Strip heatsink

a heatsink and strip technology, applied in semiconductor devices, lighting and heating apparatus, semiconductor devices, etc., can solve the problems of insufficient heat conduction, insufficient surface area, and inability to dissipate heat of electronic components inside the computer, so as to improve the efficiency of conduction and convection, and increase the heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

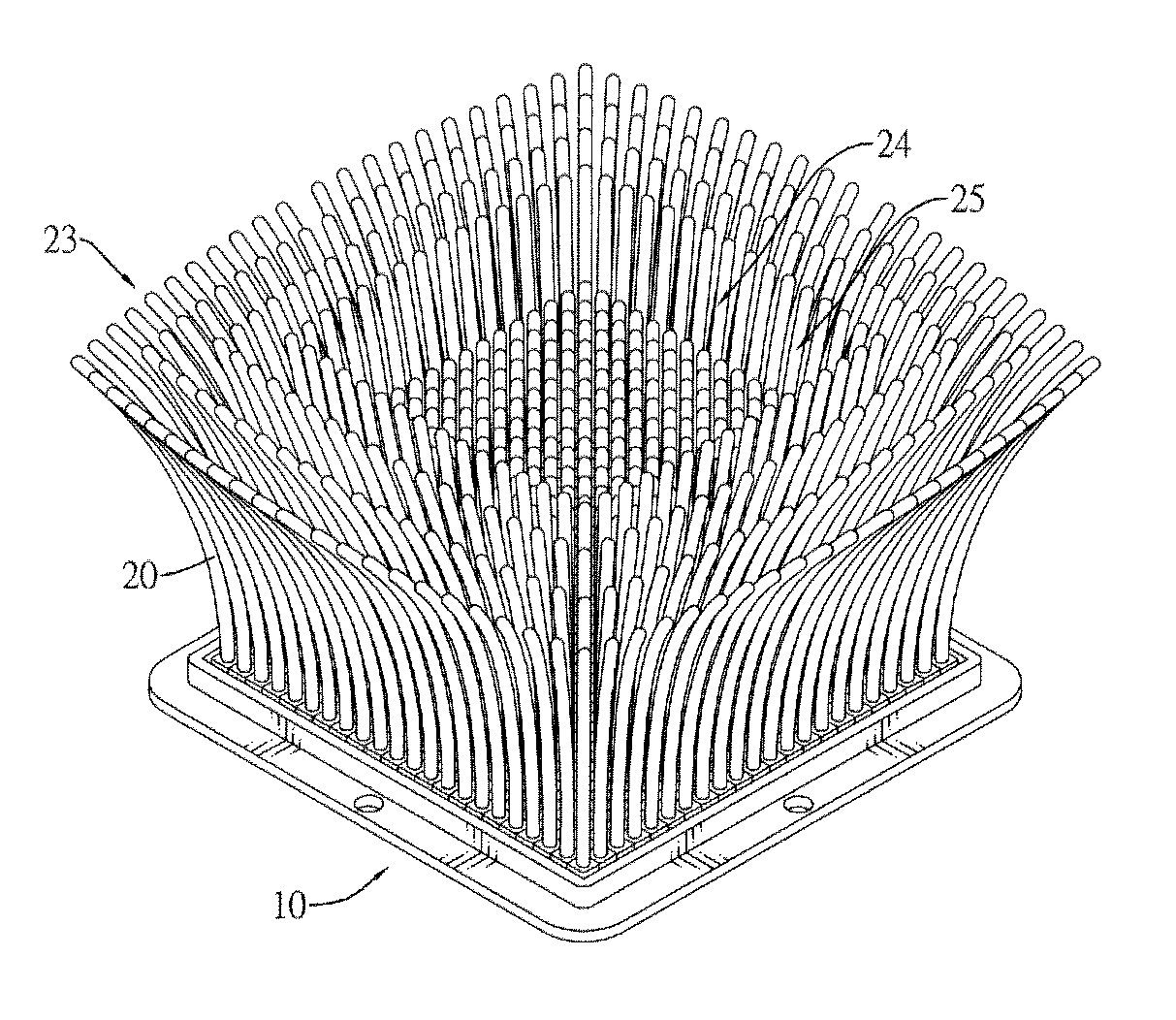

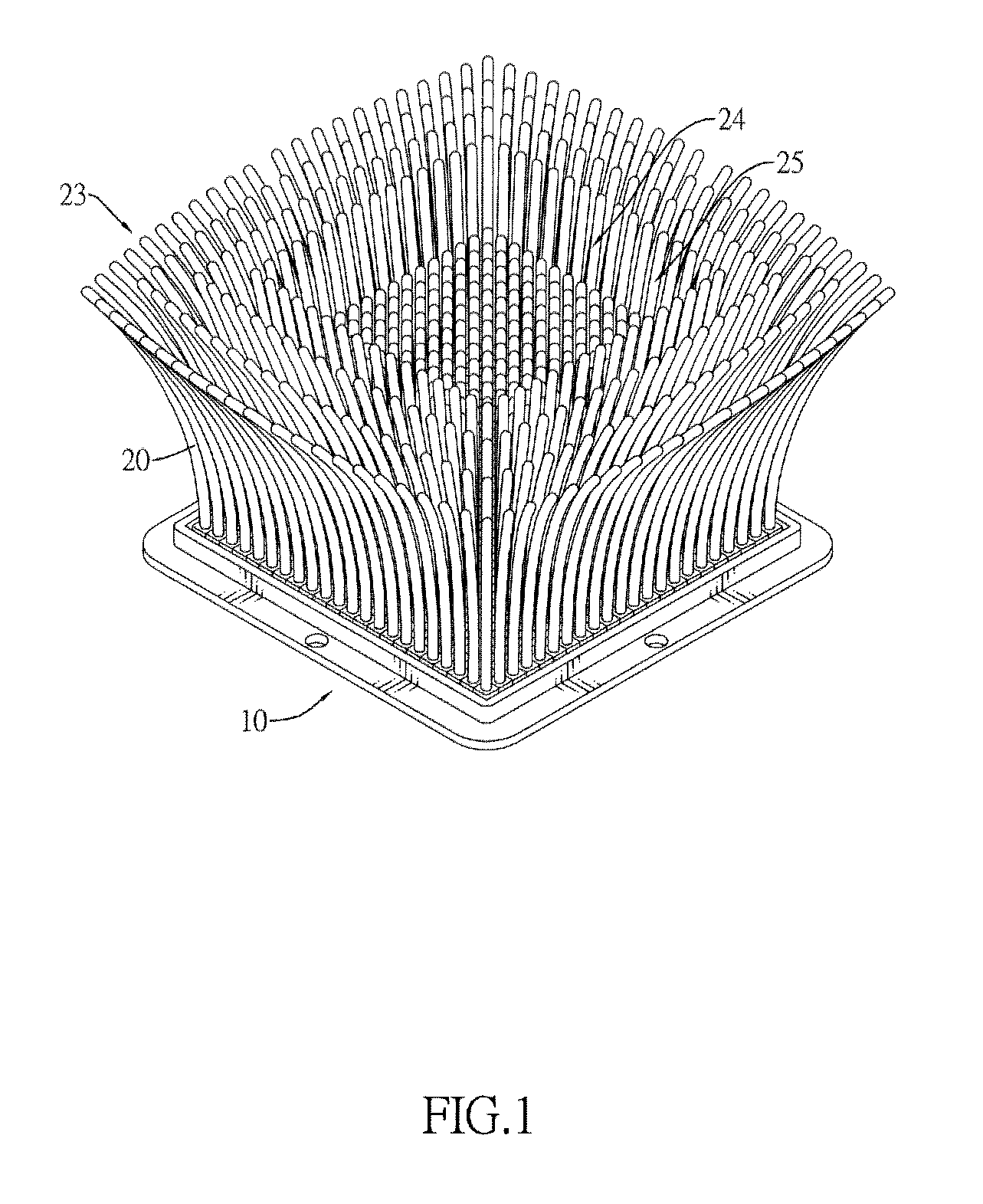

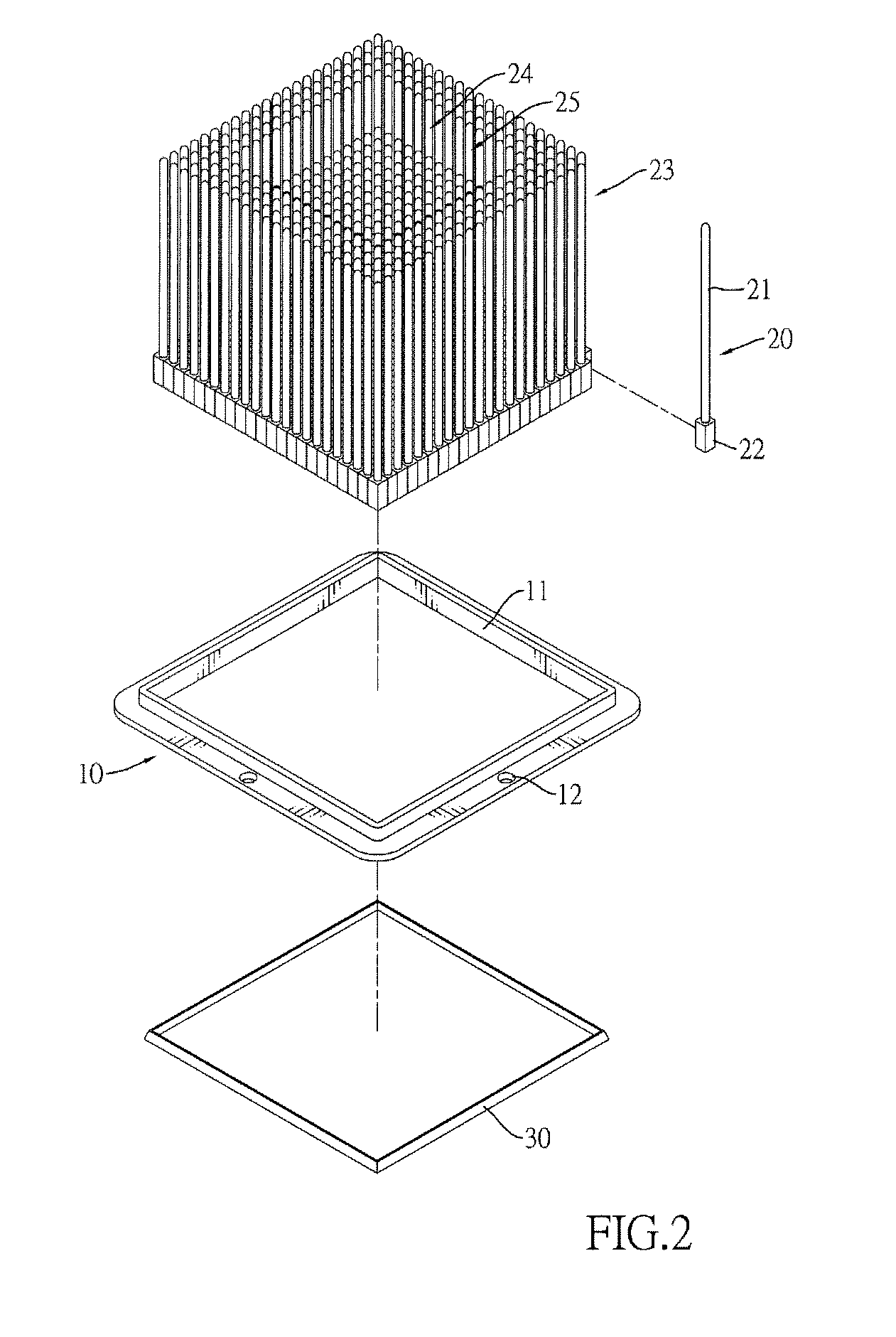

[0019]With reference to FIGS. 1 and 2, a strip heatsink in accordance with the present invention comprises a base 10, a periphery dissipating assembly 23, a central dissipating assembly 24 and a fastening loop 30.

[0020]With reference to FIGS. 2 to 4, the base 10 has a mounting hole 11 formed through the base 10. In a preferred embodiment, the mounting hole 11 is rectangular. Besides, the base 10 has multiple connecting holes 12. The connecting holes 12 are formed through the base 10 and are arranged surrounding the mounting hole 11.

[0021]With reference to FIGS. 1 and 3, the central dissipating assembly 24 is surrounded by the periphery dissipating assembly 23. Each dissipating assembly 23, 24 comprises multiple dissipating strips 20. The dissipating strips 20 are mounted securely in the mounting hole 11 of the base 10. Each dissipating strip 20 has a strip part 21 and a mounting part 22. The strip part 21 has a top end. The mounting part 22 is formed on a bottom of the strip part 21...

second embodiment

[0027]The mounting part 22 of the dissipating strips 20 may be formed in different shapes. In a second embodiment as shown in FIGS. 5 and 6, the cross section of the mounting part 22A of each dissipating strip 20A is hexagonal, thereby also making the dissipating strip 20A arranged in order and forming the interval between the strip parts 21 A of the dissipating strip 20A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com