Subterranean continuous loop heat exchanger, method of manufacture and method to heat, cool or store energy with same

A heat exchanger, continuous loop technology, used in the field of transferring and/or storing thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

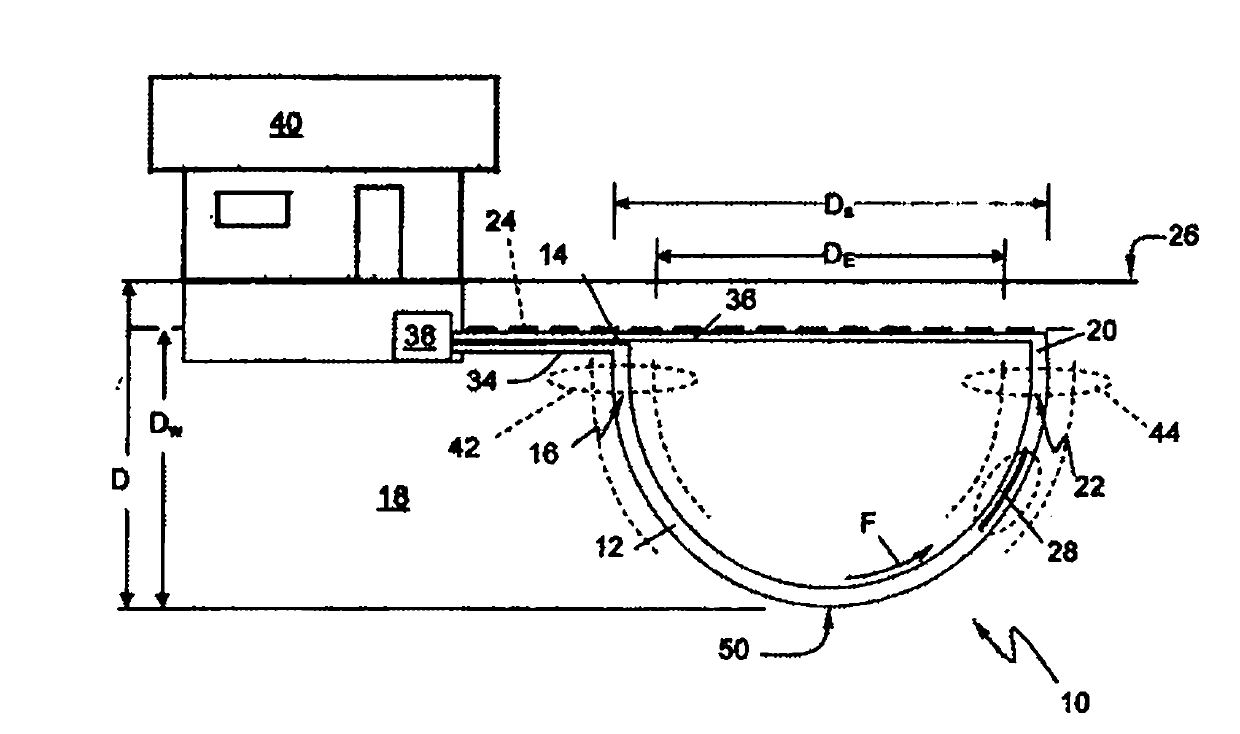

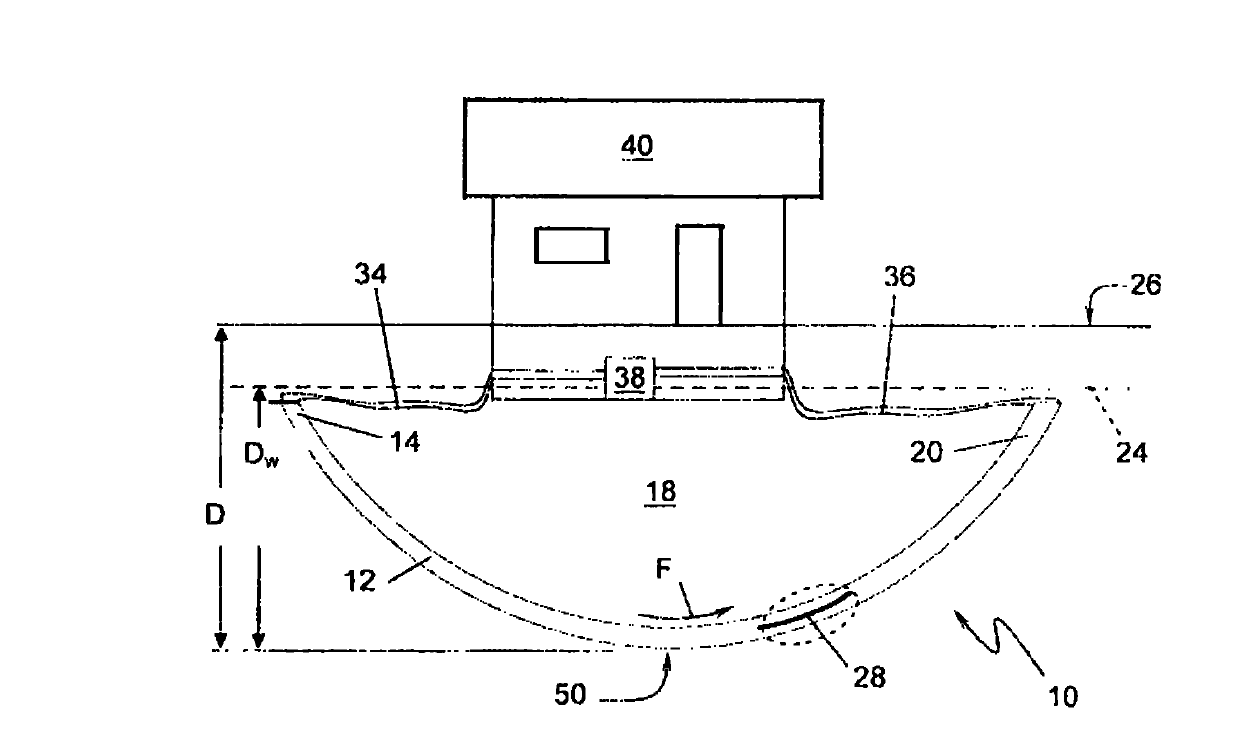

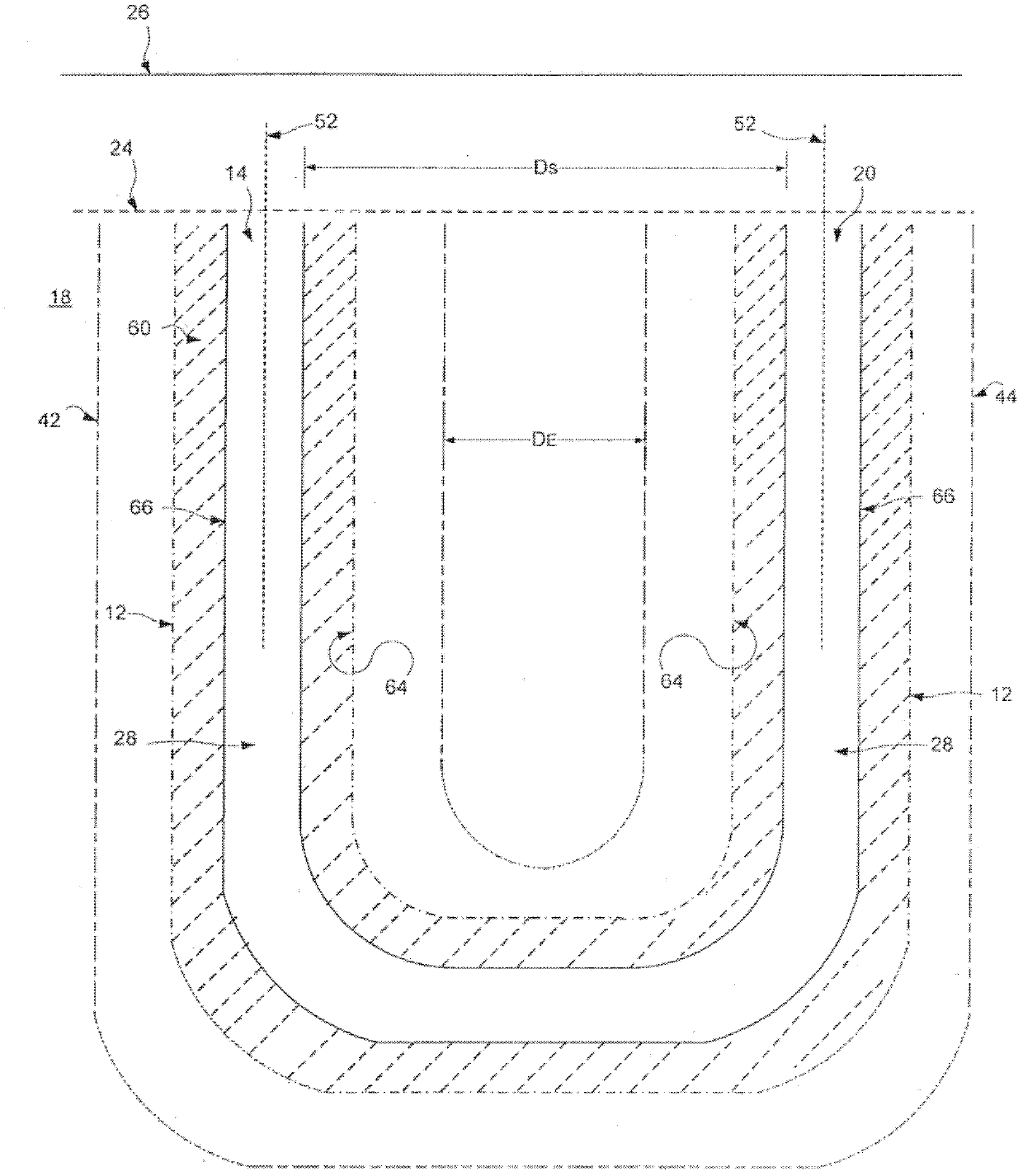

[0048] figure 1 An example embodiment of a subterranean continuous loop heat exchanger is shown having a borehole drilled within a continuous loop through the earth's surface. The subterranean continuous loop heat exchanger 10 includes a borehole 12 including an inlet 14 at a first end 16 and an outlet 20 at a second end 22 where the borehole 12 is at a first Open at a location, such as within the formation 18 for a buried system or on the surface of the formation 18 for a ground system, i.e. on the surface, and at a second end 22, the borehole 12 is open at a second location in the formation 18, such as Openings are made in the formation 18 for buried systems or on the surface of the formation 18 for surface systems, ie on the surface. The majority of borehole 12 is located sufficiently deep below surface level 24 that is susceptible to seasonal temperatures, ie, typically between two and eight feet below surface 26 . A conduit 28 (shown in cross-section) for fluid is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com