Method for improving permeability of oil sand reservoir by squeezing saturated CO2 brine

A permeability and CO2 technology, applied in earth-moving drilling, wellbore/well components, production fluid, etc., can solve the intensification of permeability heterogeneity, increase reservoir permeability, weaken permeability heterogeneity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

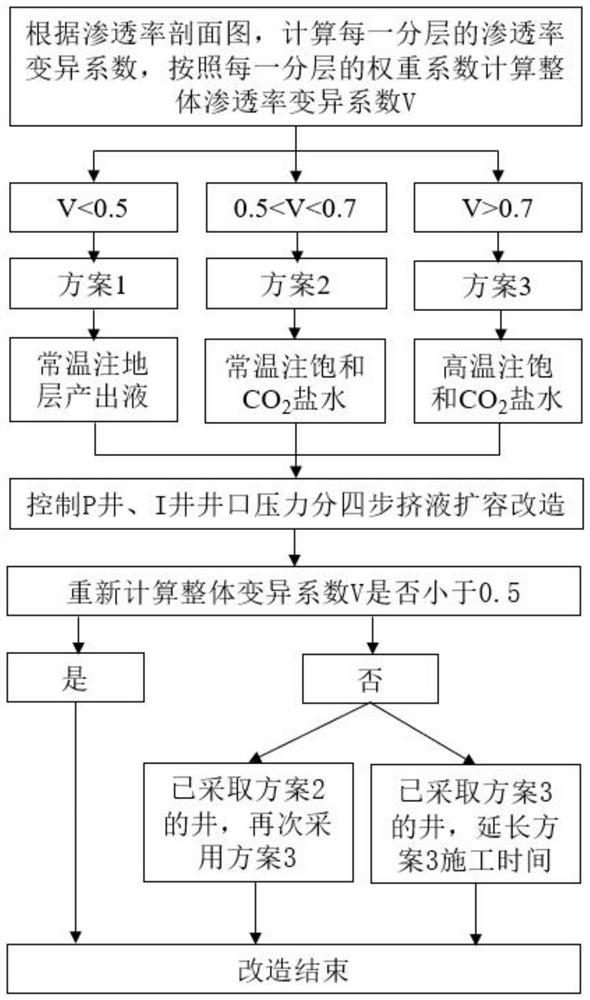

[0084] According to the present invention by squeezing saturated CO 2 Another embodiment of the method for improving the permeability of oil sand reservoirs with brine, its modification steps, working principle, beneficial effect, etc. are the same as those of Embodiment 1, the difference is the coefficient of variation of the permeability of the 12 layers: from top to bottom The coefficients of variation in permeability of the 12 layers are 0.35, 0.22, 0.35, 0.46, 0.34, 0.24, 0.58, 0.49, 0.38, 0.56, 0.77, and 0.43, respectively. The weight coefficients of the permeability variation coefficients of the 12 layers from top to bottom are 1 / 45, 2 / 45, 1 / 15, 4 / 45, 1 / 9, 1 / 9, 4 / 45, 1 / 15, 4 / 45, 1 / 9, 1 / 9, 4 / 45. The coefficient of variation of the overall permeability can be calculated to be 0.4502.

[0085] Because the overall permeability coefficient of variation is less than 0.5, conventional water injection is used for capacity expansion. In this example, wells I and P use conven...

Embodiment 3

[0087] According to the present invention by squeezing saturated CO 2 Another embodiment of the method for improving the permeability of oil sand reservoirs with brine, its modification steps, working principle, beneficial effect, etc. are the same as those of Embodiment 1, the difference is the coefficient of variation of the permeability of the 12 layers: from top to bottom The coefficients of variation in permeability of the 12 layers are 0.75, 0.82, 0.65, 0.86, 0.64, 0.84, 0.58, 0.79, 0.68, 0.86, 0.77, and 0.69, respectively. The weight coefficients of the permeability variation coefficients of the 12 layers from top to bottom are 1 / 45, 2 / 45, 1 / 15, 4 / 45, 1 / 9, 1 / 9, 4 / 45, 1 / 15, 4 / 45, 1 / 9, 1 / 9, 4 / 45. The coefficient of variation of the overall permeability can be calculated to be 0.7444.

[0088] Because the overall permeability coefficient of variation is greater than 0.7, CO injection at high temperature 2 Saturated saline expansion.

[0089] When the temperature incre...

Embodiment 4

[0092] According to the present invention by squeezing saturated CO 2 Another embodiment of the method for improving the permeability of oil sand reservoirs with brine, its modification steps, working principles, beneficial effects, etc. are the same as those of Embodiment 1, the difference is the matching relationship of various parameters in the modification steps:

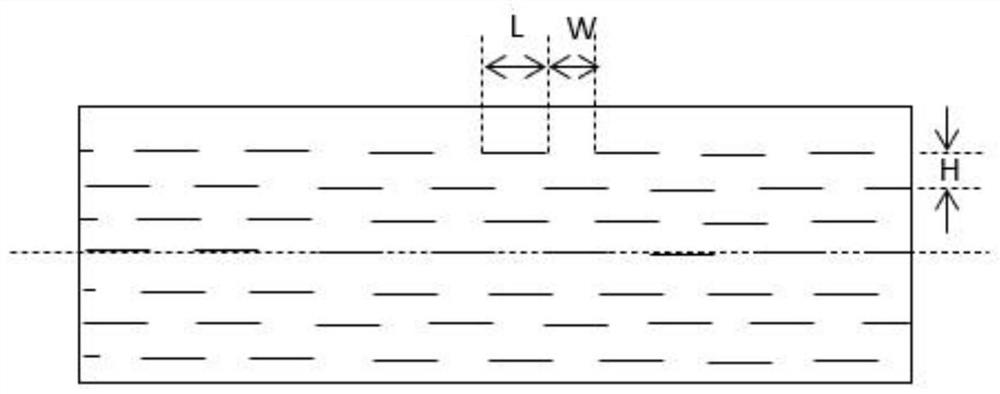

[0093] This example is a SAGD well in Fengcheng Oilfield, Xinjiang. Well I has a vertical depth of 372m, well P has a vertical depth of 377m, and the fracture pressure gradient of the reservoir formation is 0.017MPa / m. Calculate the maximum wellhead pressure P for liquid extrusion construction max出口 = 2.2MPa. Wells I and P were squeezed in four stages: in the first stage, the wellhead pressures of the two wells were loaded from 0 to 0.55 MPa within 50 minutes, and the pressure of 0.55 MPa was maintained for 12 hours; in the second stage, the wellhead pressures of the two wells were from Load from 0.55MPa to 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com