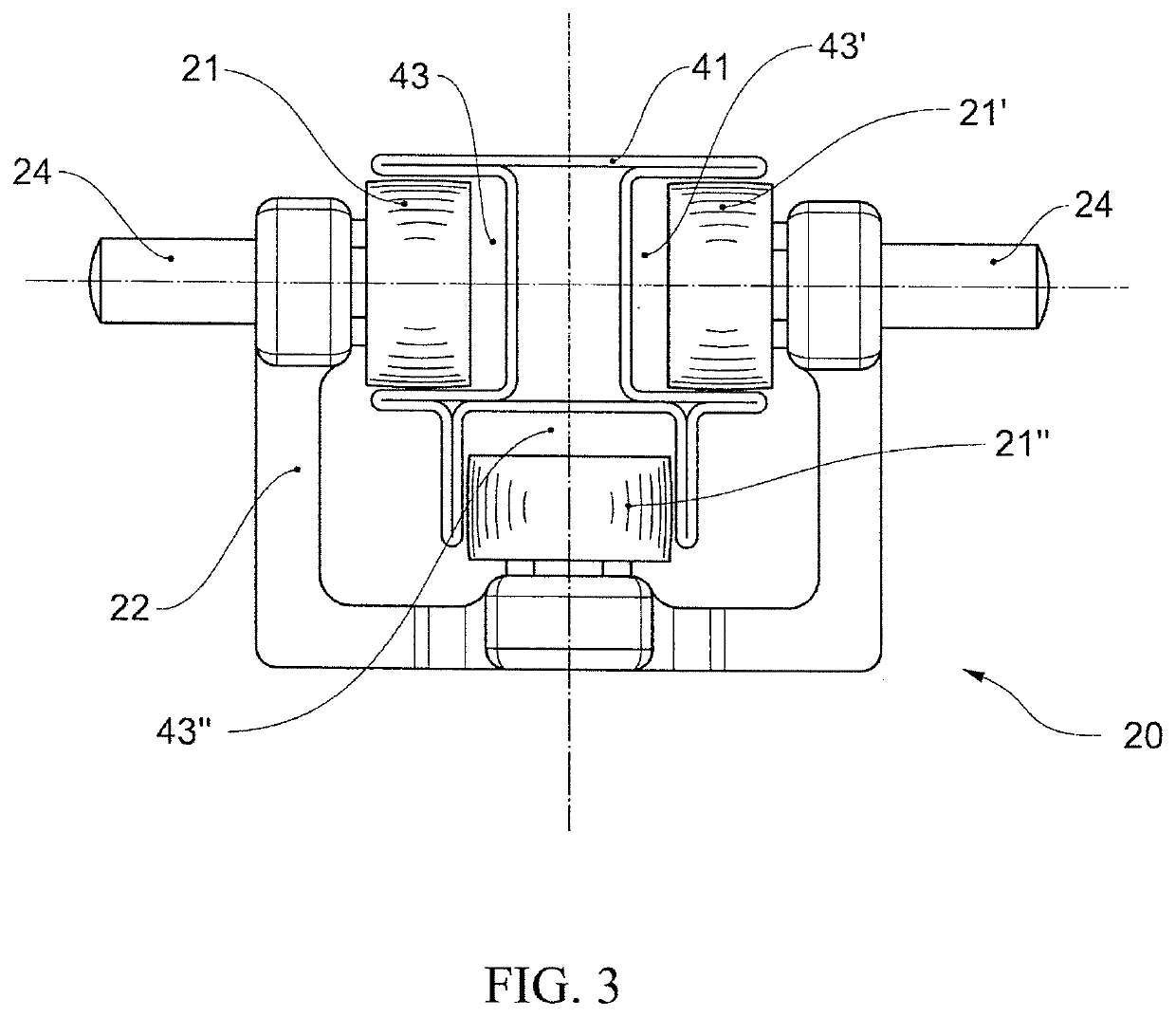

Transport bag for suspended conveyor systems

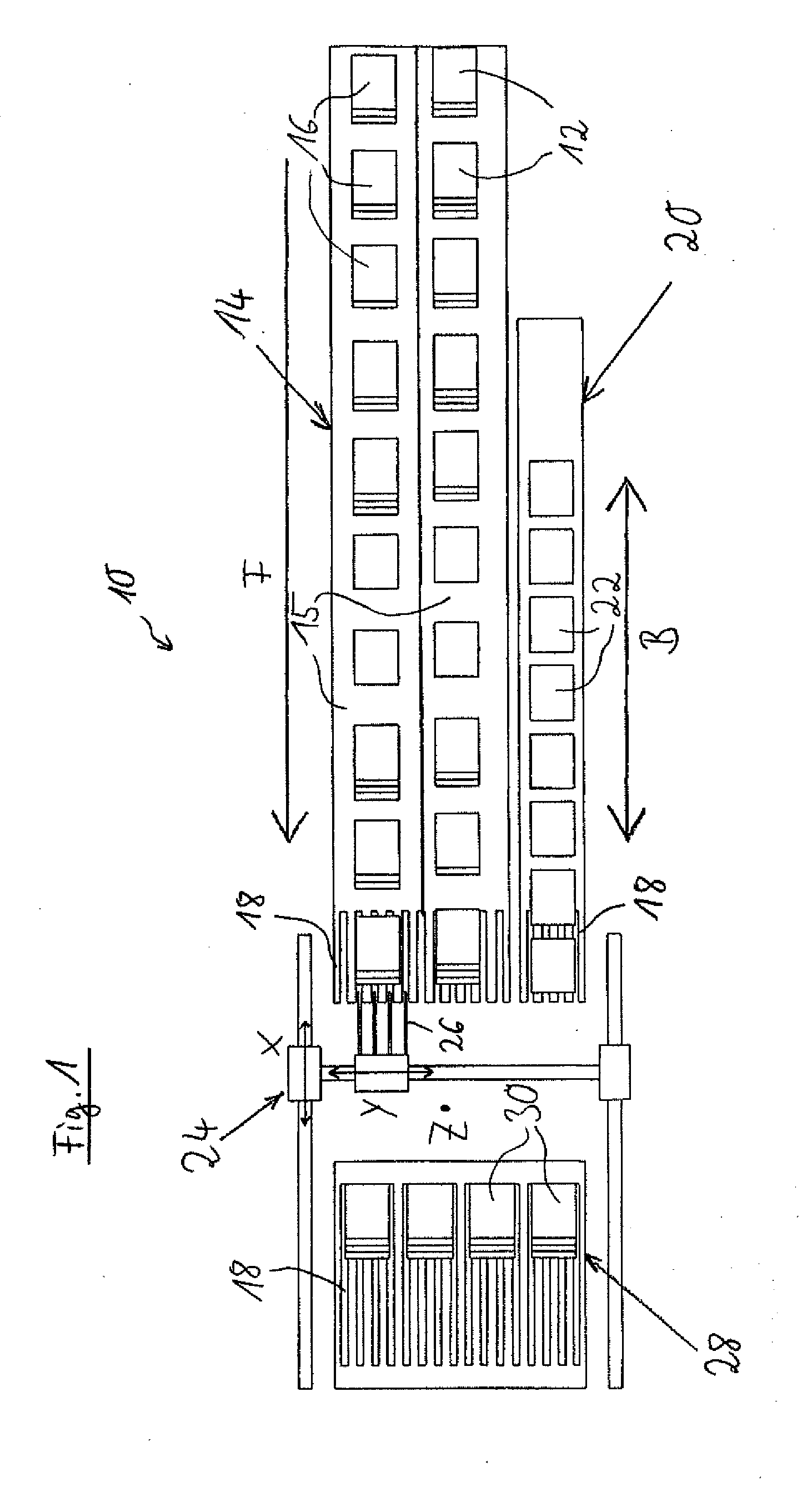

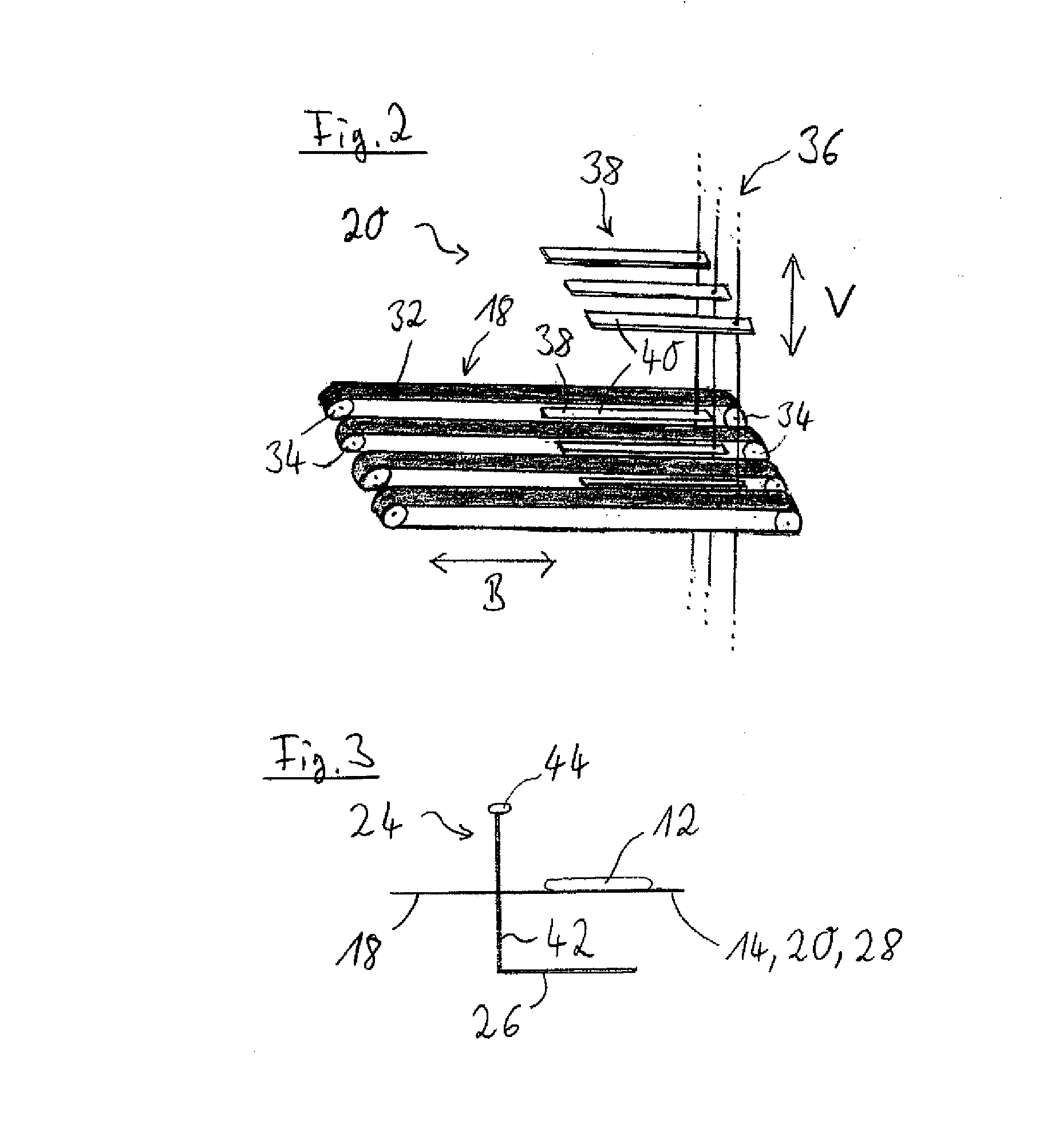

A transport bag (10) for a suspended conveyor system, particularly a rail-guided conveyor system or a transport chain conveyor system, has a conveyor member, particularly a carriage (20) of a rail-guided (41) conveyor system or a conveyor chain link of a transport chain conveyor system, and a transport bag (10) having a receiving region for receiving one or a plurality of units of goods (91). The transport bag is attached, via a suspension means (17), in a suspended manner to a carrying means (23) of the conveyor member. The transport bag has two frame brackets (15, 16) which are pivotally connected to the suspension means. The two frame brackets (15, 16) are substantially 2-fold rotationally symmetrical to one another, but not mirror symmetrical to one another.

Owner:FERAG AG

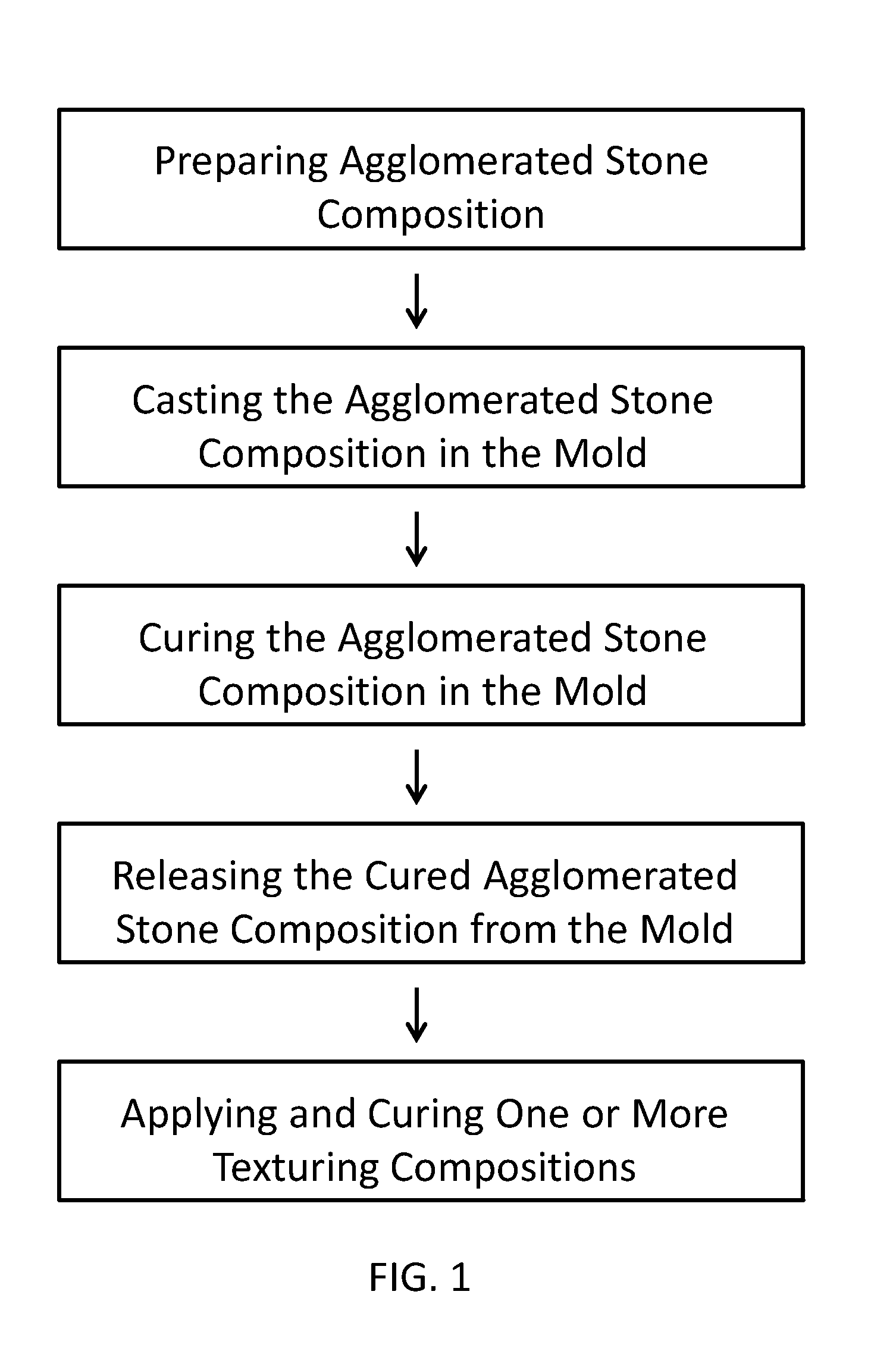

Decorative Stone Compositions and Methods

InactiveUS20120177882A1Little surface manipulationImprove impact resistanceSolid waste managementSynthetic resin layered productsStone compositionMaterials science

Owner:SICHTNIK LASZLO

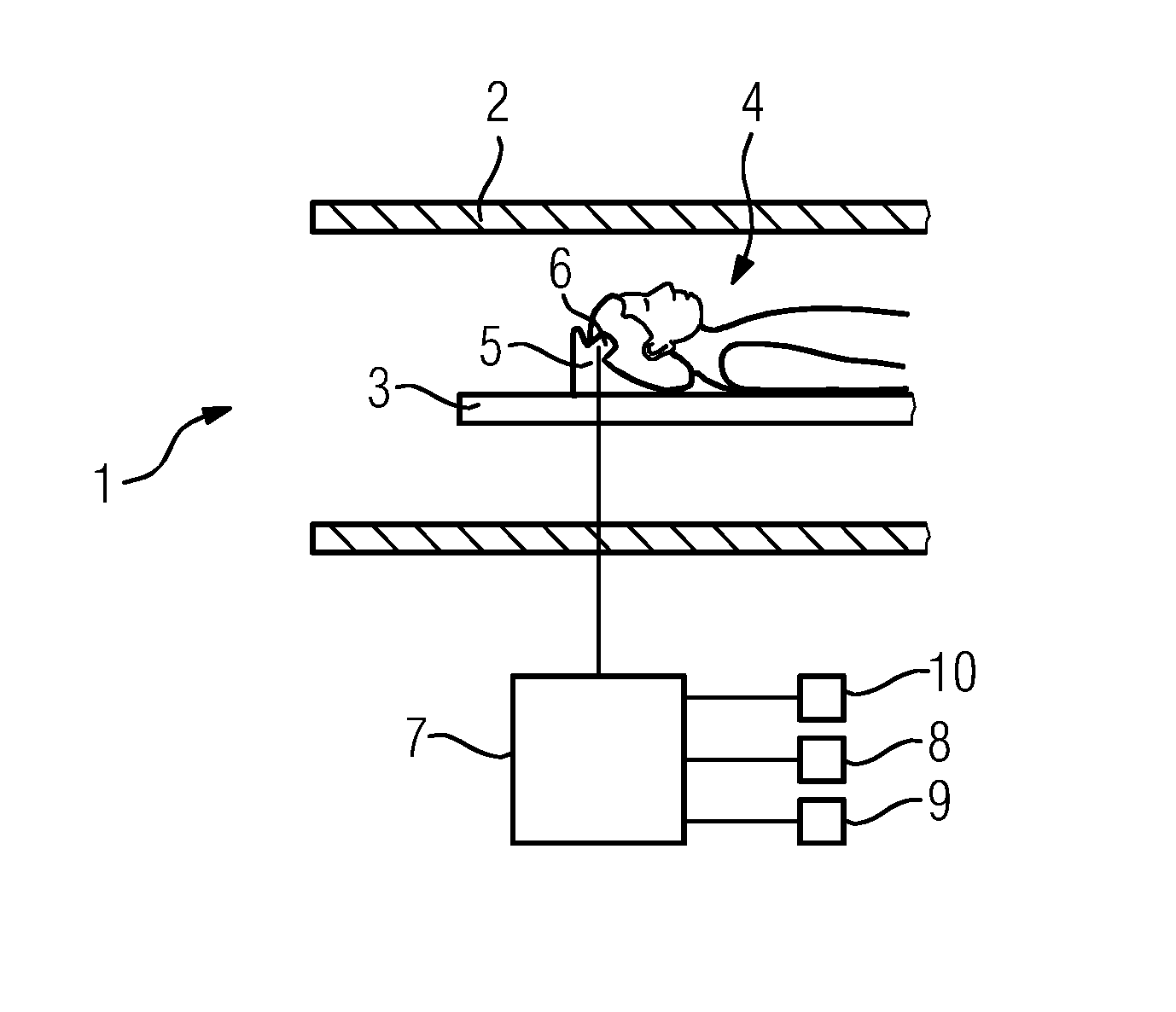

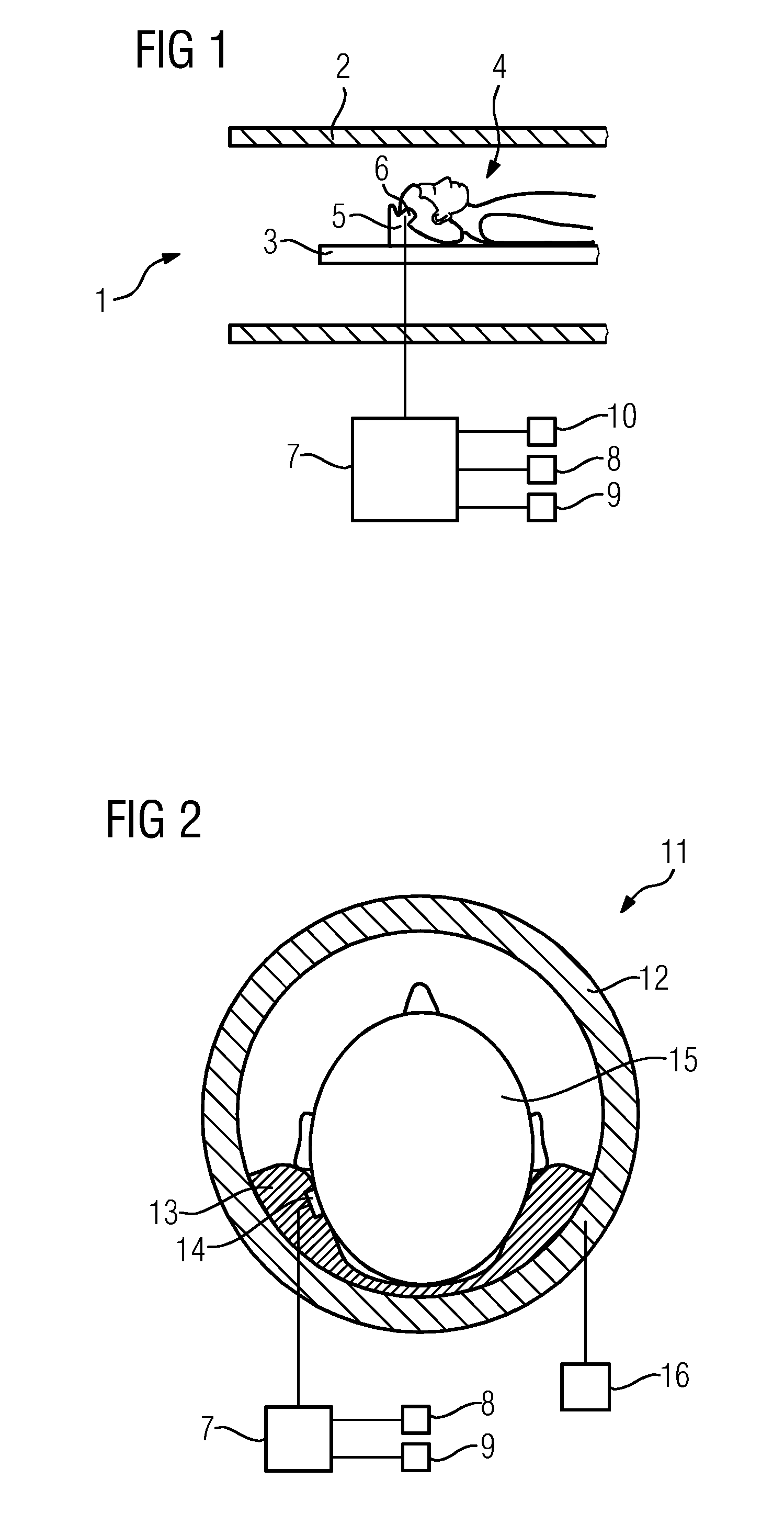

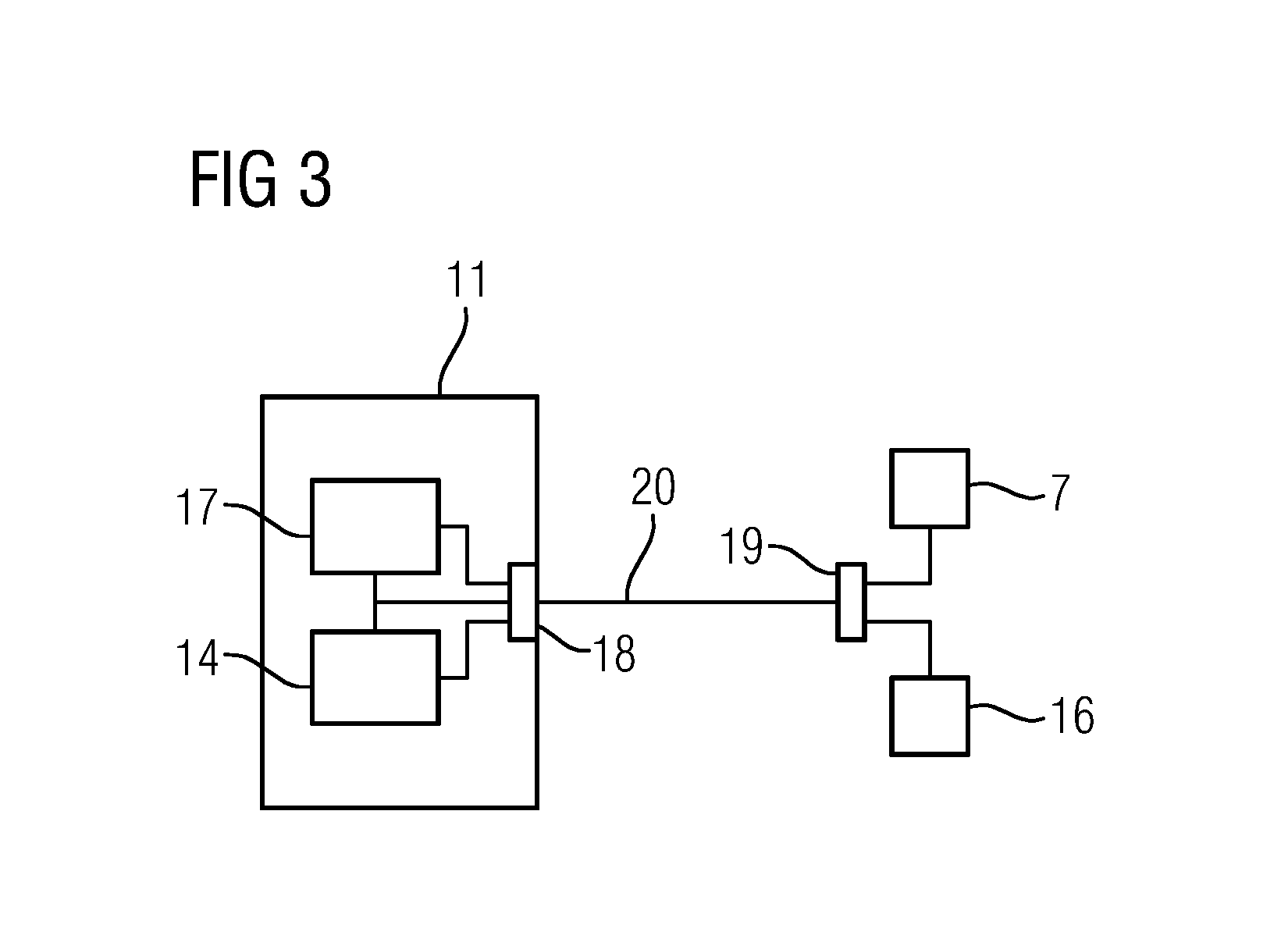

Patient Communication in Magnetic Resonance Tomography

InactiveUS20150226816A1Surfaces with very littleReduce inductionSensorsTelemetric patient monitoringPatient communicationResonance

A magnetic resonance tomograph has a component on which the head of a patient rests during imaging in a contact area. The magnetic resonance tomograph also has a patient communication device for communicating information to the patient. The patient communication device has a control device and also an actuator assigned to the contact area. The actuator, upon actuation with electric control signals by the control device, vibrates the surface of the contact area.

Owner:SIEMENS AG

Metal foil provided with filler-containing resin layer and method for manufacturing metal foil provided with filler-containing resin layer

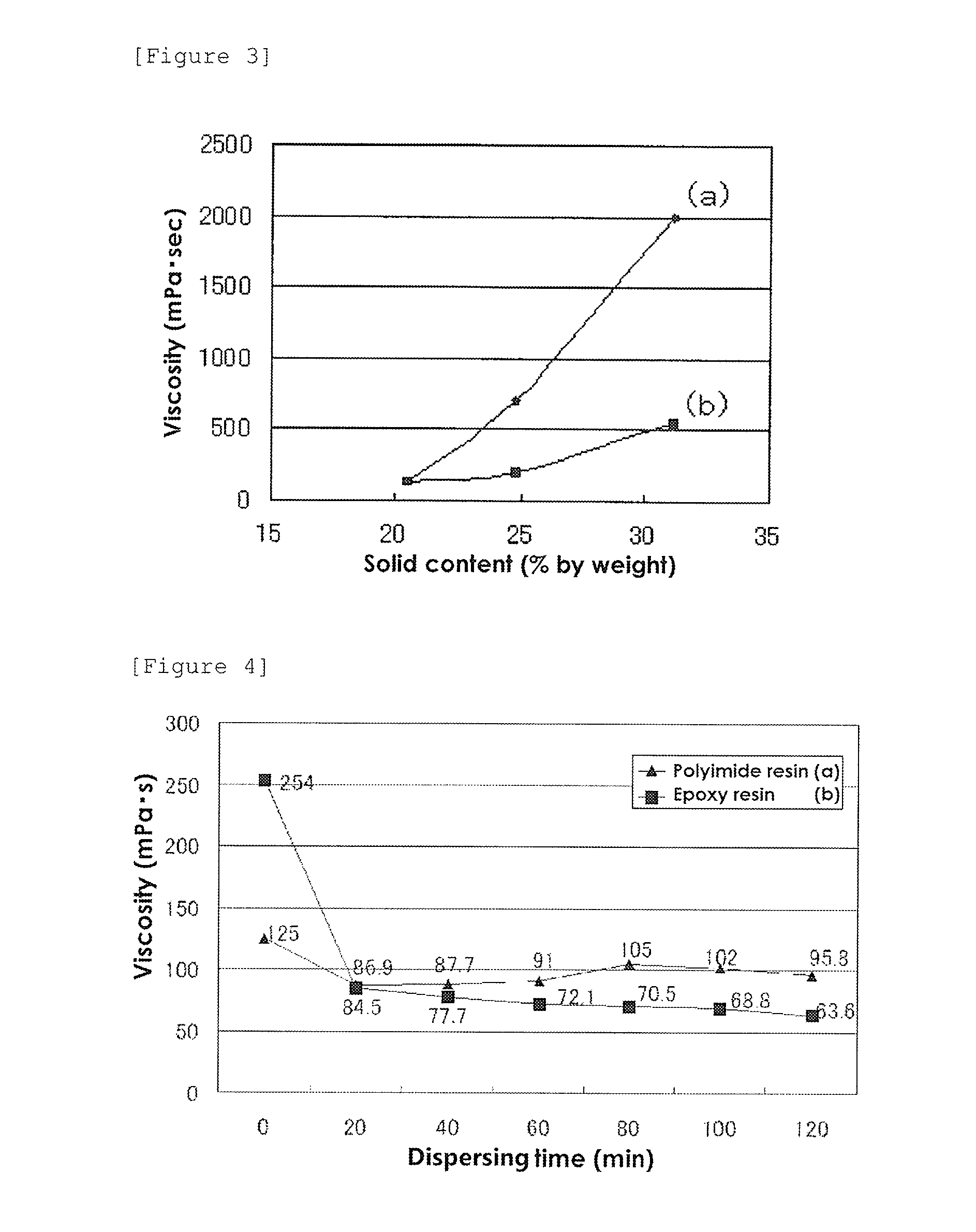

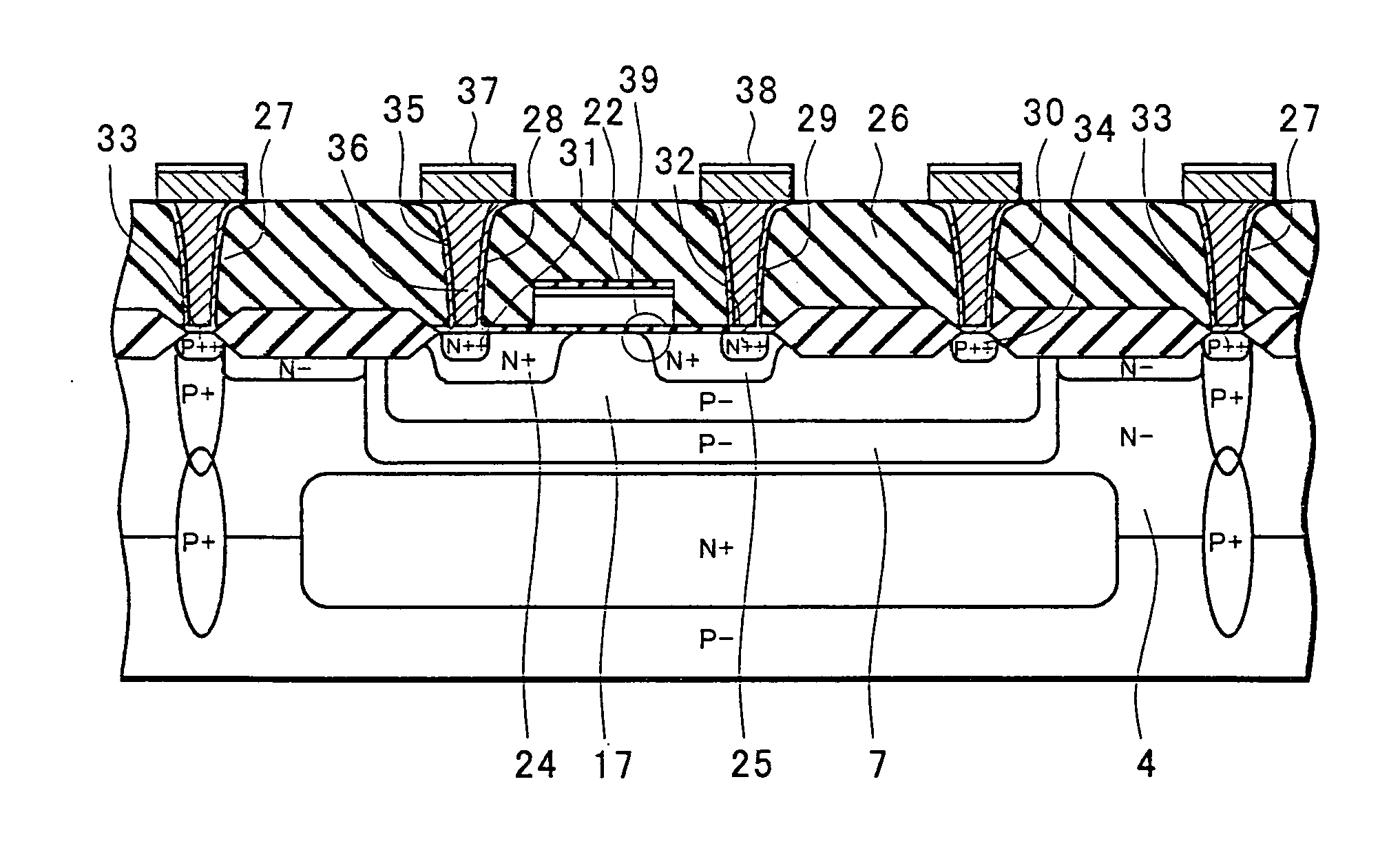

ActiveUS20130177739A1Improve smoothnessAvoid influenceRecord information storageMagnetic recordingMetal foilSmooth surface

A metal foil is provided with a filler-containing resin layer that is thin and has a smooth surface as a metal foil provided with an insulating layer. The filler-containing resin layer having a thickness of 0.1 μm to 3.0 μM, the gloss at the surface of the filler-containing resin layer is 200 or more, and the surface roughness (Ra) measured by an atomic force microscope in a measurement area of 5 μm×5 μM on the filler-containing resin layer is 25 nm or less is stacked on the smooth surface of the metal foil having a gloss exceeding 400 and surface roughness (Ra) measured by an atomic force microscope in a measurement area of 5 μm×5 μm of 10 nm or less.

Owner:MITSUI MINING & SMELTING CO LTD

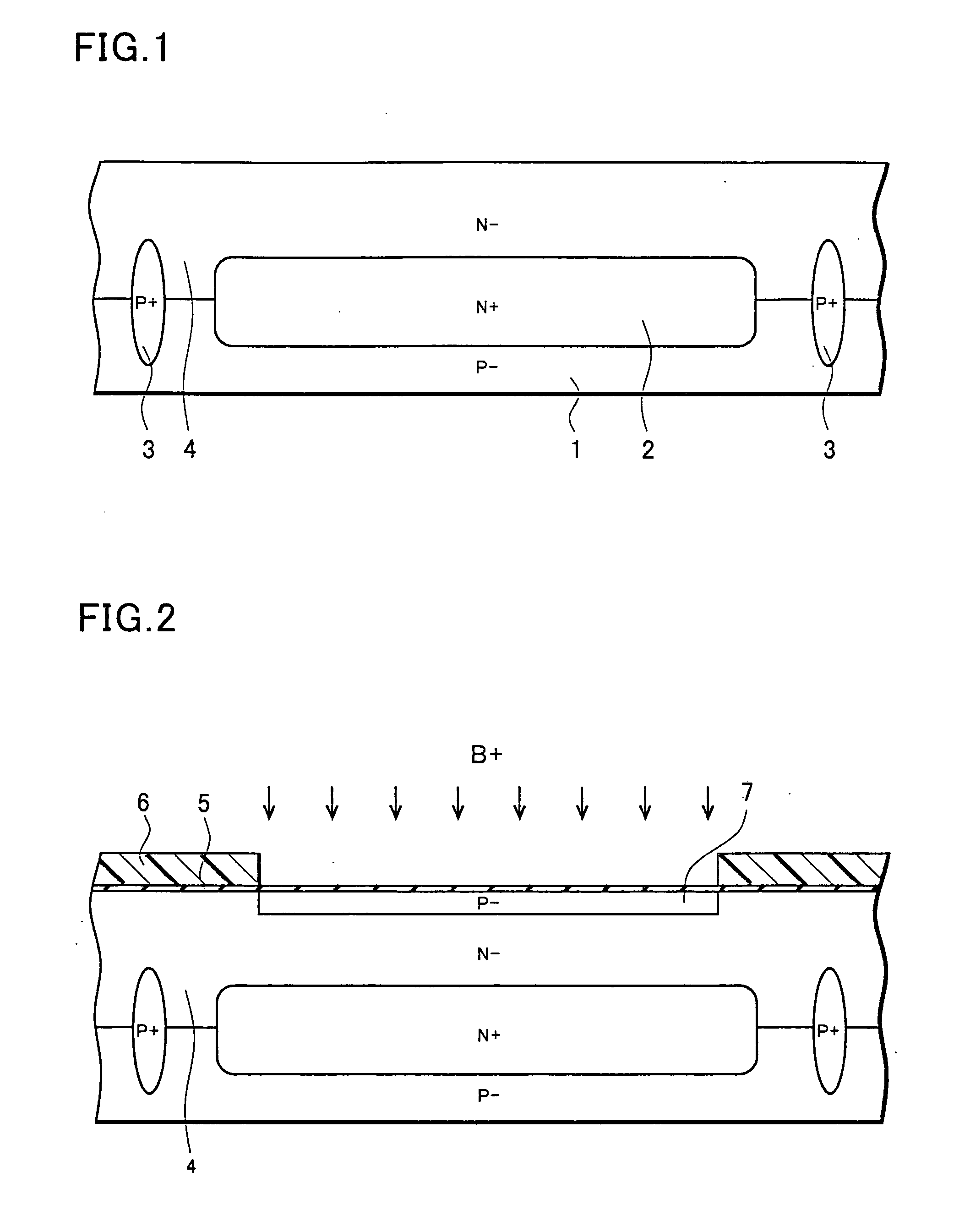

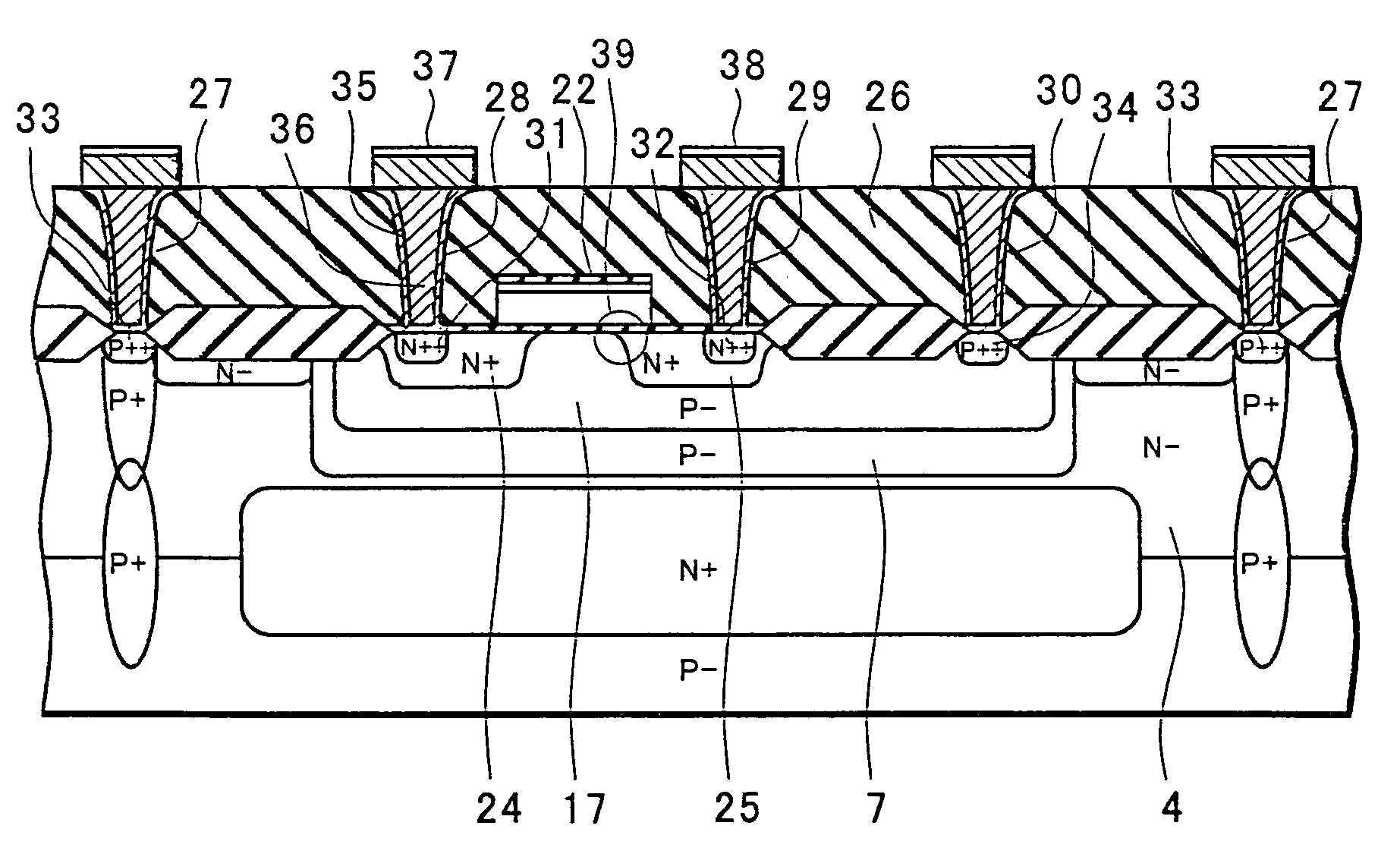

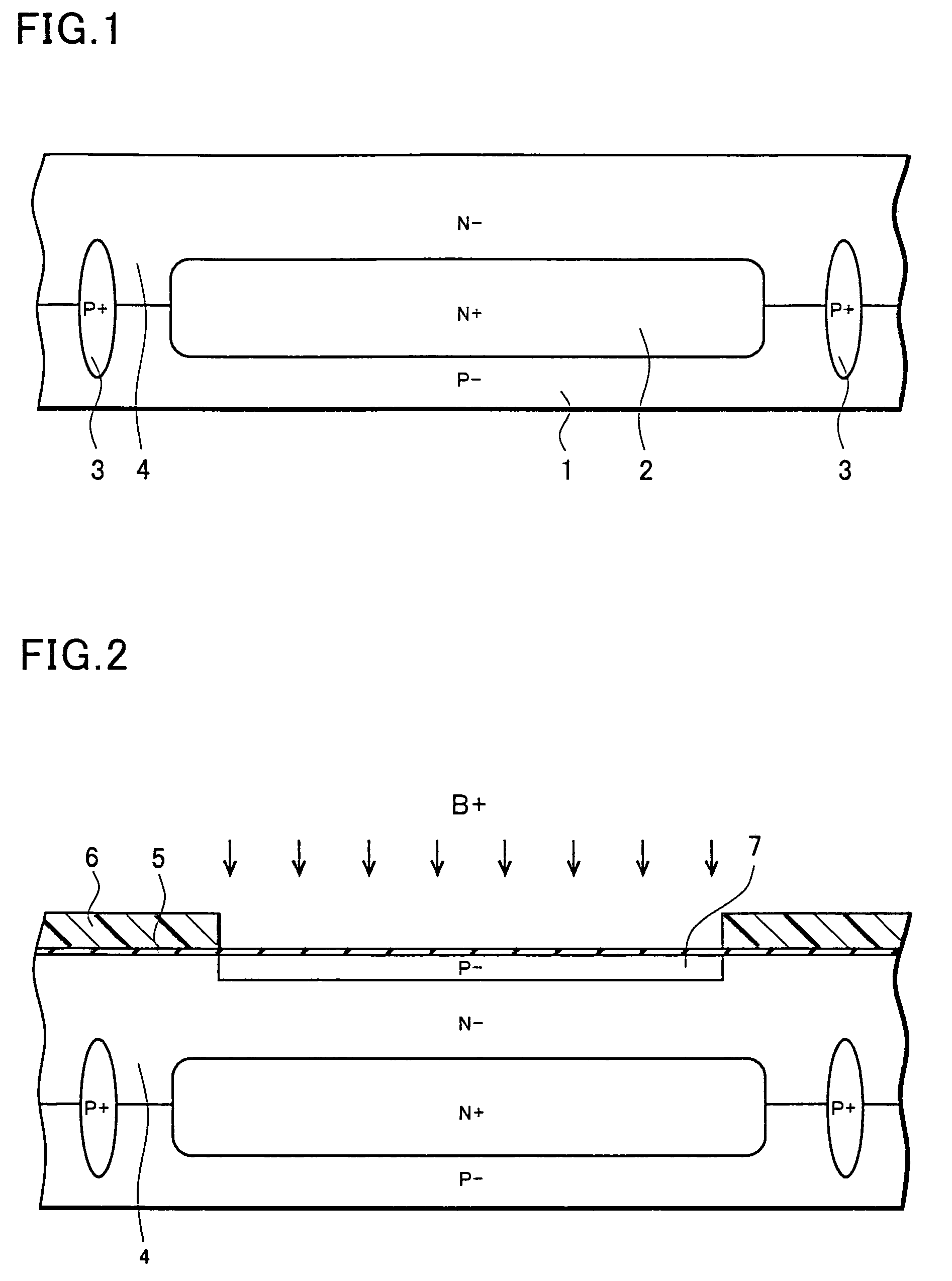

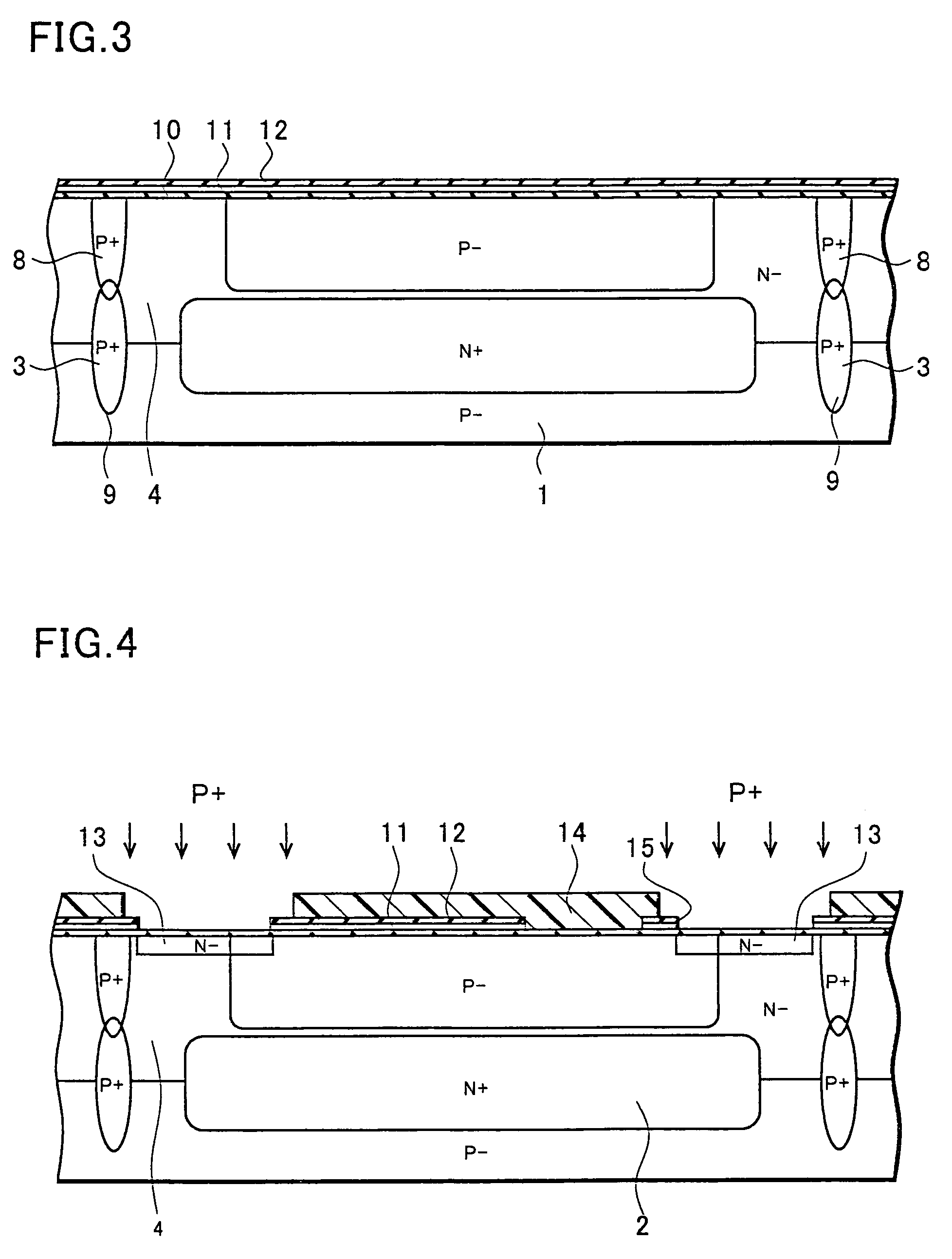

Method of manufacturing semiconductor device

InactiveUS20060223259A1Reduce in quantitySuppress manufacturing costTransistorSemiconductor/solid-state device manufacturingImpurity ionsPeak value

Disclosed is that in a method of manufacturing a semiconductor device of the present invention, when first and second P type diffusion layers using as a backgate region, these layers are formed in such a way that their impurity concentration peaks are shifted, respectively. Then, in the backgate region, a concentration profile of a region where an N type diffusion layer is formed is gradually established. After that, impurity ions, which form the N type diffusion layer, are implanted, and thereafter a thermal treatment is performed to diffuse the N type diffusion layer in a y shape at a lower portion of a gate electrode. This manufacturing method makes it possible to implement an electric filed relaxation in a drain region.

Owner:SEMICON COMPONENTS IND LLC

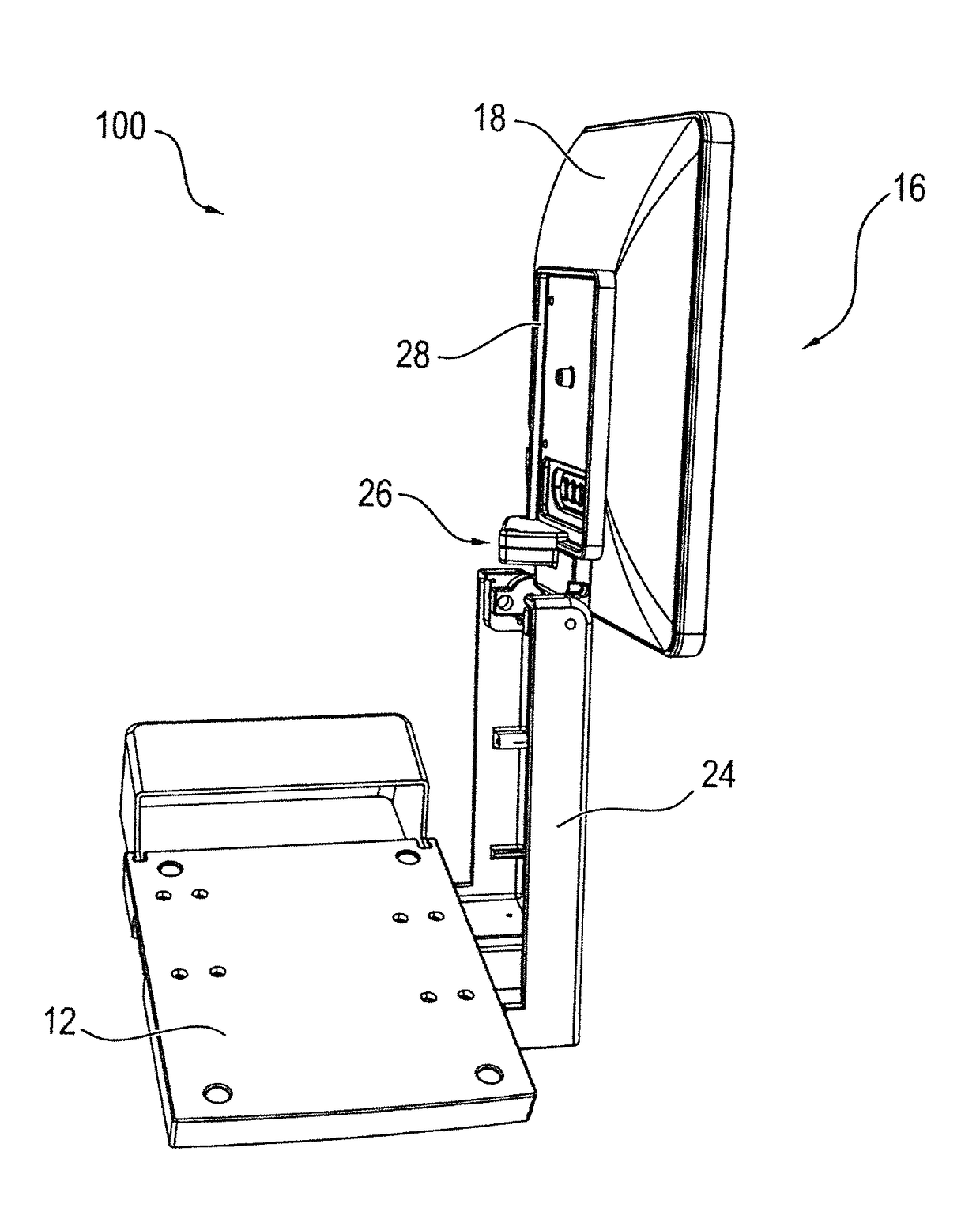

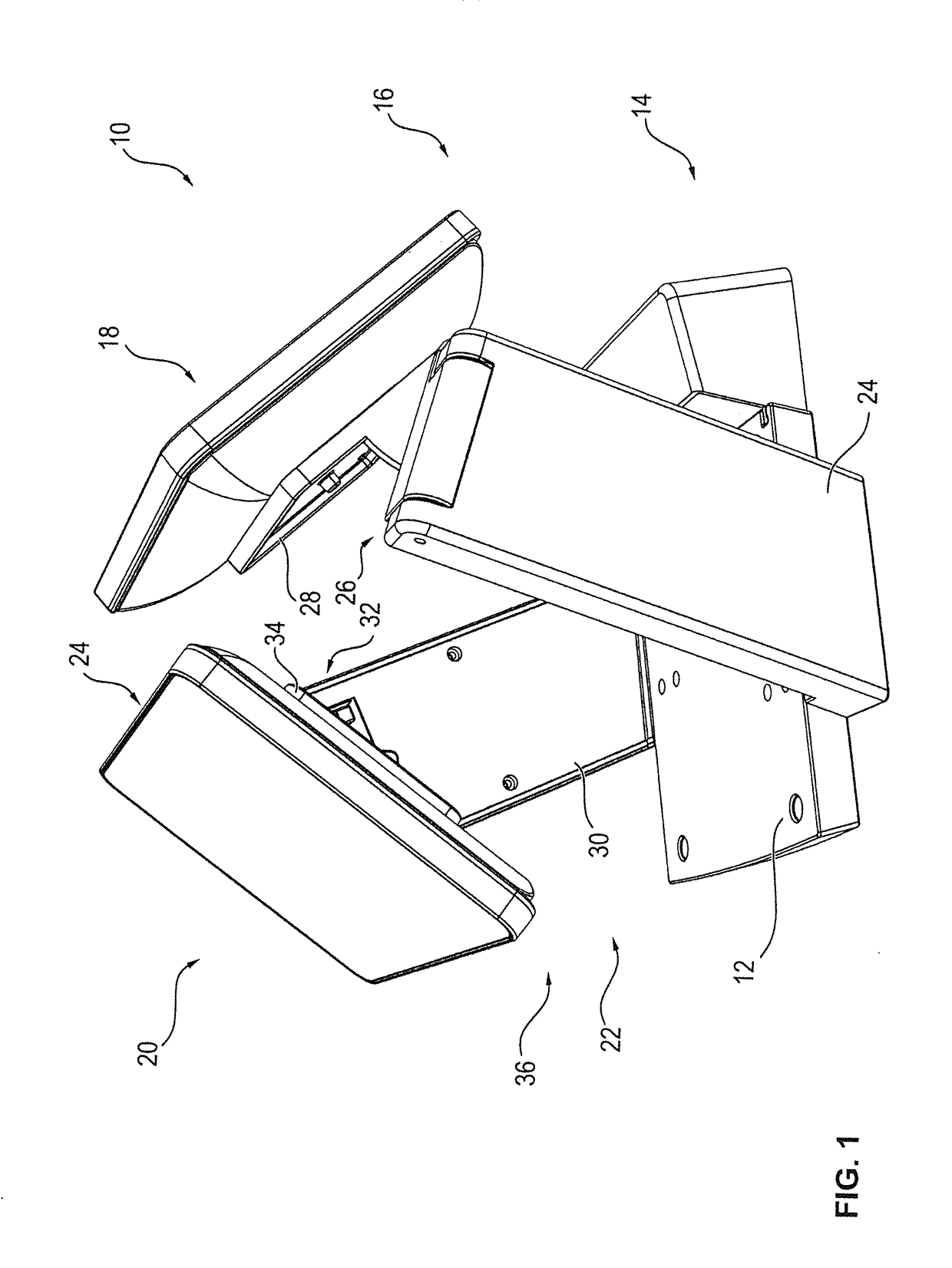

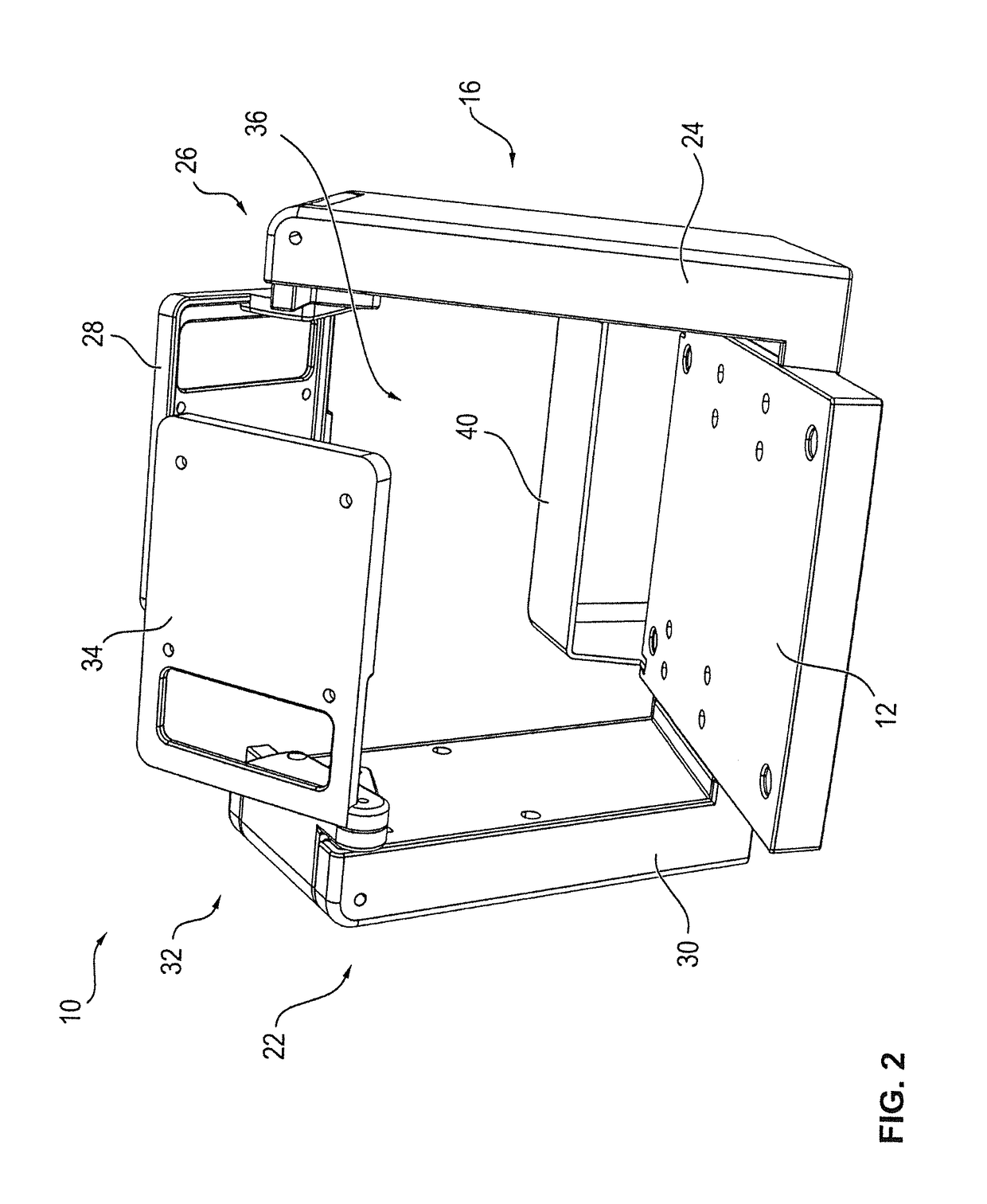

Cash register system with pivotable arms

ActiveUS20170206750A1Surfaces with very littleEasy to removeCash registersStands/trestlesMechanical engineeringEngineering

A cash register system (10, 100) has an arm (16, 22) for holding a display unit (18, 24). The arm (16) has a first section (24, 30) and a second section (28, 34) pivotable relative thereto. The second section (28, 34) is pivotable relative to the first section (28) between a first position in which the display unit (18, 24) is arranged above a receiving area (36) and a second position in which the display unit (18, 24) is not arranged above this receiving area (36).

Owner:DIEBOLD NIXDORF SYST GMBH

Sensor system for detecting high pressures

InactiveUS20120073379A1High overload resistanceSimple and cost-effectiveFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsEngineeringHigh pressure

A sensor system for detecting high pressures includes a micromechanical sensor element which is situated on a support and is mounted via this support. A diaphragm is formed in the upper surface of the sensor element, the diaphragm spanning a cavern having a rear opening. The support has a passage opening and is connected to the rear side of the sensor element in such a way that the passage opening opens into the rear opening of the cavern. An annular recess is formed in the rear side of the sensor element, the annular recess being situated above the edge area of the passage opening, so that the joining surface between the sensor element and the support does not extend to the edge of the passage opening.

Owner:ROBERT BOSCH GMBH

Magnetic disk drive

InactiveUS7944646B2Strong recording magnetic fieldSurfaces with very littlePatterned record carriersNanoinformaticsMagnetic polesElectrical and Electronics engineering

In a patterned perpendicular magnetic recording medium, embodiments of the present invention provide a magnetic head in which magnetic field to be applied to adjacent tracks can be suppressed and a recording device equipped with the magnetic head. In one embodiment of the present invention, a sum of a width Pw of a main pole of a magnetic head and distances between right and left magnetic substances on a width-directional side of tracks and the main pole, so-called widths of side gap lengths s_g1—1 and s_g1—2 is, in a magnetic recording medium having a soft-magnetic underlayer, made to be not more than a sum of a width w_land of a convexity or land of the soft-magnetic underlayer and widths w_groove—1 and w_groove—2 of concavities or grooves adjacent to the land on both its sides.

Owner:WESTERN DIGITAL TECH INC

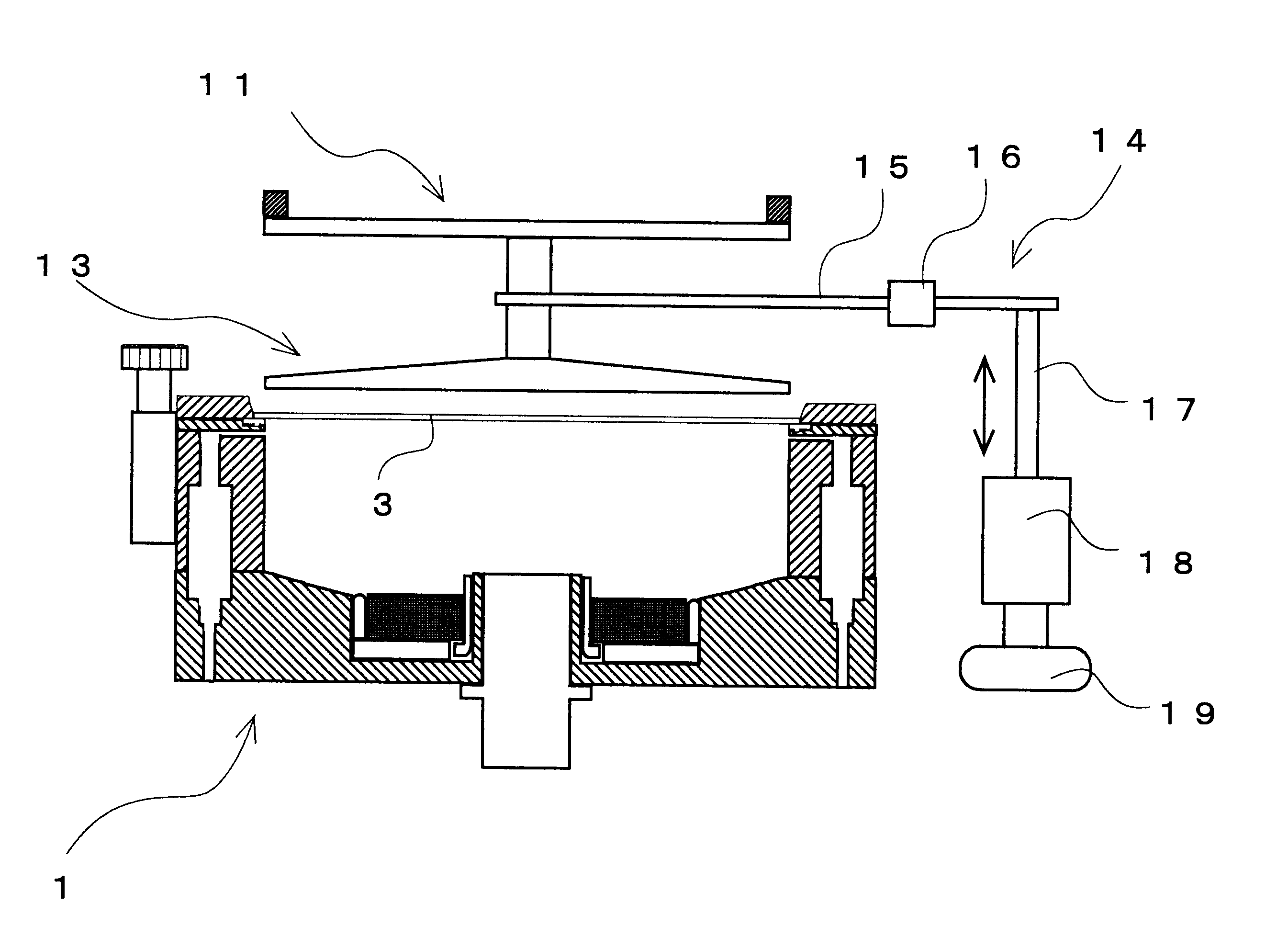

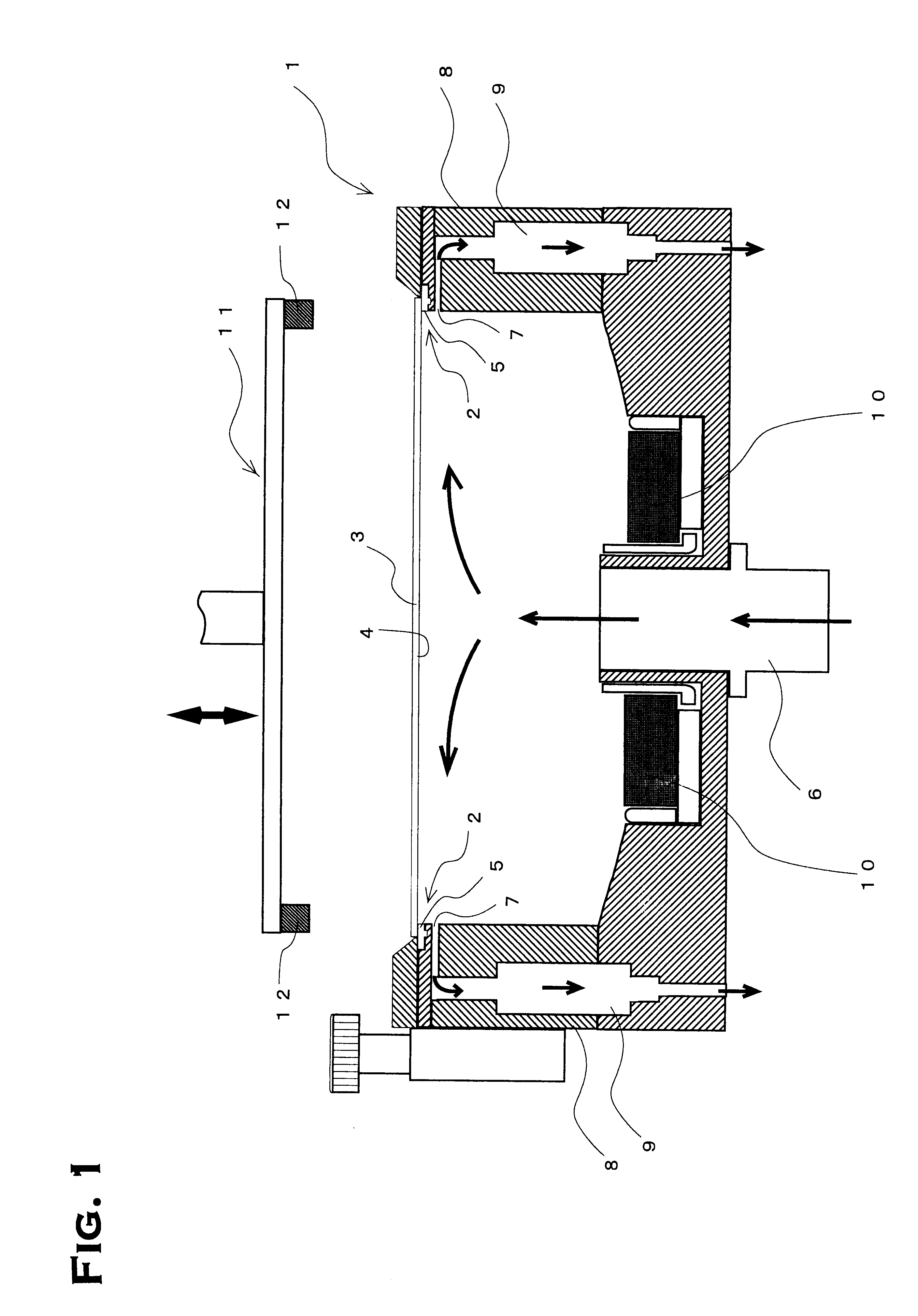

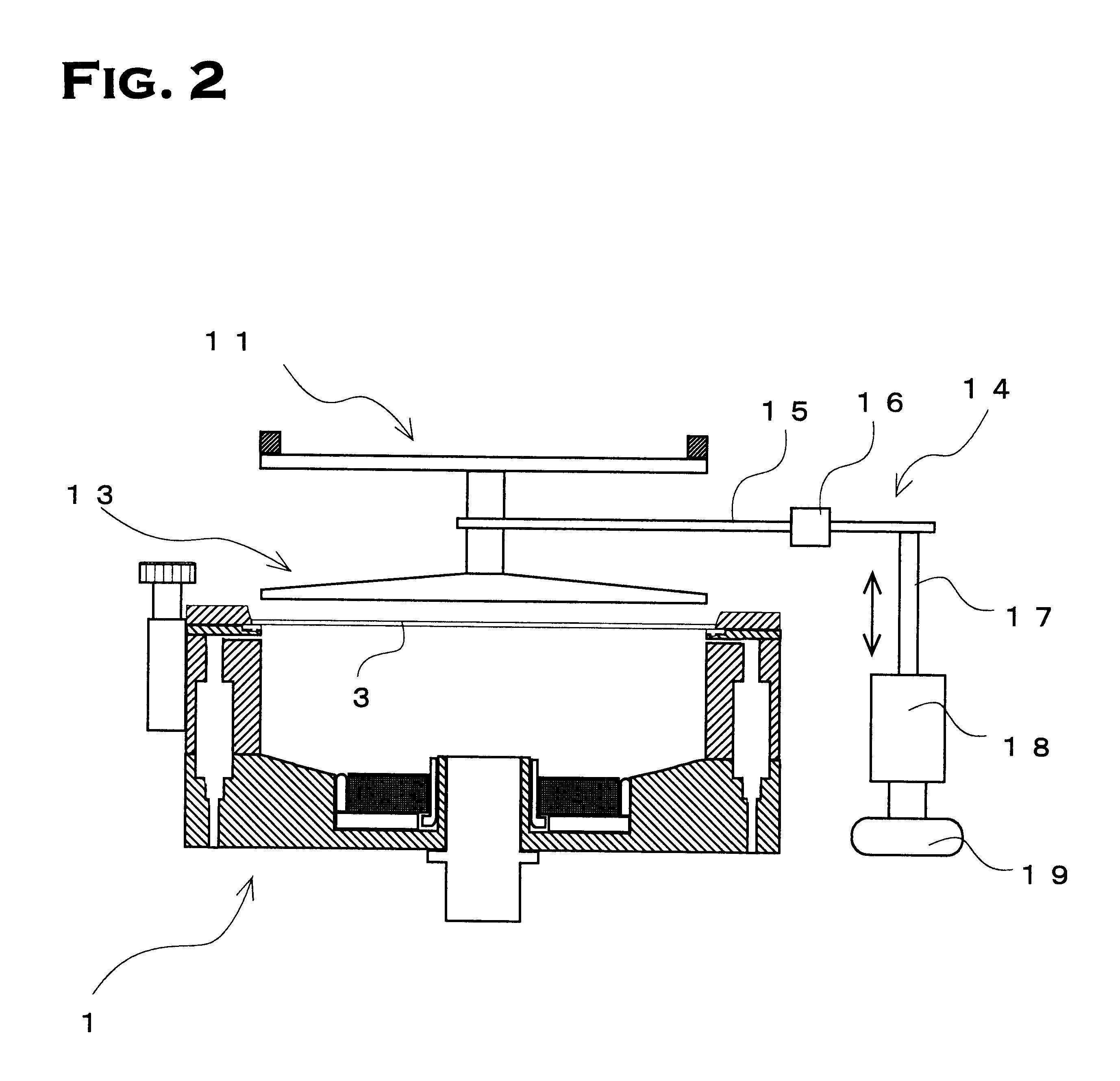

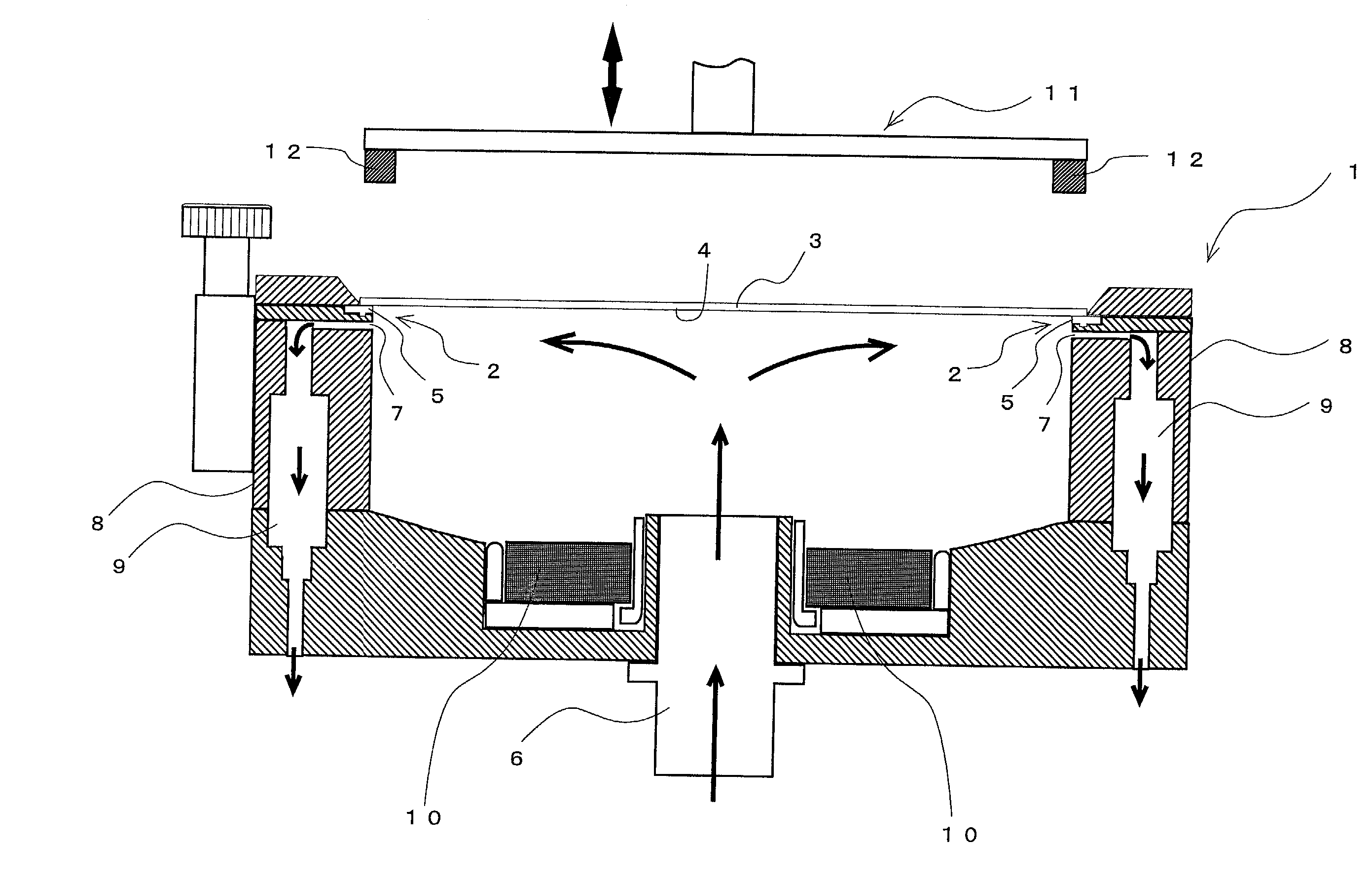

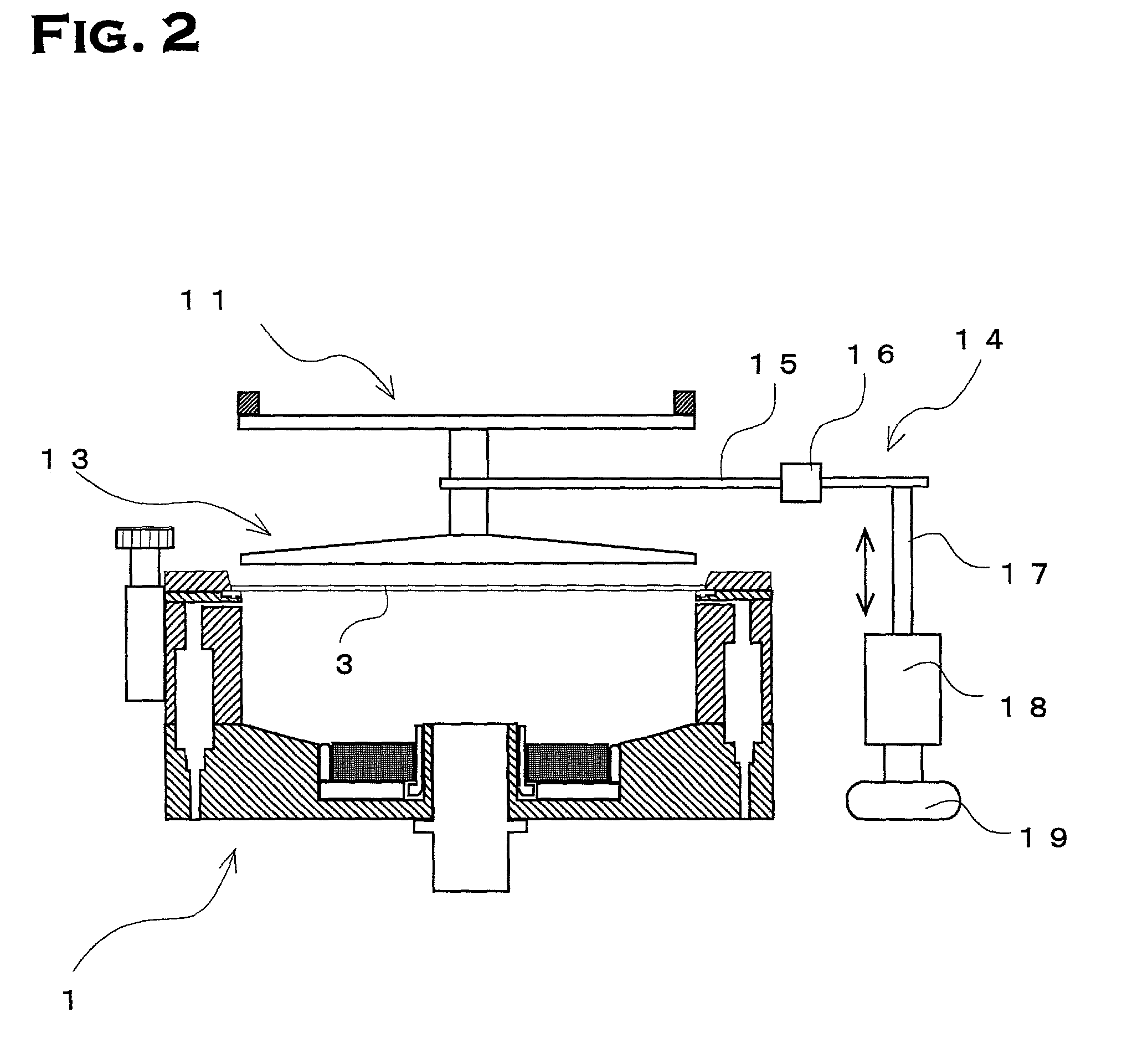

Cup-type plating apparatus and method for plating wafers

The present cup-type plating apparatus improves a conventional cup-type plating apparatus and prevents the surface of a wafer due to a mist of the plating solutions from being contaminated. A plating solution is supplied to a wafer which is placed on a wafer support provided along an opening at the top of a plating tank from a solution-supply port provided at the bottom of the plating tank by an upward-moving stream; the plating solution is made to flow out of a solution-outlet port provided for the plating tank; and plating is performed while the plating solution is brought into contact with a surface of the placed wafer, which is to be plated, wherein the solution-outlet port has a solution-outlet path in which the discharged plating solution is isolated from the outer space.

Owner:ELECTROPLATING ENGINEERS OF JAPAN LTD

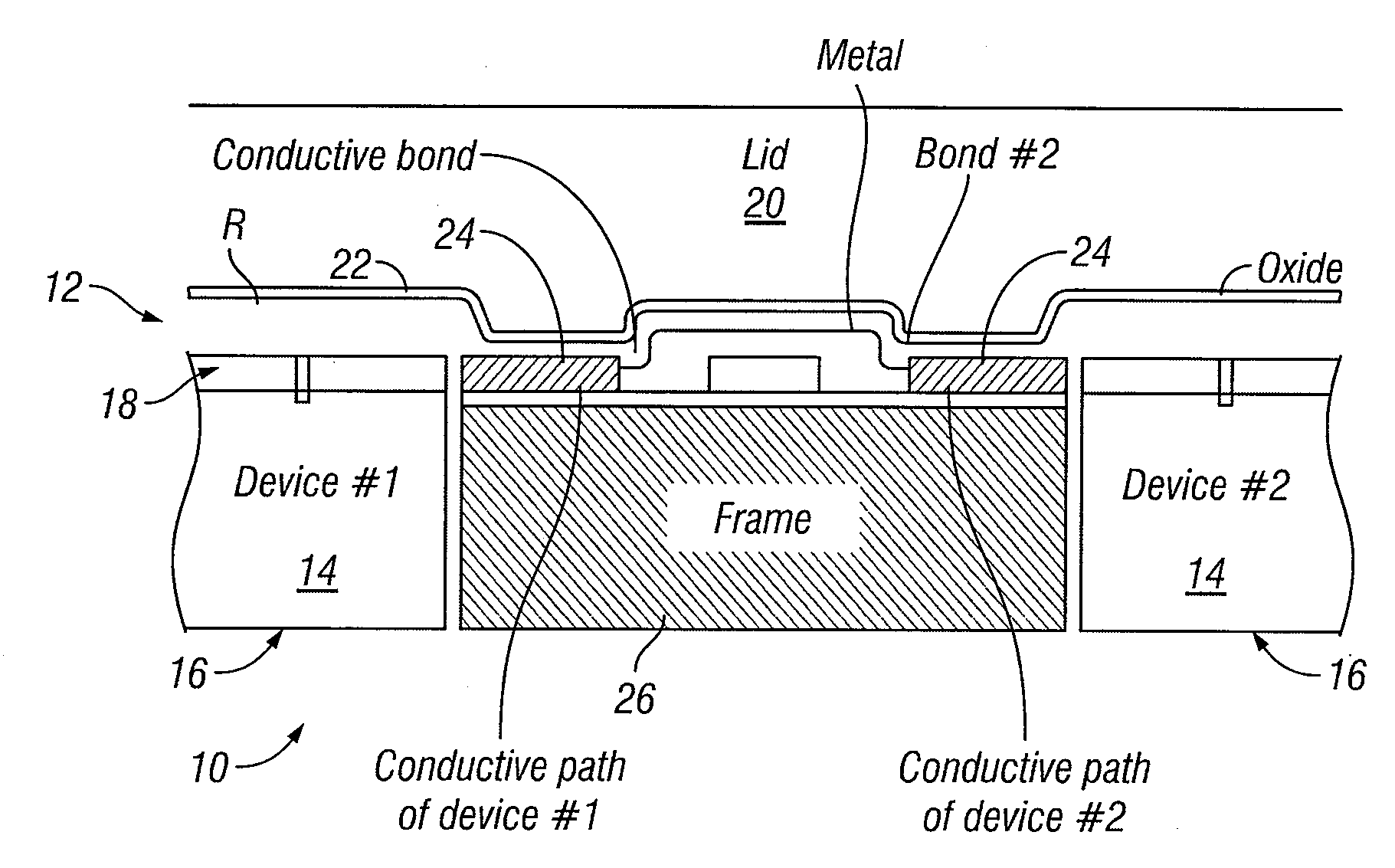

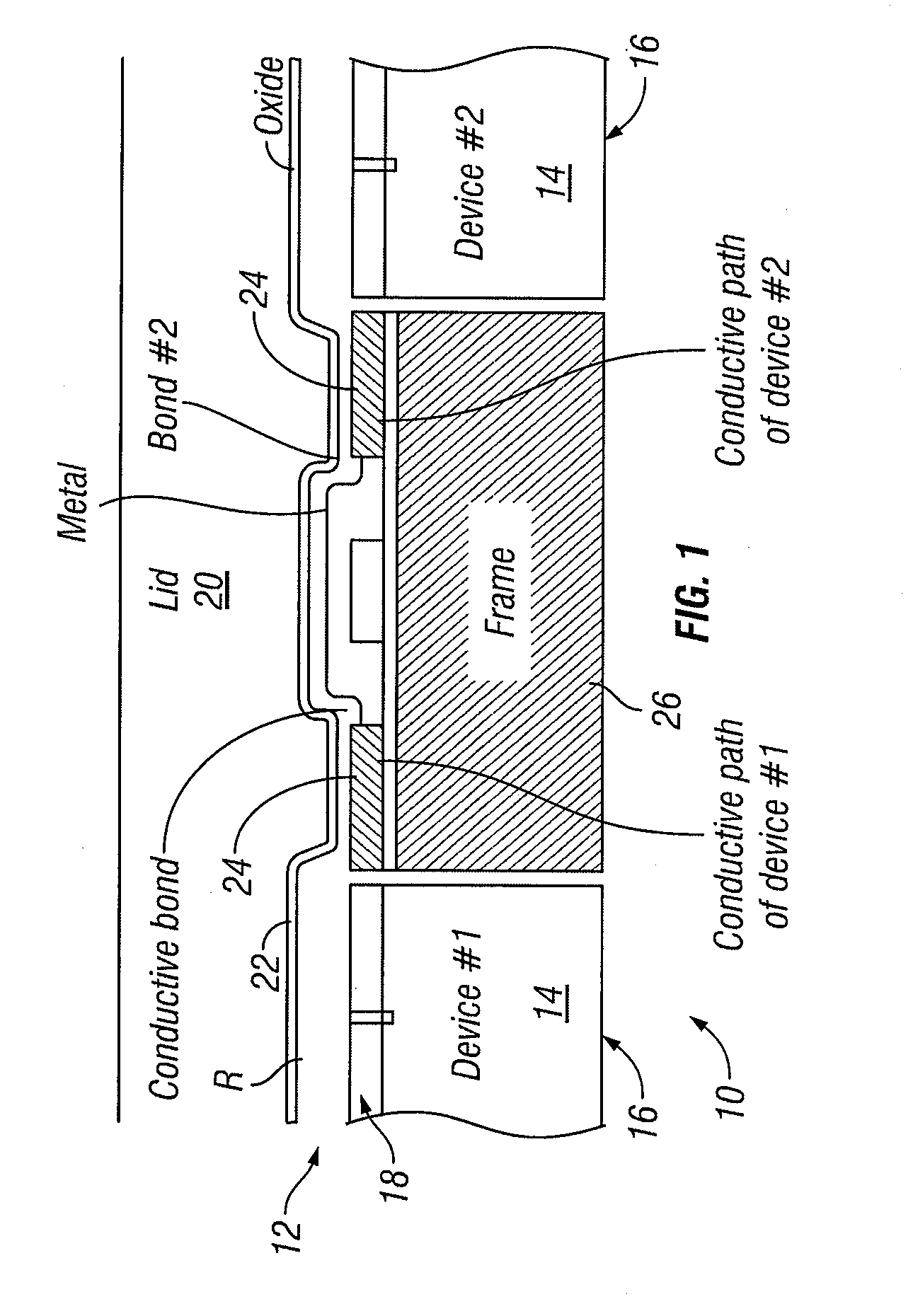

Interconnection system on a plane adjacent to a solid-state device structure

ActiveUS20090261432A1Minimizes amount of surfaceSurfaces with very littleTransducer detailsSemiconductor/solid-state device detailsInterconnectionSecondary layer

An interconnection system is provided for a solid-state device. The solid-state that includes, a first layer, multiple devices and a first face. A second layer is bonded to the first face at a bonded face of the second layer that faces the first face. Electrically conductive bonds are between the first and second faces. Conductive paths are on the bonded face of the second layer and connect two or more of the conductive bonds.

Owner:PCB PIEZOTRONICS OF NORTH CAROLINA

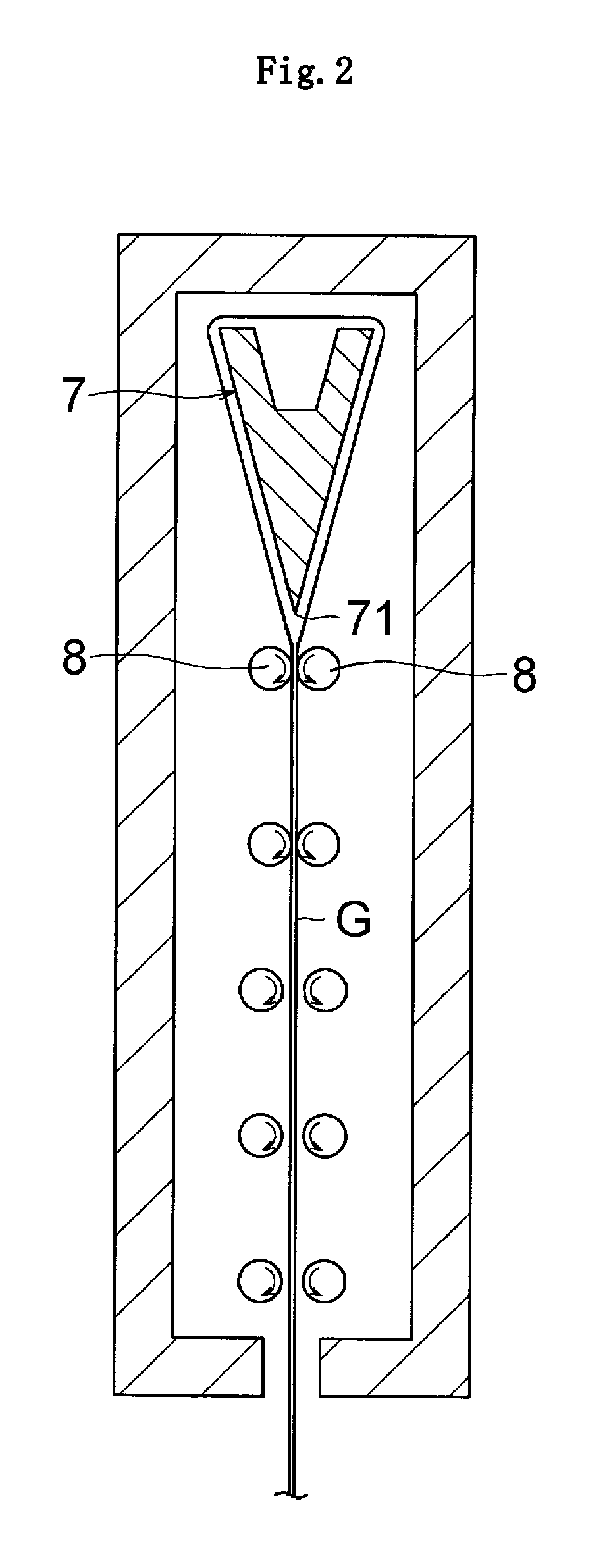

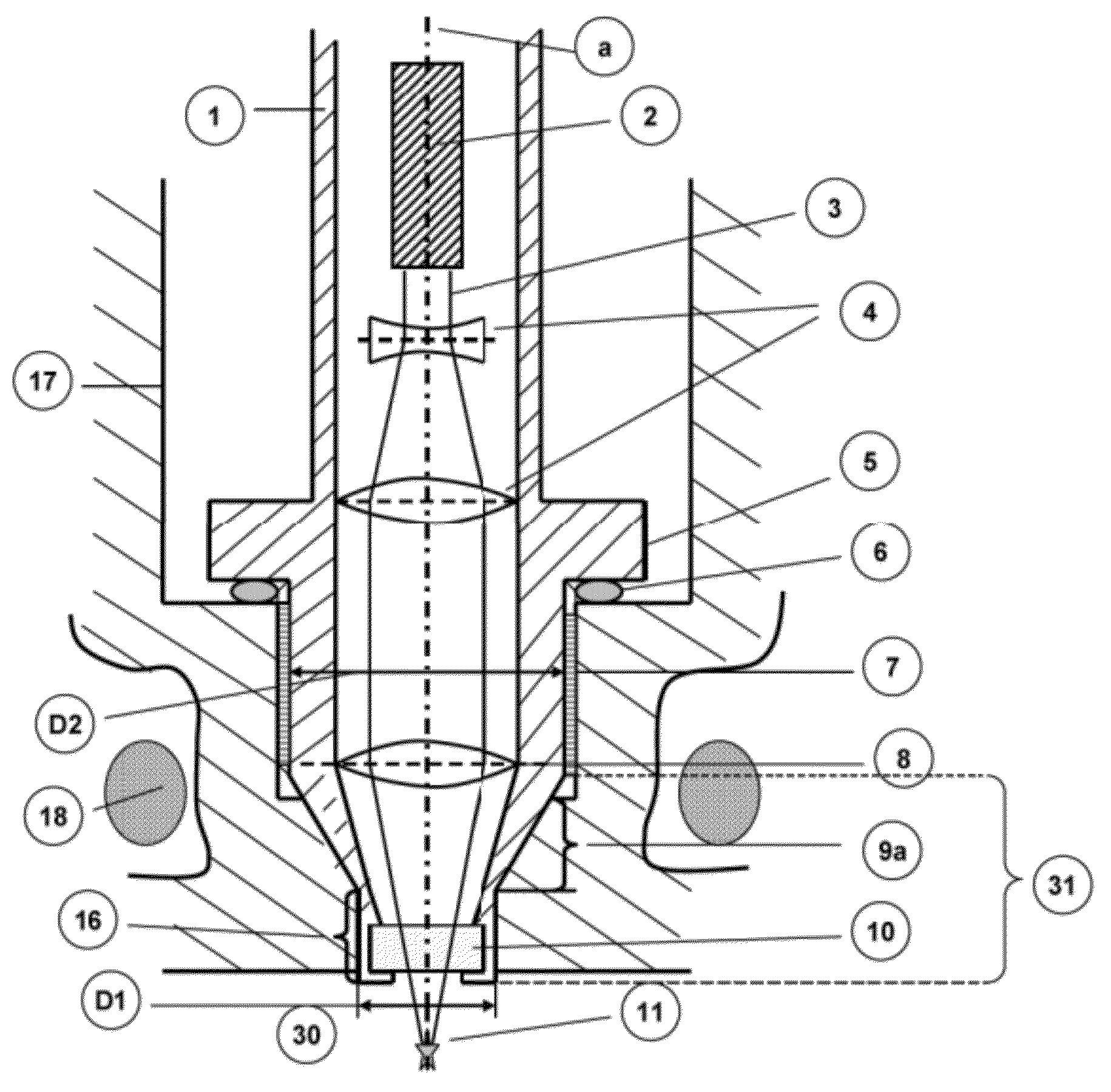

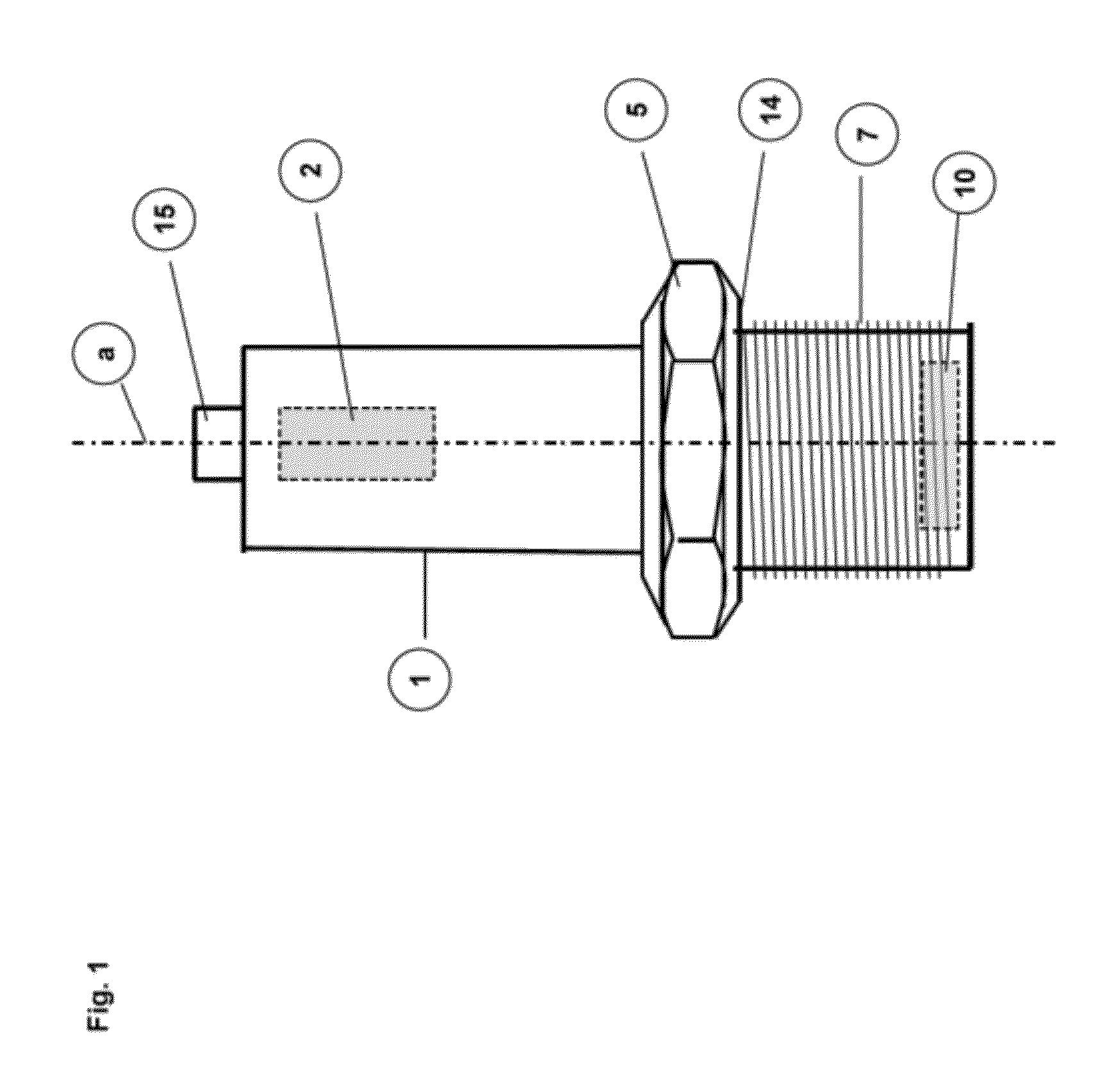

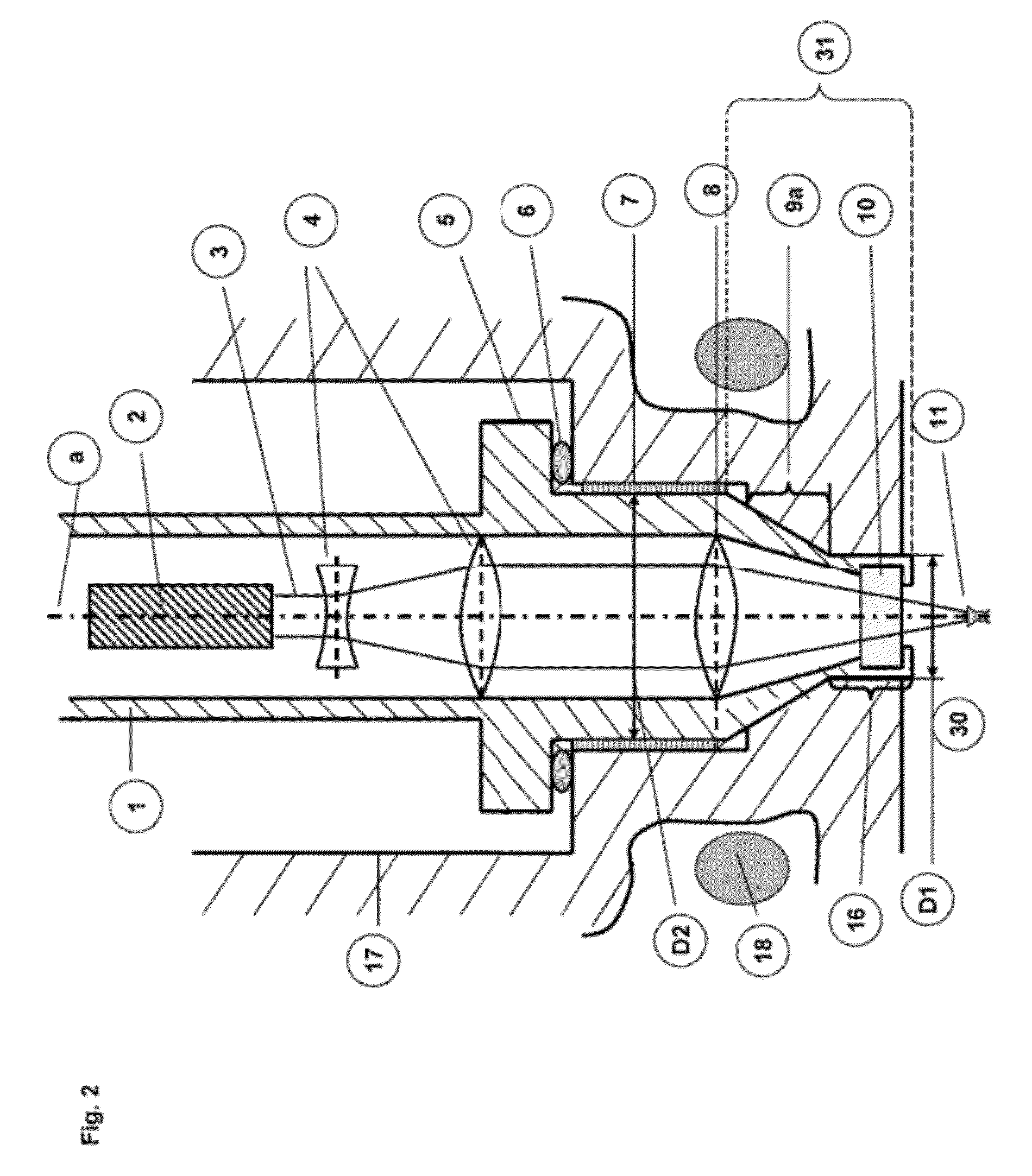

Laser spark plug for an internal combustion engine

InactiveUS8826876B2Improve cooling effectSurfaces with very littleSparking plugsCombustion enginesCombustion chamberCylinder head

A laser spark plug includes a laser light-producing device and a spark plug housing at the end of which facing the combustion chamber an injection lens for injecting laser light into the combustion chamber of an internal combustion engine is arranged. The spark plug housing includes a fastening zone for fastening the laser spark plug in a cylinder head of the internal combustion engine. A projection on the end of the spark plug housing facing the combustion chamber houses the injection lens. The outer diameter (D1) of the projection is smaller in the area of the injection lens than the outer diameter (D2) of the spark plug housing in the fastening zone.

Owner:GE JENBACHER

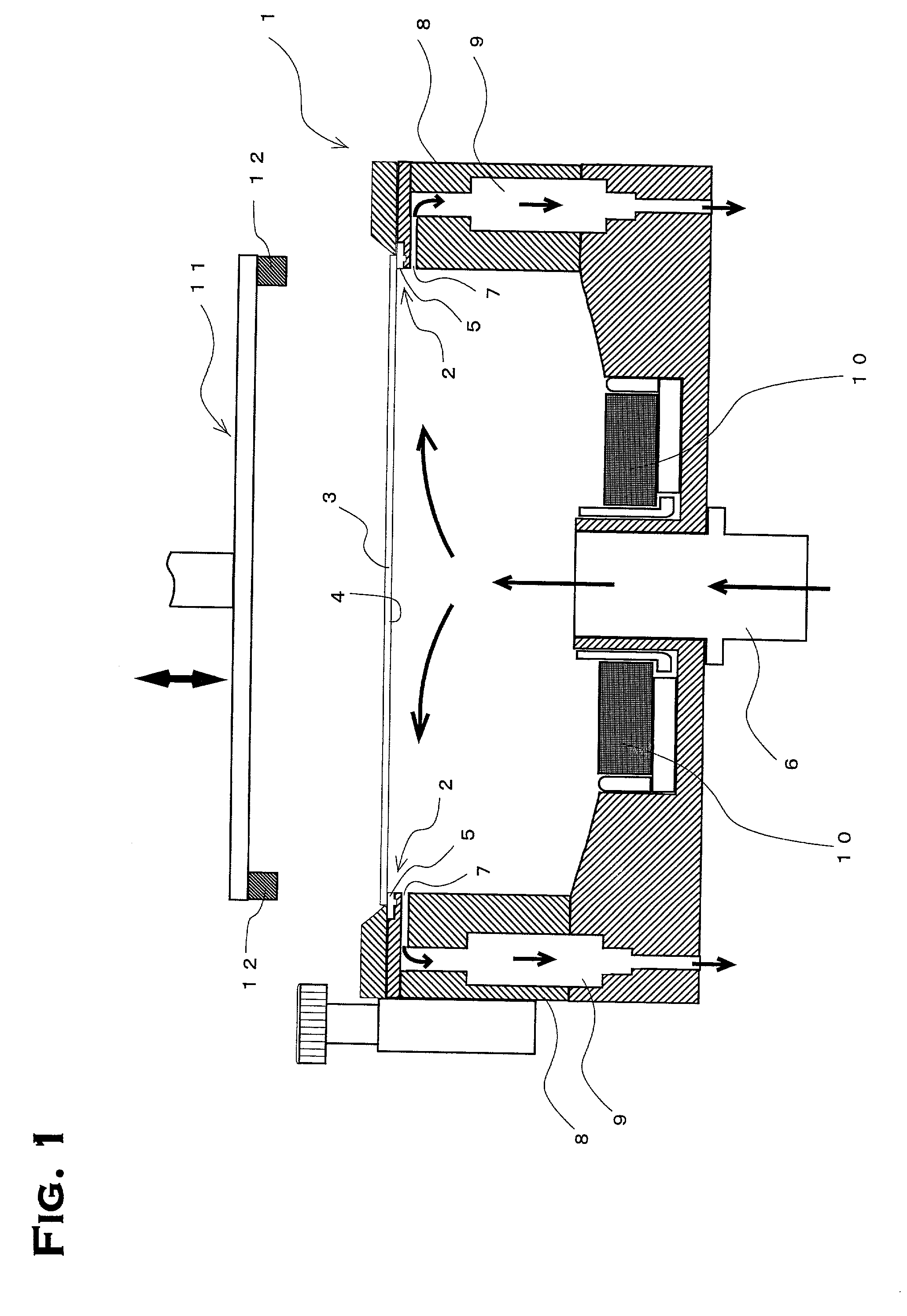

Cup - type plating apparatus

InactiveUS20020066665A1Prevent surfaceAvoid pollutionAnodisationCellsEngineeringMechanical engineering

The present cup-type plating apparatus improves a conventional cup-type plating apparatus and prevents the surface of a wafer due to a mist of the plating solutions from being contaminated. A plating solution is supplied to a wafer which is placed on a wafer support provided along an opening at the top of a plating tank from a solution-supply port provided at the bottom of the plating tank by an upward-moving stream; the plating solution is made to flow out of a solution-outlet port provided for the plating tank; and plating is performed while the plating solution is brought into contact with a surface of the placed wafer, which is to be plated, wherein the solution-outlet port has a solution-outlet path in which the discharged plating solution is isolated from the outer space.

Owner:ELECTROPLATING ENGINEERS OF JAPAN LTD

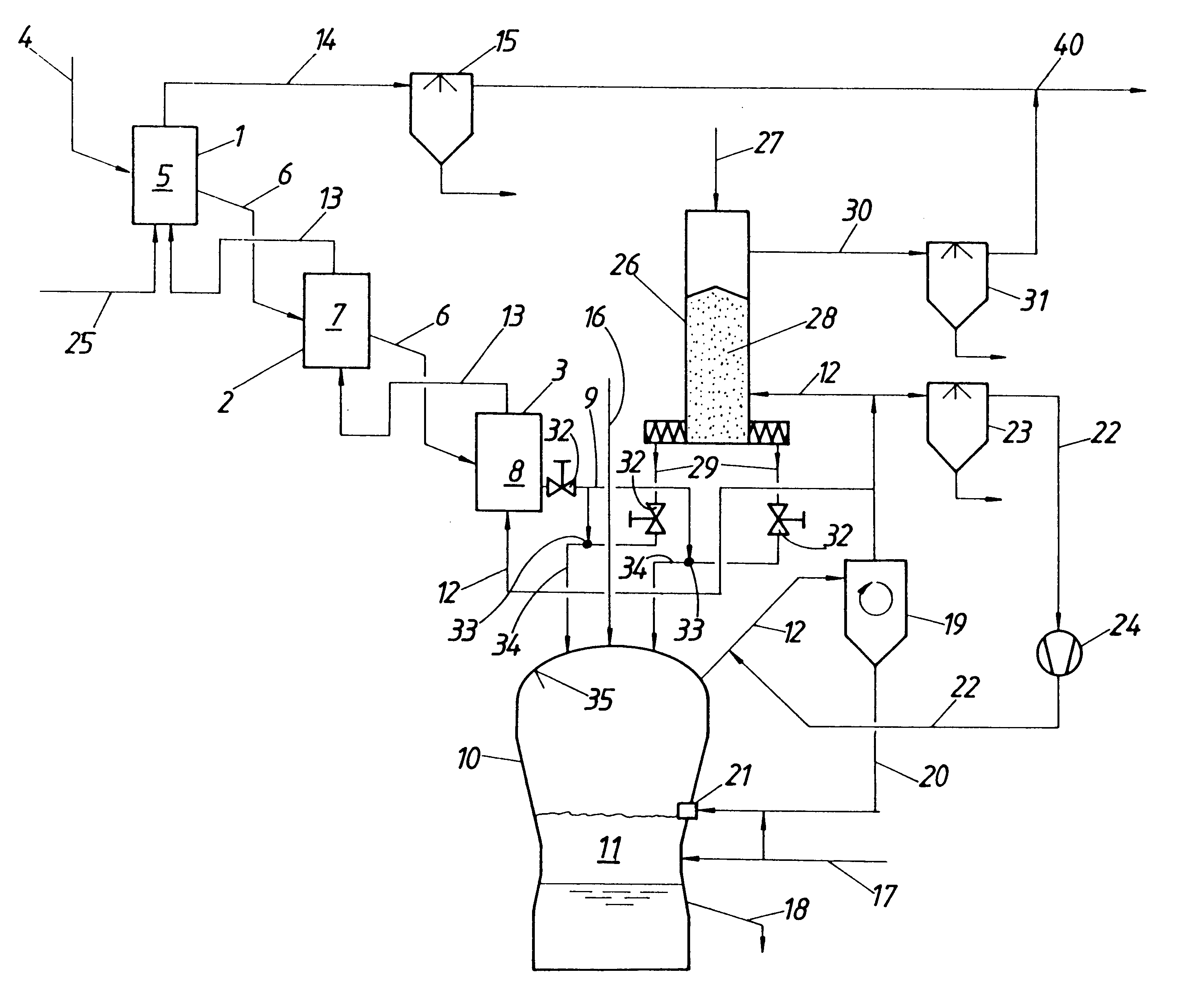

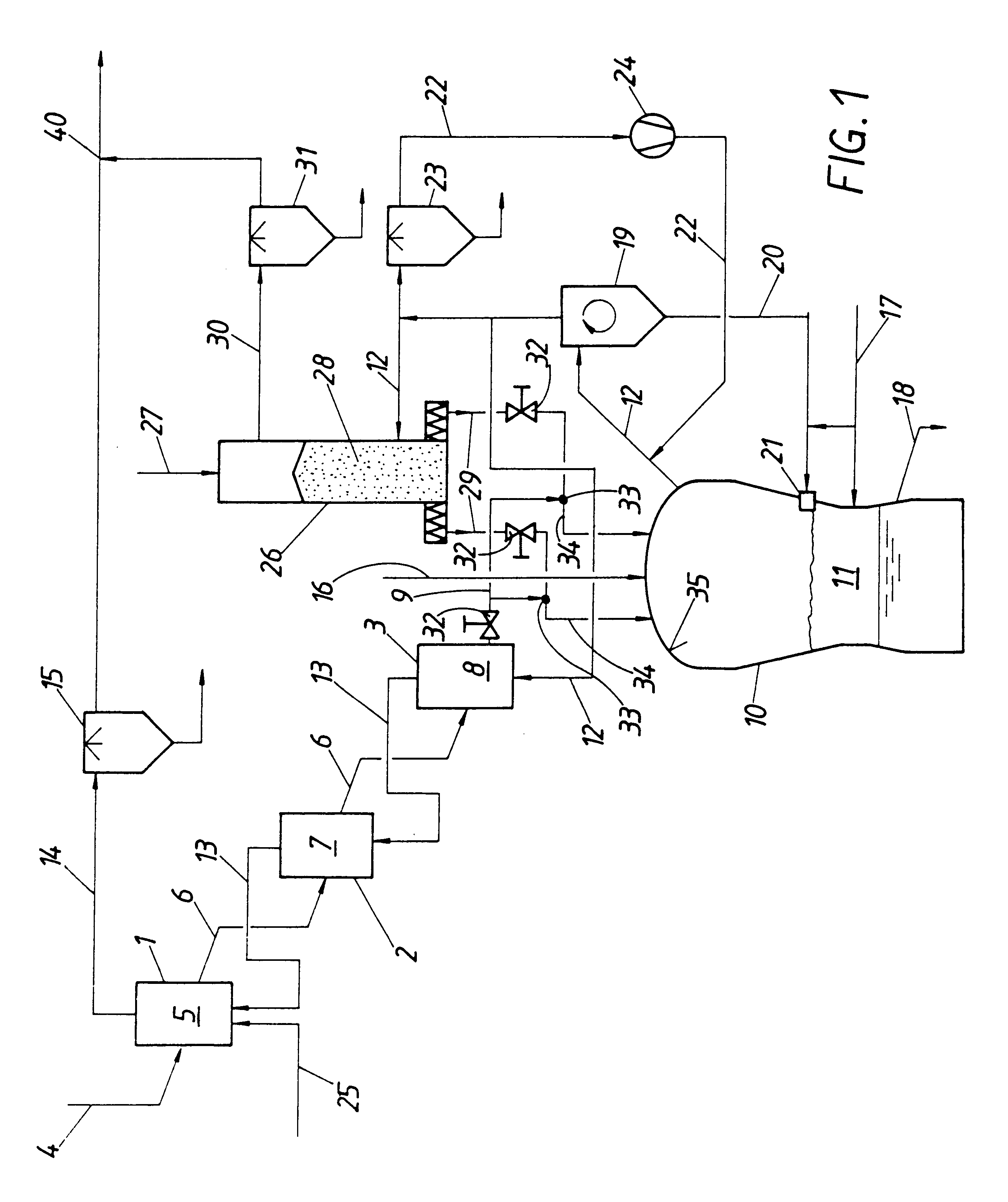

Method and plant for producing iron from lumpy and fine-particulate sponge iron

InactiveUS6214083B1Easy to operateReduce lossesExhaust gas handlingShaft furnaceBrown iron oxideLiquid steel

In a method of producing liquid pig iron or liquid steel pre-products from iron-oxide-containing material, fine-particulate iron-oxide-containing material is reduced to fine-particulate sponge iron by the fluidized bed method by passing a reducing gas through at least one fluidized bed reduction stage (7, 8), and lumpy ore is reduced to lumpy sponge iron in a fixed bed reduction stage (28). The sponge iron is charged into a melting-gasifying zone (11) and is molten there under a supply of carbon carriers and oxygen-containing gas, in which a CO- and H2-containing reducing gas is generated for reducing the iron-oxide-containing material. To avoid treating the fine-particulate sponge iron separately from the lumpy sponge iron, the fine-particulate sponge is charged directly to the melting-gasifying zone (11) in an untreated condition and in fine-particulate form, and there, is melted together with the lumpy sponge iron.

Owner:SIEMENS VAI METALS TECH GMBH

Method of making a transistor with a sloped drain diffusion layer

InactiveUS7629214B2Reduce in quantitySuppress manufacturing costTransistorSemiconductor/solid-state device manufacturingDiffusionImpurity ions

Owner:SEMICON COMPONENTS IND LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com