Patents

Literature

85results about How to "Speed up heat convection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

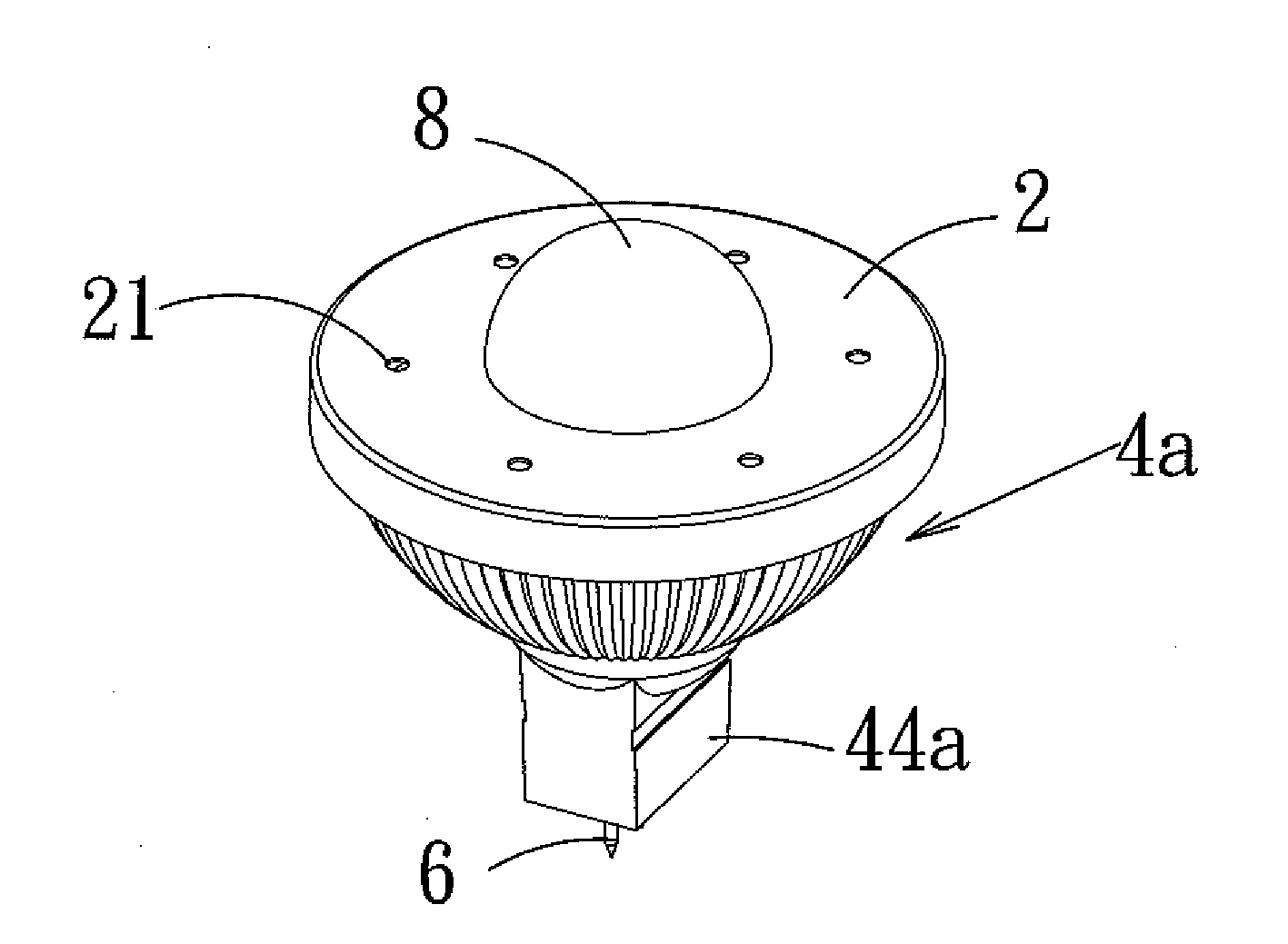

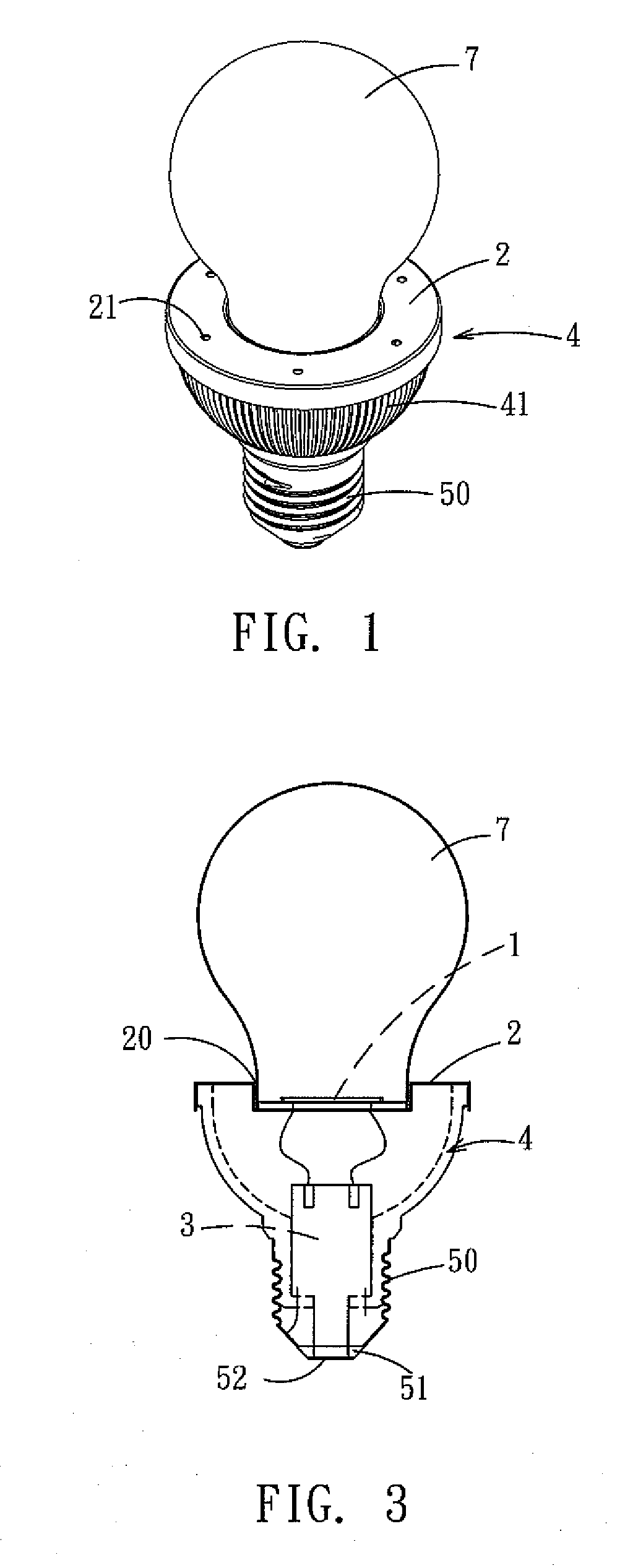

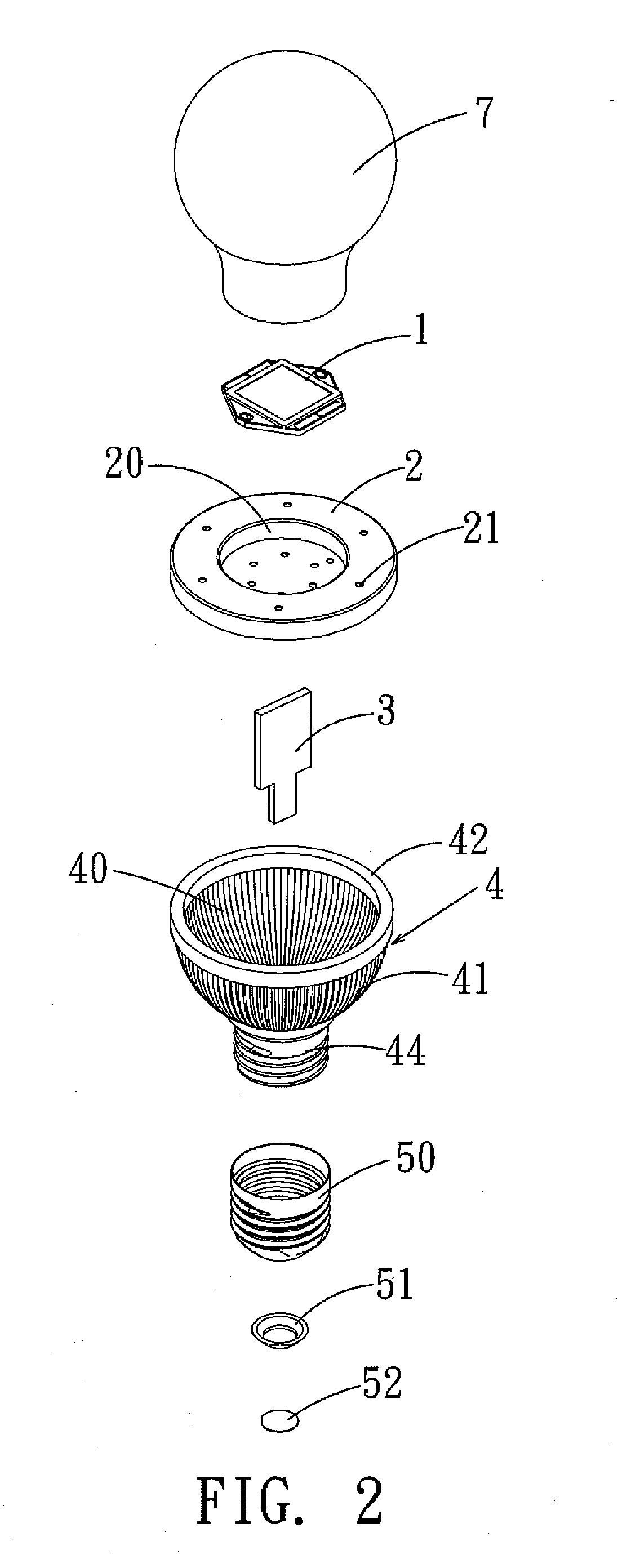

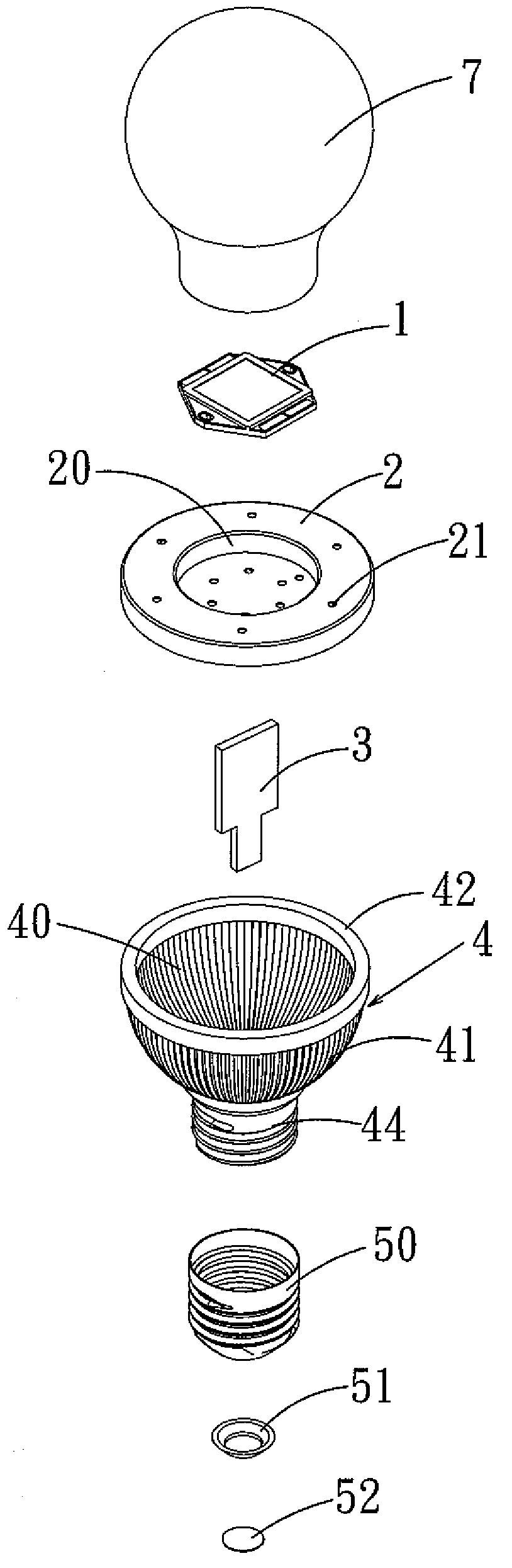

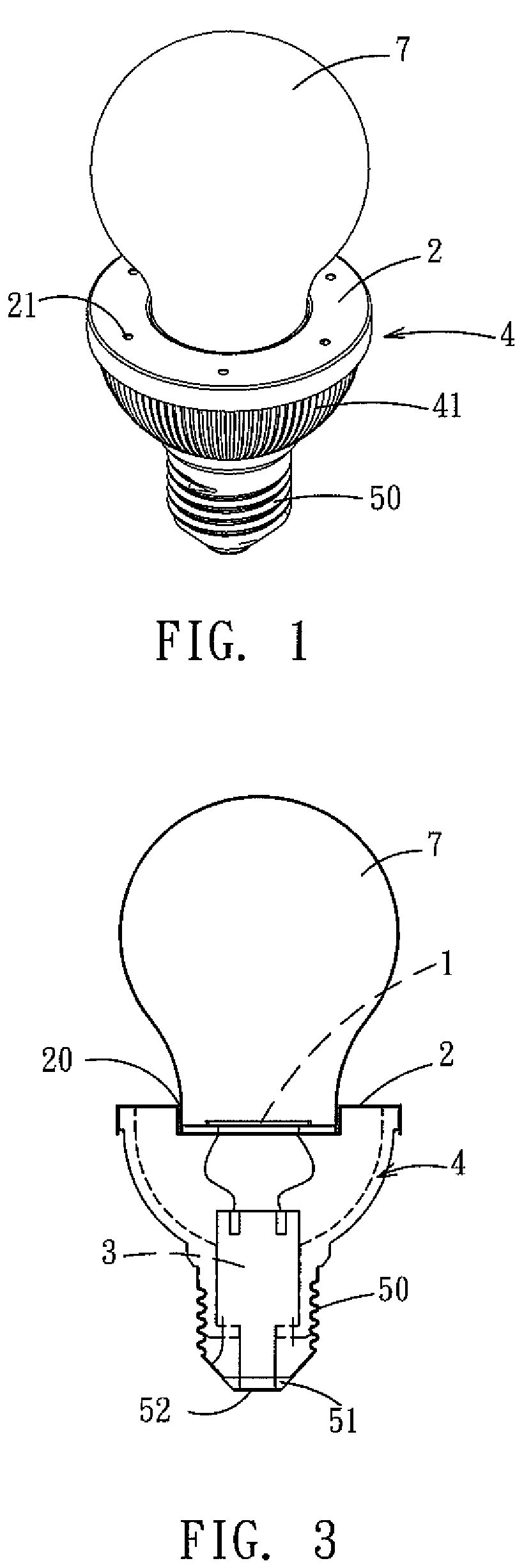

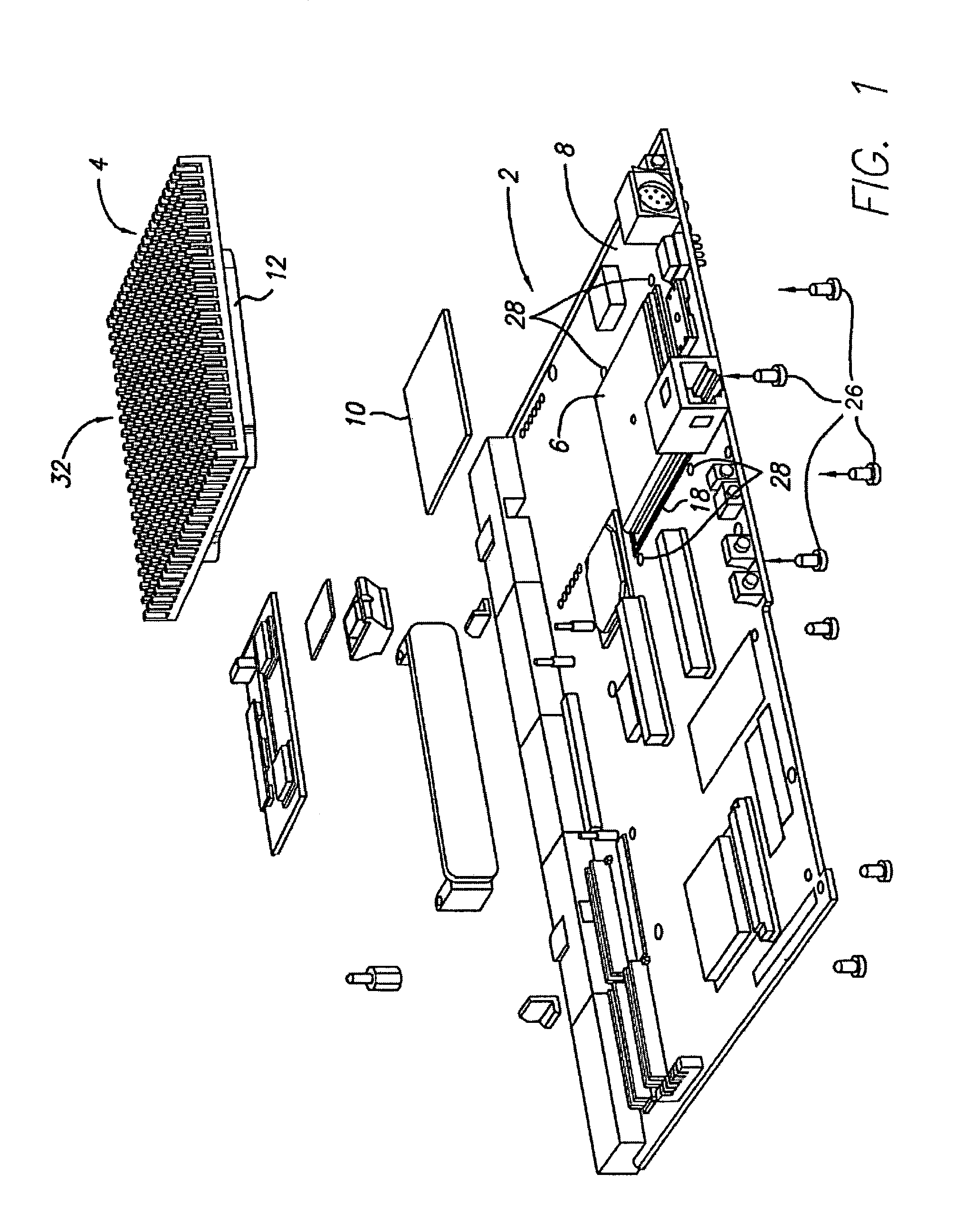

LED Lamp Having Higher Efficiency

InactiveUS20090244899A1Enhance heat convection effectIncrease surface areaPoint-like light sourceElectric circuit arrangementsElectricityEngineering

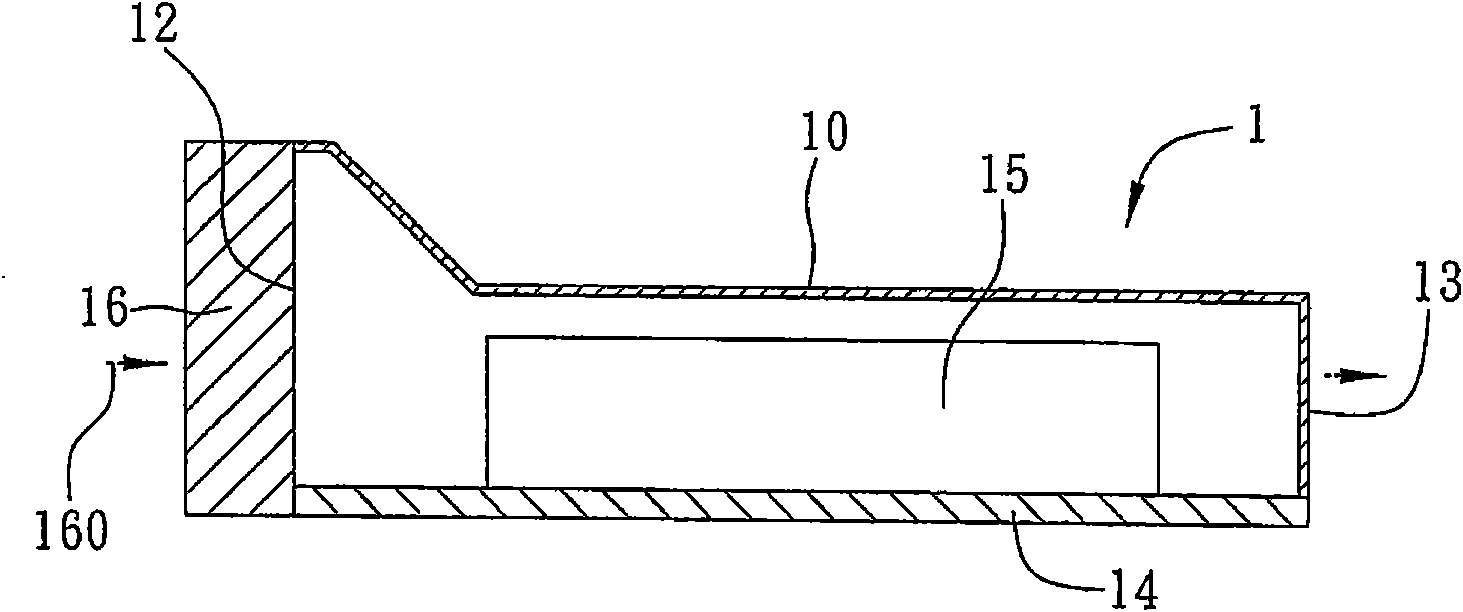

An LED lamp includes a heatsink housing, a heatsink plate mounted on the heatsink housing, an LED module mounted on the heatsink plate, and a circuit board mounted in the heatsink housing and electrically connected to the LED module. Thus, when the LED module is operated, the heat produced by the LED module is transferred by a heat conduction of the heatsink plate and by a heat convection between the heatsink plate and the heatsink housing, so that the heat produced by the LED module is carried away exactly and quickly, thereby enhancing the heat dissipation effect of the LED module.

Owner:CHYN WEN LONG

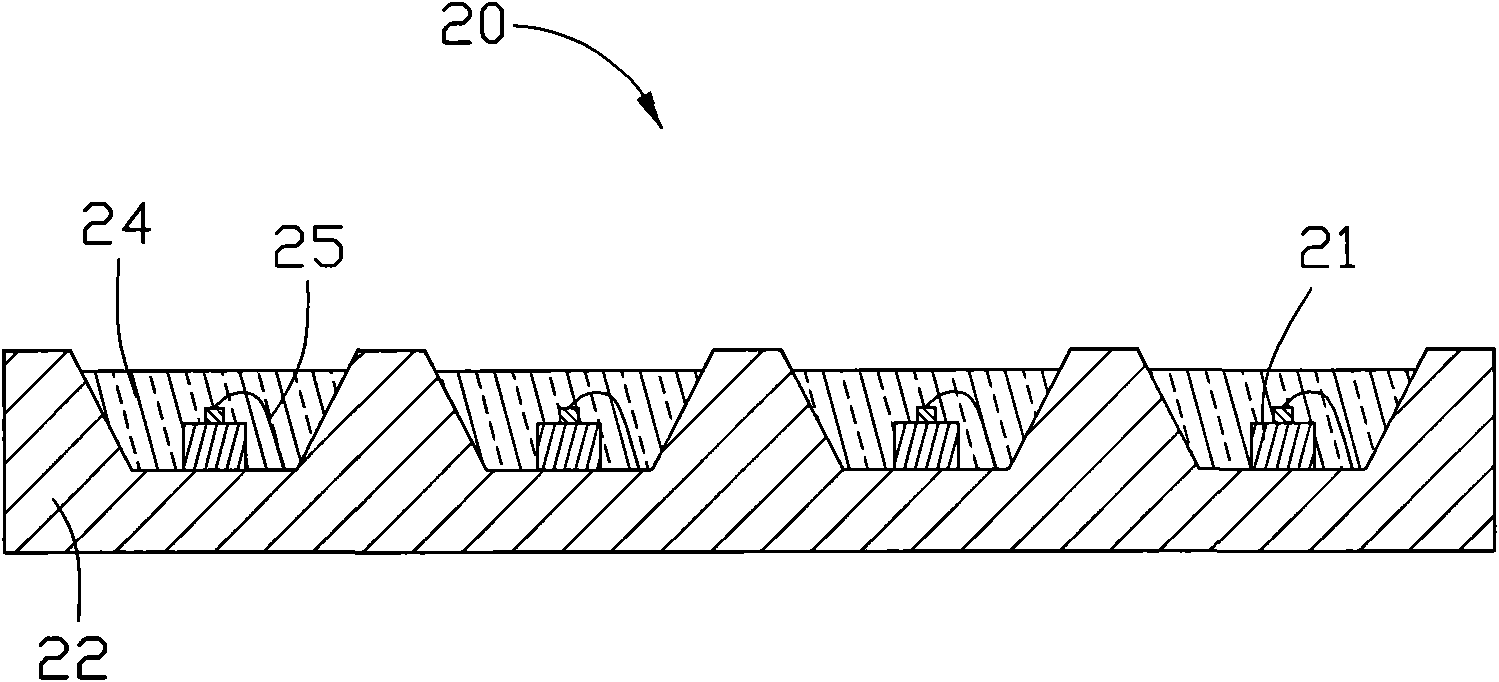

LED lamp having higher efficiency

InactiveUS7677767B2Improve efficiencyImprove cooling effectLighting support devicesPoint-like light sourceElectricityEngineering

An LED lamp includes a heatsink housing, a heatsink plate mounted on the heatsink housing, an LED module mounted on the heatsink plate, and a circuit board mounted in the heatsink housing and electrically connected to the LED module. Thus, when the LED module is operated, the heat produced by the LED module is transferred by a heat conduction of the heatsink plate and by a heat convection between the heatsink plate and the heatsink housing, so that the heat produced by the LED module is carried away exactly and quickly, thereby enhancing the heat dissipation effect of the LED module.

Owner:CHYN WEN LONG

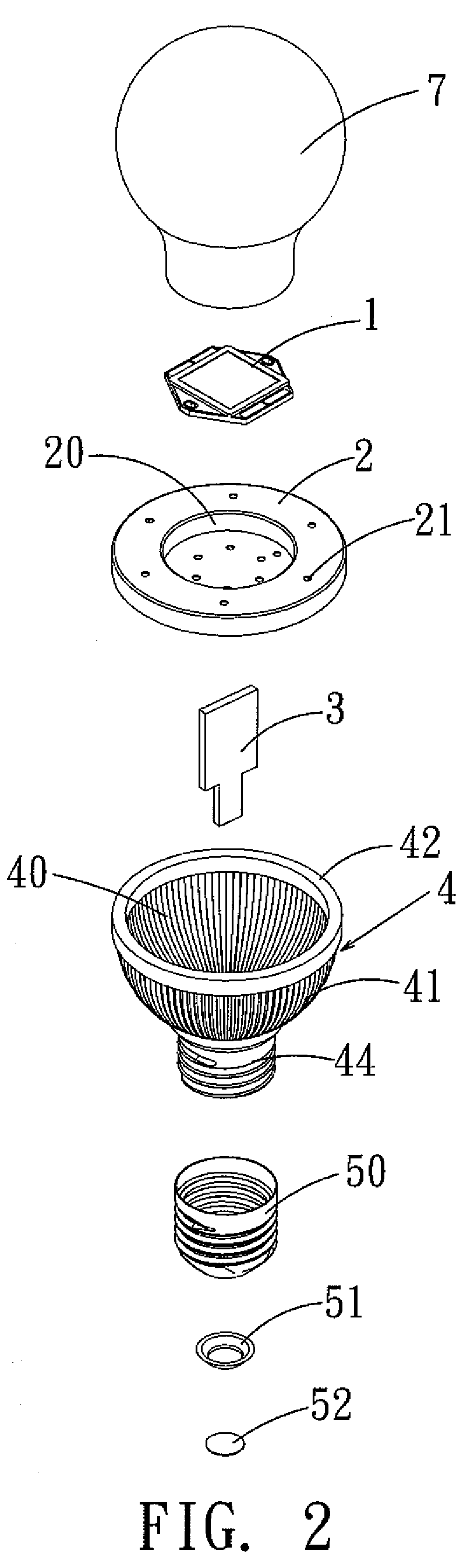

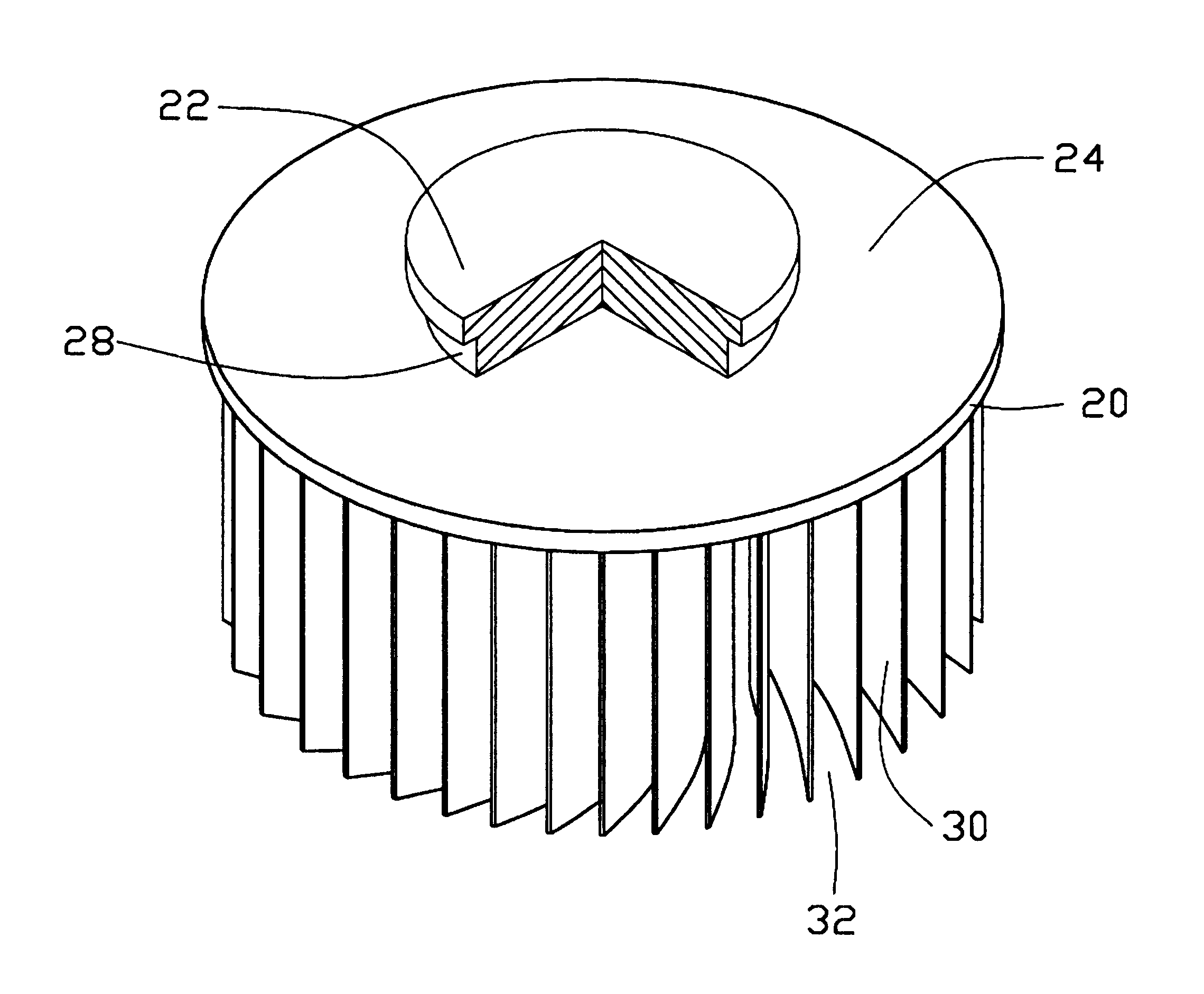

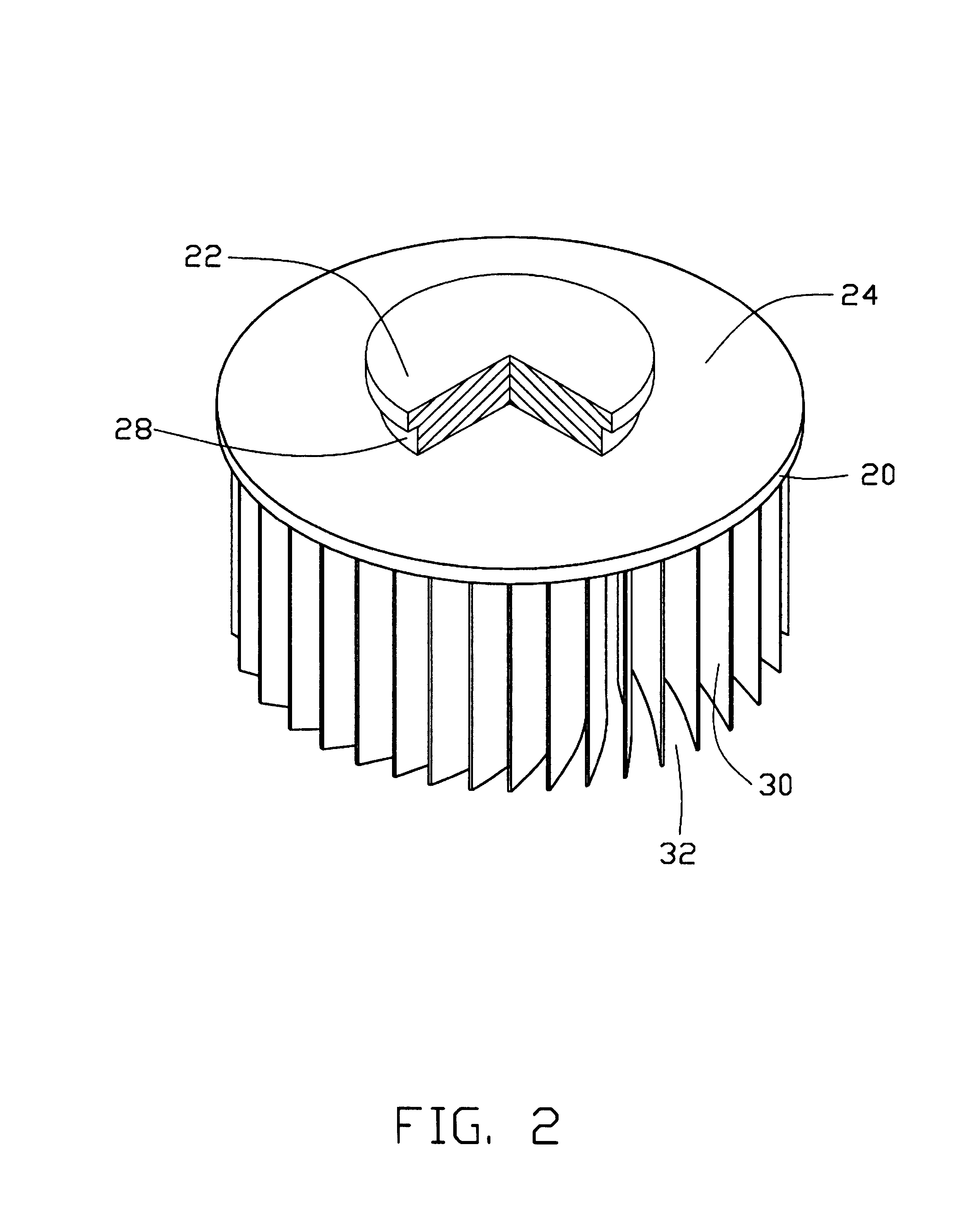

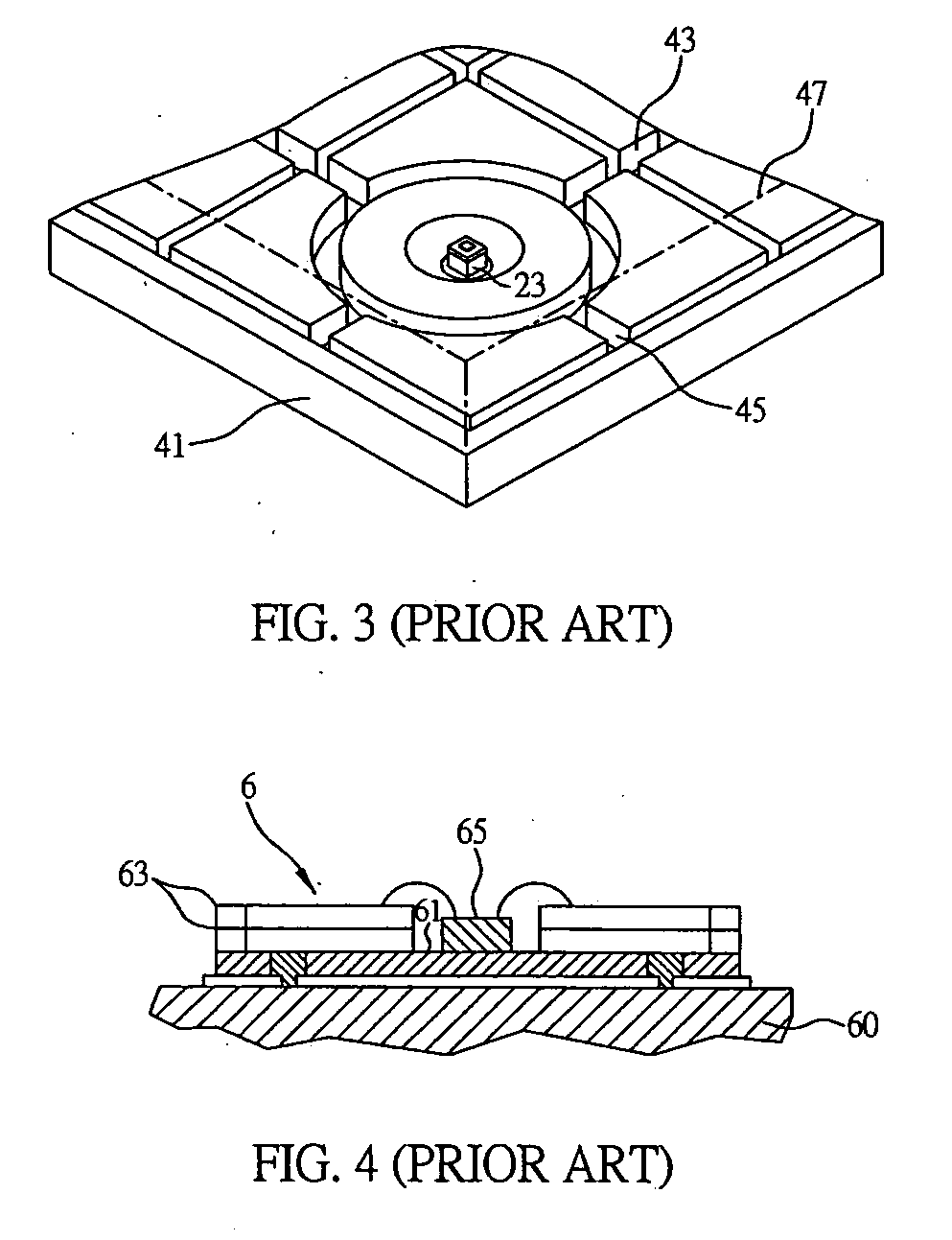

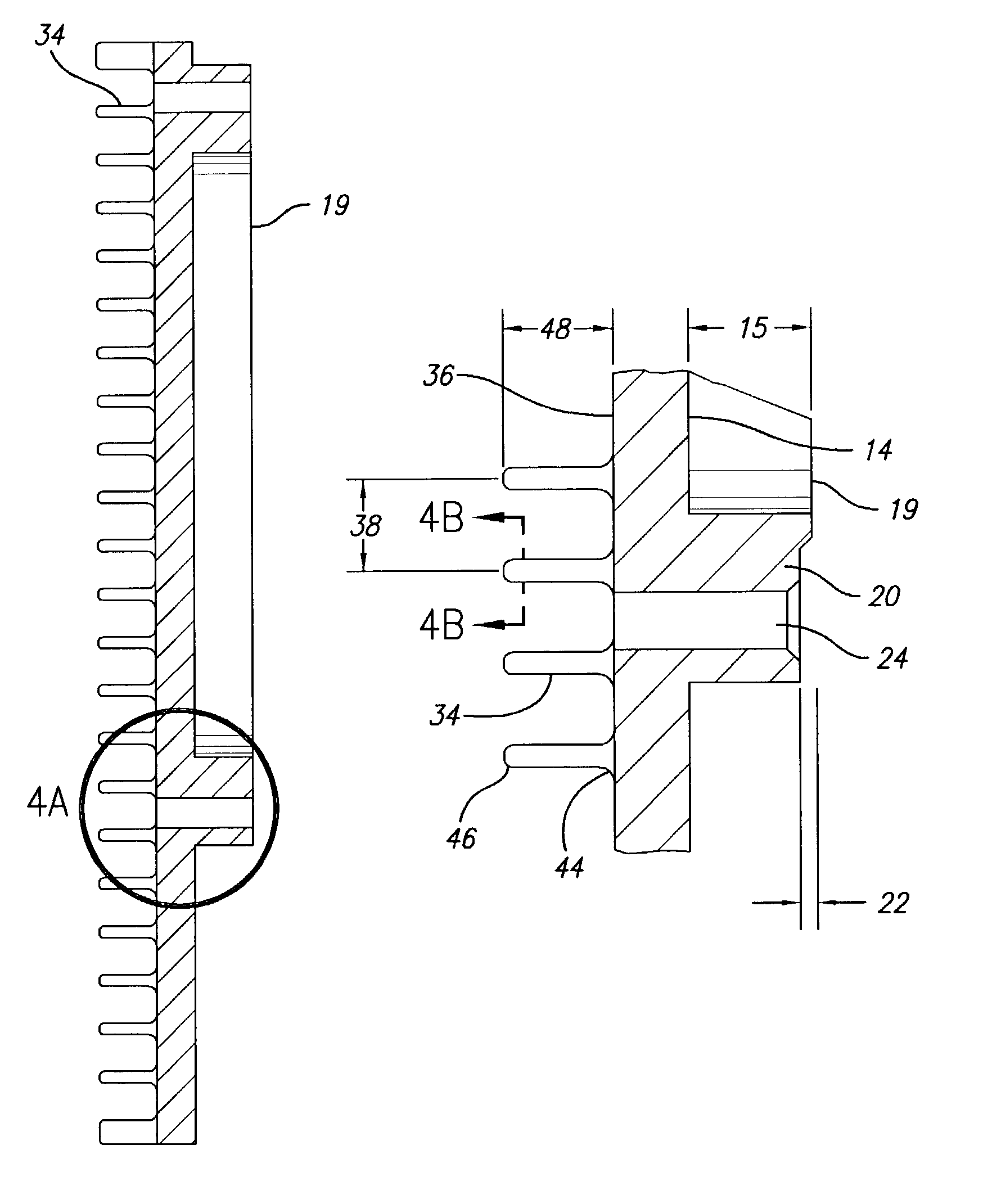

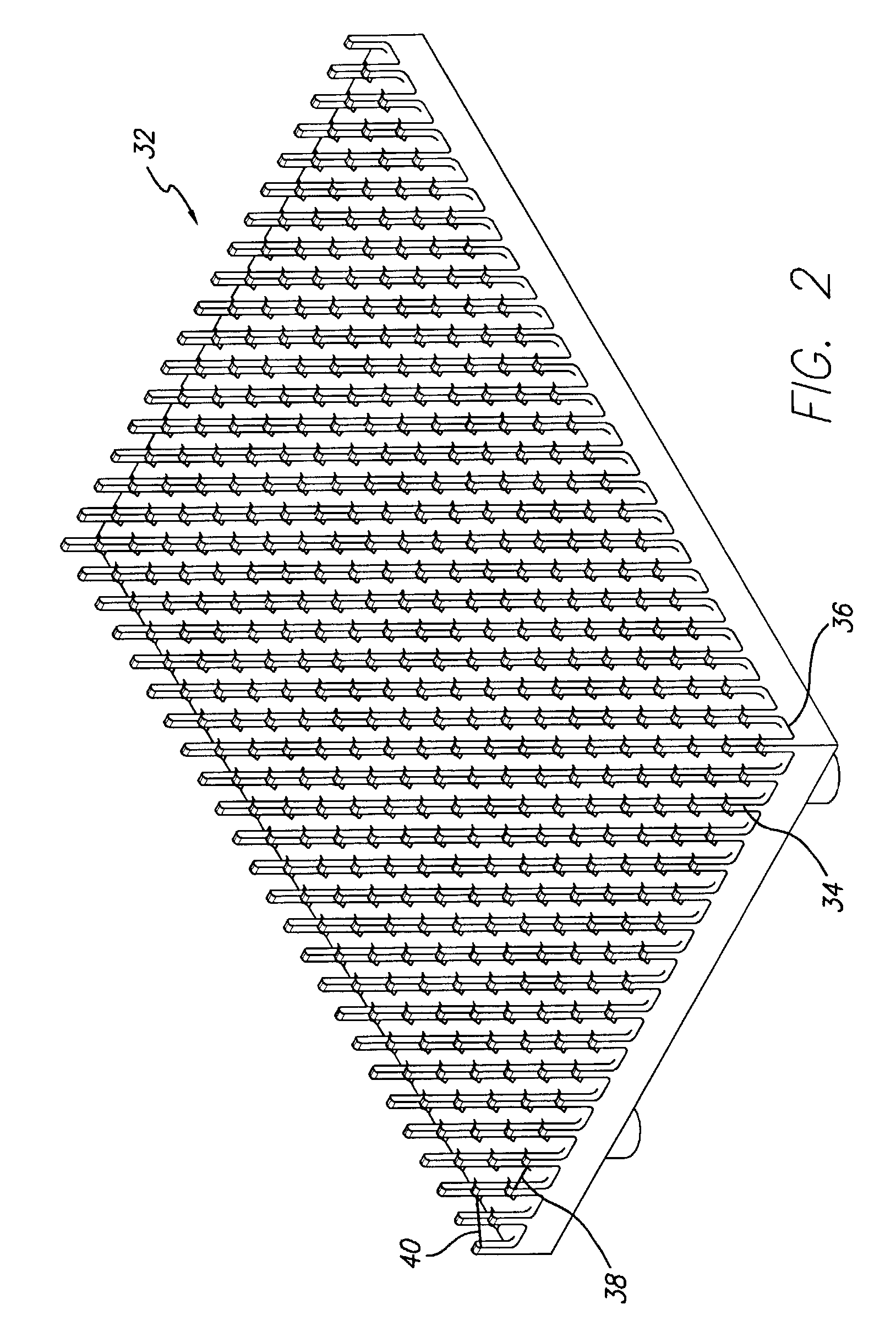

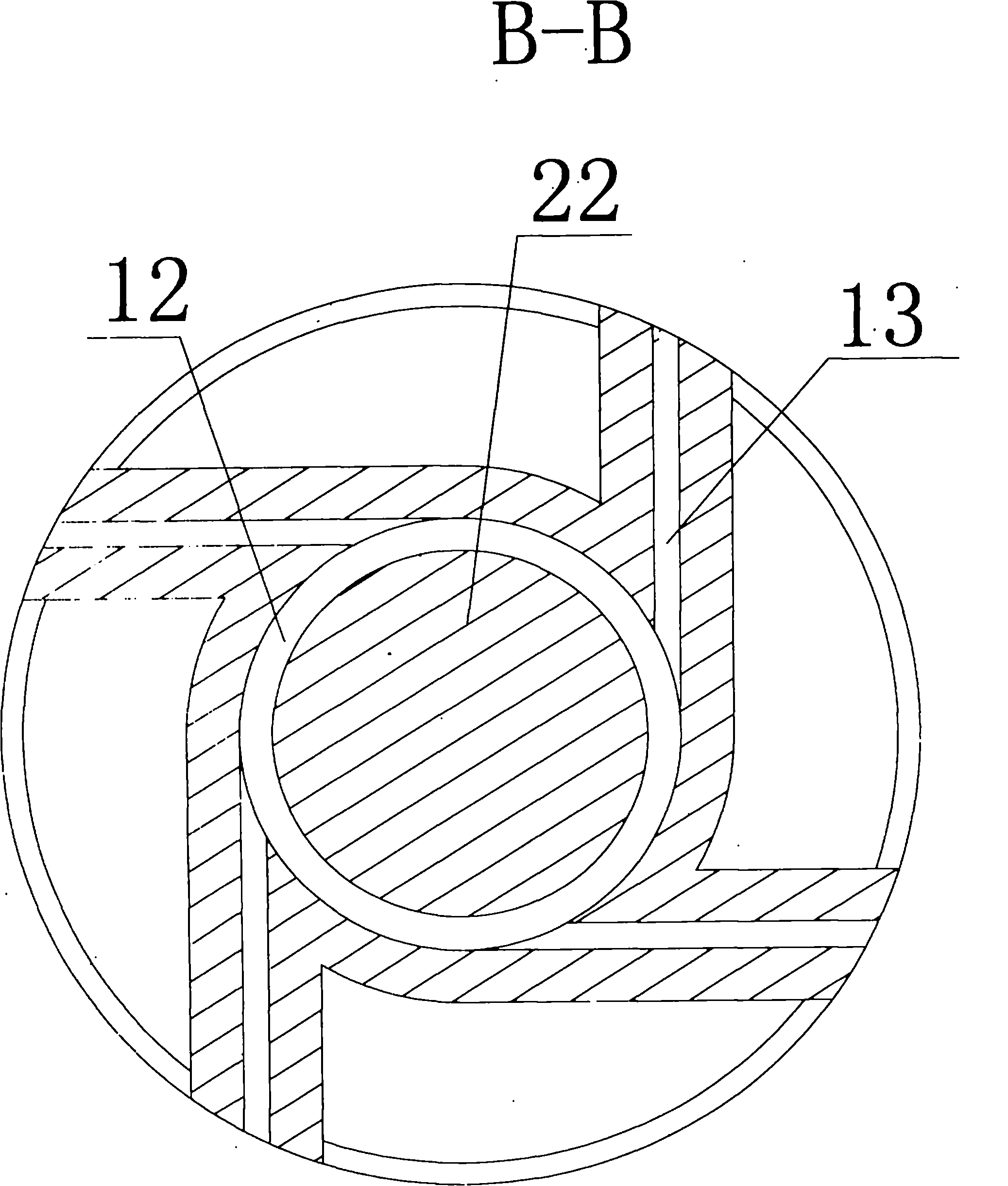

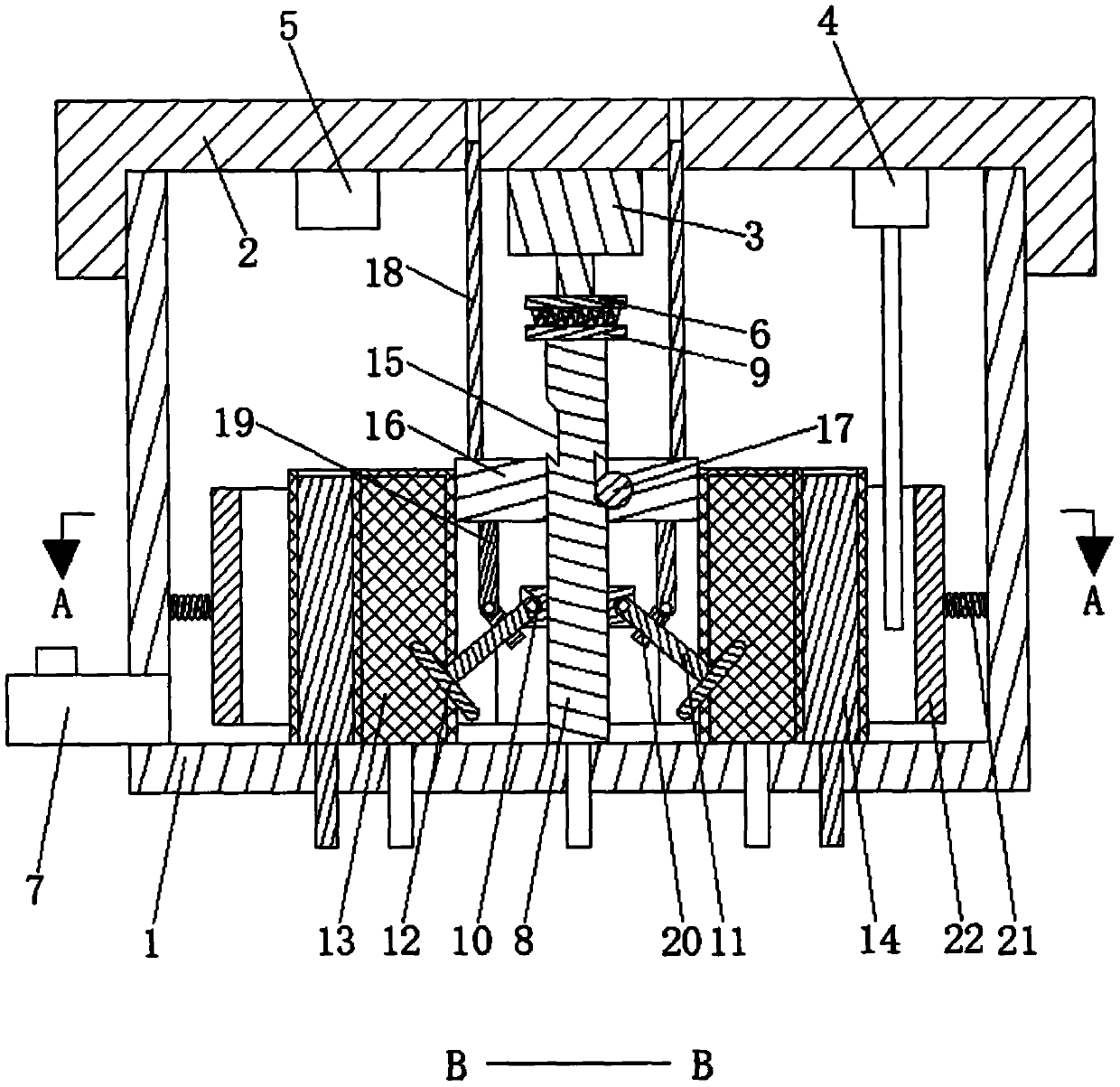

Turbinate heat sink

InactiveUS6552902B2Drag minimizationSpeed up heat convectionSemiconductor/solid-state device detailsSolid-state devicesEngineeringTurbinates

A heat sink (10) includes a circular base (20), a plurality of fins (30), and a central post (40). The base is adapted to be in thermal contact with an electronic device, to remove heat therefrom. The post extends from a top surface (26) of the base. The post has a first surface connected to the top surface and a second surface (44) dimensioned according to a heat sink fan to be attached thereon. The post also has a concave side surface (42) between the second surface of the post and the top surface of the base, for directing airflow. The fins are identical in height to the post. The fins are curved, aligned and spaced from each other at uniform intervals corresponding to directions of airflow generated from the fan. These minimize resistance to cooling air entering or exiting the heat sink.

Owner:HON HAI PRECISION IND CO LTD

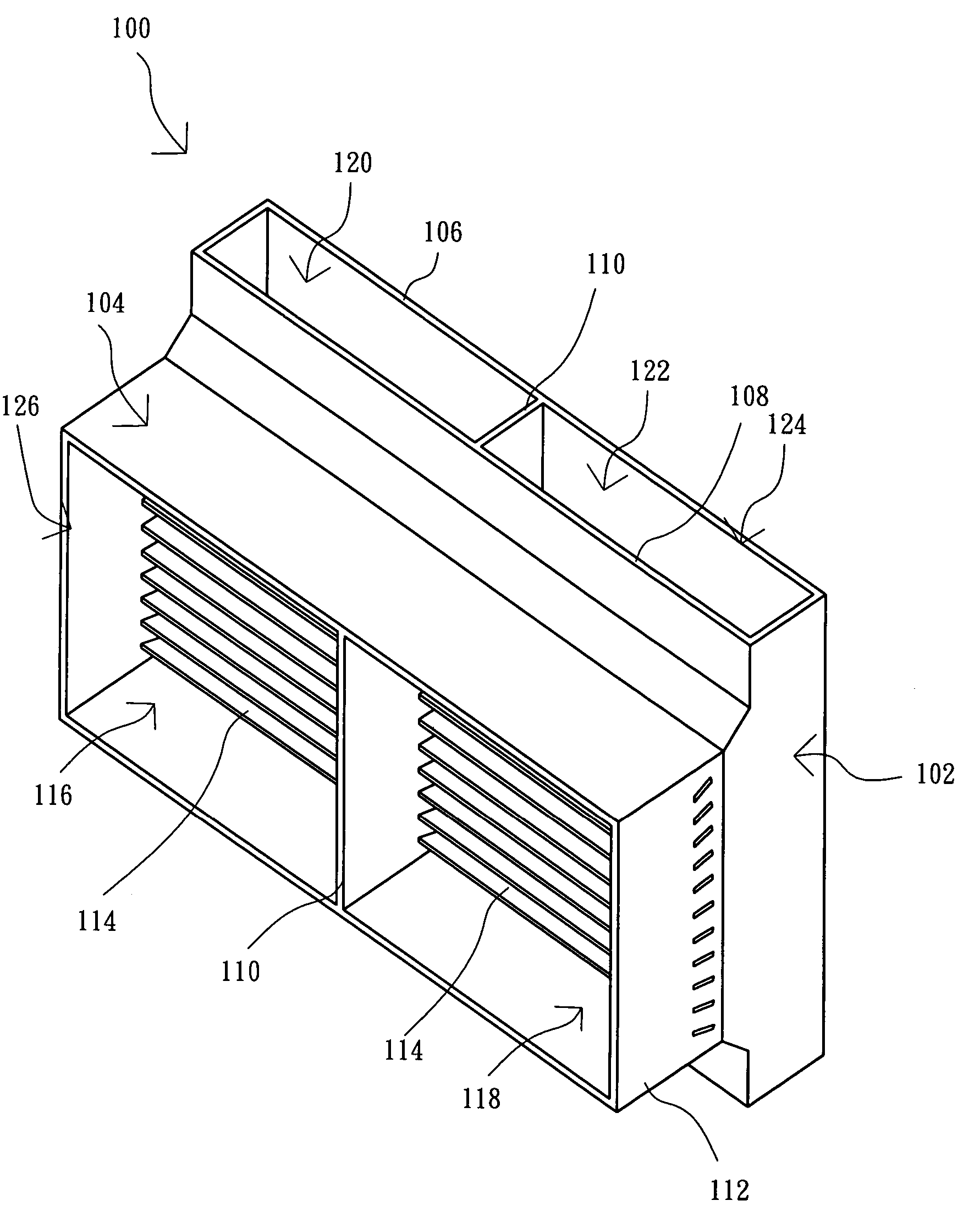

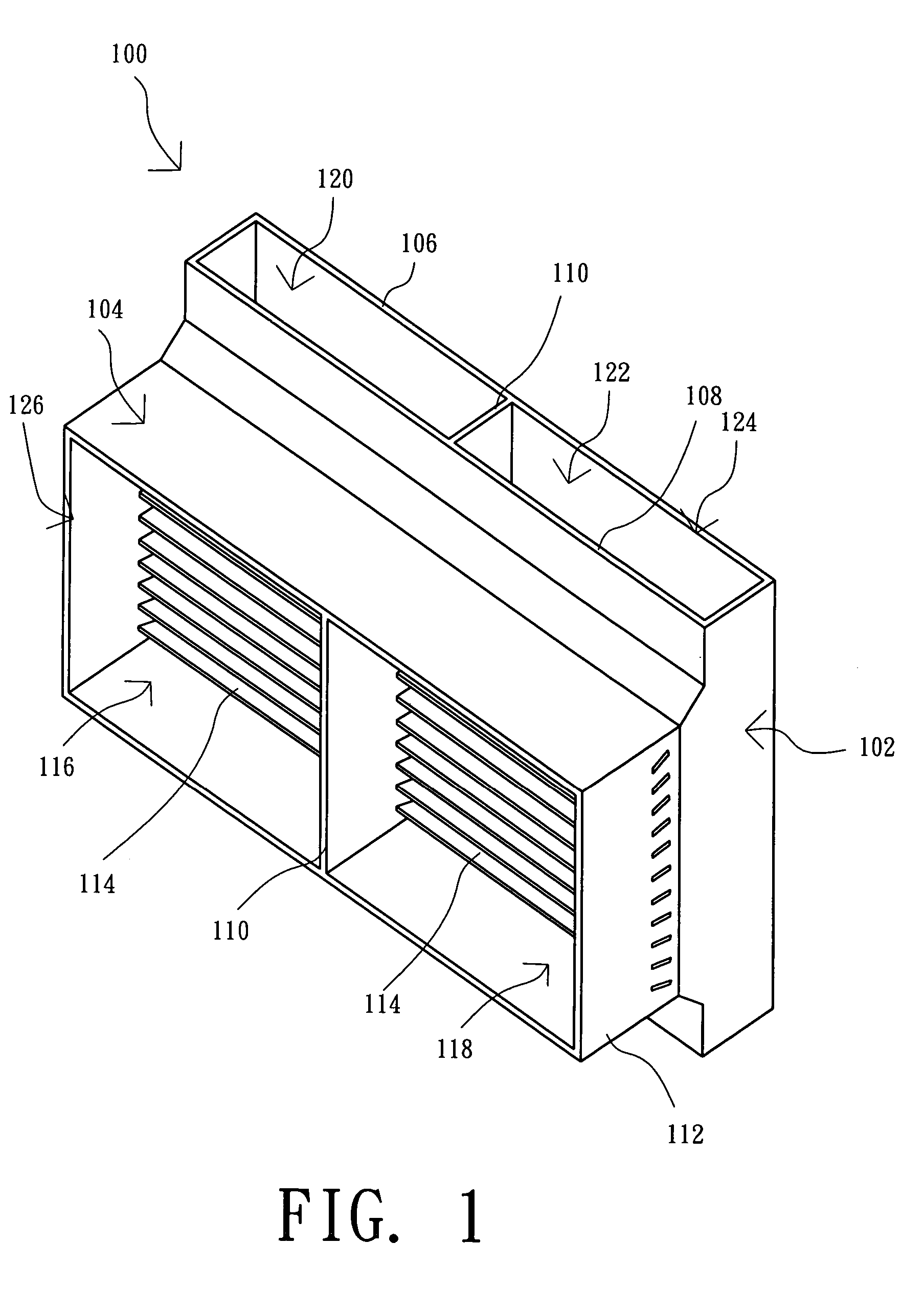

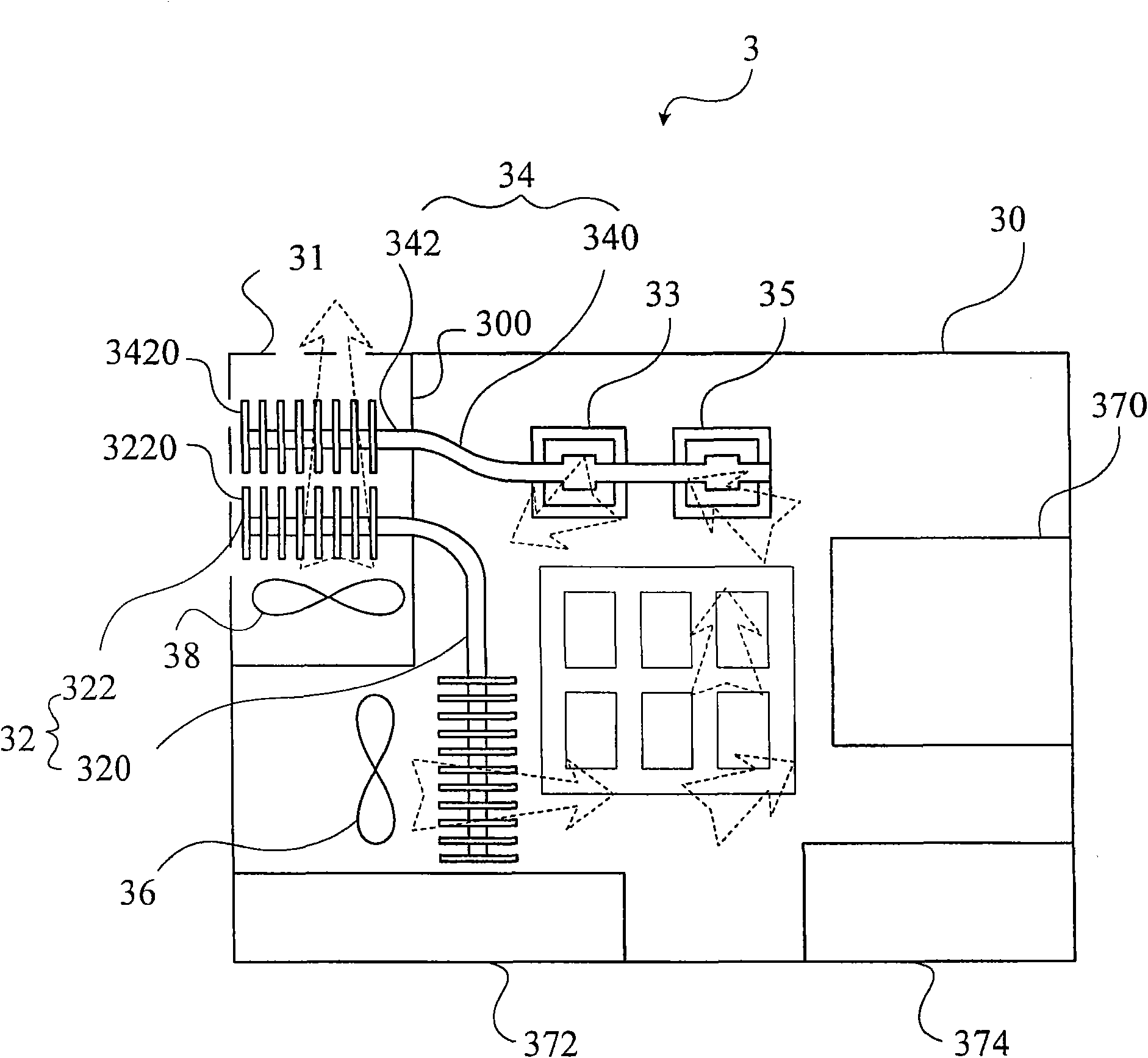

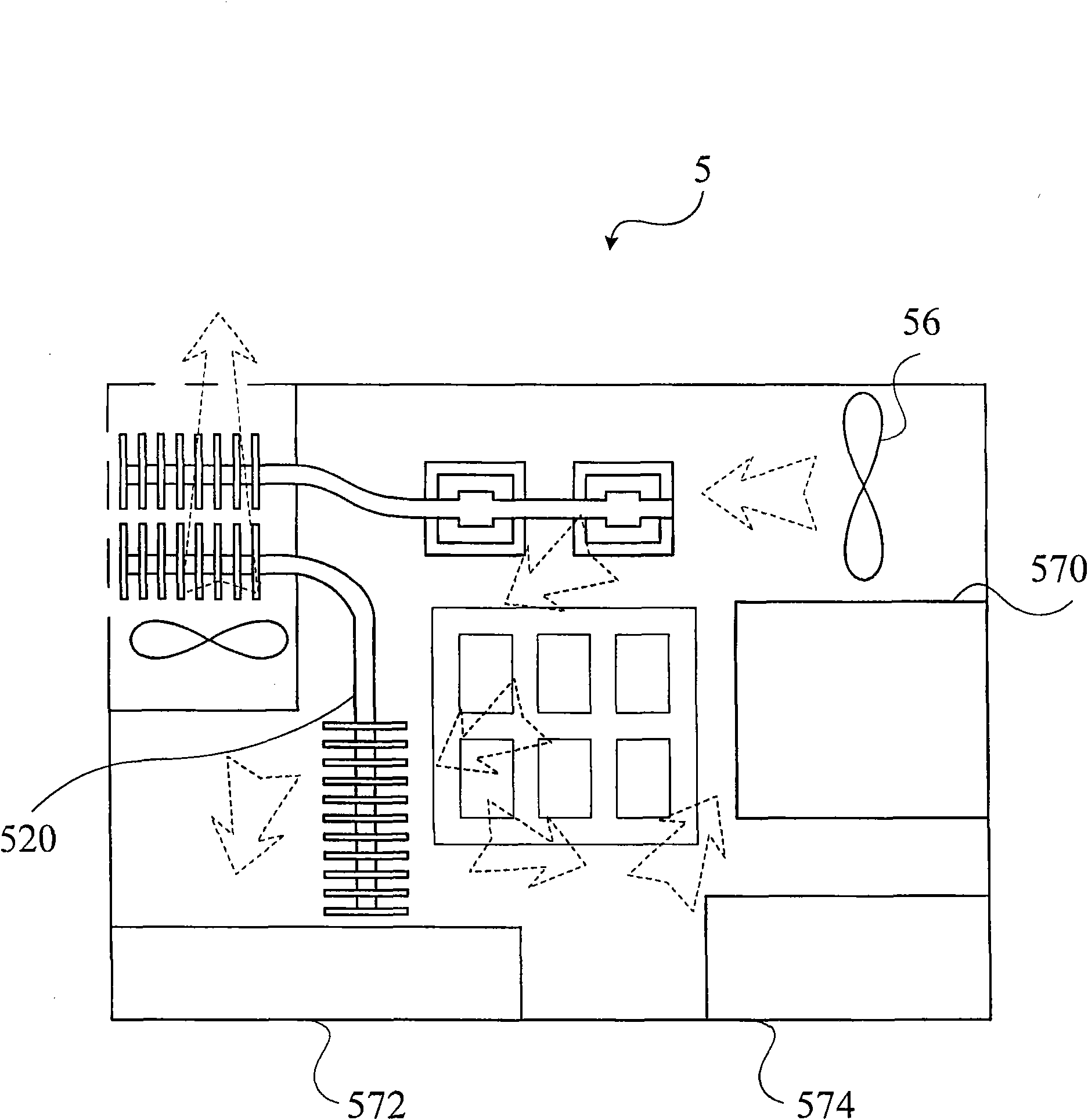

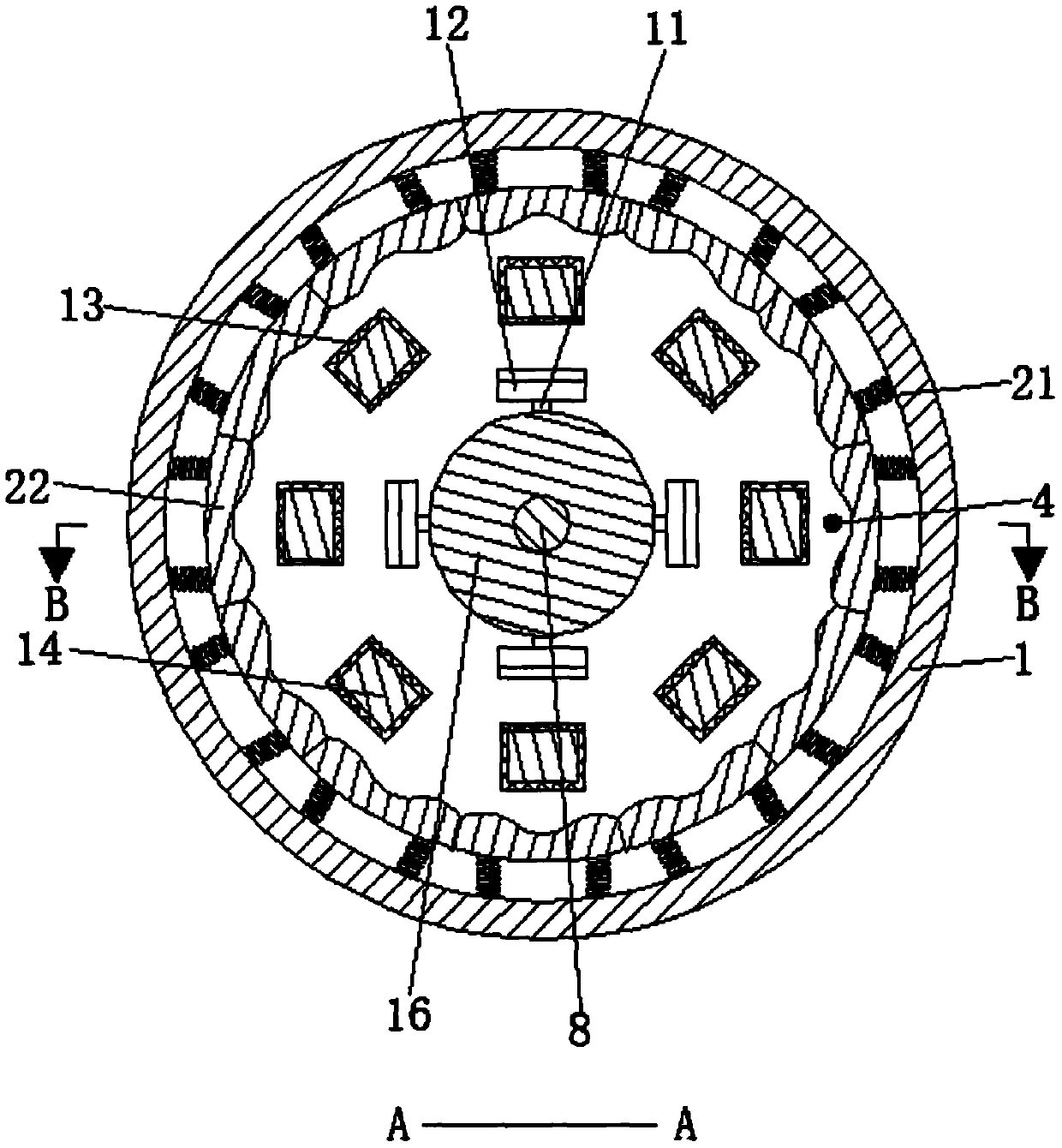

Commutate silencer of computer system

ActiveUS7161801B2Reduce noise energyReduce turbulenceMagnetic/electric field screeningDigital data processing detailsComputerized systemEngineering

A commutate silencer of a computer system is described. The commutate silencer of the computer system is installed at the back end of the computer system, and comprises a shield device, a commutate device and at least one partition. The shield device comprises a first shield and a second shield, in which the first shield comprises an opening, the first shield and the second shield construct a first cavity, and the first cavity includes a plurality of outlets. The commutate device comprises a frame and a plurality of commutate diversion plates, in which the frame construct a second cavity, the diversion plates traverse the second cavity, the second cavity has an inlet and a ventilated opening, and the ventilated opening is connected to the opening of the first shield. The at least one partition is located in the first cavity and the second cavity, so as to separate the inlet, the ventilated opening and the outlets into a plurality of sub-inlets, a plurality of sub-ventilated openings and a plurality of sub-outlets, respectively.

Owner:QUANTA COMPUTER INC

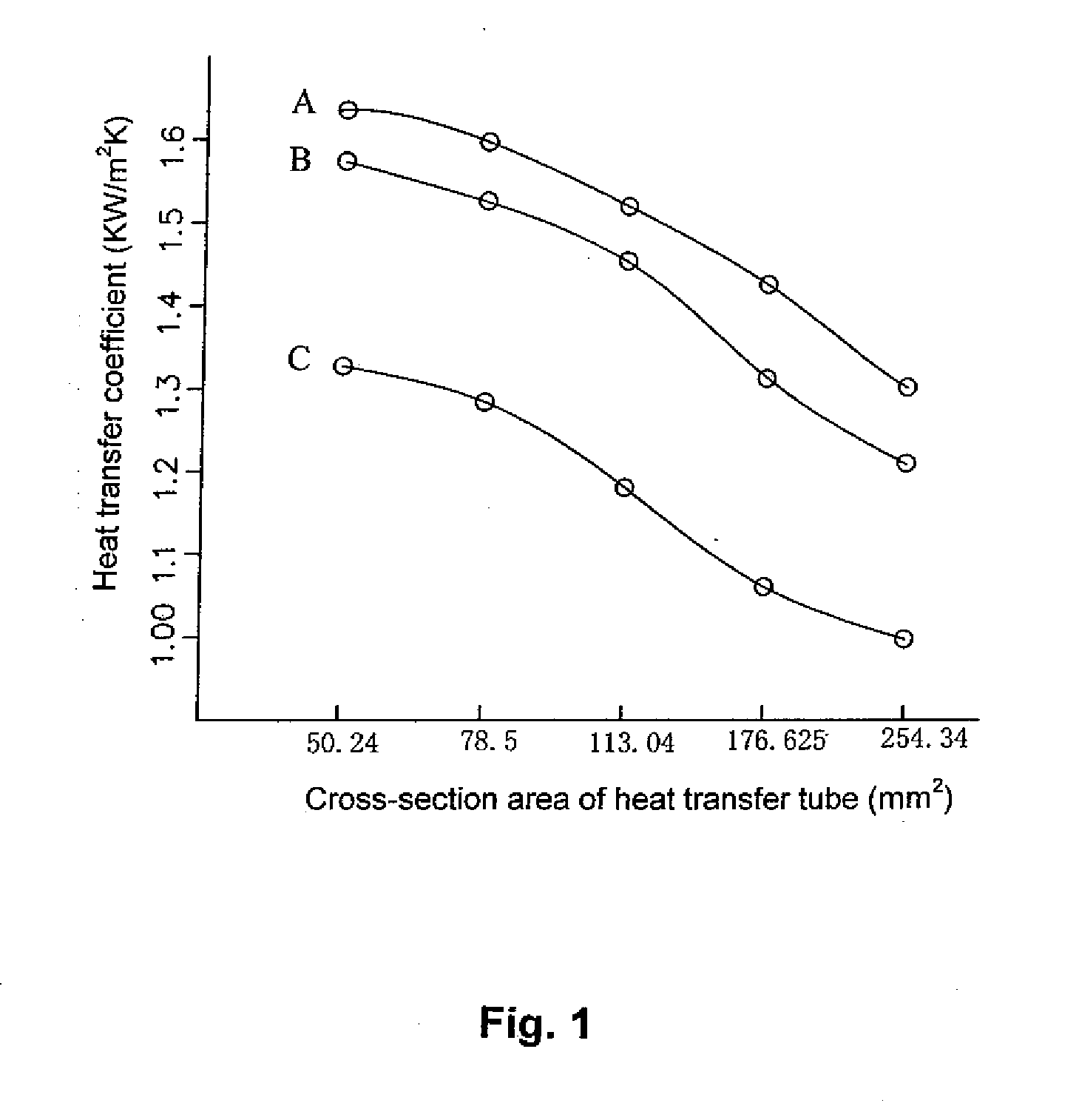

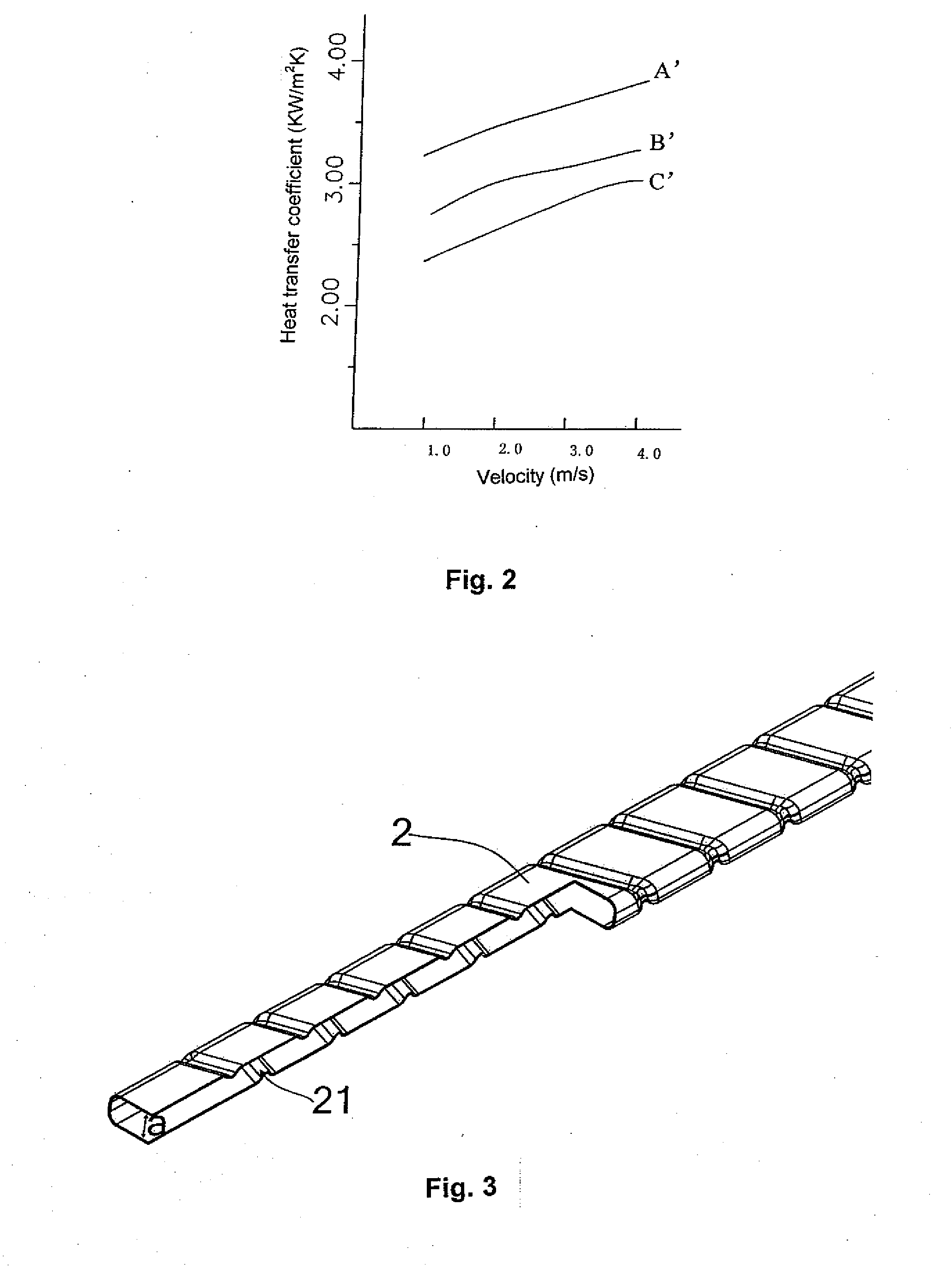

Heat exchanging tube with spiral groove

InactiveUS20070209788A1Improve thermal efficiencyHigh thermal efficiencyNon-fuel substance addition to fuelInternal combustion piston enginesSteel tubeHeat transfer tube

The present invention relates to a heat transfer tube with spiral groove, comprising a stainless steel tube body with inward convex spiral groove on surface, wherein the stainless steel tube body possesses unequal height and width in the cross sectional view. In the EGR (Exhaust Gas Recirculation) cooling system for automotive engine, such kind of spiral groove tube with the unequal height and width in the cross-section acting as the heat transfer tube for the cooler make the cooler gain higher heat transfer effect, and it is hard to make dirt deposited inside or outside the tube, which greatly improves the emissions performance for automotive engine, and satisfies higher requirement of environmental protection.

Owner:BEIJING U BRIDGE CHAOYANG

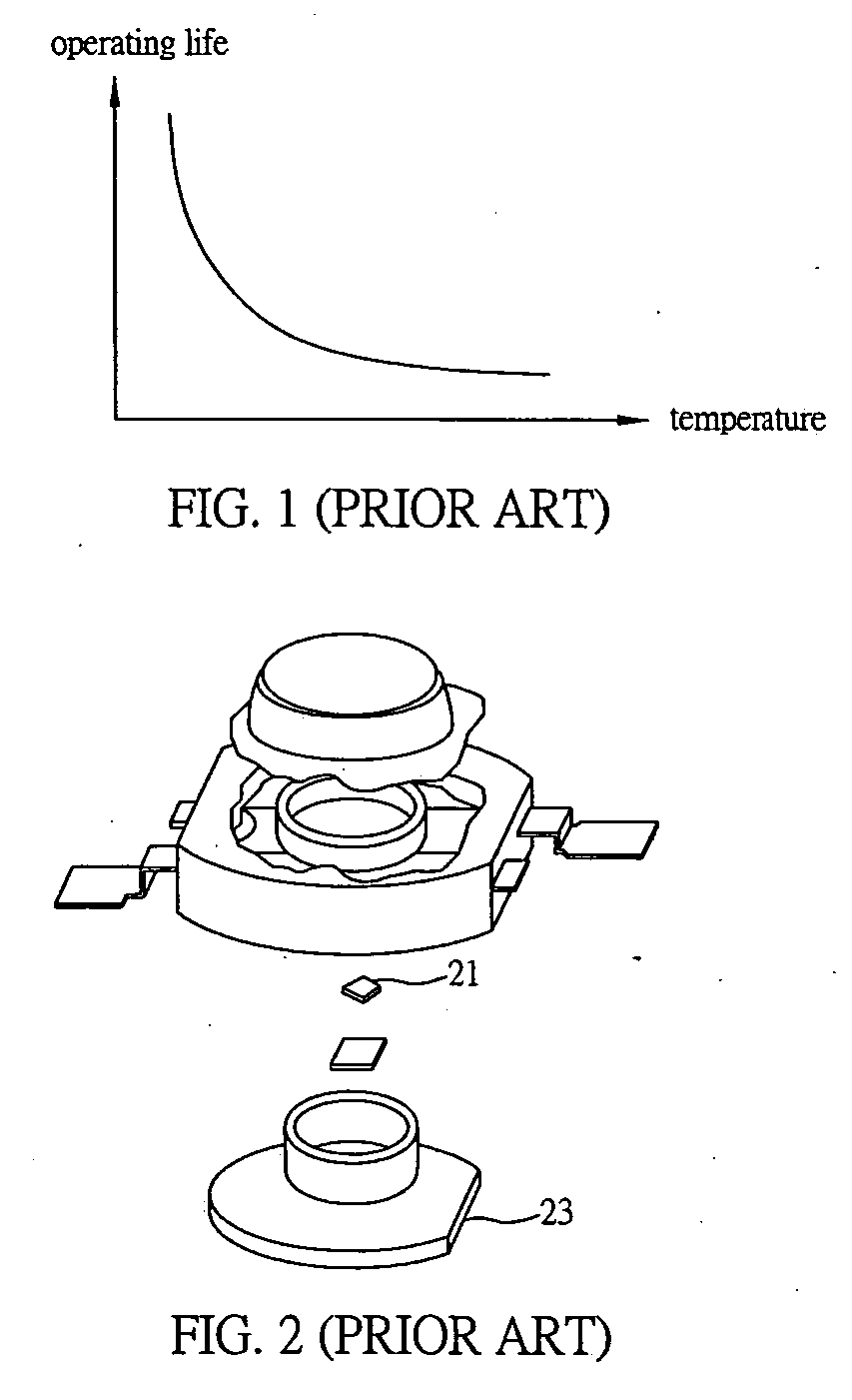

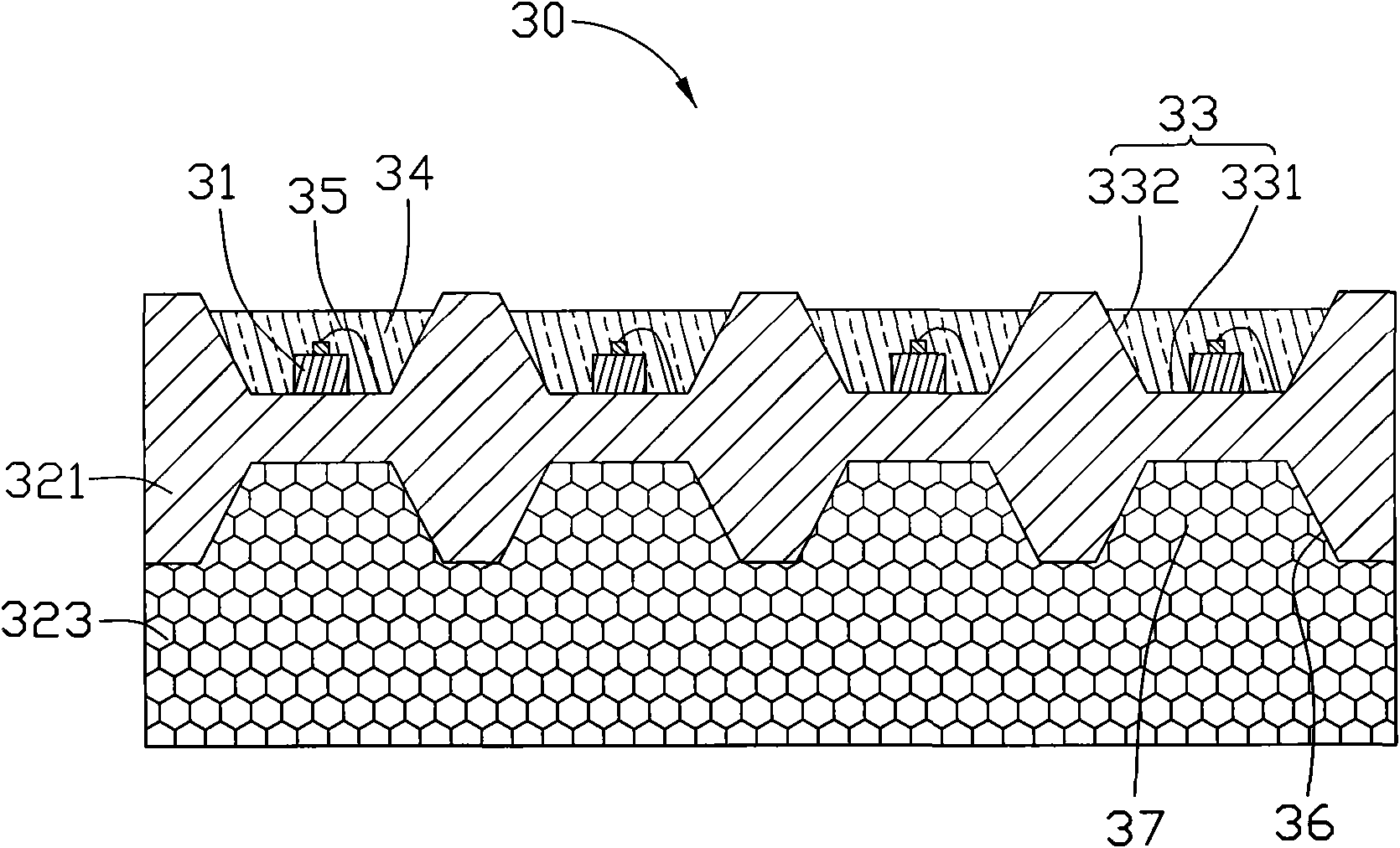

High power LEDs

InactiveUS20060243997A1Increase powerImprove thermal conductivitySolid-state devicesSemiconductor devicesThermal transmittanceMaterials science

A high power LED has at least a porous material layer, a thermal conductive layer and a chip. The thermal conductive layer is disposed on the surface of the porous material layer and the chip is disposed on the thermal conductive layer. Heat generated by the chip is conducted from the thermal conductive layer to the porous material layer, and convected outside via the porous material layer. Thereby, surface area in contact with the air is increased and high thermal conductivity and high heat convection are also achieved.

Owner:IND TECH RES INST

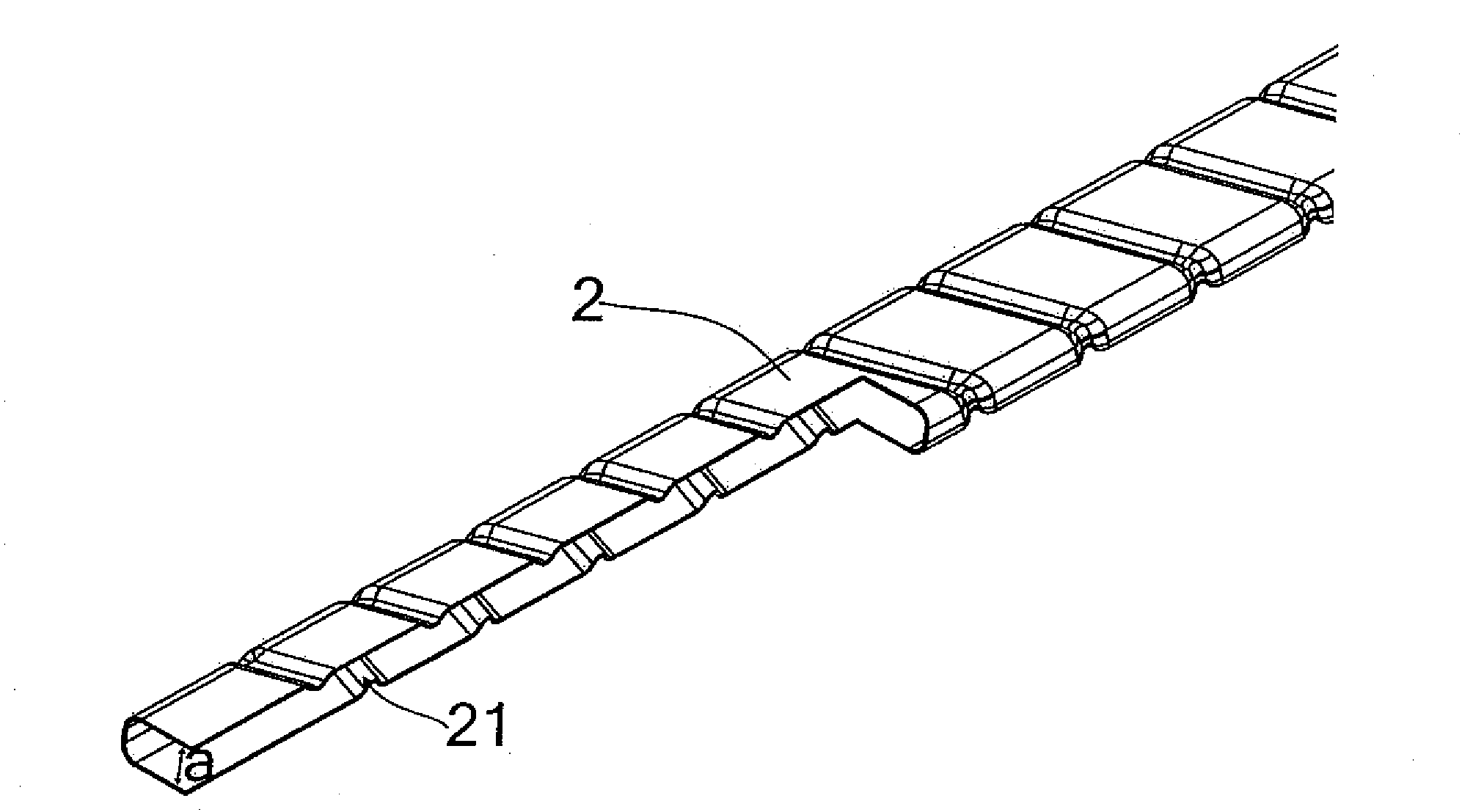

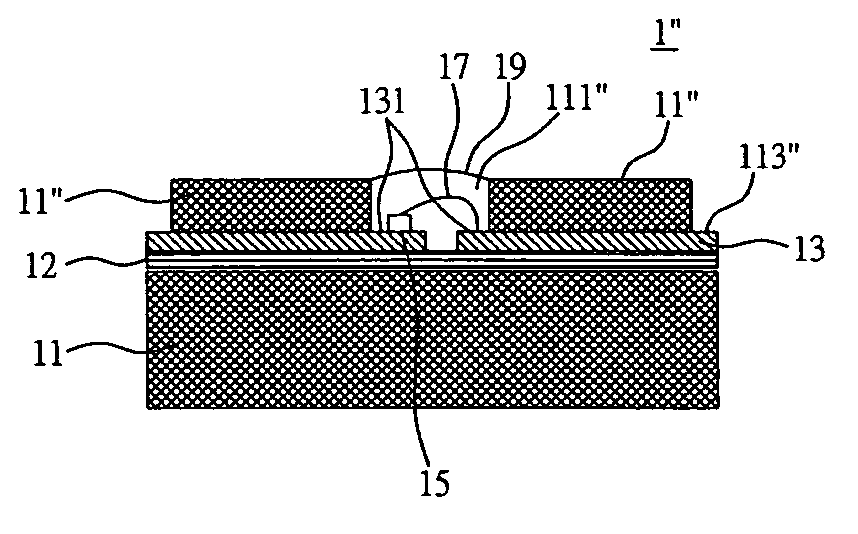

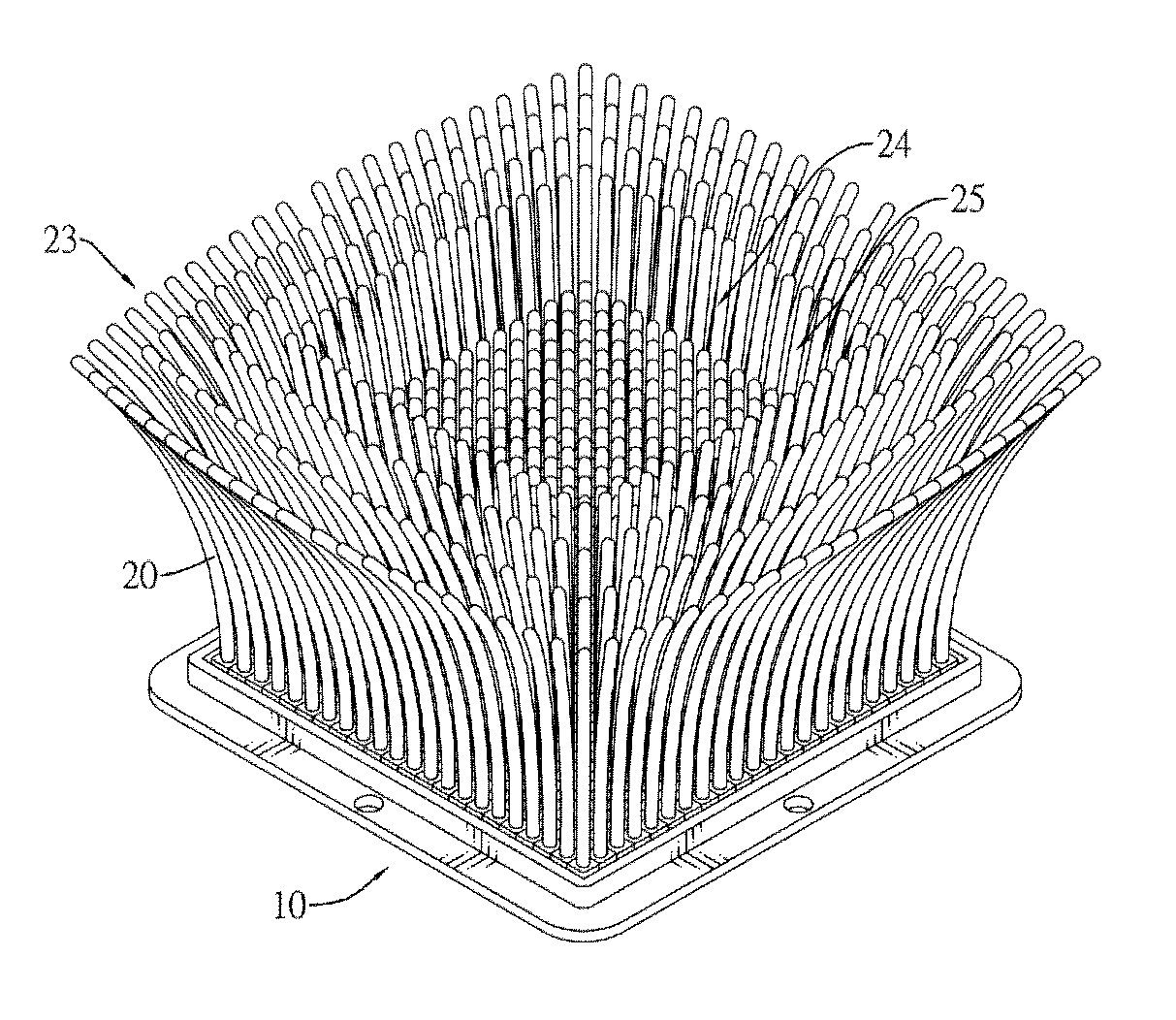

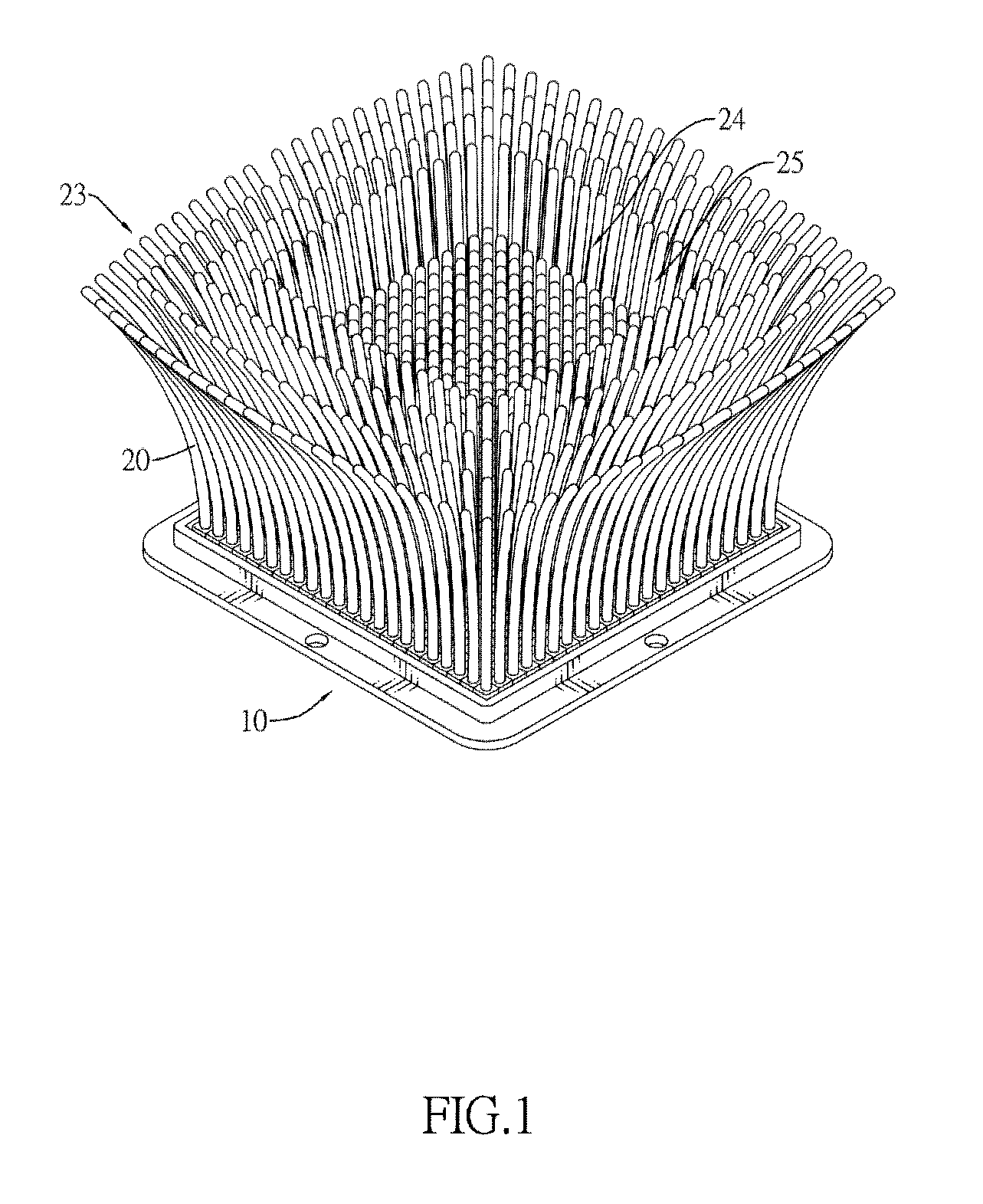

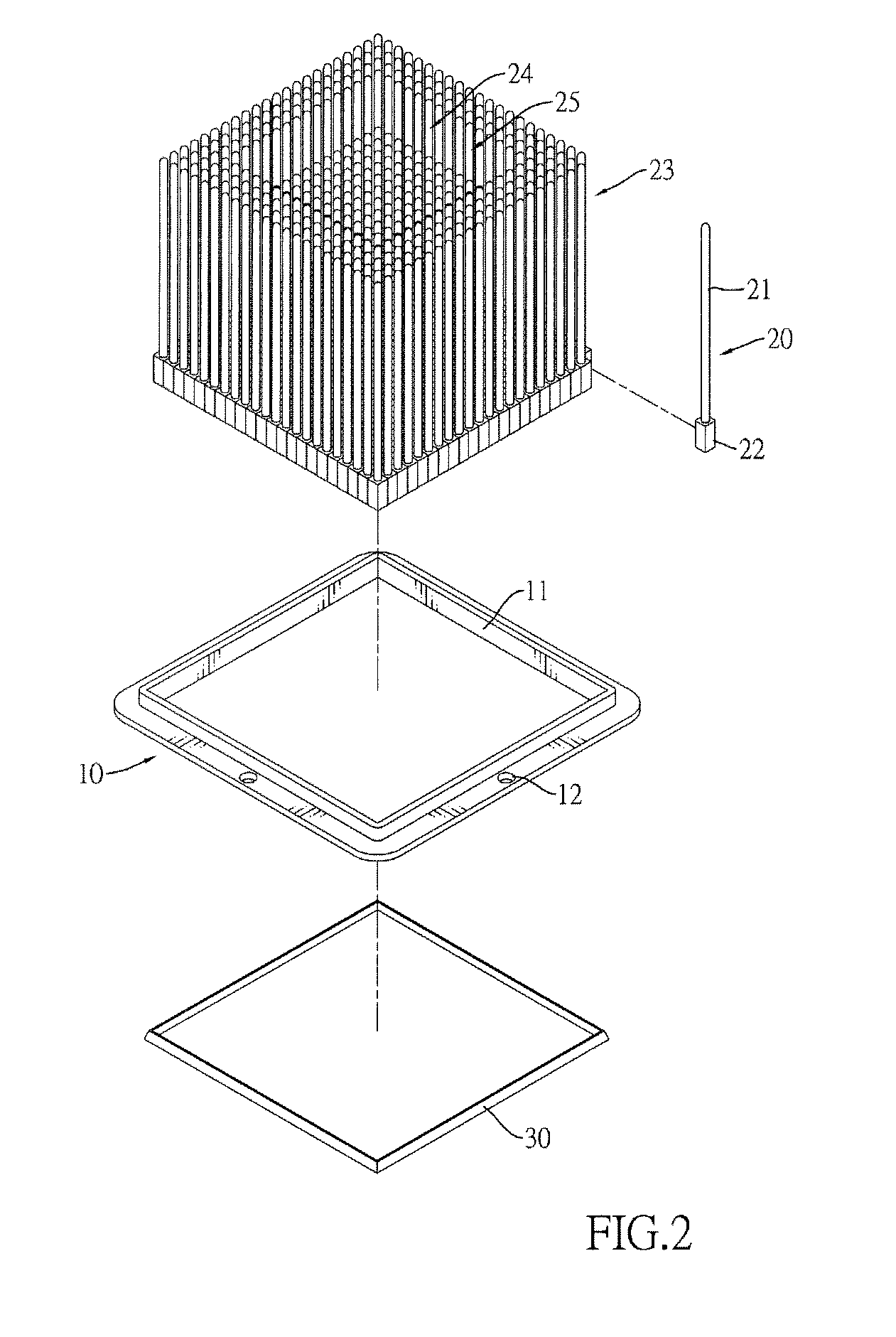

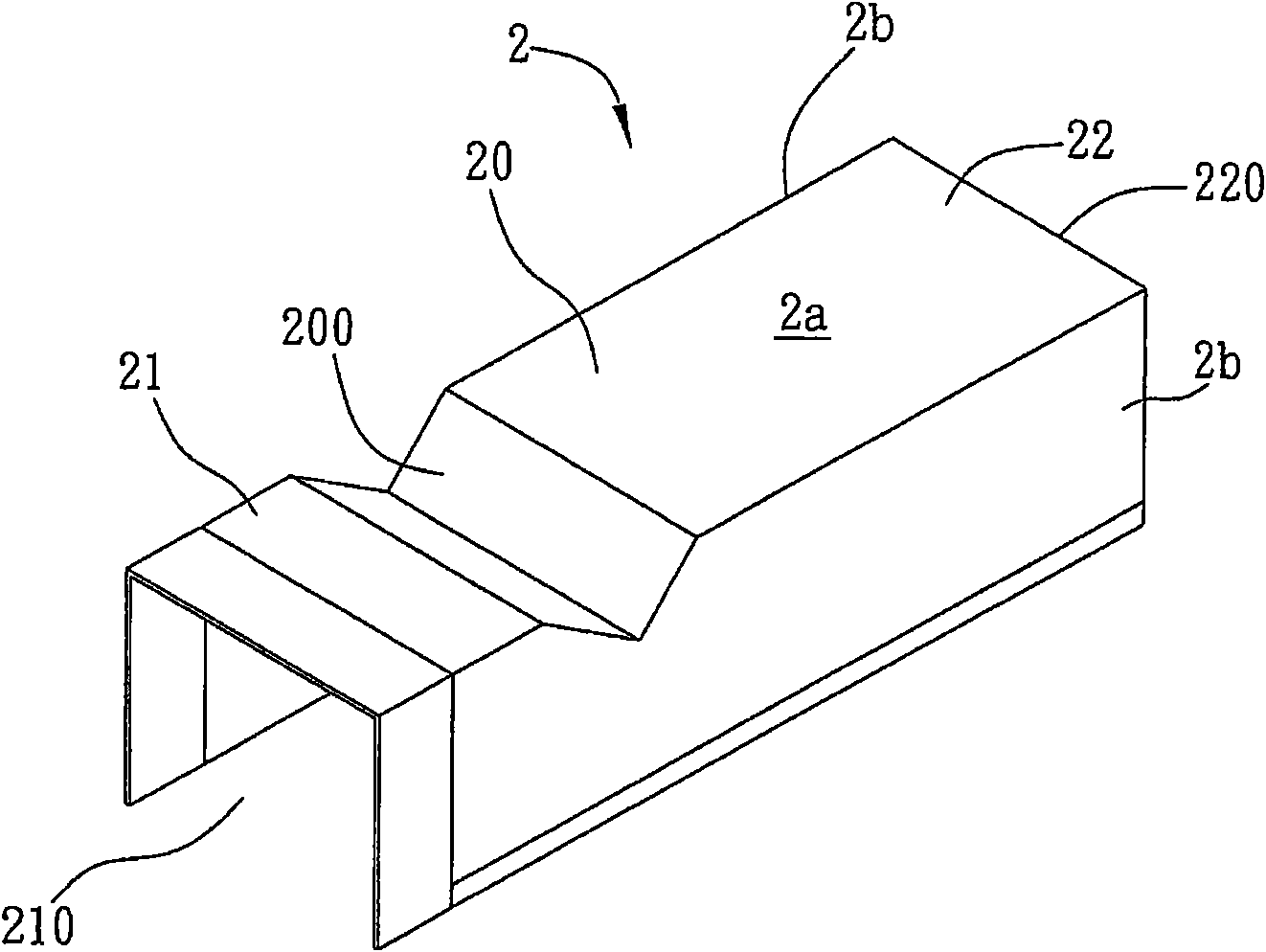

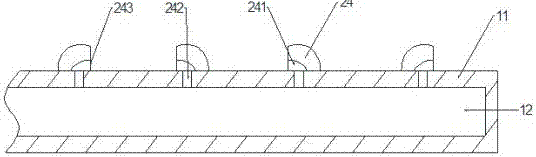

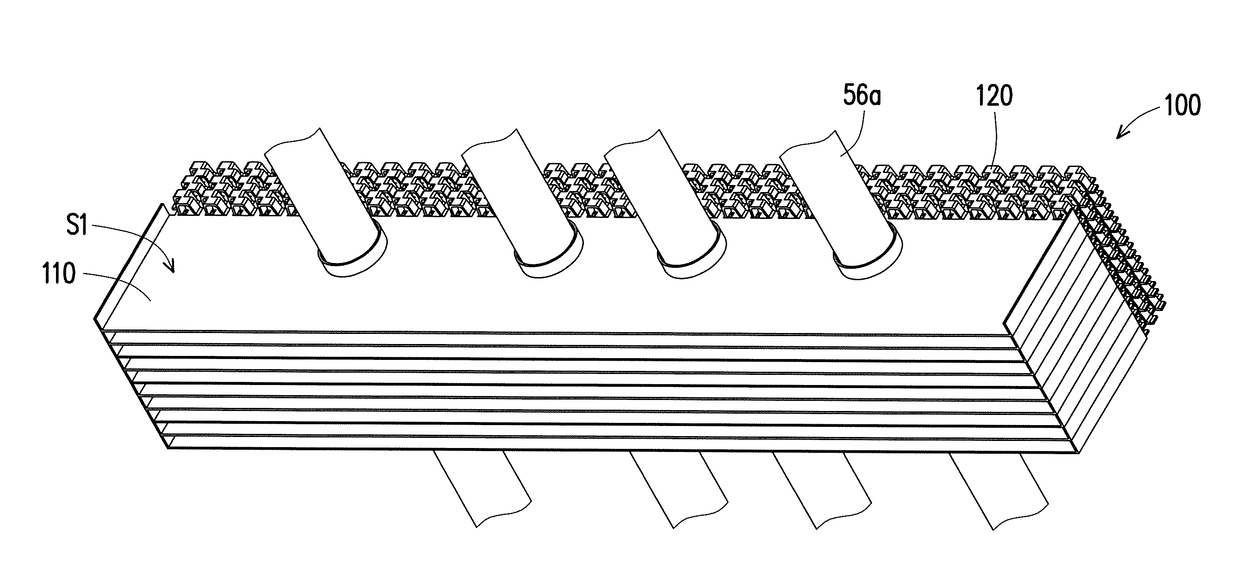

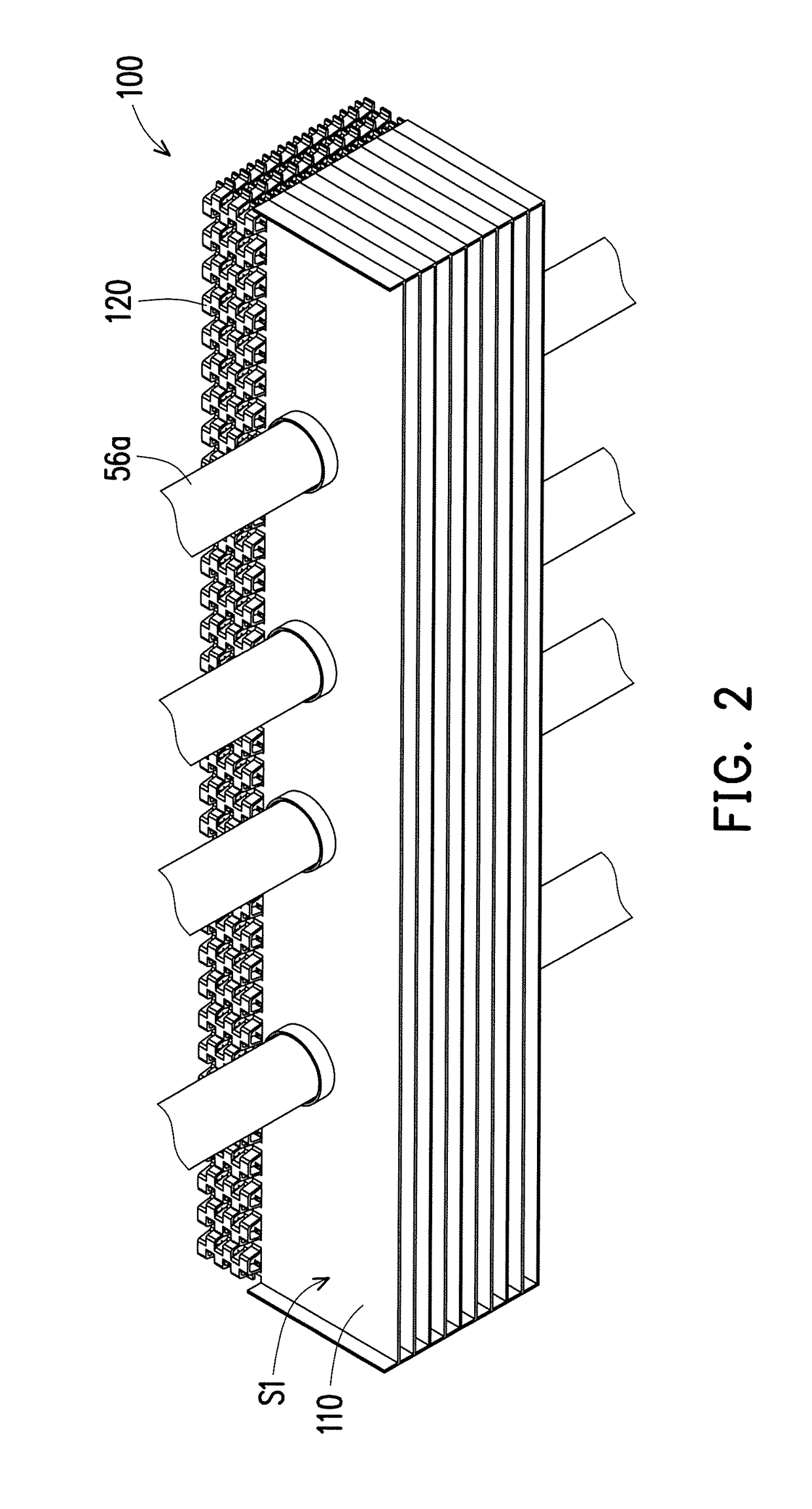

Strip heatsink

InactiveUS20130306291A1Improve efficiencyImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringConvection

A strip heatsink has a base, multiple dissipating strips and a fastening loop. The strip heatsink uses a row of the dissipating strips to replace one conventional fin, and a shape of the strip part of each dissipating strip is circular. Therefore a whole surface area of the row of the dissipating strips is much bigger. Besides, because a cross section area of the mounting part is bigger than a cross section area of the strip part in a dissipating strip, the strip parts of the dissipating strips are mounted separately, and the blocking of the airflow is reduced. Therefore, air can flow more smoothly in an interval between the strip parts. To sum up, the strip heatsink enhances the heat conduction by increasing the whole surface area, and enhances the heat convection by making more space between the dissipating strips.

Owner:TUNG CHIA MING

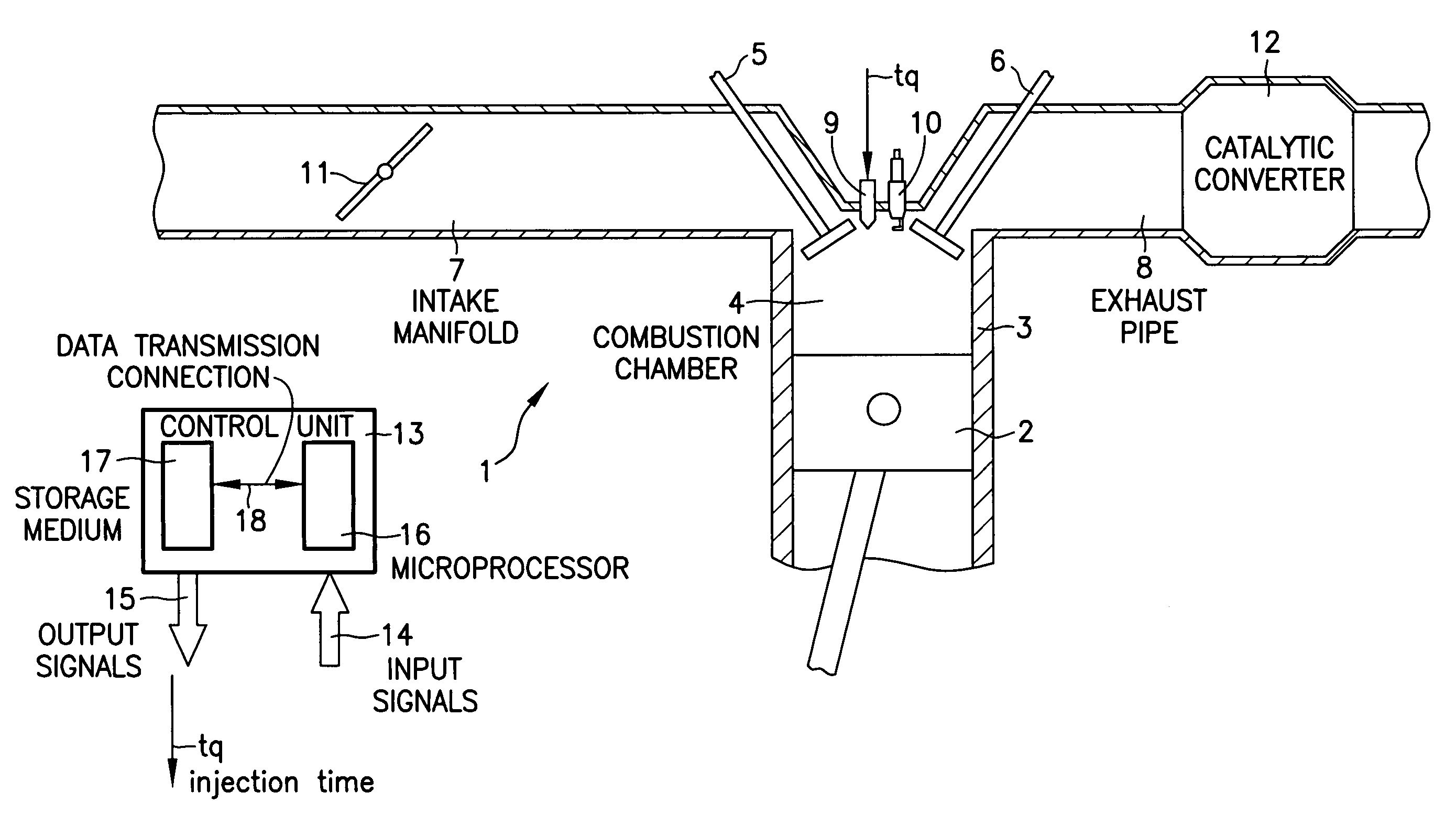

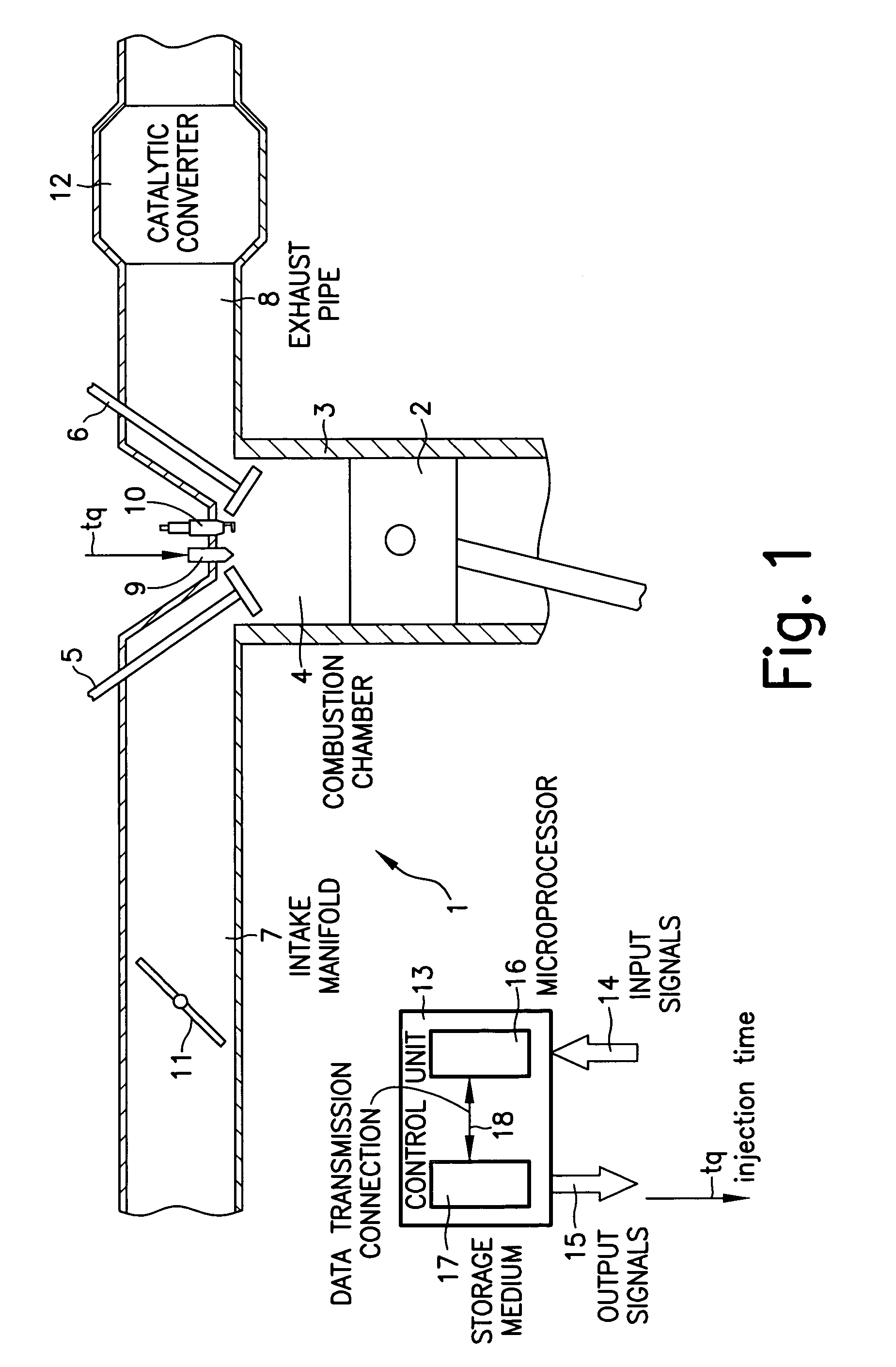

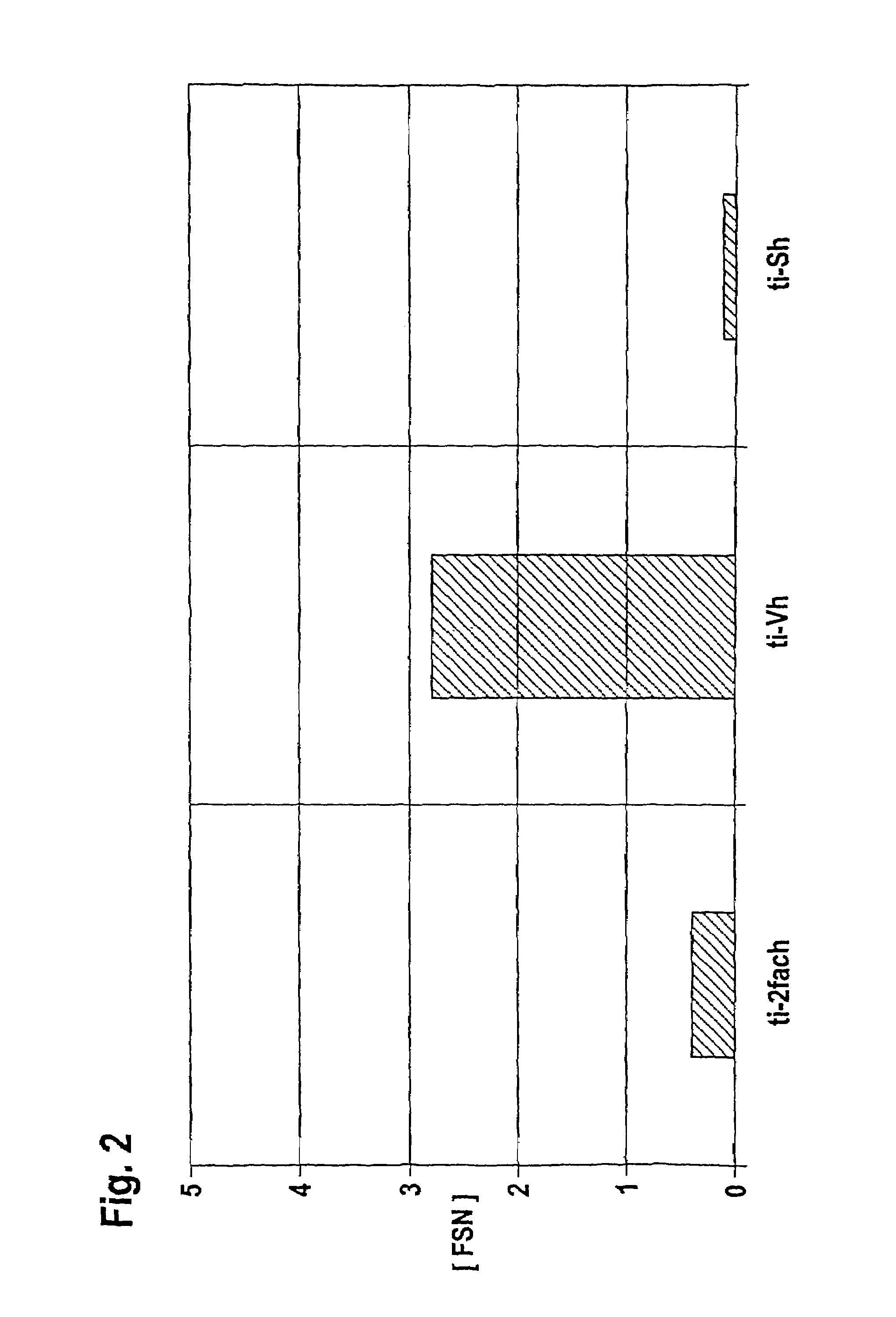

Method for avoiding an internal coking of an injection hole for injection holes in a multi-hole injection valve

InactiveUS7080624B2Improve efficiencyReduce depositionElectrical controlInternal combustion piston enginesMultiple injectionCombustion chamber

A method for avoiding an injector orifice internal coking of the spray orifices of a multi-orifice fuel injector of a direct injection internal combustion engine, e.g., of a motor vehicle, is provided. Fuel is injected into a combustion chamber of the internal combustion engine by multiple injections. The fuel is injected by a first main injection during the intake stroke and by a subsequent postinjection during the compression stroke before the ignition time. Thereby, during a long operation of the internal combustion engine, especially in a homogeneous operation, the injection time does not have to be continually increased in order to compensate for the increasingly shrinking cross section of the spray orifices.

Owner:ROBERT BOSCH GMBH

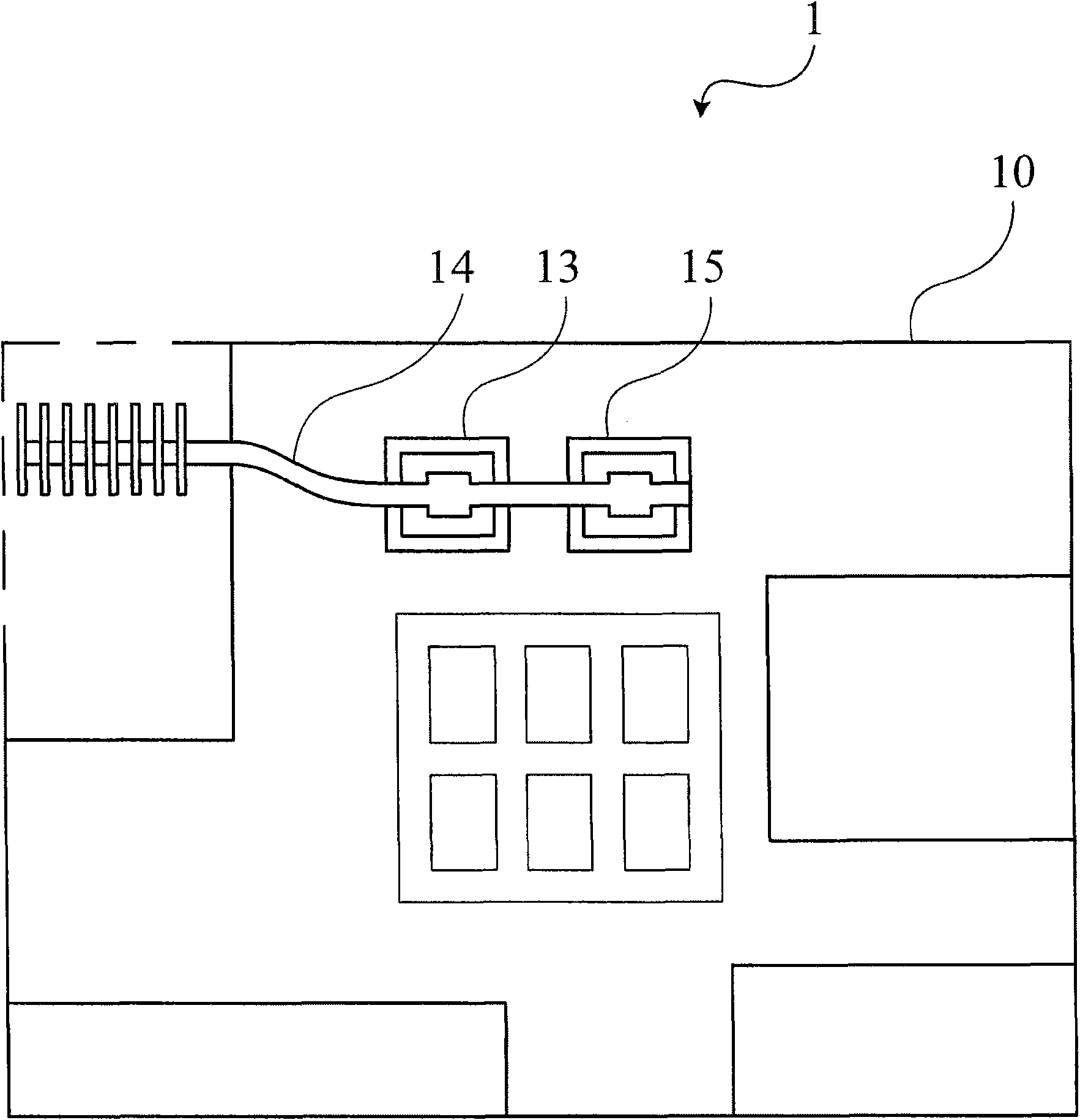

Heat sink and electromagnetic interference reduction device

InactiveUS7115817B2Save spaceSpeed up heat convectionLocalised screeningSemiconductor/solid-state device detailsThermal energyElectromagnetic interference

An electrical assembly comprising a circuit board an electrical device, and a heat dissipation device. The electrical device is capable of emitting thermal energy and electromagnetic interference (EMI). The electrical device is secured to the circuit board. The heat dissipation device is secured to the circuit board and is in thermal communication with the electrical device. The heat dissipation device also includes a continuous EMI fence and a plurality of fins disposed in a matrix orientation. The fins are spaced from one another to allow for efficient heat dissipation and have a substantially square cross-sectional shape.

Owner:ORACLE INT CORP

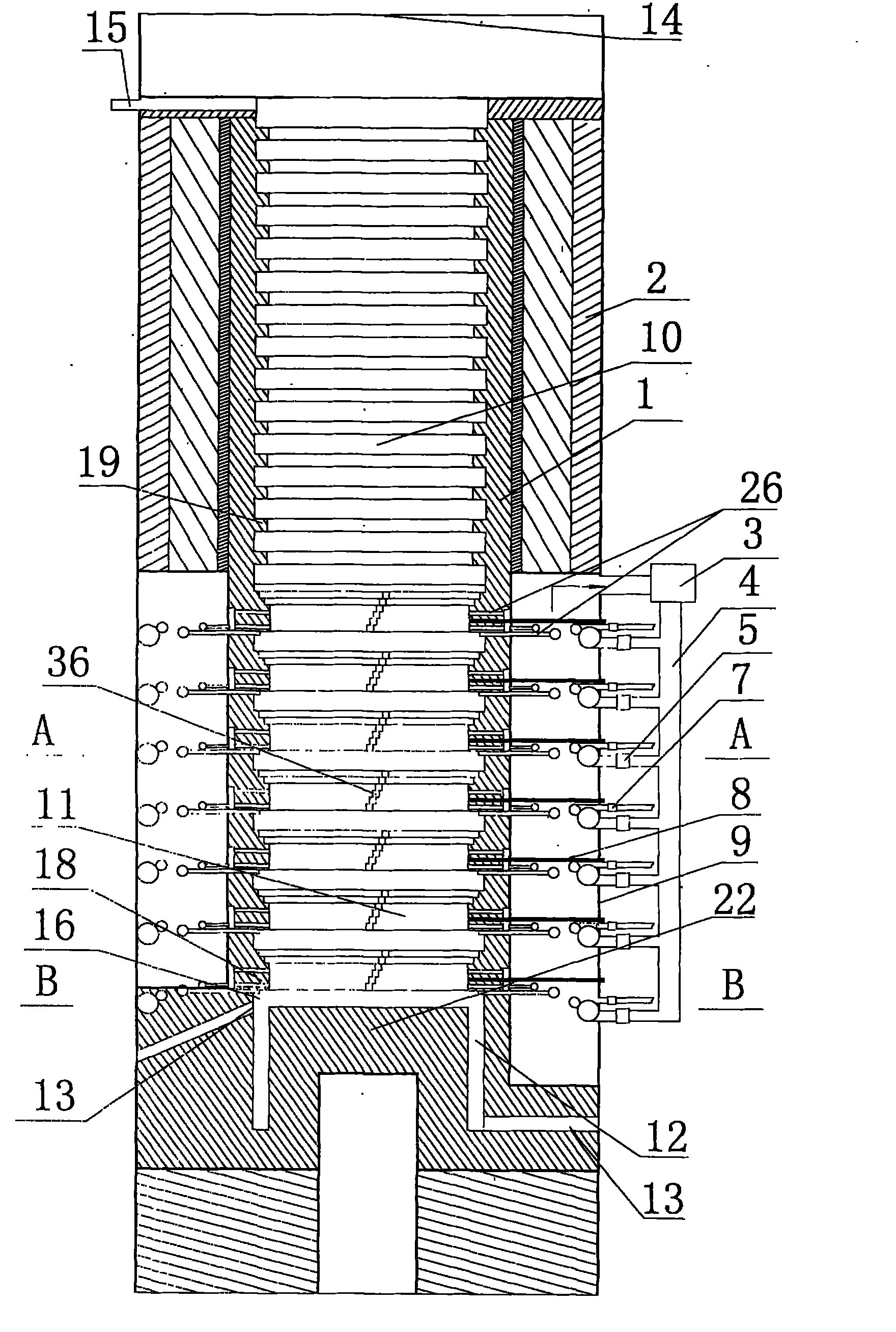

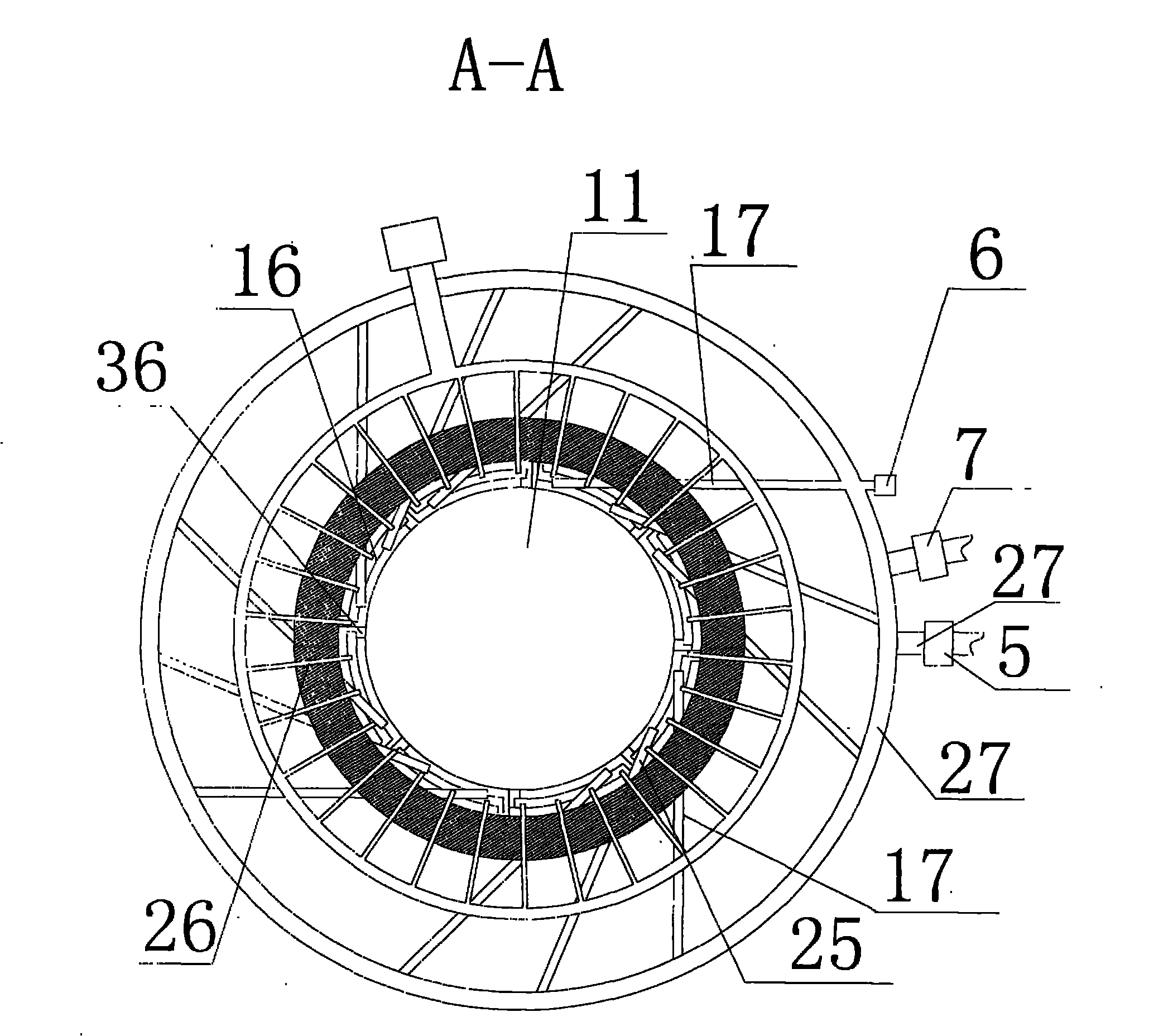

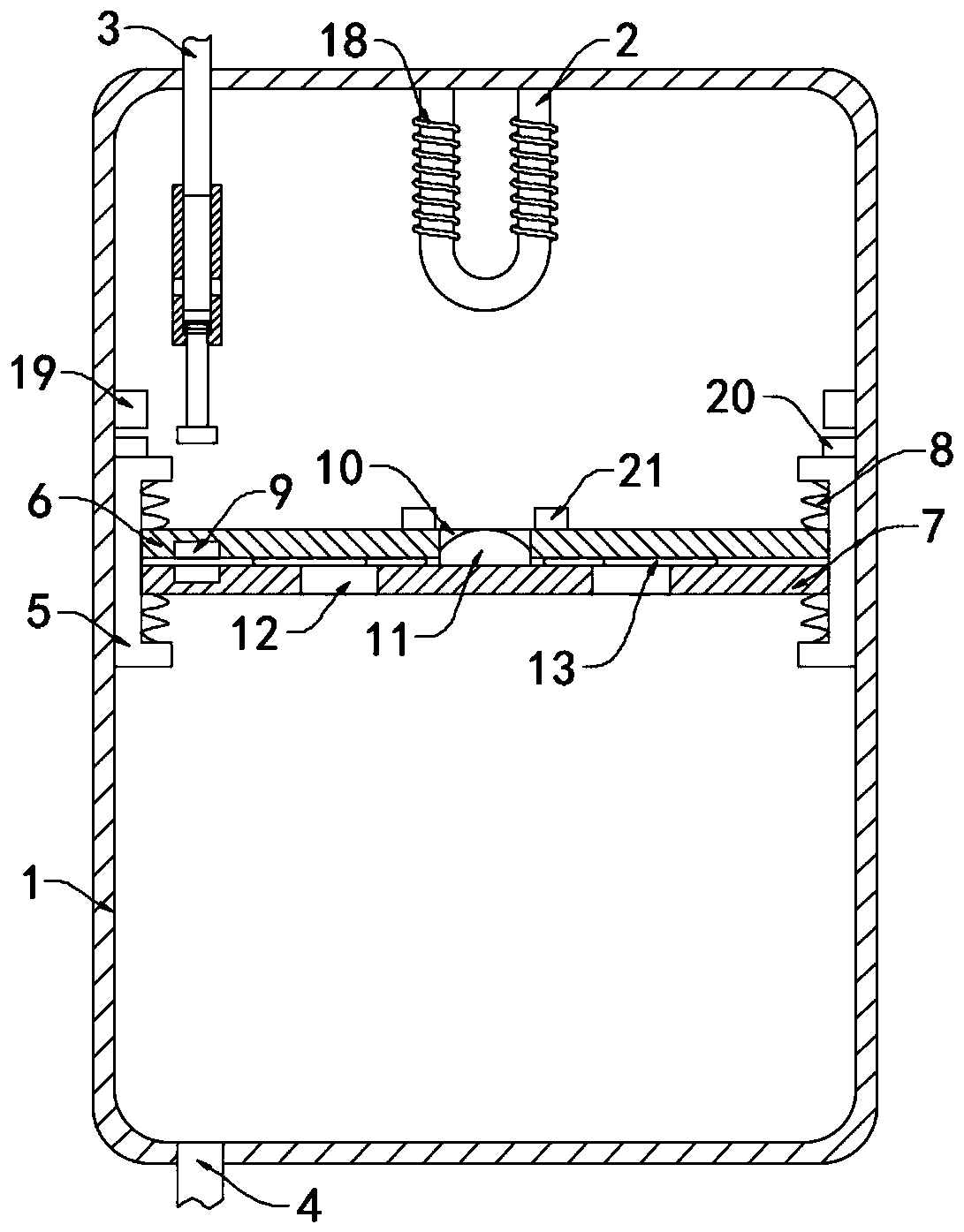

Smelting furnace

InactiveCN102121788AReduce pollutionReduce wasteVertical furnacesCeramic materials productionSteelmakingInlet channel

The invention provides a smelting furnace. The smelting furnace comprises refractory materials, heat insulating materials, a blower, a pipeline, valves, ignition devices, fuel supply devices and temperature measuring devices. The smelting furnace is characterized in that a furnace chamber is provided with a heating chamber and a smelting chamber; the lower part of the heating chamber is communicated with the smelting chamber; the lower part of the smelting chamber is provided with a hearth; the hearth is provided with hearth discharge holes; the upper part of the heating chamber is provided with a heating chamber feeding hole and a heating chamber gas outlet; at least a flame path is arranged around the inner wall of the smelting chamber; at least an inlet channel is arranged on the side walls of the flame paths; and the inlet channels are communicated with the flame paths. The smelting furnace is energy-saving and environment-friendly, can be used for smelting various metals and alloys, can be used for smelting aluminium by a fire method and can be used for refining aluminium alloys. The smelting furnace can adopt any mineral for smelting, can realize carbothermal reduction of any metallic oxide and can smelt alloys even with soil or garbage, so the smelting furnace can turn stone and soil into gold and is true alchemy. The smelting furnace dispenses with cokes and synchronously completes ironmaking and steelmaking. The heat generated through steelmaking is fully utilized and the waste gases are unitedly treated. The smelting furnace can be used for producing glass, ceramic frits, sodium silicate and the like. The smelting furnace can adopt various materials, can refine precious elements, does not produce slag and can bring metallurgy revolution.

Owner:陈久斌

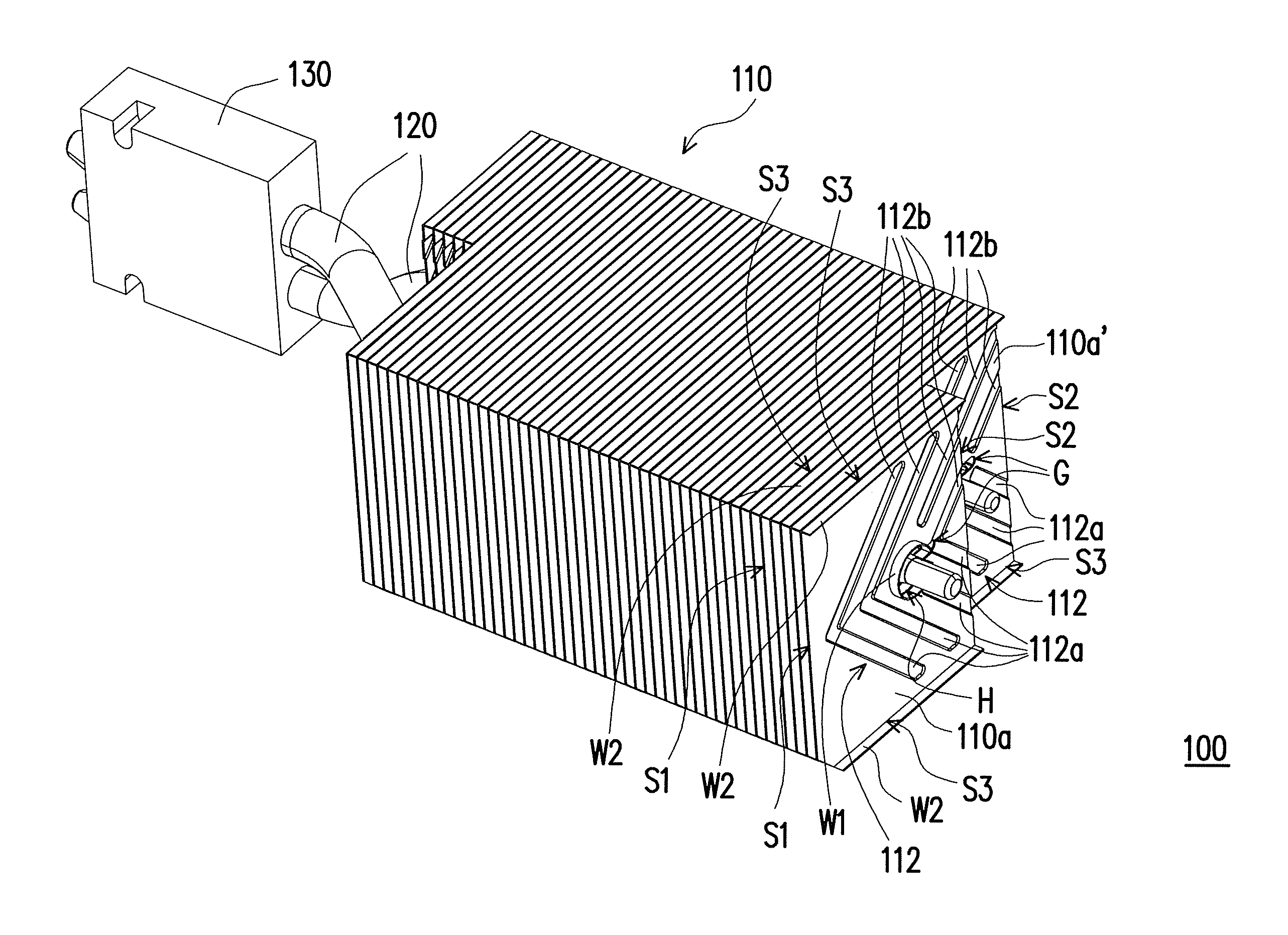

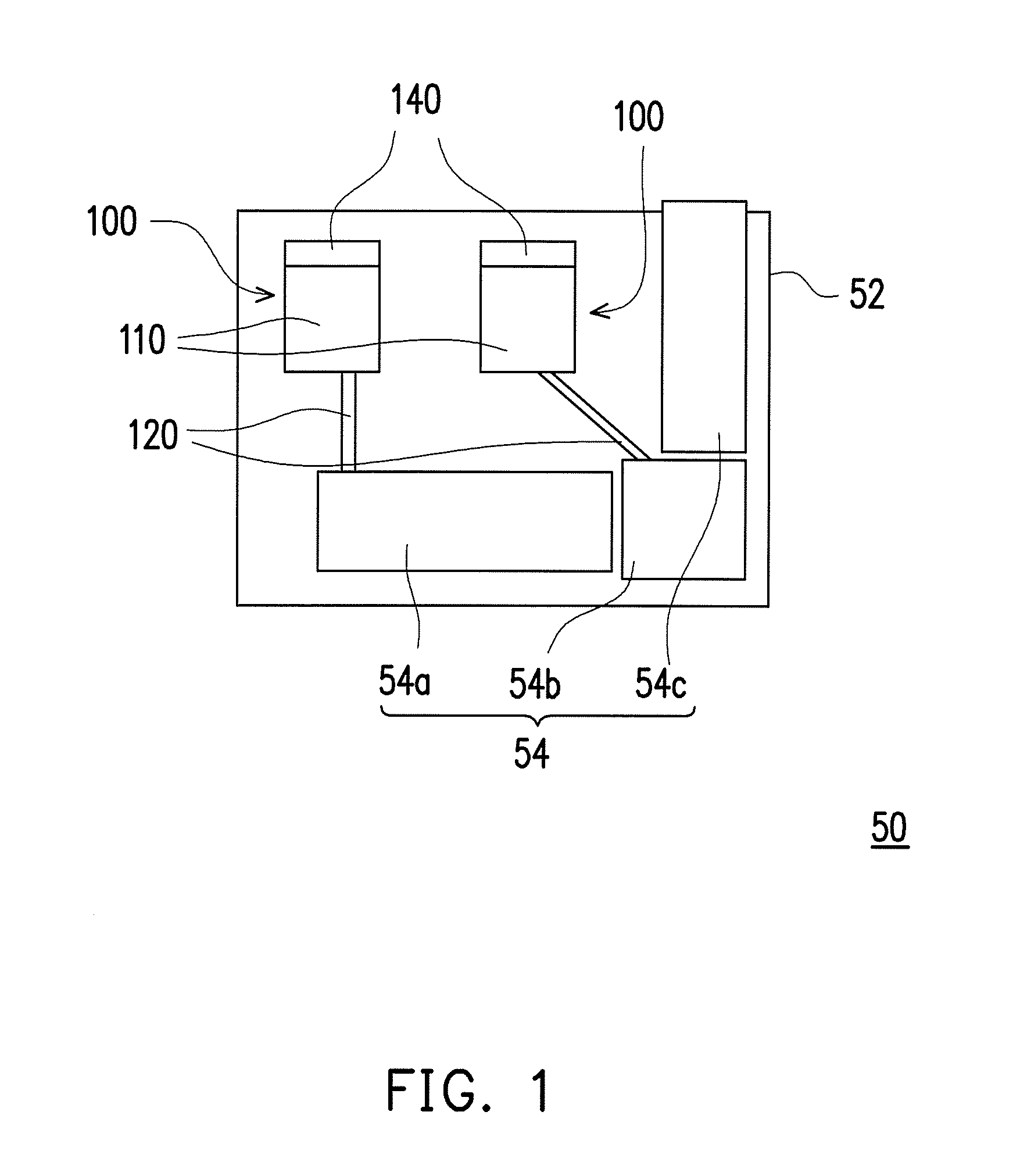

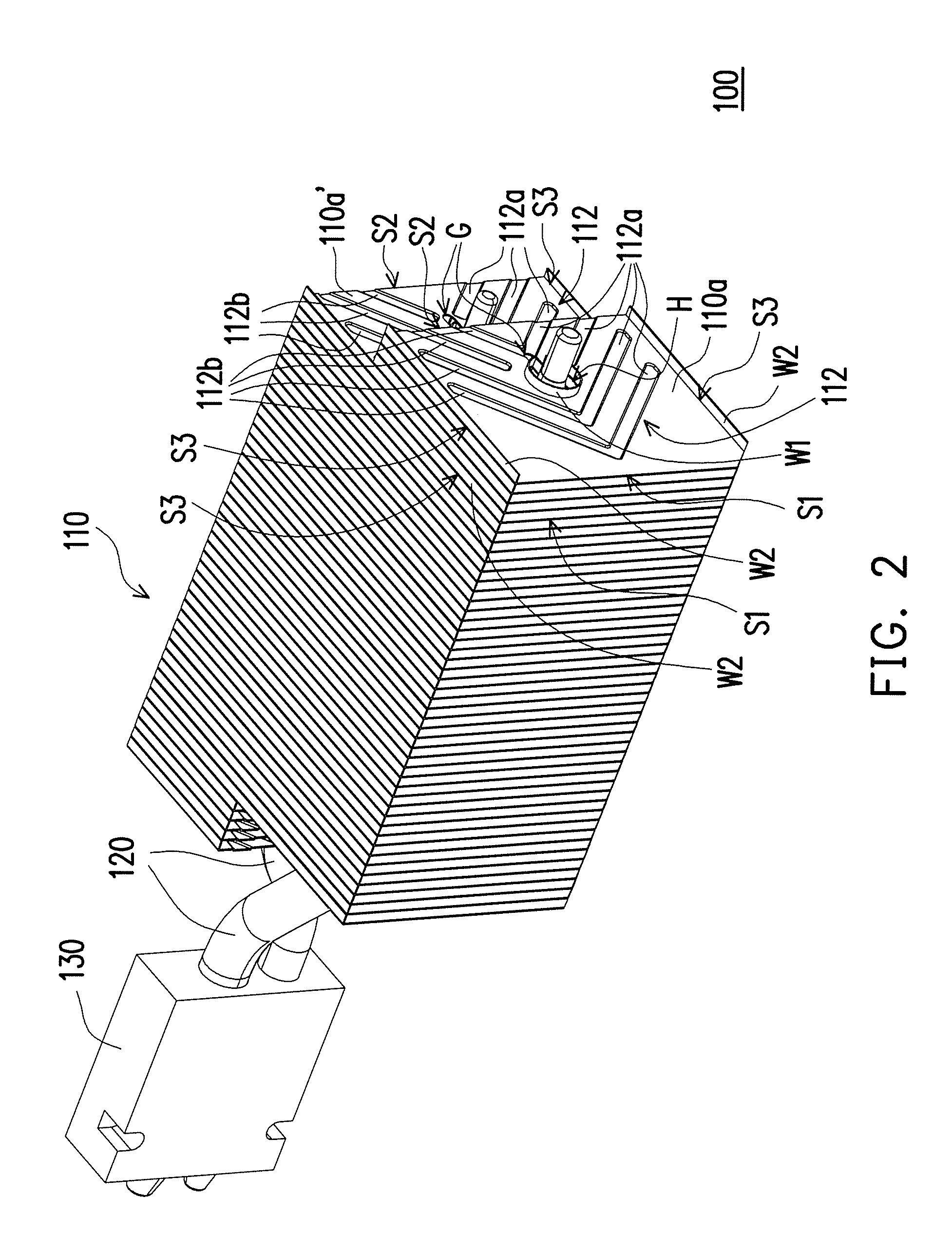

Heat dissipating module having turbulent structures

ActiveUS20160178283A1Improve cooling efficiencyIncrease heatProjectorsHeat transfer modificationEngineeringAirflow

A heat dissipation module includes a heat dissipation fin set. The heat dissipation fin set includes a plurality of heat dissipation fins, wherein these heat dissipation fins are stacked on each other, and each of the heat dissipation fins has a front side, a rear side opposite to the front side and at least one turbulent structure set. The turbulent structure set is located between the front side and the rear side and includes a plurality of first turbulent structures. The first turbulent structures are arranged from the front side to the rear side in sequence. A heat dissipation airflow flows from the front side toward the turbulent structure set along a flowing direction, and passes through the turbulent structure set to flow toward the rear side. An extending direction of each of the first turbulent structures is tilted relative to the flowing direction.

Owner:CORETRONIC

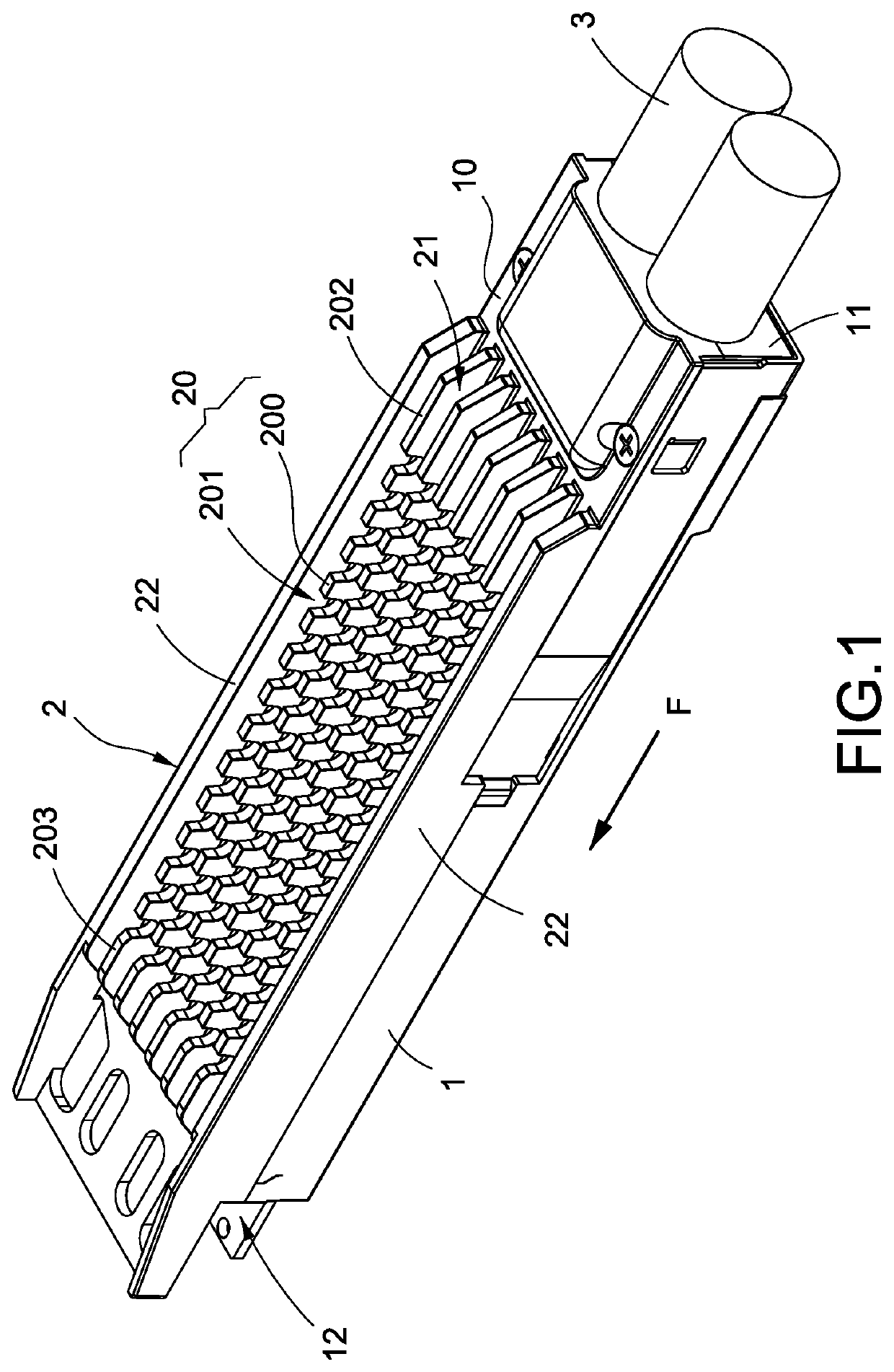

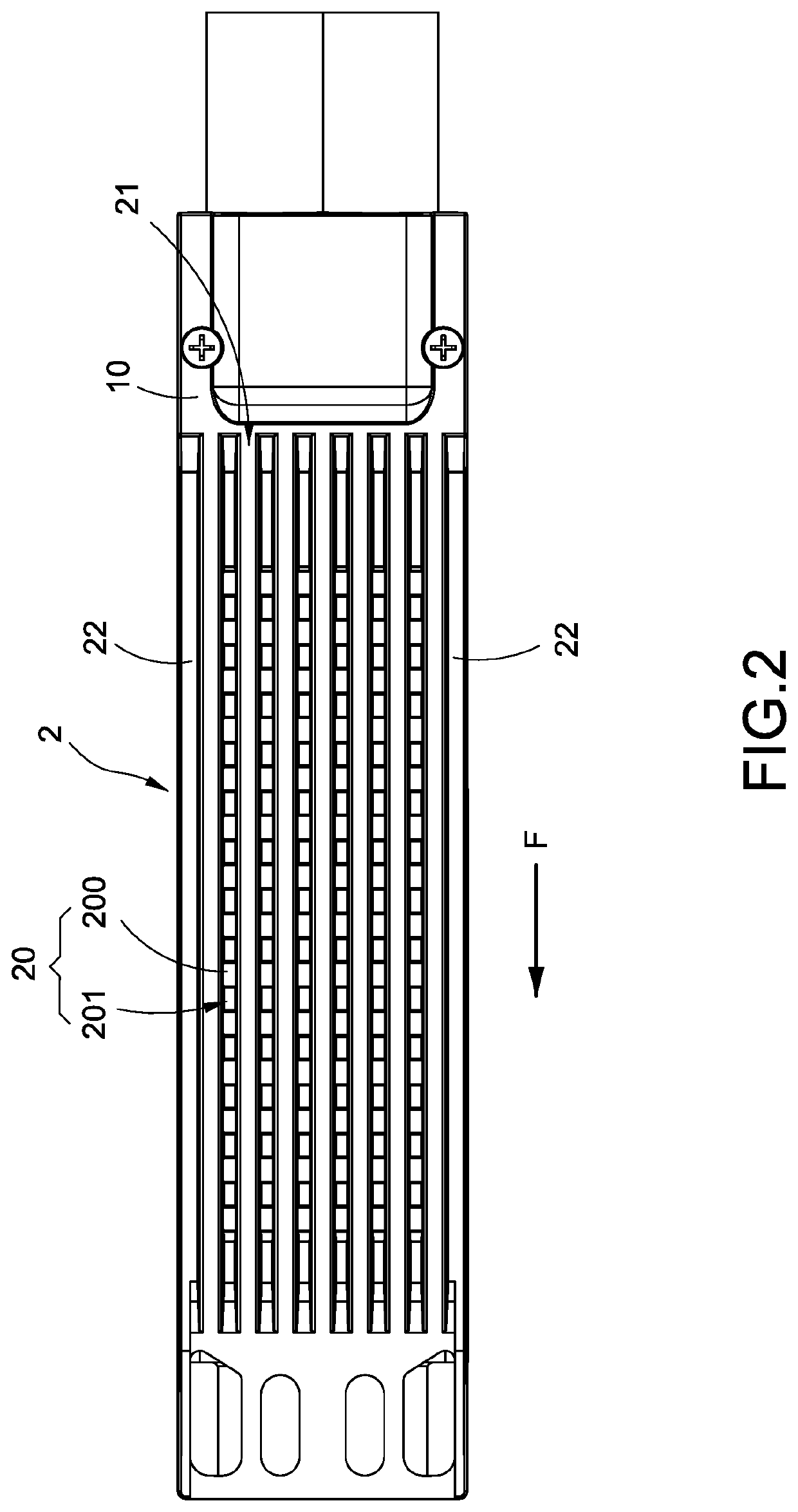

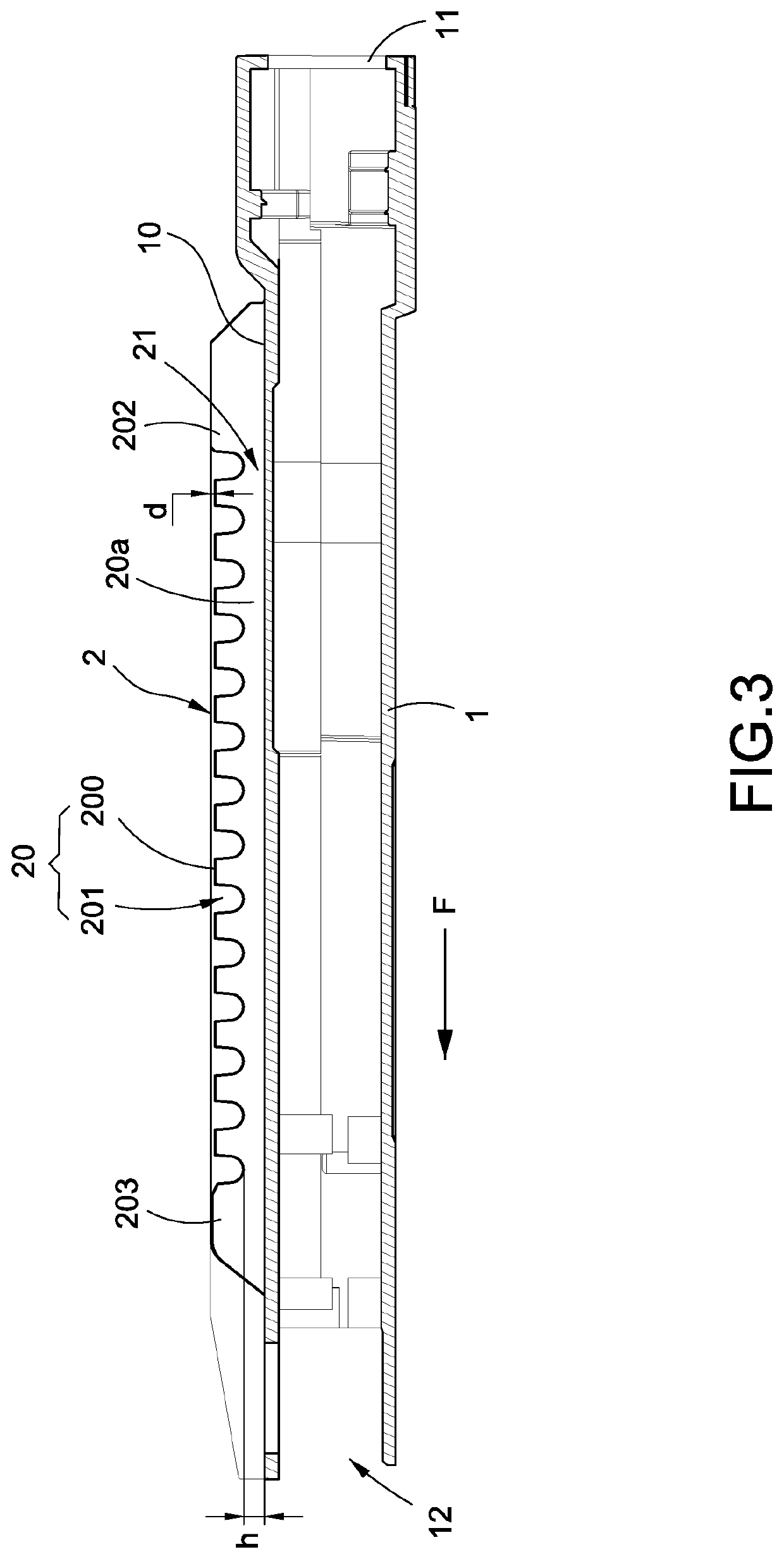

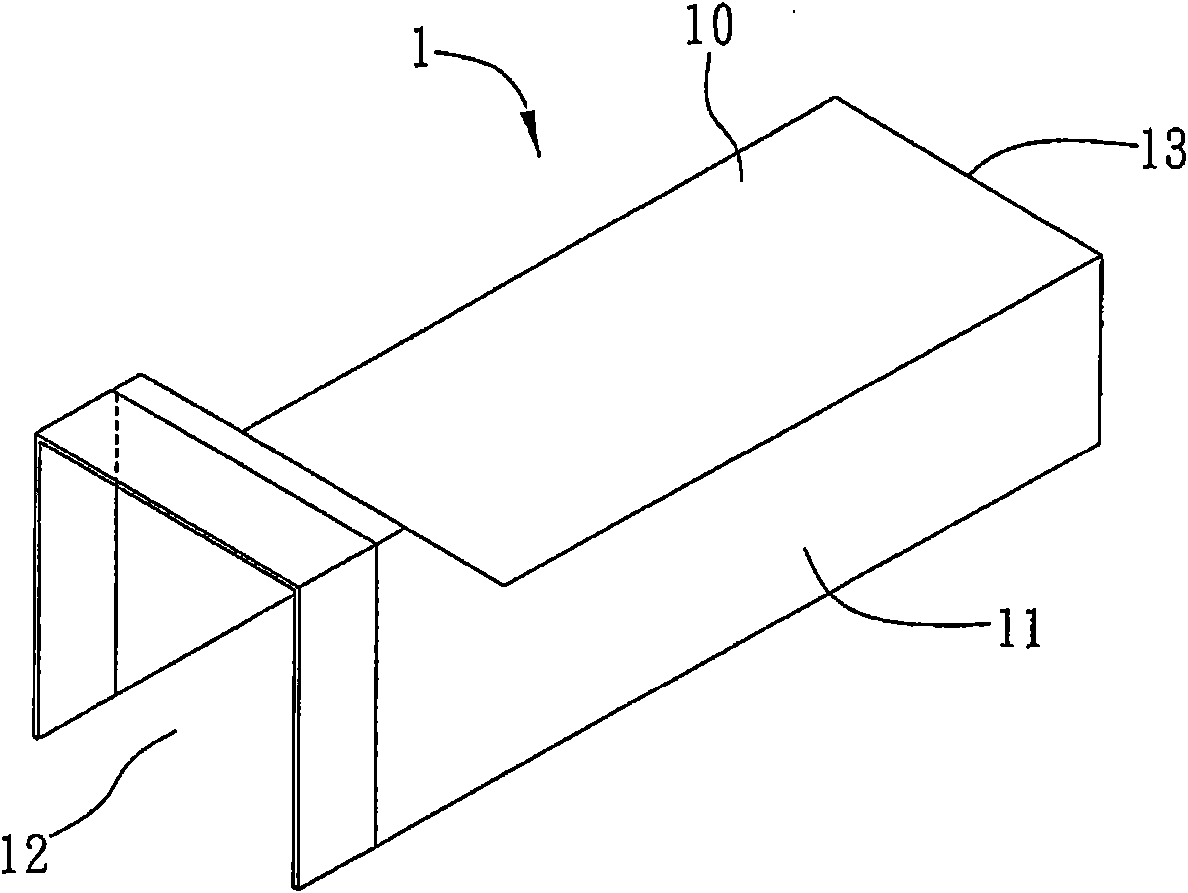

Shell heat dissipating structure of small form-factor pluggable transceiver

ActiveUS11073336B2Increase heat dissipation structureImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesTransceiverEngineering

A shell heat dissipating structure of a small form-factor transceiver includes a hollow shell and a heat dissipating structure. The hollow shell has a setting surface disposed on the outside; the setting surface is formed along an extending direction of the hollow shell. The heat dissipating structure has plural fins formed along the extending direction of the hollow shell and spaced on the setting surface; a plurality of channels is formed among the fins. Each of the fins is formed by plural projecting portions and recess portions disposed along the extending direction and alternated continuously such that the channels among the fins communicate with each other through the recess portions.

Owner:JESS-LINK PRODUCTS

Wind guiding cover

InactiveCN101652050AEnhance heat convection effectImprove convective heat transfer coefficientDigital data processing detailsSemiconductor/solid-state device detailsAirflowEngineering

The invention discloses a wind guiding cover, which comprises a wind inlet part provided with a wind inlet, a wind outlet part provided with a wind outlet opposite to the wind inlet, and a heat exchange area arranged between the wind inlet and the wind outlet. The heat exchange area is provided with an airflow turbulence part close to the wind inlet part. When the wind guiding cover covers a heating element of a main plate, the wind guiding cover and the main plate form a wind passage; and the heat exchange area is positioned above the heating element so that the airflow passes through the airflow turbulence part to increase airflow turbulence so as to reinforce the heat convection effect and increase the convection heat exchange coefficient.

Owner:INVENTEC CORP

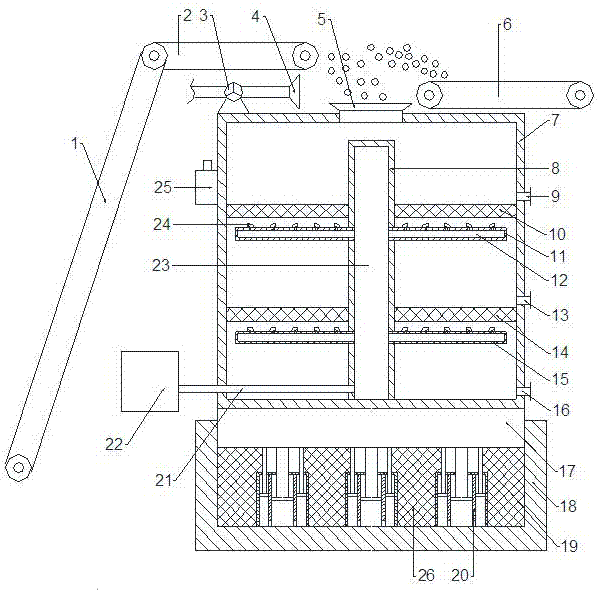

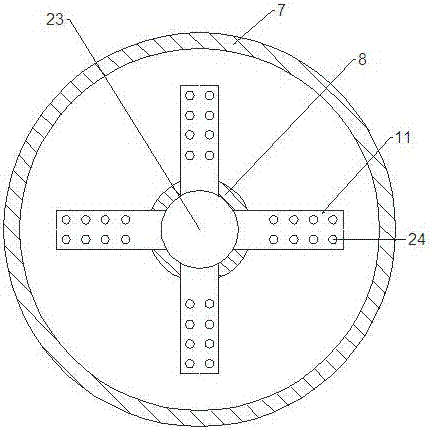

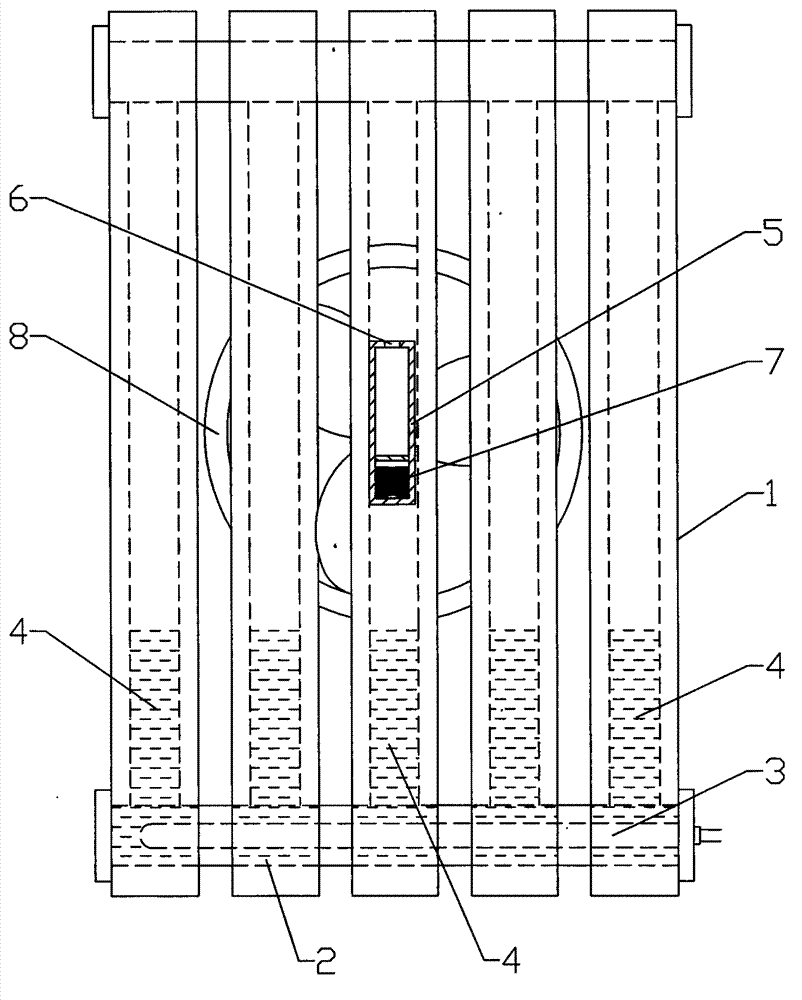

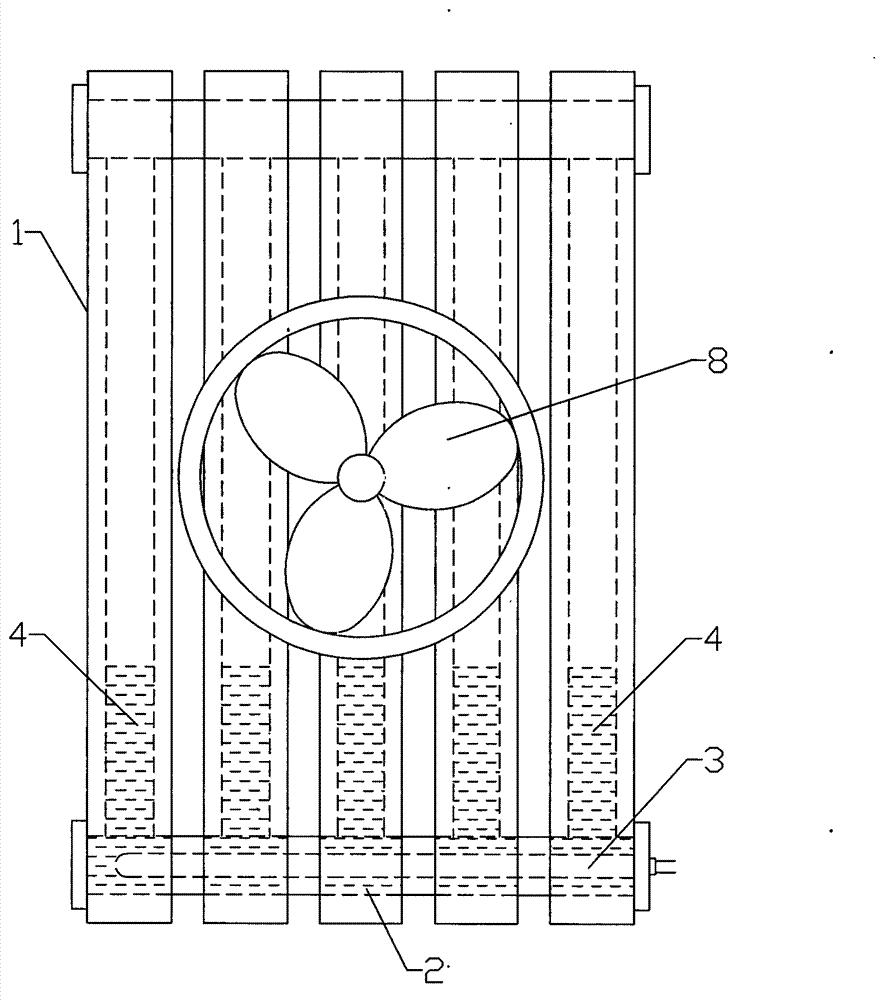

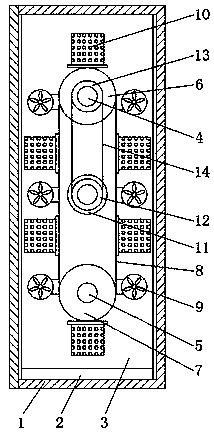

Farm grain preprocessing device integrating drying and screening

ActiveCN107062870AReduce duplicationLow costDrying gas arrangementsDrying chambers/containersScreening effectEngineering

The invention discloses a farm grain preprocessing device integrating drying and screening. The device comprises a feeding device and a shell. The feeding device comprises an inclined conveying belt and a first horizontal conveying belt. The first horizontal conveying belt is connected with the inclined conveying belt. The first horizontal conveying belt is located above the shell. The upper end of the shell is provided with an air blower. An air outlet of the air blower is located under the right end of the first horizontal conveying belt. A second horizontal conveying belt is arranged above the right side of the shell. A first screen net is arranged in the shell. A second screen net is arranged below the first screen net. The mesh diameter of the first screen net is larger than the mesh diameter of the second screen net. The preprocessing device integrated screening and drying, effectively saves equipment investment, reduces the cost and can achieve the effects that classification effect is obvious and drying is uniform, meanwhile has the advantages of being reasonable in structural design, convenient to use, good in screening effect, high in drying efficiency and the like, and has the wide application prospect and the high practical value.

Owner:凤阳昊成粮油贸易有限公司

Multifunctional electric heater

InactiveCN102927611AHeating fastRapid expansionLighting and heating apparatusElectric heating systemWater storageRoom temperature

The invention relates to a multifunctional electric heater which comprises a radiating main body, wherein a heating cavity is arranged in the radiating main body, electric heating elements and heating media are arranged in the heating cavity, and a humidifying device is arranged on the outer surface of the radiating main body. The humidifying device comprises a water storage box arranged on the radiating main body and a water outlet arranged on the water storage box, wherein an electric vibrator opposite to the water outlet is arranged in the water storage box, and an auxiliary element used for fastening heat circulation is further arranged on the outer surface of the radiating main body. The heating media in the heating cavity are heated through the electric heating elements and gradually diffuse in the whole peripheral space with heated air serving as heat transfer medium to form hot air circulation. Water in the water storage box is changed to vapor and escapes from the water outlet position. The vapor temperature at the time is room temperature so that the phenomena of scalding and water dropping are avoided during use, and the multifunctional electric heater is good in humidifying effect.

Owner:QINGZHOU SHENGHONG IND & TRADE

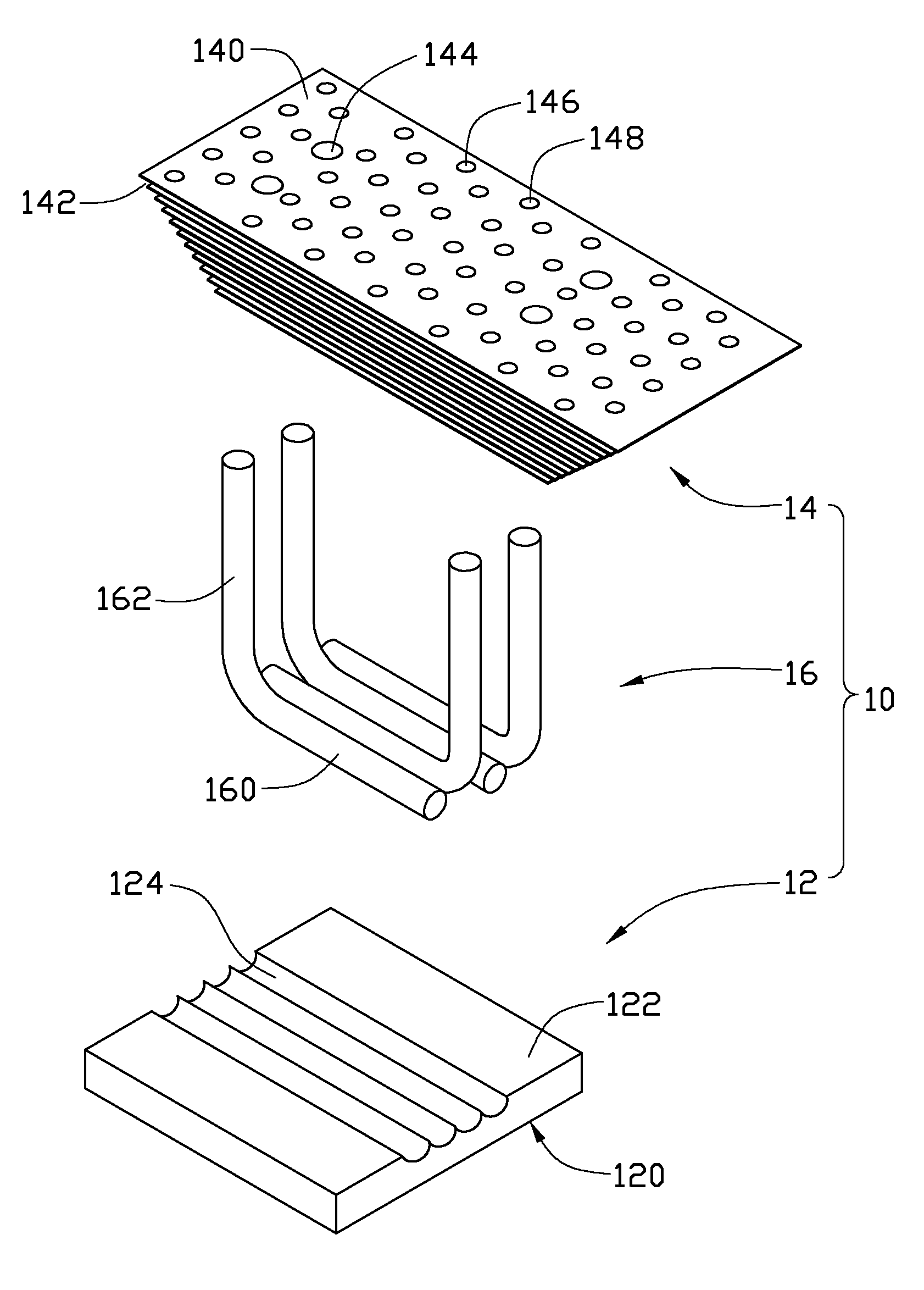

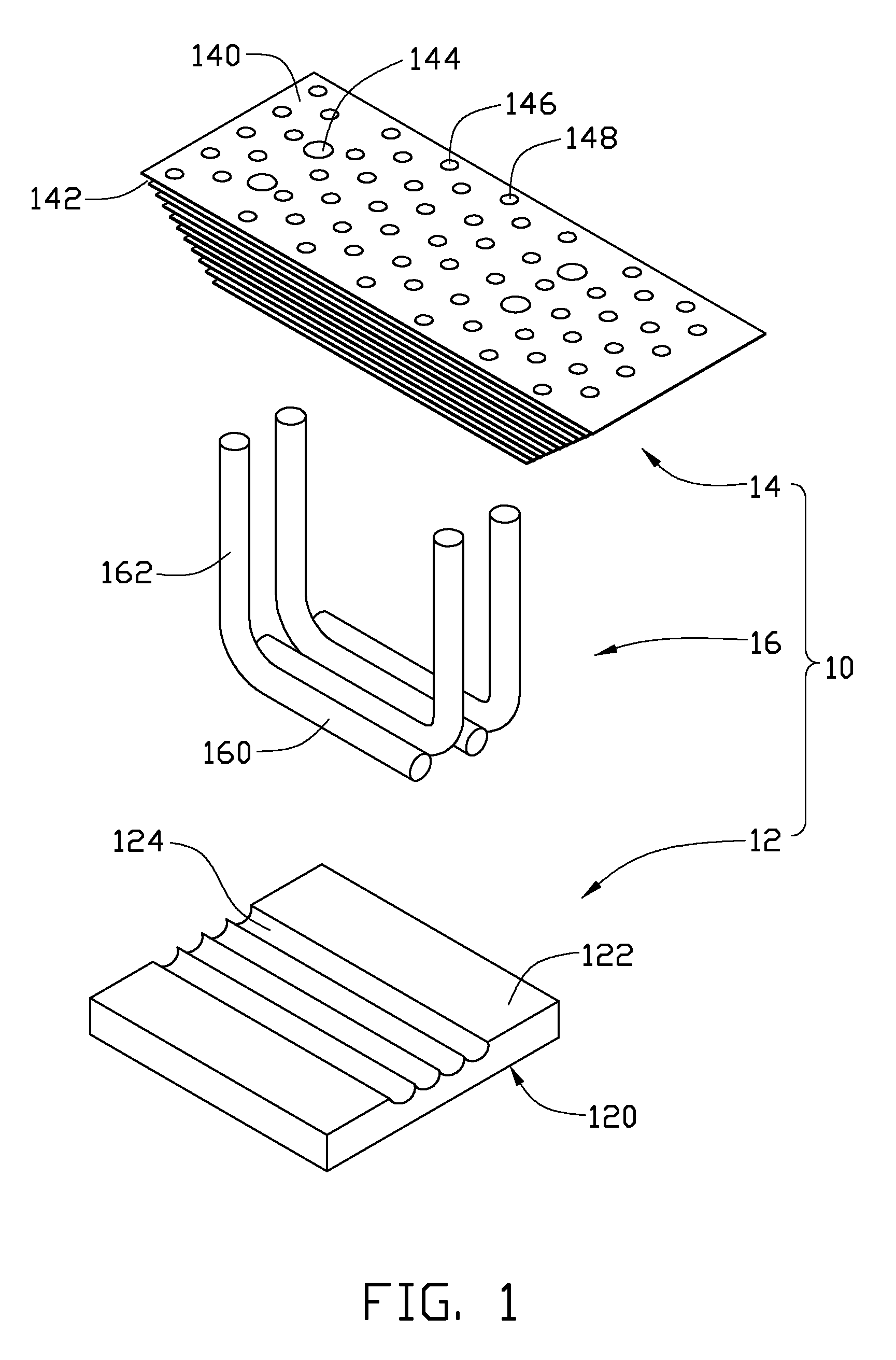

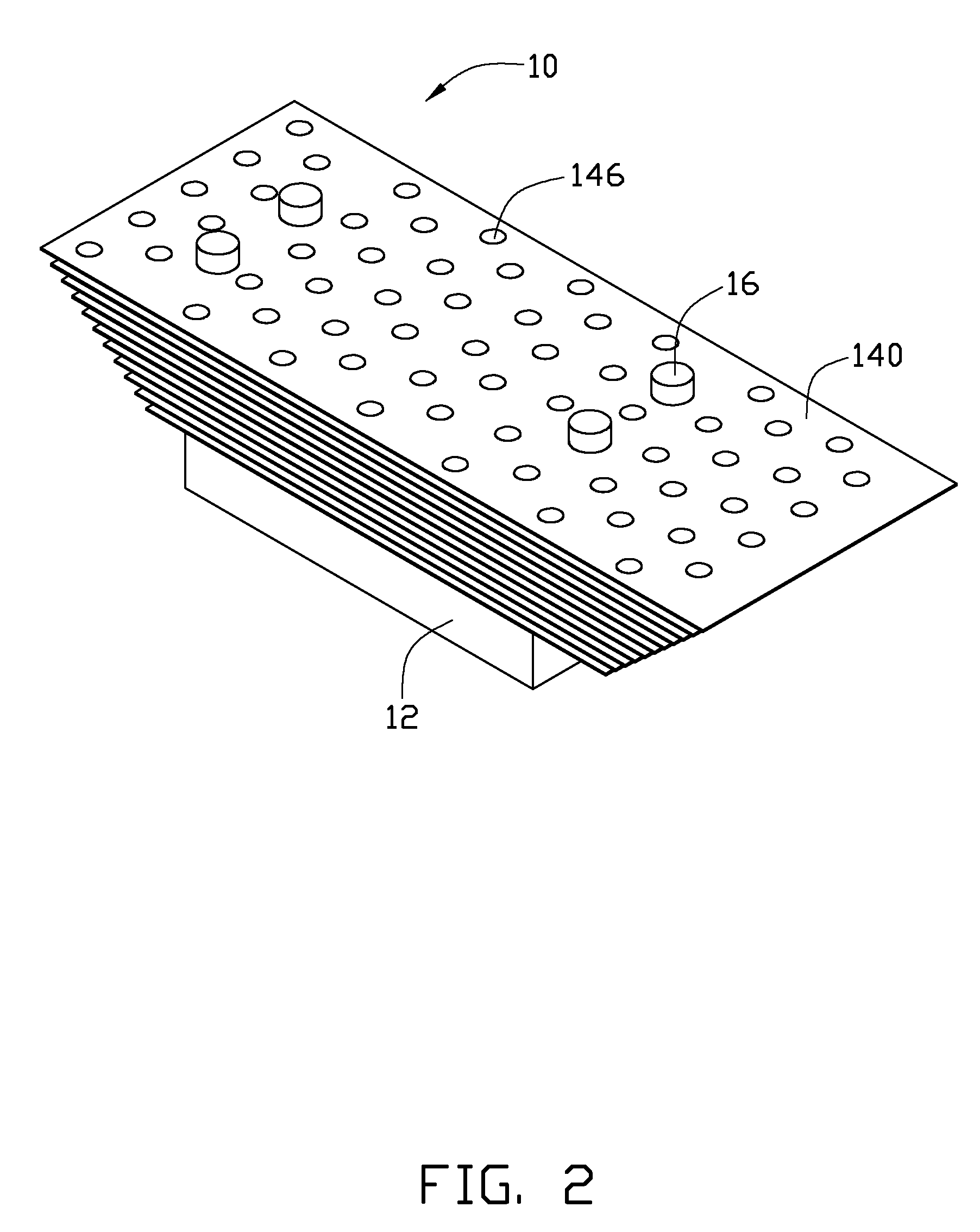

Heat dissipation device

InactiveUS20110073283A1Speed up heat convectionOccupy large spaceDigital data processing detailsSemiconductor/solid-state device detailsEngineeringAmbient air

A heat dissipation device comprises a substrate, a fin assembly located above the substrate and at least one heat pipe connecting the substrate with the fin assembly together. The fin assembly comprises a plurality of fins stacked one above another along a bottom to top direction and space from each other with a gap defined between two neighboring fins. Each of the fins defines a plurality of ventilating holes therein. The ventilating holes of the fins are aligned with each other and form a plurality of vertical air channels in the fin assembly along the bottom to the top direction for ambient air in the gaps flowing therethrough upwardly to escape the fin assembly.

Owner:HON HAI PRECISION IND CO LTD

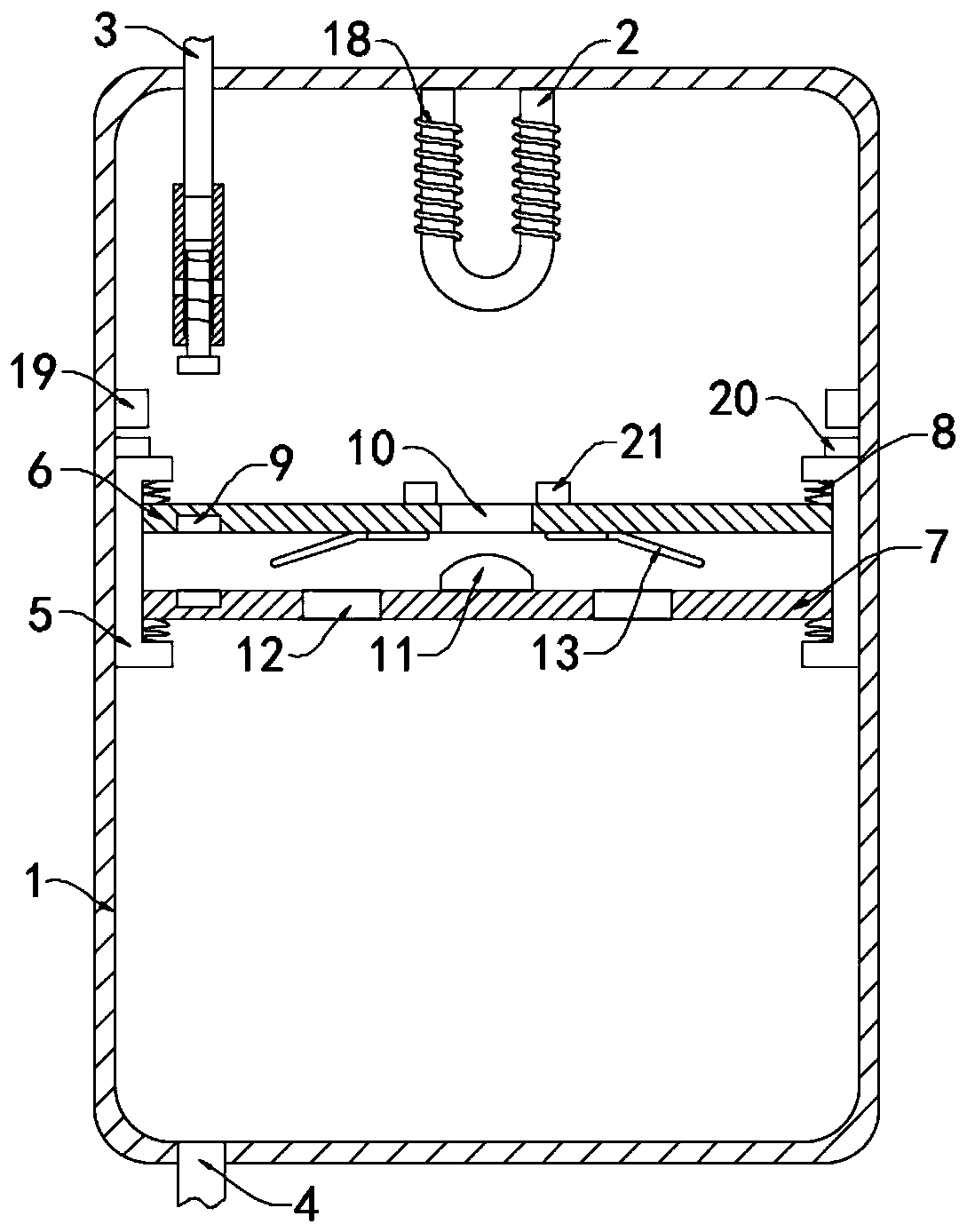

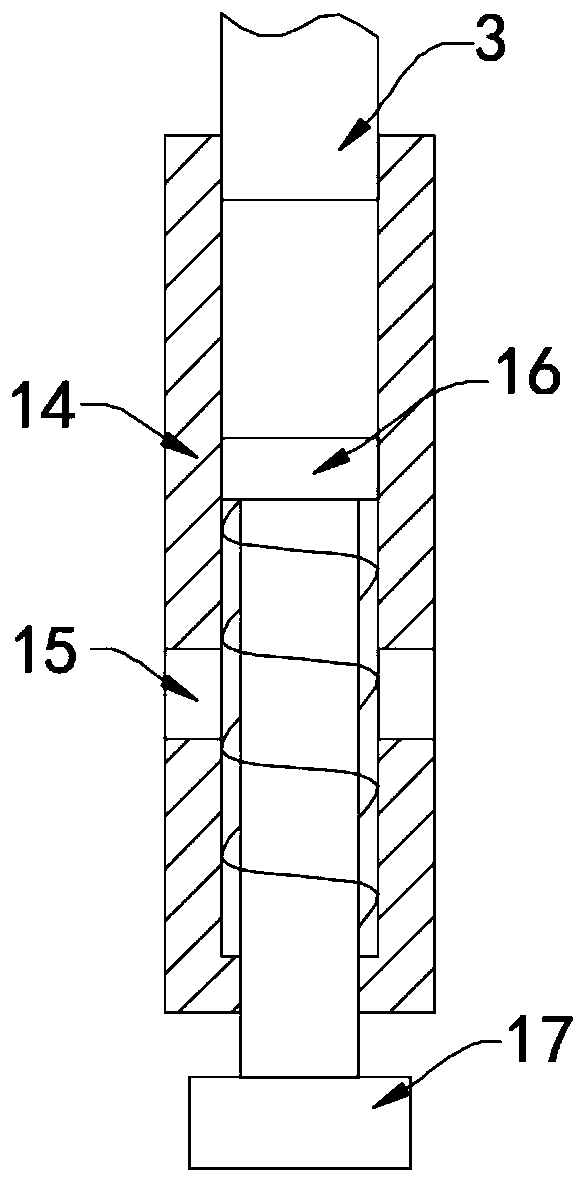

Automatic pressure-stabilizing descaling water heater

ActiveCN110986355AEfficient separationAvoid conditions that affect useWater heatersThermodynamicsEngineering

The invention belongs to the field of household appliances, and especially relates to an automatic pressure-stabilizing descaling water heater. The water heater comprises a water tank, a heating pipe,a heating pipe and a water outlet pipe. The heating pipe is arranged at the inner top surface of the water tank, the water inlet pipe and the water outlet pipe fixedly communicate with the upper endand the lower end of the water tank, two sliding blocks with U-shaped sections are arranged in the water tank, the two sliding blocks are symmetrically arranged relative to a heat receiving pipe and are in sealed sliding connection with the side wall of the water tank, an upper plate and a lower plate are arranged between the two sliding blocks, the opposite faces of the upper plate and the lowerplate are connected with the inner side walls of the sliding blocks through extension springs and are in sealed sliding connection with the side walls of the sliding blocks, permanent magnets with thesame polarity attracting each other are fixedly embedded in the opposite side walls of the upper plate and the lower plate, a plurality of upper through holes are formed in the upper plate, a plurality of stand columns matched with the upper through holes are arranged on the lower plate, and a plurality of lower through holes are formed in the lower plate. By arranging the descaling mechanism, scale on the heating pipe is scraped off along with up-down movement of an induction coil on the heating pipe, and cleanliness of the heating pipe can be effectively guaranteed.

Owner:金迪(聊城市)知识产权运营有限公司

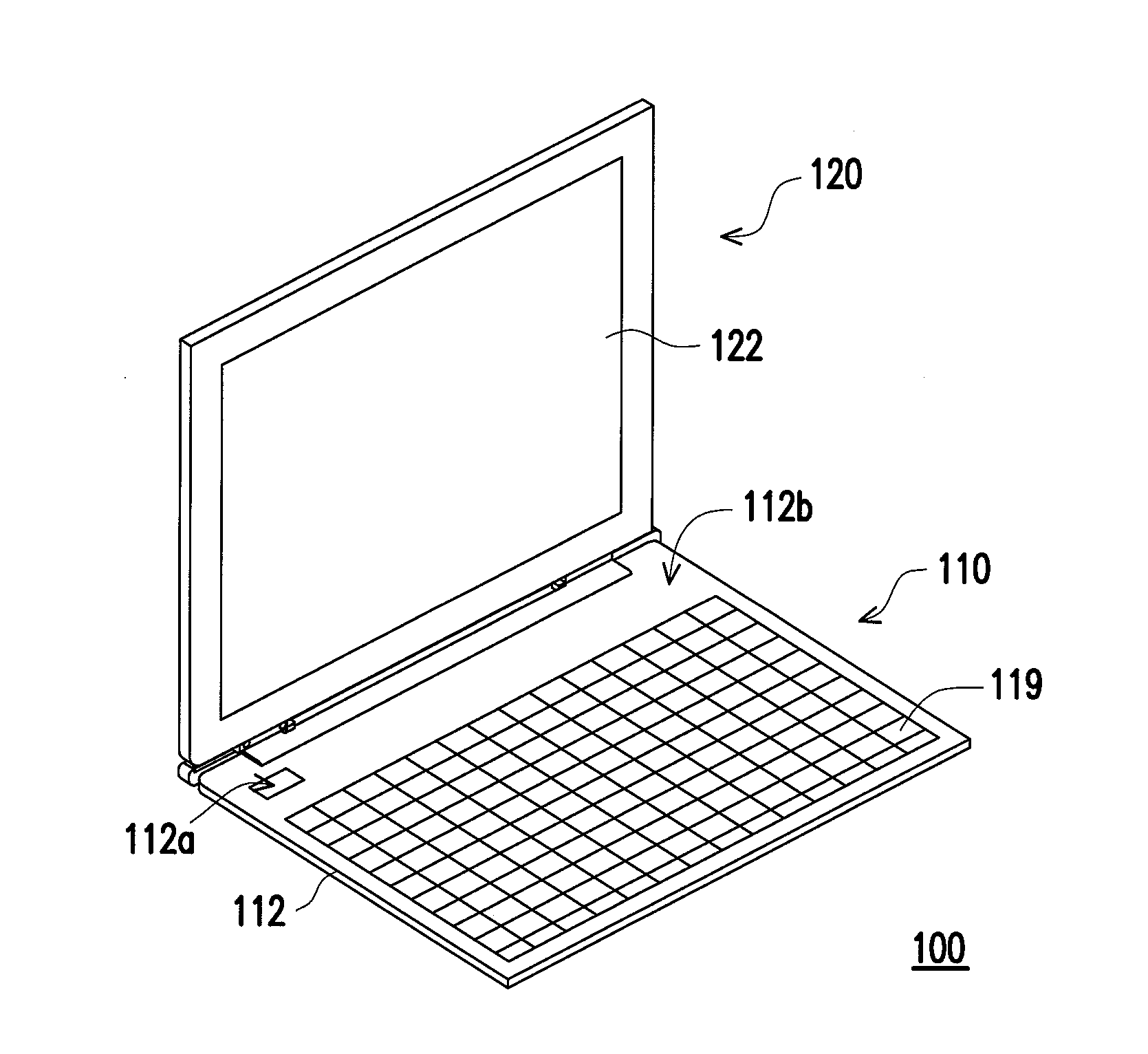

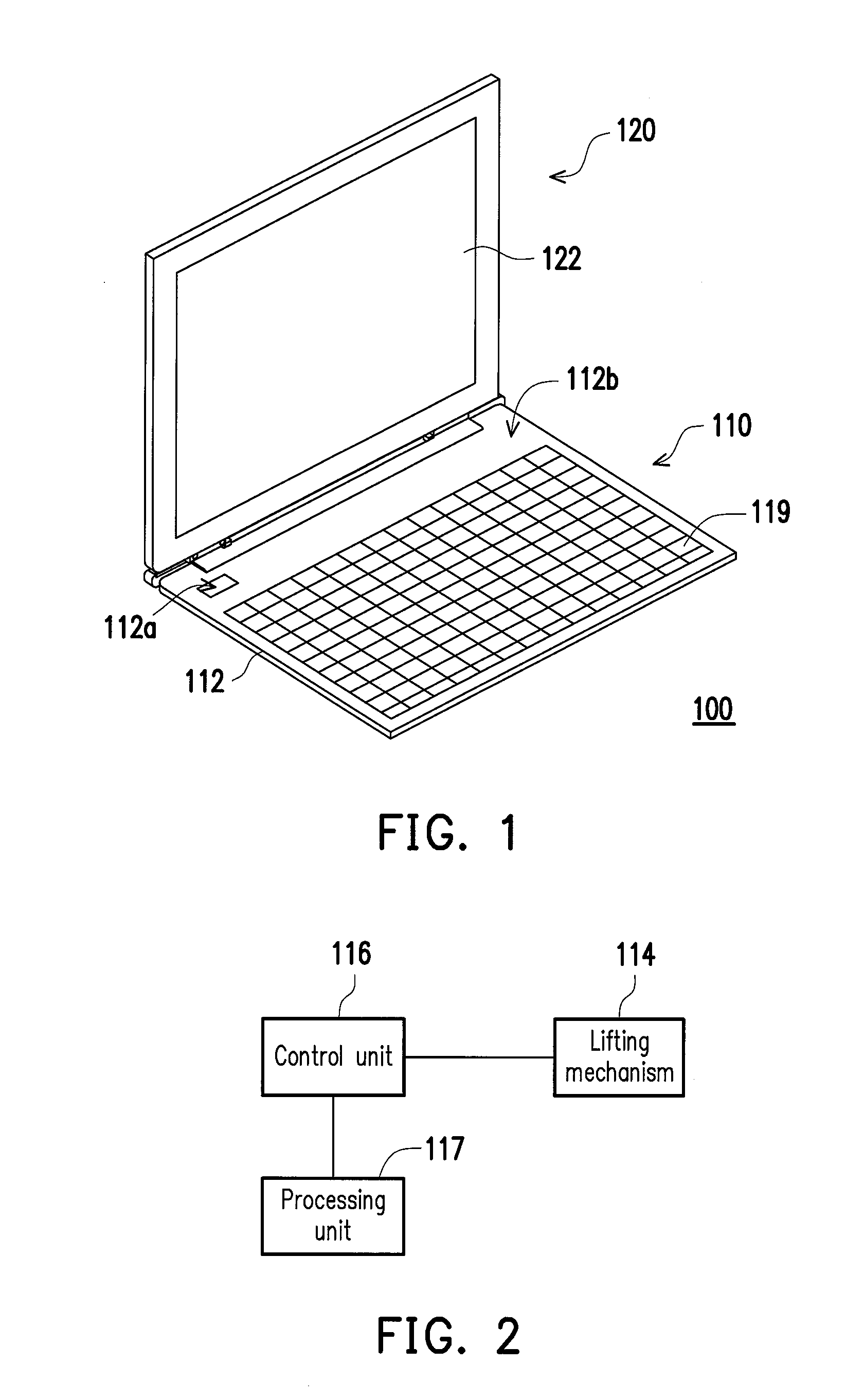

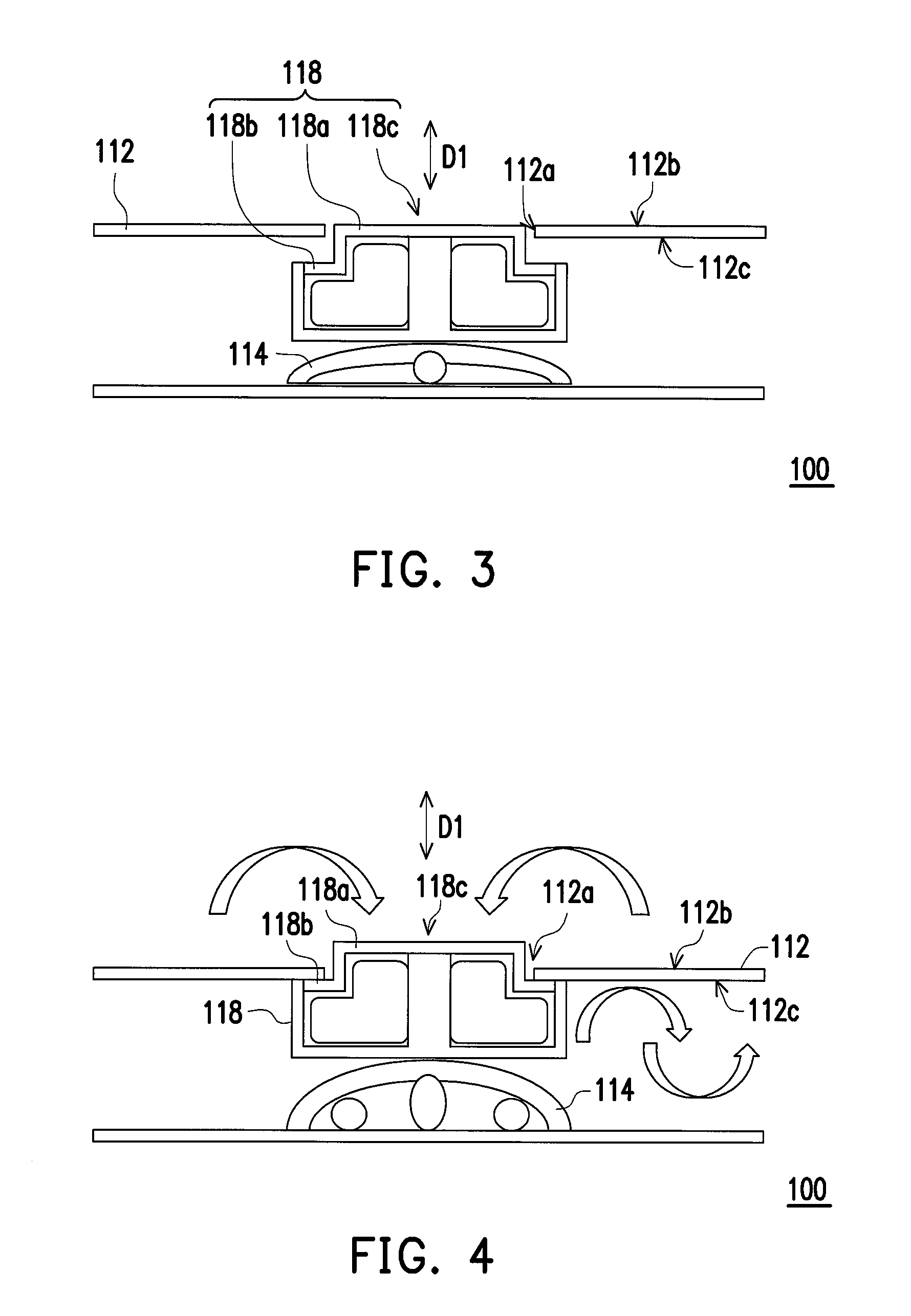

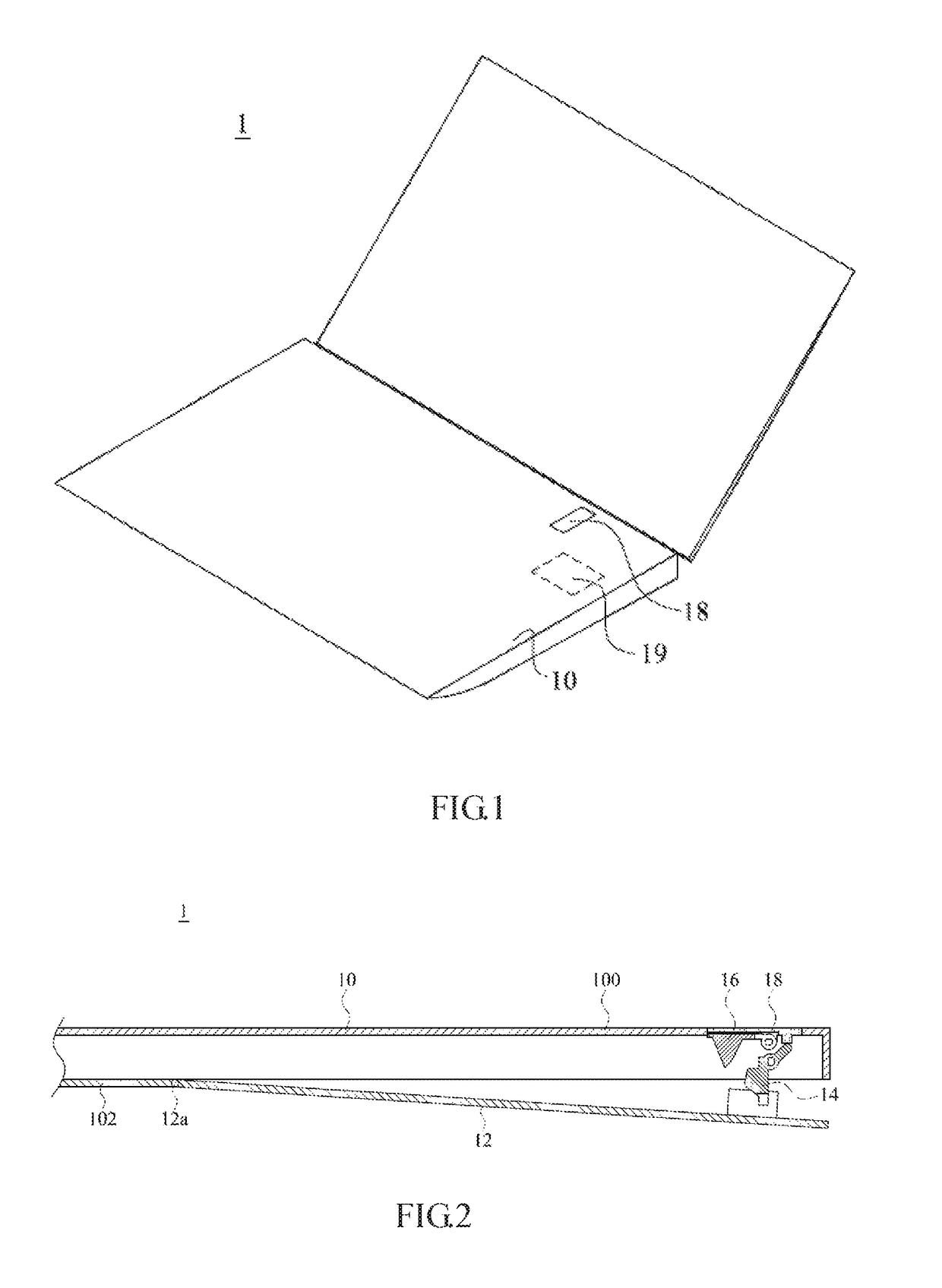

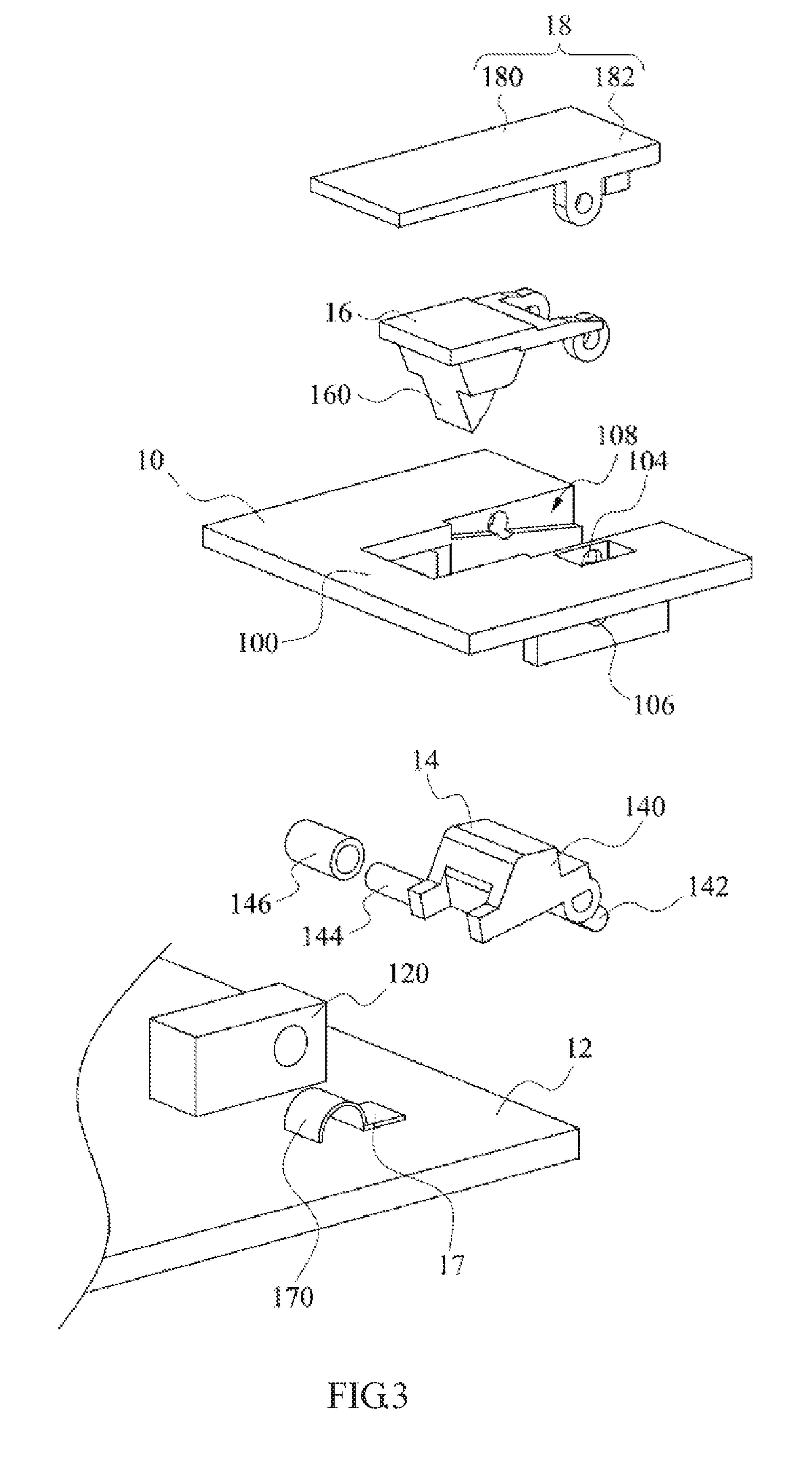

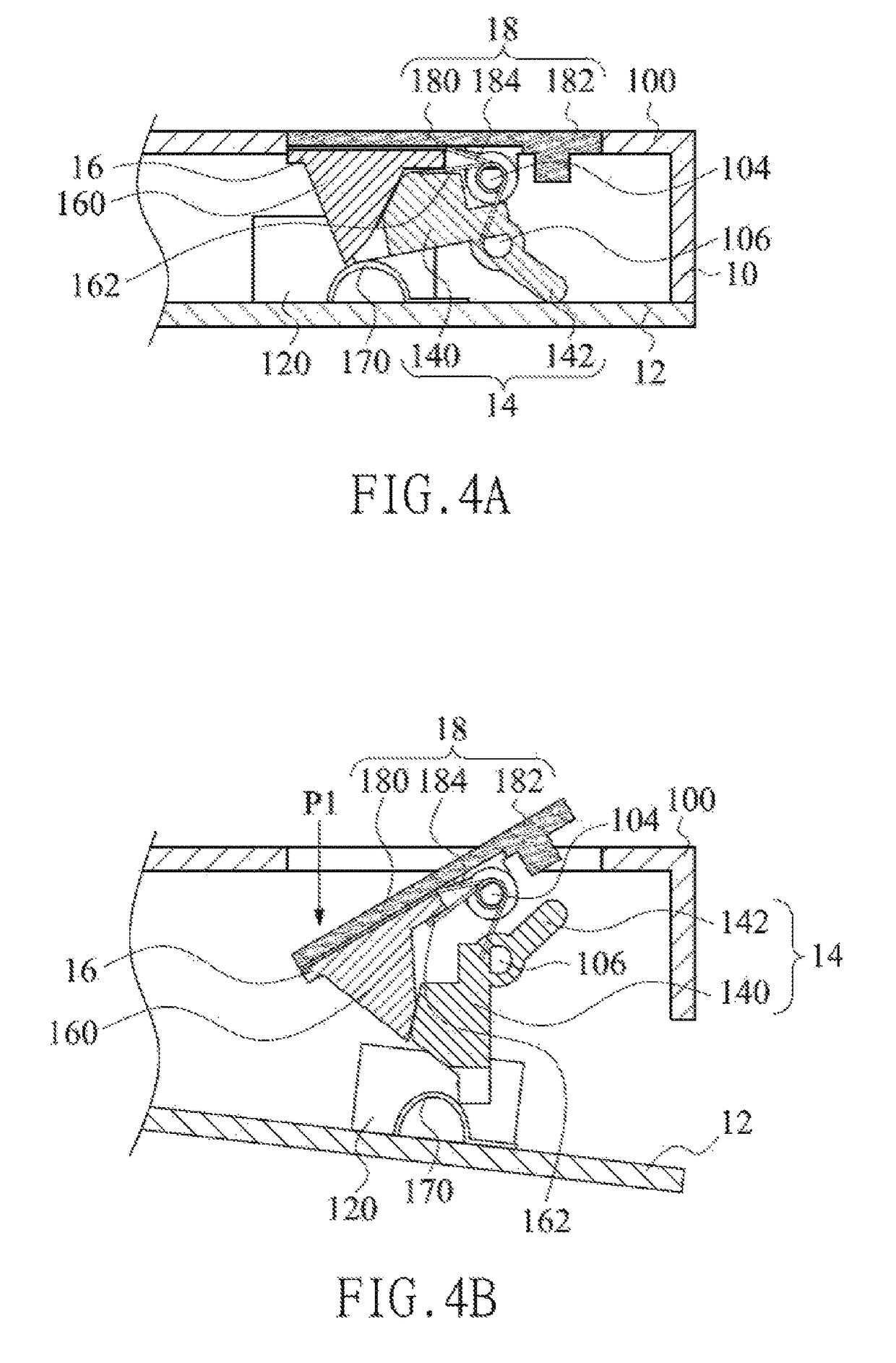

Portable electronic device

ActiveUS20160330864A1Increase heat flowImprove cooling efficiencyDigital data processing detailsModifications using gaseous coolantsControl cellEngineering

The electronic portable device of the invention includes a housing, a lifting mechanism, a controlling unit, and a heat dissipation fan. The housing includes an opening The lifting mechanism is movably disposed in the housing and corresponds to the opening. The lifting mechanism is configured to move toward or away from the opening. The control unit is coupled to the lifting mechanism and configured to control the lifting mechanism to move toward or away from the opening. The heat dissipation fan is disposed on the lifting mechanism and corresponds to the opening. When the lifting mechanism moves towards the opening, the heat dissipation fan is lifted toward the opening by the lifting mechanism, and is protruded from an outer surface of the housing through the opening.

Owner:ACER INC

Electronic device

ActiveUS10149405B2Heat convectionSpeed up heat convectionCasings/cabinets/drawers detailsDetails for portable computersEngineeringMechanical engineering

Owner:ASUSTEK COMPUTER INC

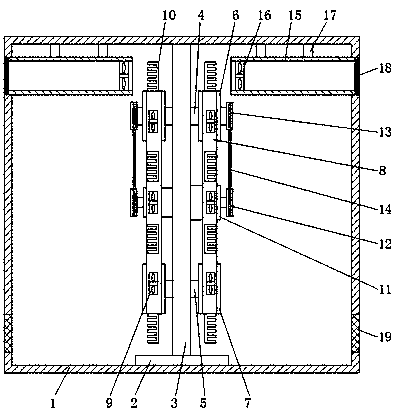

Wireless communication equipment cabinet

InactiveCN107683077AUniform temperature distributionAvoid damageCooling/ventilation/heating modificationsDrive shaftWorking environment

The invention discloses a wireless communication equipment cabinet, which comprises a cabinet body, a base is connected to the center of the inner bottom surface of the cabinet body, a vertical plate is connected to the center of the top surface of the base, and the two sides of the vertical plate are respectively A group of heat dissipation devices are provided, and the heat dissipation devices include a driving shaft and a driven shaft that are rotatably connected to the vertical plate. The driving shaft and the driven shaft are respectively connected with a driving double sprocket and a driven double sprocket. The outer side of the driving double sprocket and the driven double sprocket is sleeved with a conveyor chain plate, and the outer surface of the conveyor chain plate is respectively equipped with a stirring fan and a cooling fin, and a driving motor is installed on the side of the vertical plate, and the driving The output end of the motor is connected with a driving sprocket. In the present invention, the circularly moving agitating fan and cooling fins can form space turbulent gas in the cabinet, make the temperature distribution uniform, effectively improve the working environment in the cabinet, have reasonable structure design, and have good popularization and use value.

Owner:石明忠

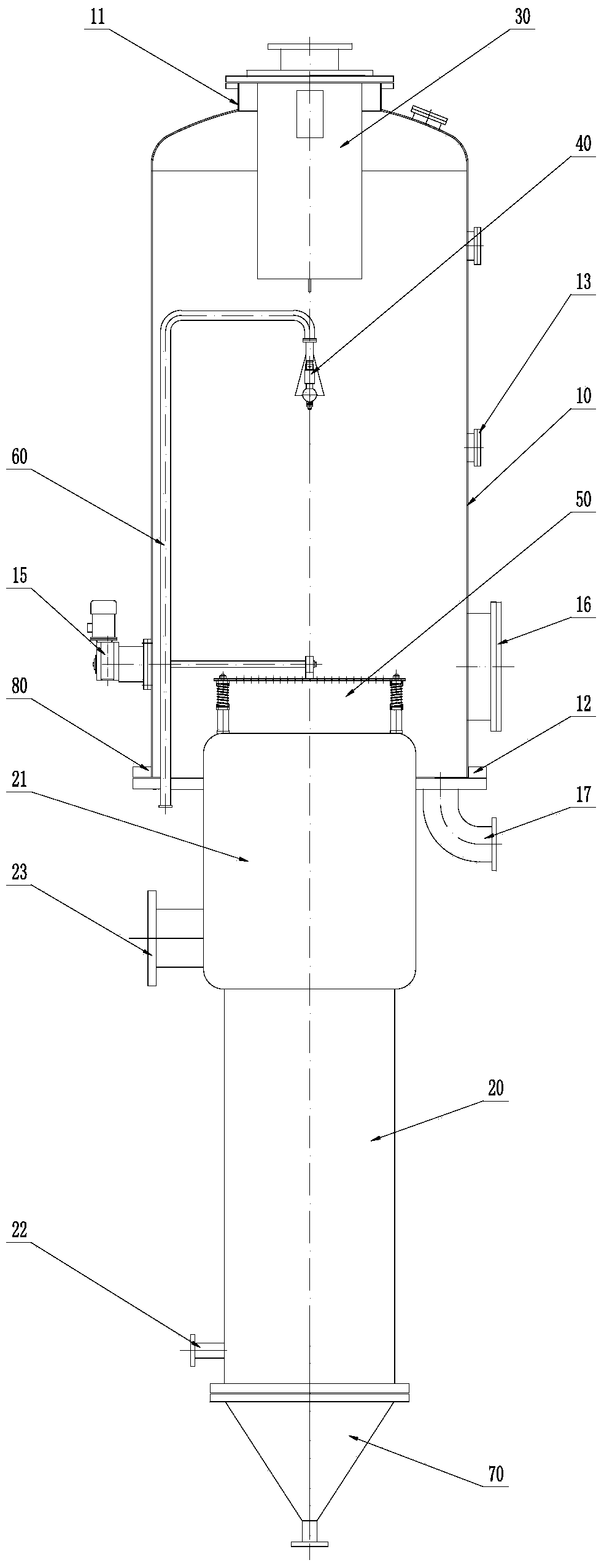

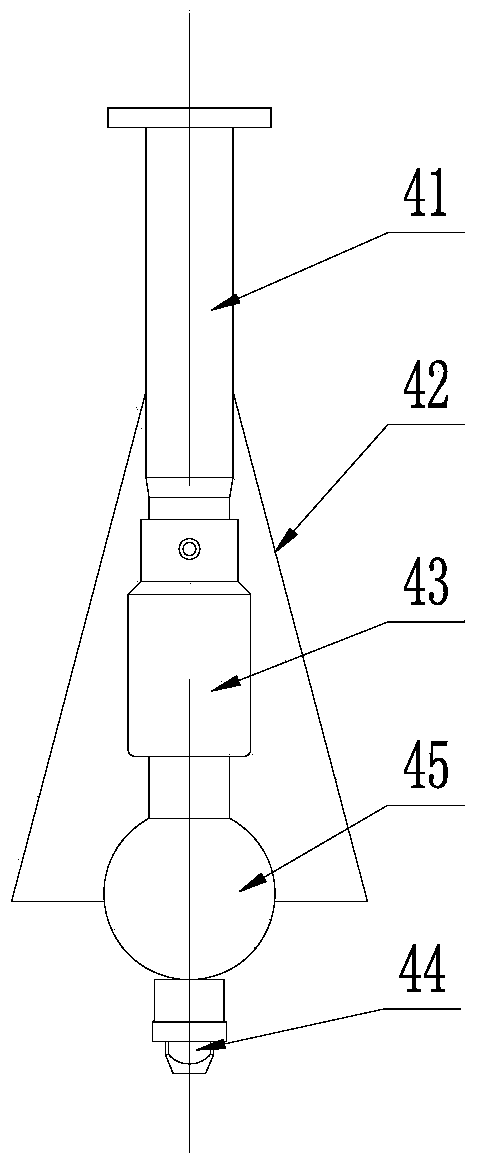

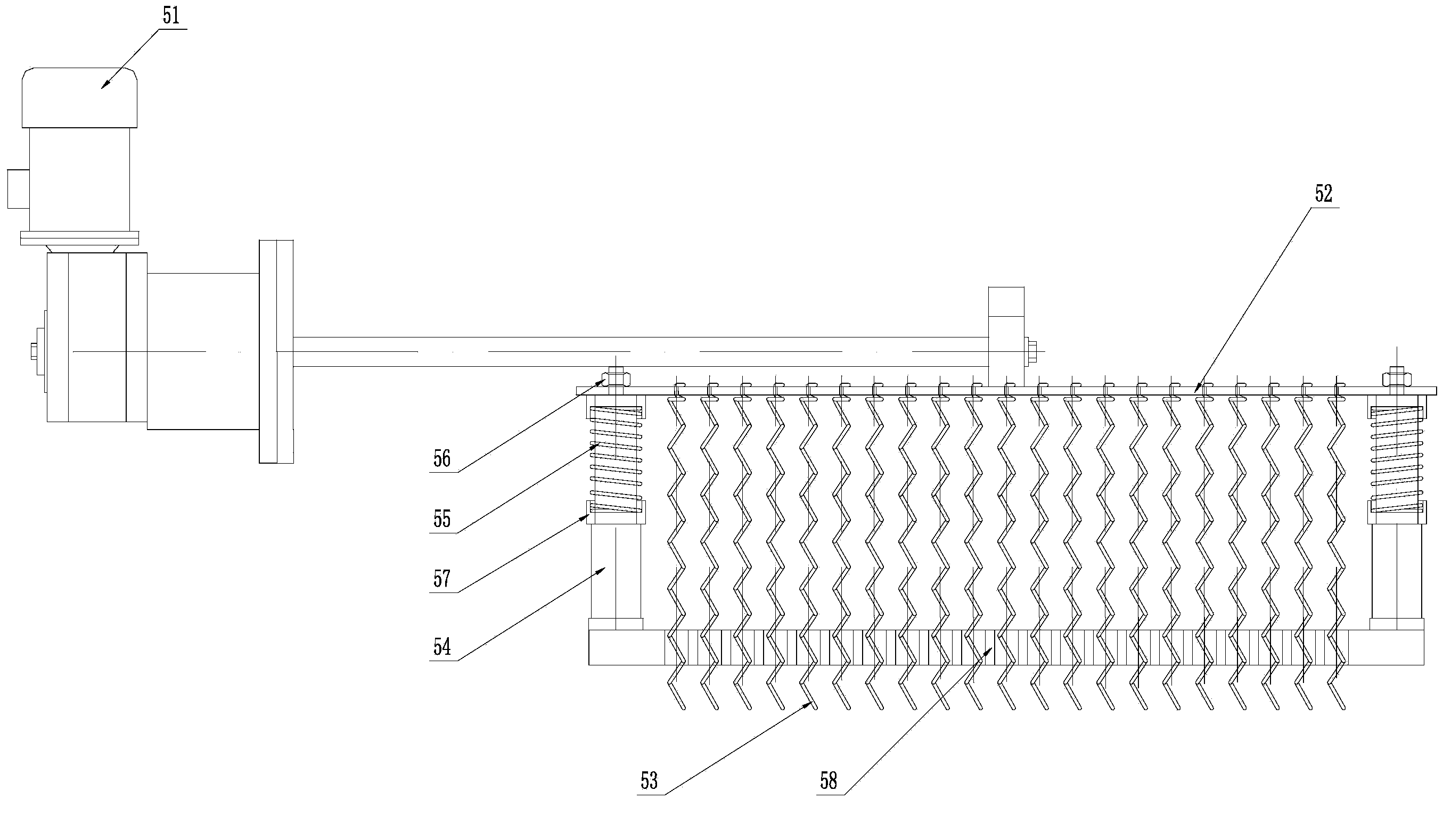

Medicament concentration evaporation apparatus

InactiveCN103520942AActive ingredients evenlyPlay a stirring roleEvaporator accessoriesEvaporationEngineering

A disclosed medicament concentration evaporation apparatus comprises a separator, an evaporator, a gas-liquid separating device, a foam-removing device, a shake-type cleaning device and a liquid-inlet end enclosure; the evaporator is arranged at the bottom of the separator and communicated with the separator; the gas-liquid separating device is arranged at the top of the separator and communicated with the separator; the foam-removing device is arranged in the separator and disposed below the gas-liquid separating device; the shake-type cleaning device is arranged between the separator and the evaporator and is relatively static compared with the separator and the evaporator; and the liquid-inlet end enclosure is arranged at the bottom of the evaporator. The medicament concentration evaporation apparatus is capable of effectively eliminating foams of the medicament liquid, effectively cleaning medicament dirty on the inner wall and improving medicament preparation quality.

Owner:XIANGSHAN MEDICAL PRECISION INSTR

Light-emitting diode structure

InactiveCN101587887AIncrease contact areaEasy to passSemiconductor/solid-state device detailsLighting heating/cooling arrangementsEngineeringLight-emitting diode

Owner:FU ZHUN PRECISION IND SHENZHEN +1

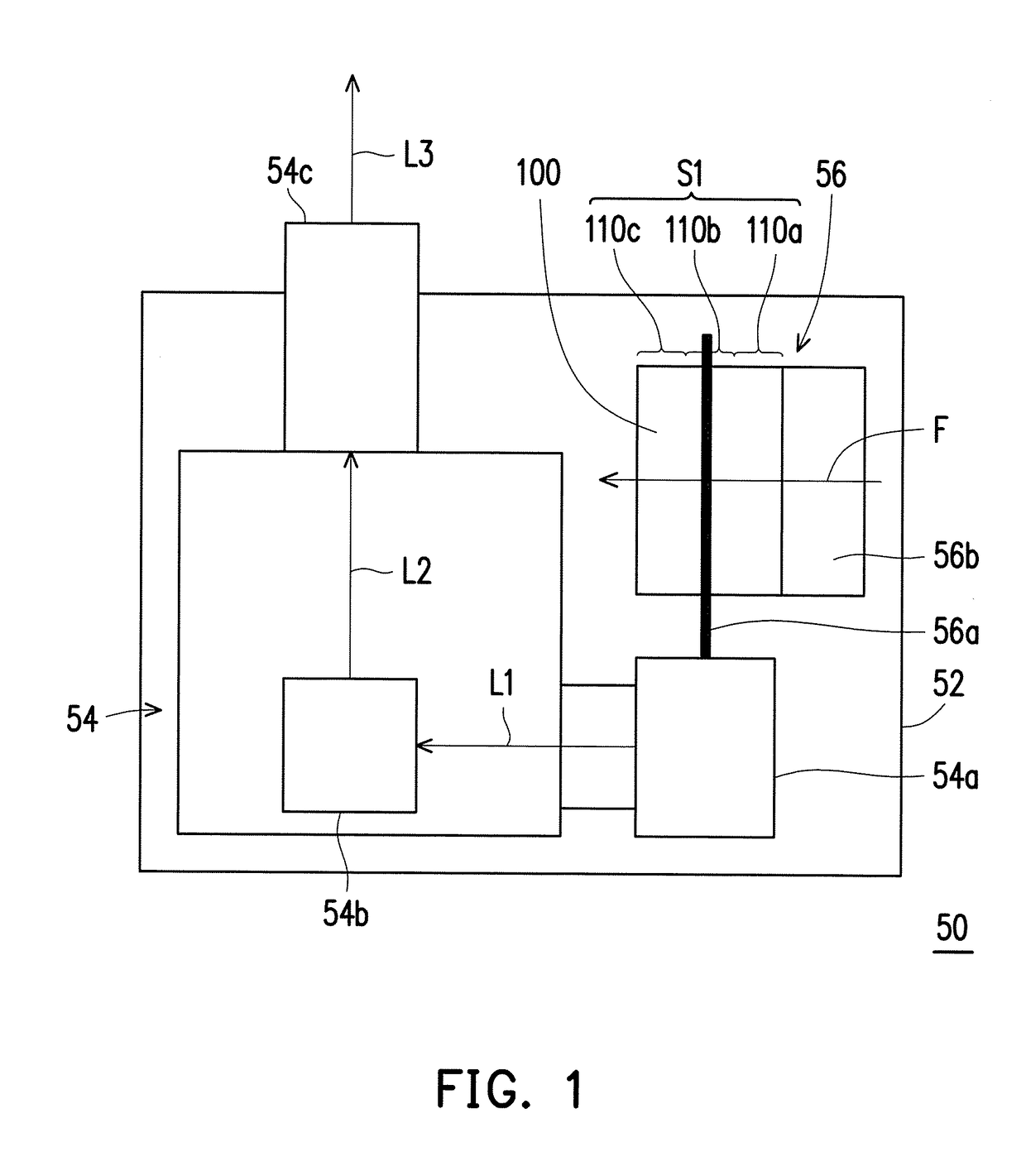

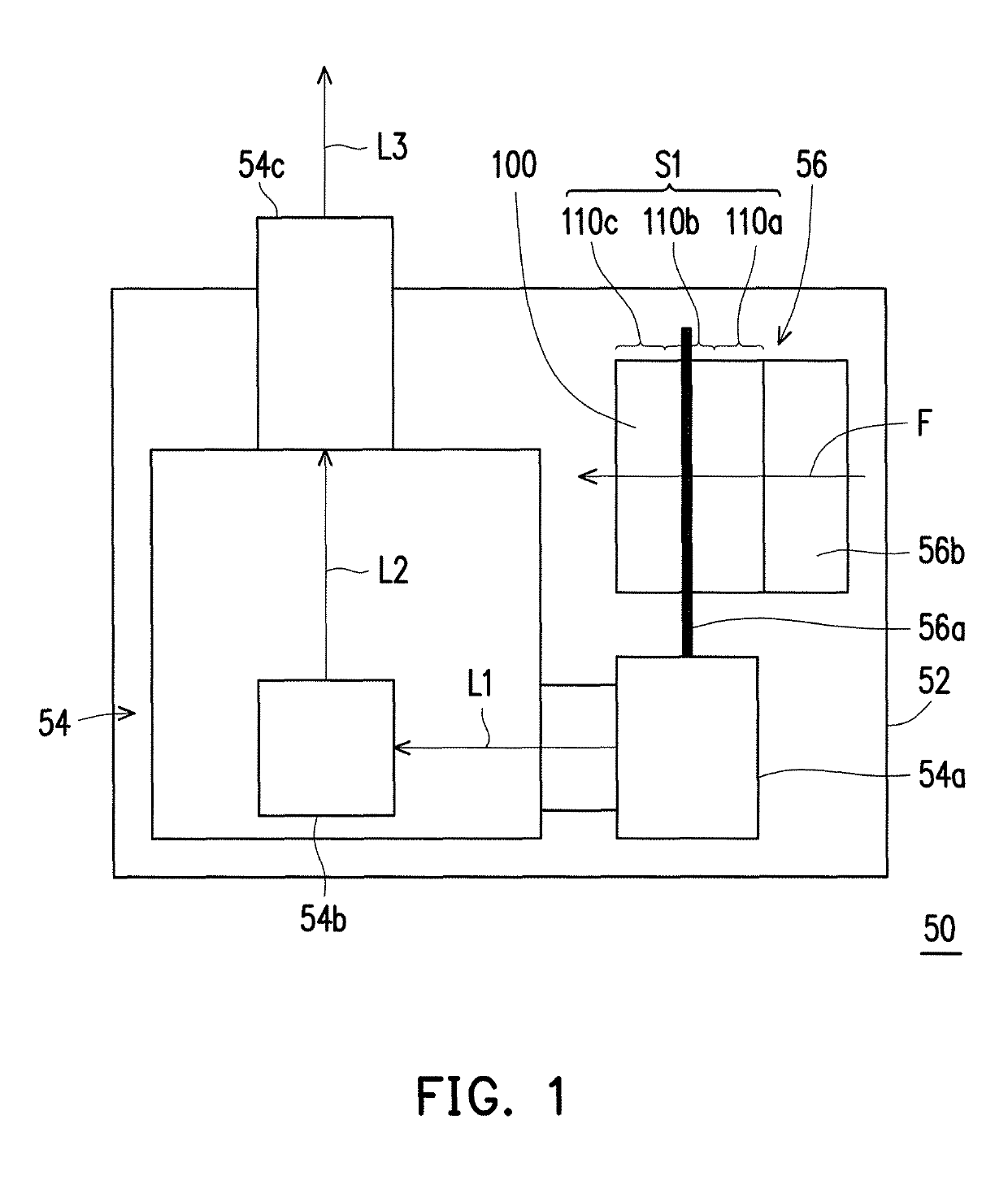

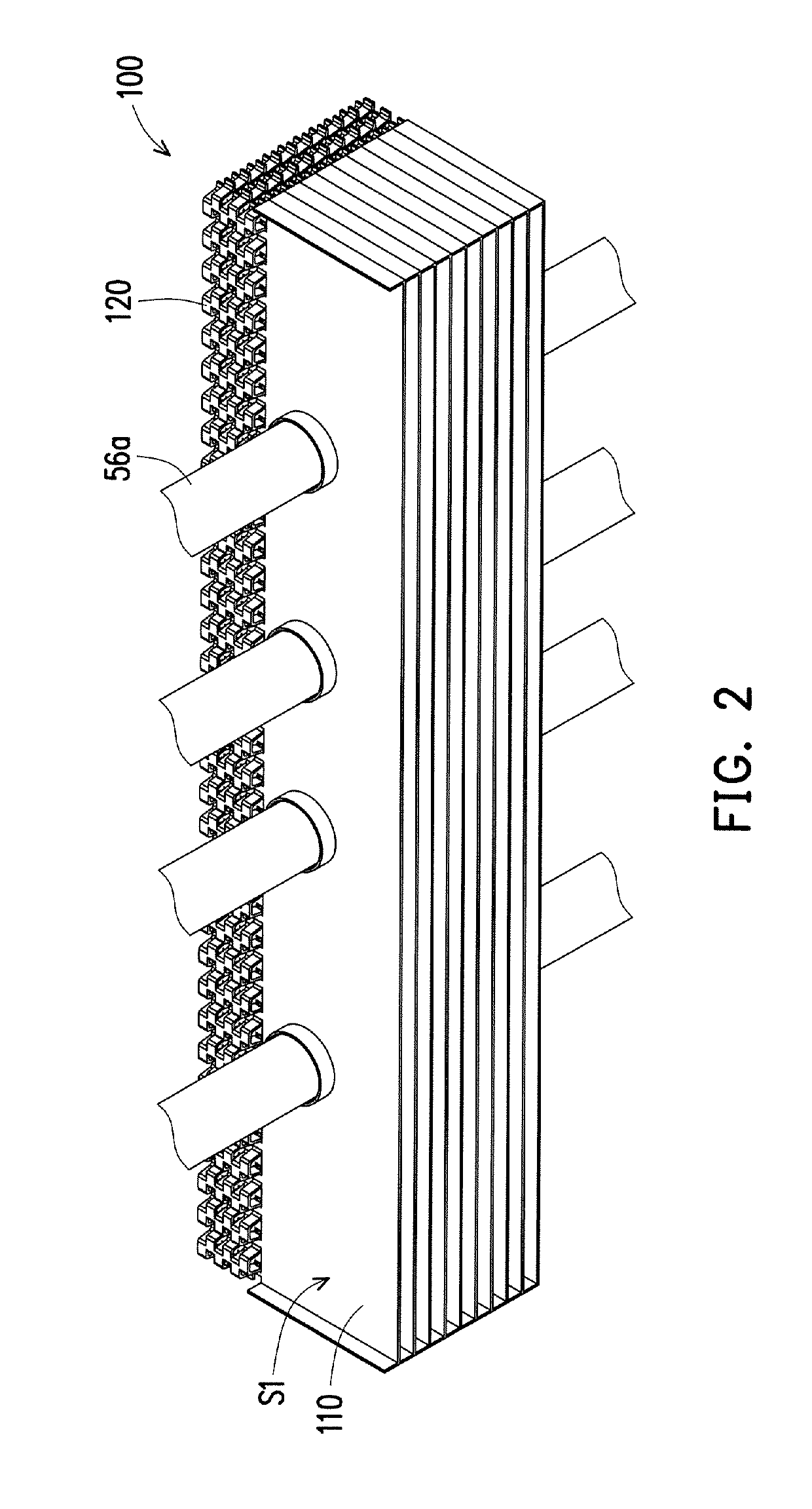

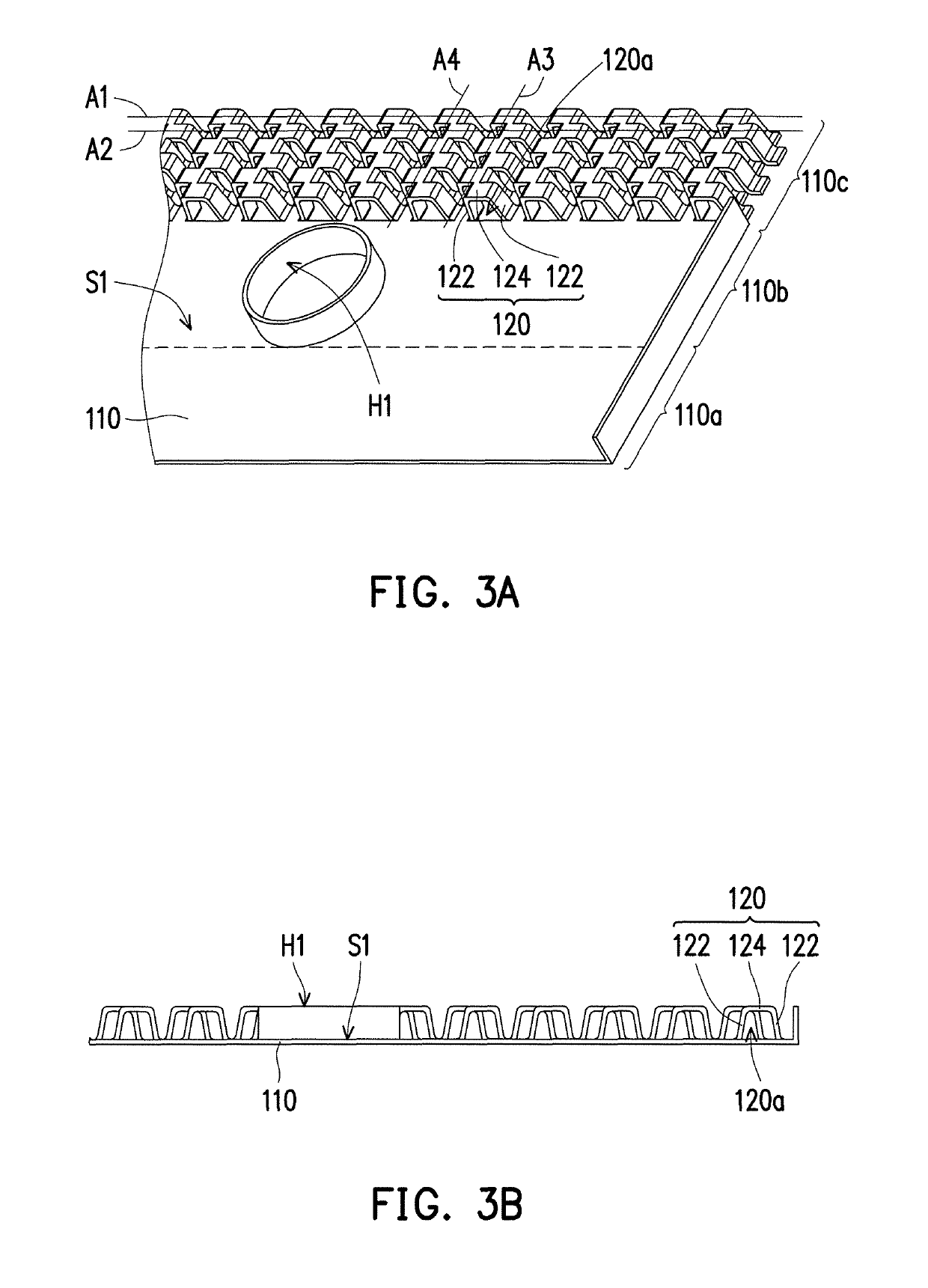

Projector, heat dissipation module, and heat dissipation fin set

ActiveUS20180196337A1Improve cooling efficiencySpeed up heat convectionProjectorsInsulated cablesEngineeringHeat sink

A projector includes a casing, an optical engine module, and a heat dissipation module. The optical engine module is disposed in the casing. The heat dissipation module is disposed in the casing and includes a heat dissipation fin set. The heat dissipation fin set includes at least one heat dissipation fin and at least one turbulent structure. The heat dissipation fin has a surface. The surface includes a first turbulent region and a second turbulent region. The first turbulent region is adjacent to the second turbulent region. The turbulent structure is disposed at least one of the first turbulent region and the second turbulent region, and the turbulent structure protrudes from the surface. An opening is formed between a top end of the turbulent structure and the surface.

Owner:CORETRONIC

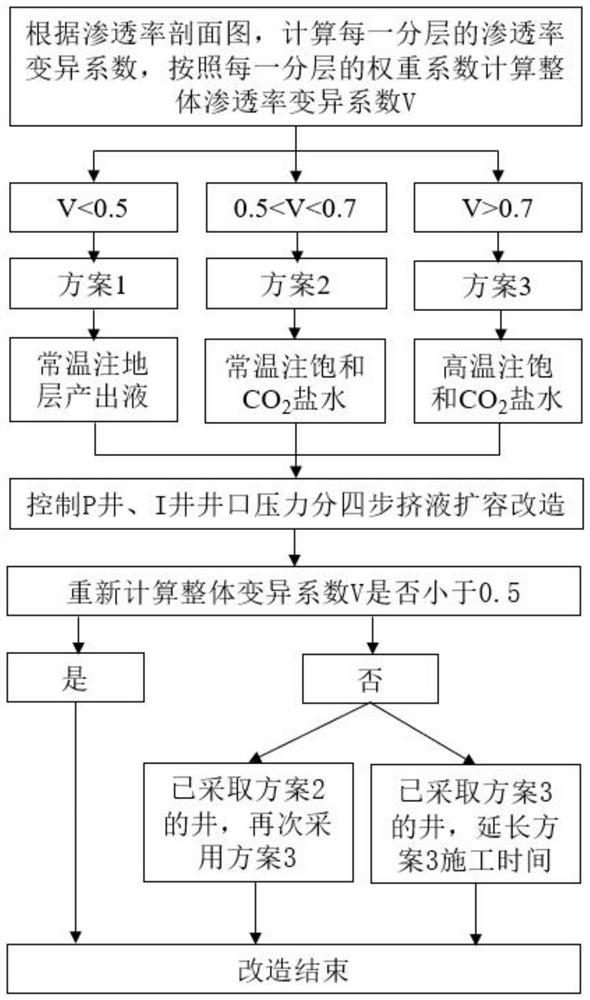

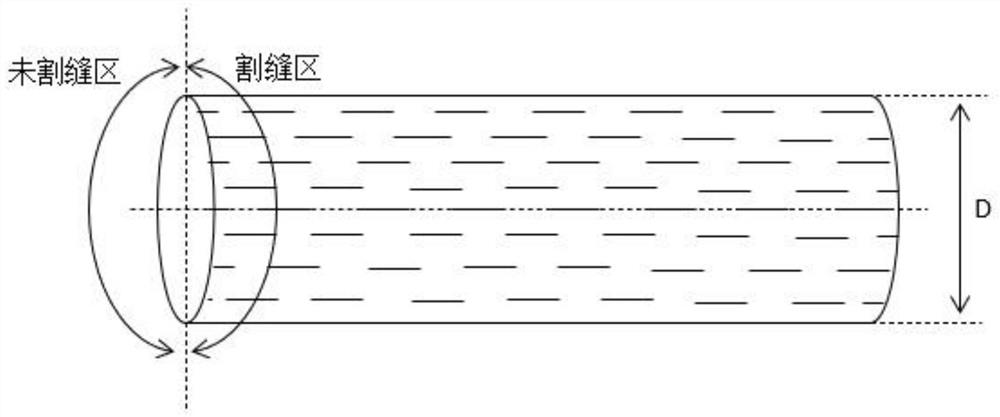

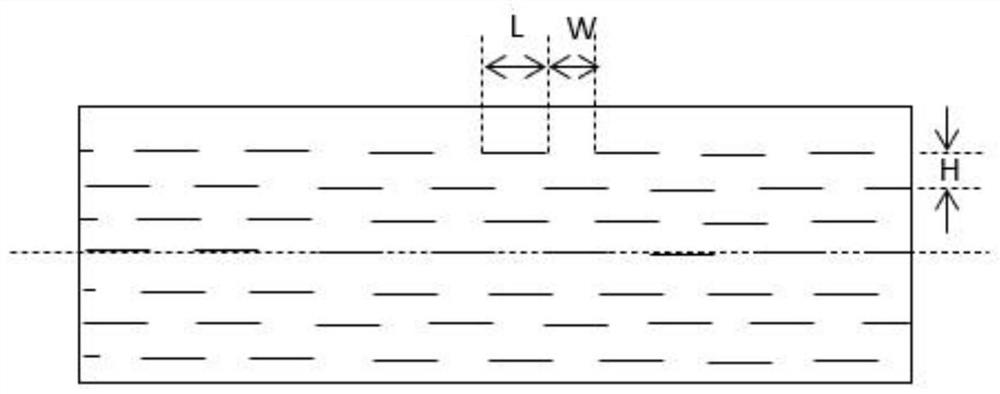

Method for improving permeability of oil sand reservoir by squeezing saturated CO2 brine

ActiveCN113266333AHigh porosityImprove permeabilityFluid removalOther gas emission reduction technologiesPhysicsSaline water

The invention relates to a method for improving the permeability of an oil sand reservoir by squeezing saturated CO2 brine. The method comprises the following steps of calculating the overall permeability variable coefficient of a permeability profile, and reasonably selecting conventional water injection, injecting saturated CO2 brine at normal temperature and injecting CO2 saturated brine at high temperature; calculating a permeability improvement coefficient, and drawing a relationship between the initial permeability and the permeability improvement coefficient; reasonably controlling the pressure of the wellhead to gradually and slowly squeeze the saturated CO2 brine into the reservoir; recalculating the overall permeability variation coefficient, and when the overall variation coefficient of the stratum is reduced to be less than 0.5, determining that the transformation succeeds; and if the variable coefficient of the overall permeability of the stratum is still larger than 0.5, injecting CO2 saline water again at high temperature for 24 hours or prolonging the injection time by 2 days. On the premise of not influencing the traditional liquid extrusion expansion effect, the CO2 solution selectively corrodes argillaceous components, the permeability heterogeneity in the borehole direction is weakened while the overall permeability of a reservoir is increased, and therefore it is guaranteed that a steam cavity is evenly expanded in the borehole direction, the crude oil yield is increased, and the crude oil recovery rate is increased.

Owner:NORTHWEST UNIV

Projector, heat dissipation module, and heat dissipation fin set

ActiveUS10281807B2Improve cooling efficiencySpeed up heat convectionProjectorsInsulated cablesComputer moduleEngineering

A projector includes a casing, an optical engine module, and a heat dissipation module. The optical engine module is disposed in the casing. The heat dissipation module is disposed in the casing and includes a heat dissipation fin set. The heat dissipation fin set includes at least one heat dissipation fin and at least one turbulent structure. The heat dissipation fin has a surface. The surface includes a first turbulent region and a second turbulent region. The first turbulent region is adjacent to the second turbulent region. The turbulent structure is disposed at least one of the first turbulent region and the second turbulent region, and the turbulent structure protrudes from the surface. An opening is formed between a top end of the turbulent structure and the surface.

Owner:CORETRONIC

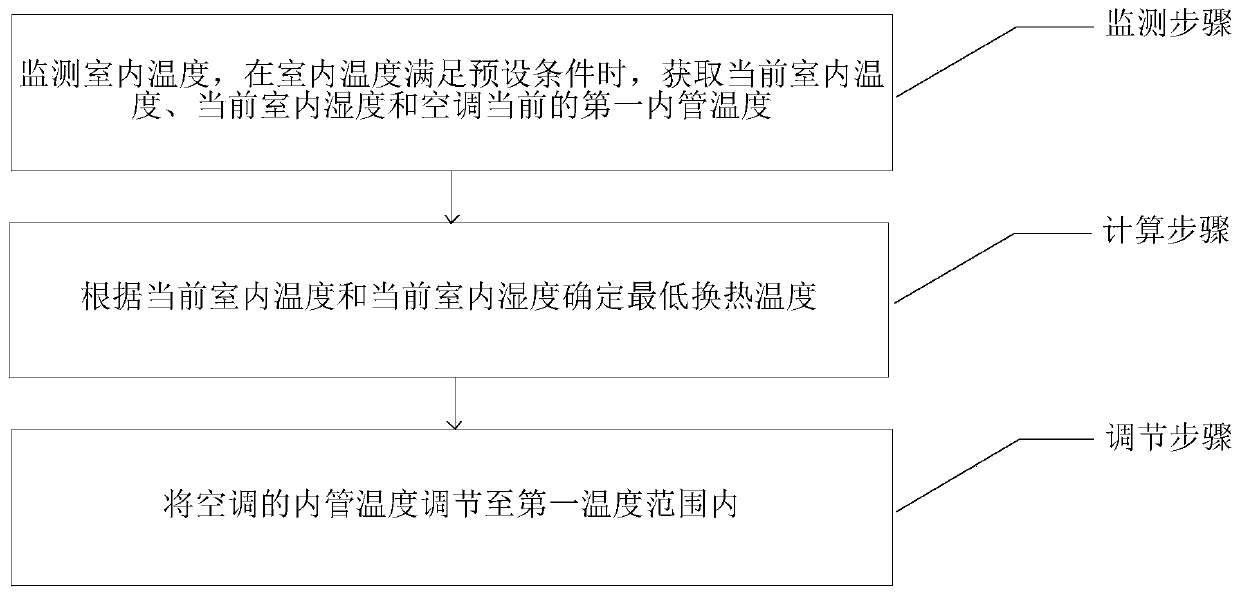

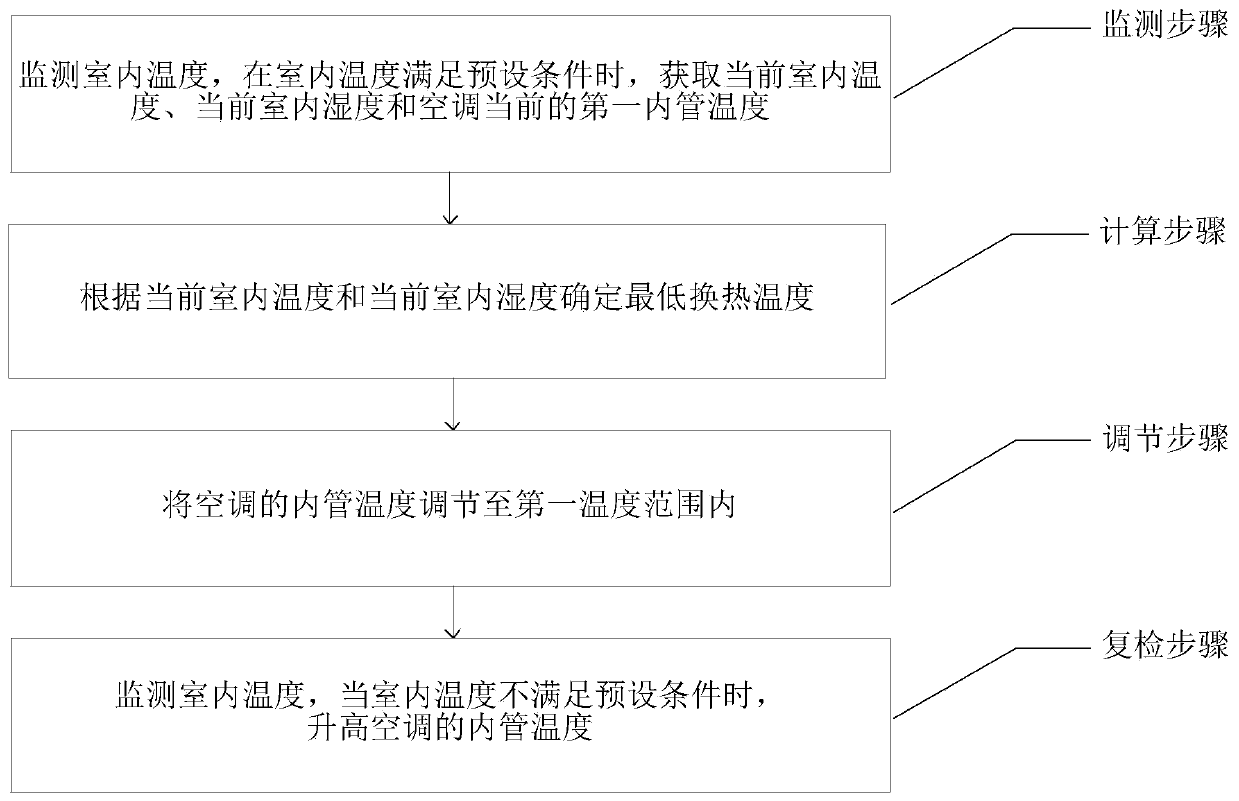

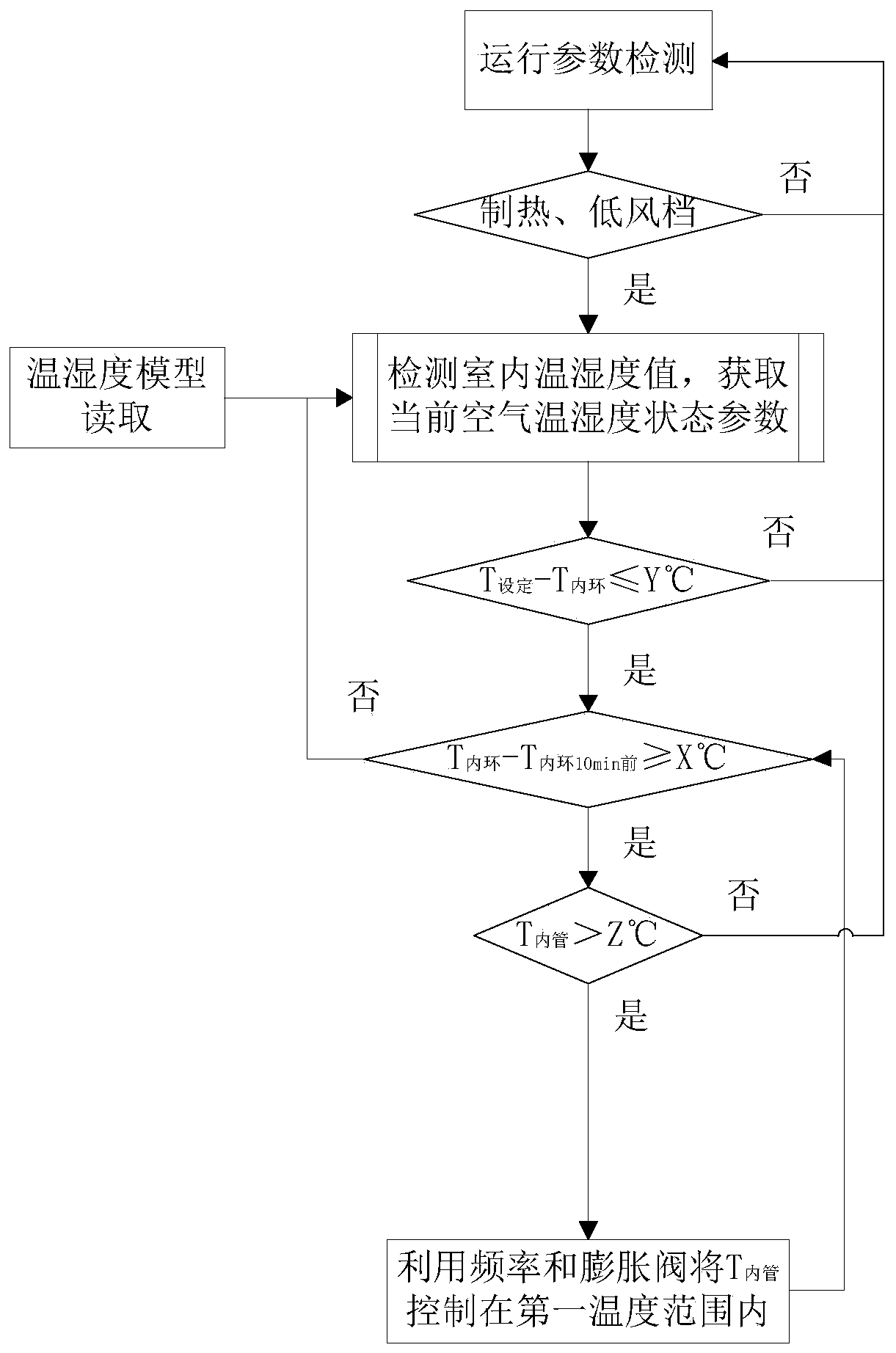

Air conditioner control method and device, and air conditioner

ActiveCN109945434AHigh densitySpeed up heat convectionMechanical apparatusSpace heating and ventilation safety systemsEngineeringWind speed

The invention provides air conditioner control method and device, and an air conditioner. The control method is applied when the air conditioner is at a low-wind-speed heating module and comprises thesteps of monitoring: monitoring the indoor temperature, acquiring the current indoor temperature, the current indoor humidity and the current first inner pipe temperature of the air conditioner whenthe indoor temperature meets the preset condition, wherein the preset condition comprises: the current indoor temperature is at least x DEG C higher than the indoor temperature before the first duration; calculating: determining the lowest heat exchange temperature according to the current indoor temperature and the current indoor humidity, wherein the lowest heat exchange temperature is the innerpipe temperature required for maintaining the current indoor temperature; and regulating: regulating the inner pipe temperature of the air conditioner to be within a first temperature range, whereinthe first temperature is larger than the lowest heat exchange temperature and smaller than the first inner pipe temperature. By utilizing an air thermal physics characteristic, heat convection betweenupper-layer air and lower-layer air indoors is improved, the room air is uniform, and meanwhile, the heat demand can be met.

Owner:GREE ELECTRIC APPLIANCES INC

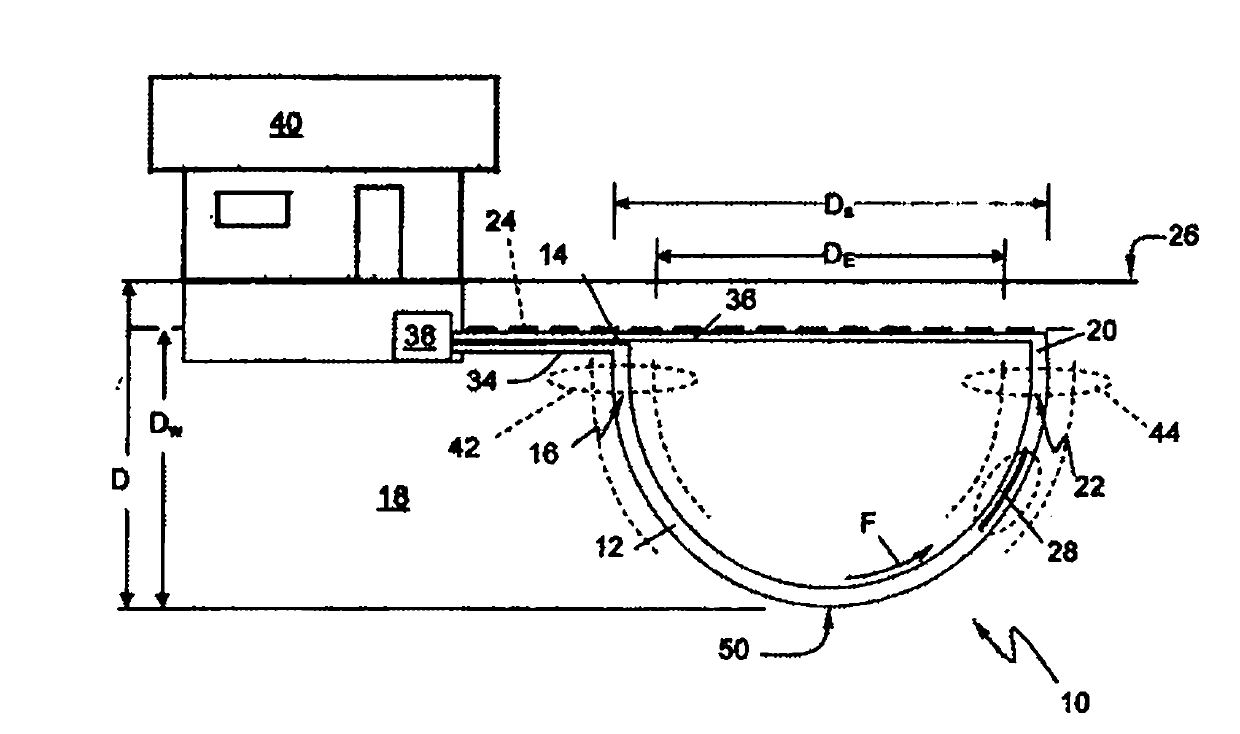

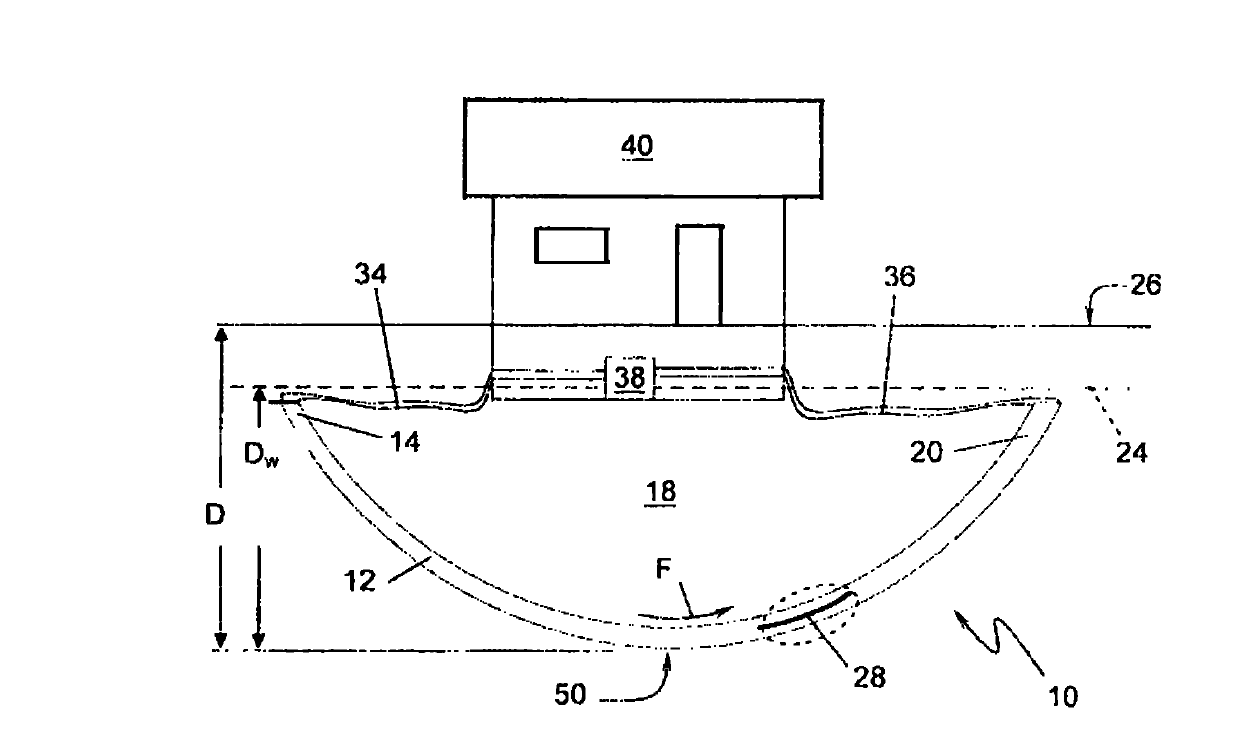

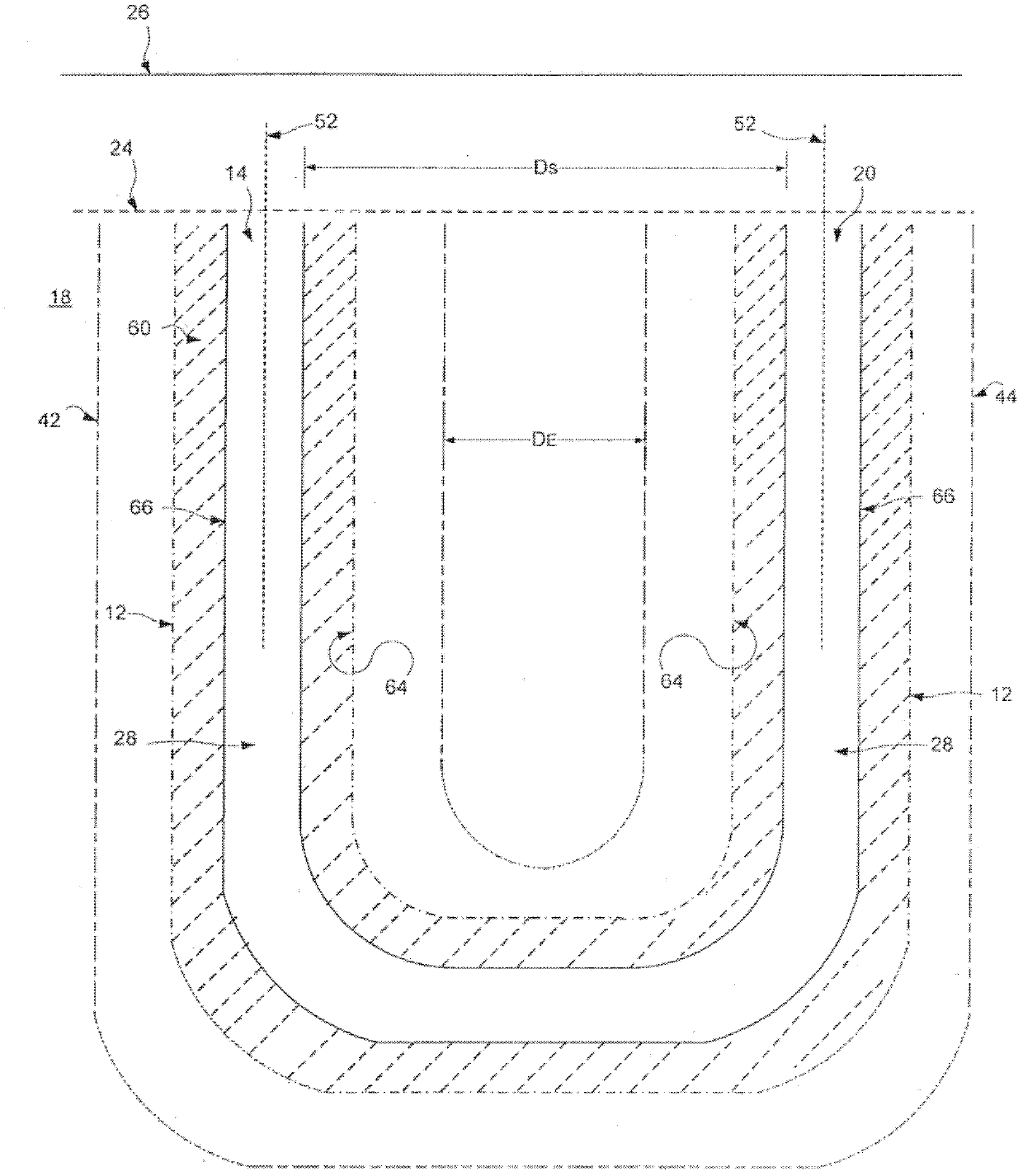

Subterranean continuous loop heat exchanger, method of manufacture and method to heat, cool or store energy with same

InactiveCN102483271ASpeed up heat convectionHigh heat conversion efficiencyCollector components/accessoriesHeat pumpsEngineeringHeat pump

A subterranean continuous loop heat exchanger is disclosed having a borehole including an entrance at a first end and an exit at a second end and a conduit for a fluid. A direction of fluid flow relative to the borehole is unidirectional, and a major length of the borehole is non-horizontal. The entrance and the exit are separated by a predetermined distance and a first thermal envelope at the entrance and a second thermal envelope at the exit are substantially independent. The conduit is positioned in at least a portion of the borehole and in operational connection to supply and return lines for connection to a ground sourced heat pump or to a heat exchanger system. Also disclosed are methods of constructing a subterranean continuous loop heat exchanger having at least one continuous borehole and a method of regulating a temperature in a structure with a system that includes the subterranean continuous loop heat exchanger.

Owner:ANZOIC ENERGY

Electronic device

InactiveCN101667056AAvoid local accumulationEffective Heat Exchange MechanismDigital data processing detailsAirflowEngineering

The invention discloses an electronic device which comprises a sealing shell, a heat conducting element and a fan, wherein the heat conducting element penetrates the sealing shell, and the fan is arranged in the sealing shell. The fan generates an air flow which flows in the sealing shell and flows through the heat conducting element. Air in the sealing shell is driven to flow by the fan arrangedin the sealing shell so as to conduct heat out of the shell through the heat conducting element which penetrates the sealing shell, thus local accumulation of the heat in the sealing shell can be avoided. Moreover, heat convection is also reinforced so as to improve the efficiency of heat exchange with outside cold air, thus the invention provides a more effective heat exchange mechanism which enables the electronic device with the sealing shell to operate more stably.

Owner:PEGATRON

Operating theater transfusion blood warming device

PendingCN111388776AImprove heating efficiencyImprove heating effectMedical devicesBlood transfusionOperating theatresEngineering

The invention discloses an operating theater transfusion blood warming device which comprises a warming tank, wherein the upper surface of the warming tank is covered by a cover plate; a micro servo motor, a temperature sensor and a single chip microcomputer are fixedly arranged on the lower surface of the cover plate; a main occlusion wheel is fixedly connected with the output shaft of the microservo motor of the warming tank; a water drainage valve is fixedly arranged on the lower surface of the warming tank; a transmission shaft is arranged in the middle in the warming tank in a limited rotation manner; a secondary occlusion wheel is fixedly connected with the upper surface of the transmission shaft; the secondary occlusion wheel is meshed with the main occlusion wheel; a first transmission sleeve block is fixedly connected with the shaft arm of the transmission shaft; and first transmission arms are rotationally connected with the periphery of the first transmission sleeve block through hinge pines. Due to cooperation of the structures, the blood transfusion bag warming efficiency and effect can be improved, the temperature for warming a blood transfusion bag can be monitored,the temperature can be prevented from being too high, and the activity of effective components of blood can be ensured.

Owner:郭维玲

Computer hard disk

InactiveCN107783613AImprove the anti-seismic abilityPlay a bufferReducing temperature influence on carrierUndesired vibrations/sounds insulation/absorptionResonanceMetal

The invention discloses a computer hard disk. The computer hard disk comprises a hard disk shell, a mounting board and mounting lug seats, wherein four corners of the outer side of the hard disk shellare fixedly connected with the mounting lug seats; an air inlet is formed in the central position of the bottom part of the hard disk shell; a heat dissipation box body is arranged at the bottom partof the hard disk shell outside the air inlet; a cooling fan is arranged on the bottom end of the inner part of the heat dissipation box body; a metal inner shell is arranged at the inner part of thehard disk shell through a supporting rod; cooling fins are uniformly arranged on the outer side wall of the metal inner shell; the mounting board is movably arranged in the metal inner shell; a coverboard is arranged on one end, which is far away from the metal inner shell, of the mounting board. According to the computer hard disk disclosed by the invention, by uniformly arranging the mounting lug seats which are respectively formed by a first lug board, two damping springs and a second lug board at the periphery of the hard disk shell, the resonance resistance of a hard disk can be effectively increased; meanwhile, during collision, the hard disk can be well buffered and protected, and the damage caused by collision and vibration can be avoided.

Owner:庞锦钊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com