Heat exchanging tube with spiral groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

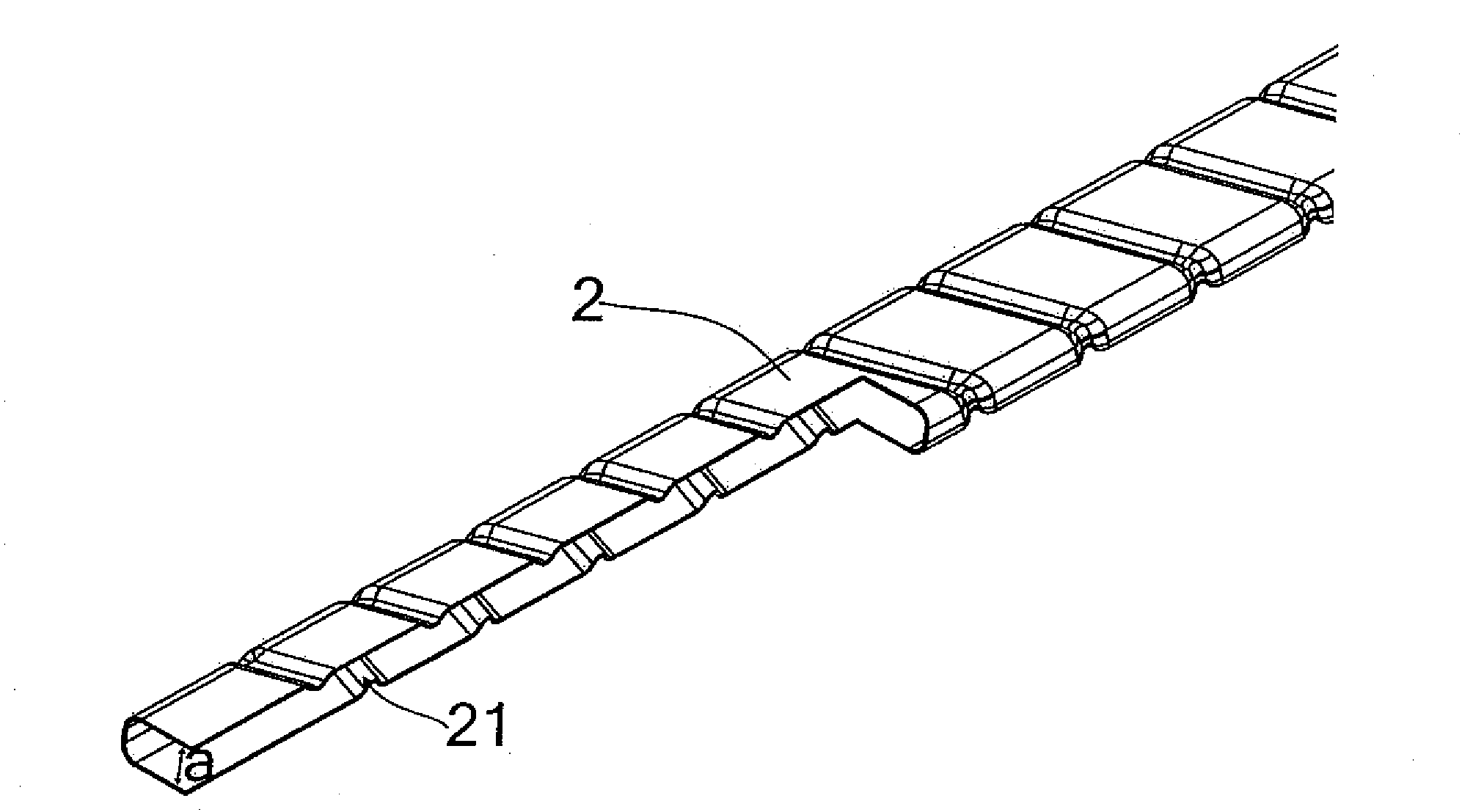

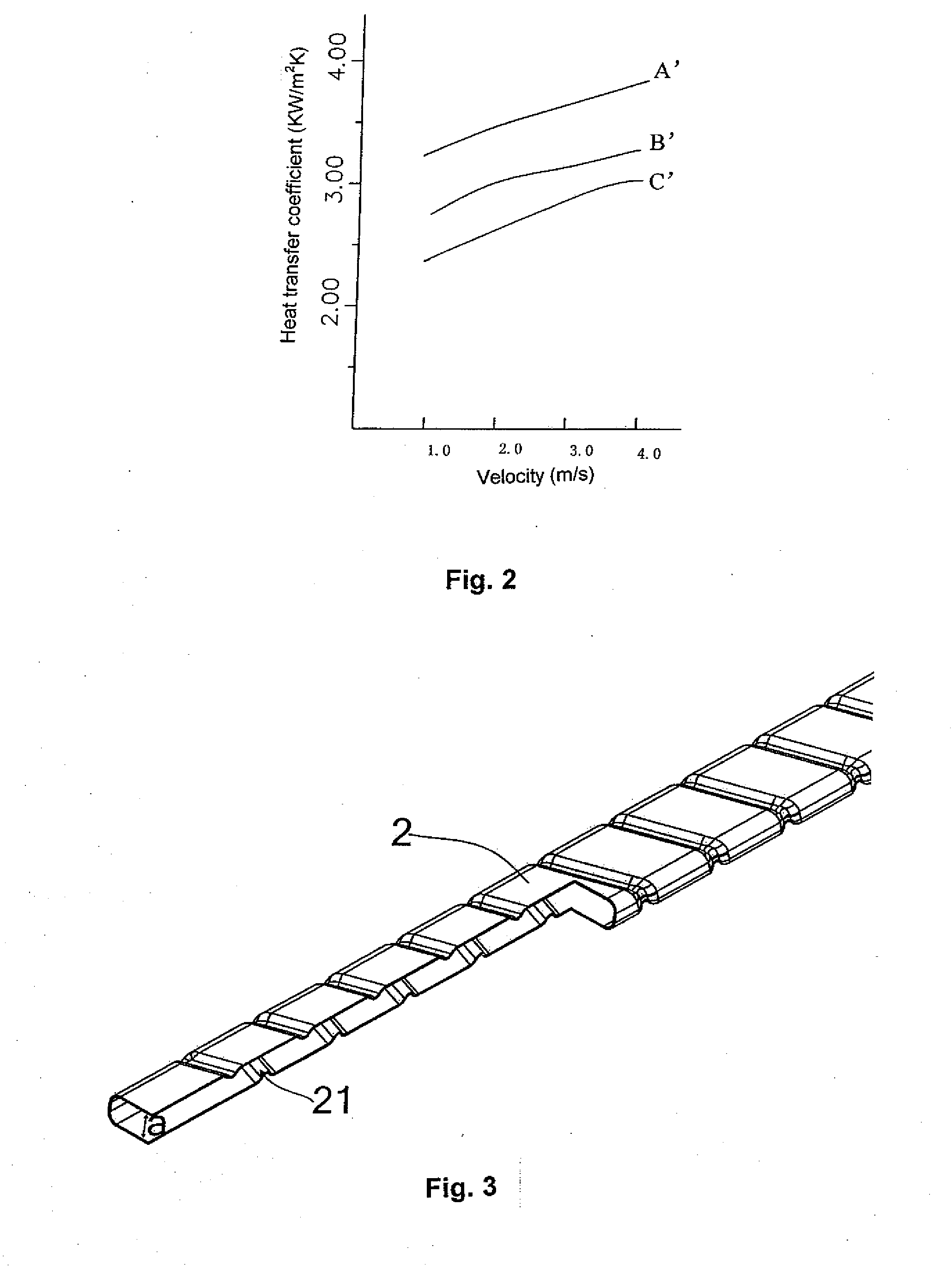

[0024]FIG. 3 and FIG. 4 are the sketch of the three dimensional drawing and the sectional view drawing of the first embodiment in the present invention respectively. In the drawings, heat transfer tube is a stainless steel tube body 2 with an internally convex spiral groove 21 on its surface. In order to realize the heat exchange with the largest efficiency by using the surface of the heat transfer tube sufficiently, and make it easy to be manufactured, the two adjacent surfaces of the heat tube are set to be connected by arc transition with the radius of R in this embodiment. Removing the sectional shape from the section of said heat transfer tube, the sectional shape of the stainless steel tube body 2 becomes rectangle, wherein the height is not equal to the width, and the adjacent two sides are connected by arc transition, which is shown in FIG. 4, wherein a is the height of the section; the spiral convex can be one or more; the sectional shape of the spiral groove can be set as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com