Light-emitting diode structure

A technology of light-emitting diodes and bases, which is applied to semiconductor devices of light-emitting elements, light sources, cooling/heating devices of lighting devices, etc., and can solve problems such as small contact area, affecting the luminous efficiency and life of light-emitting diodes, and poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific embodiments with reference to the accompanying drawings.

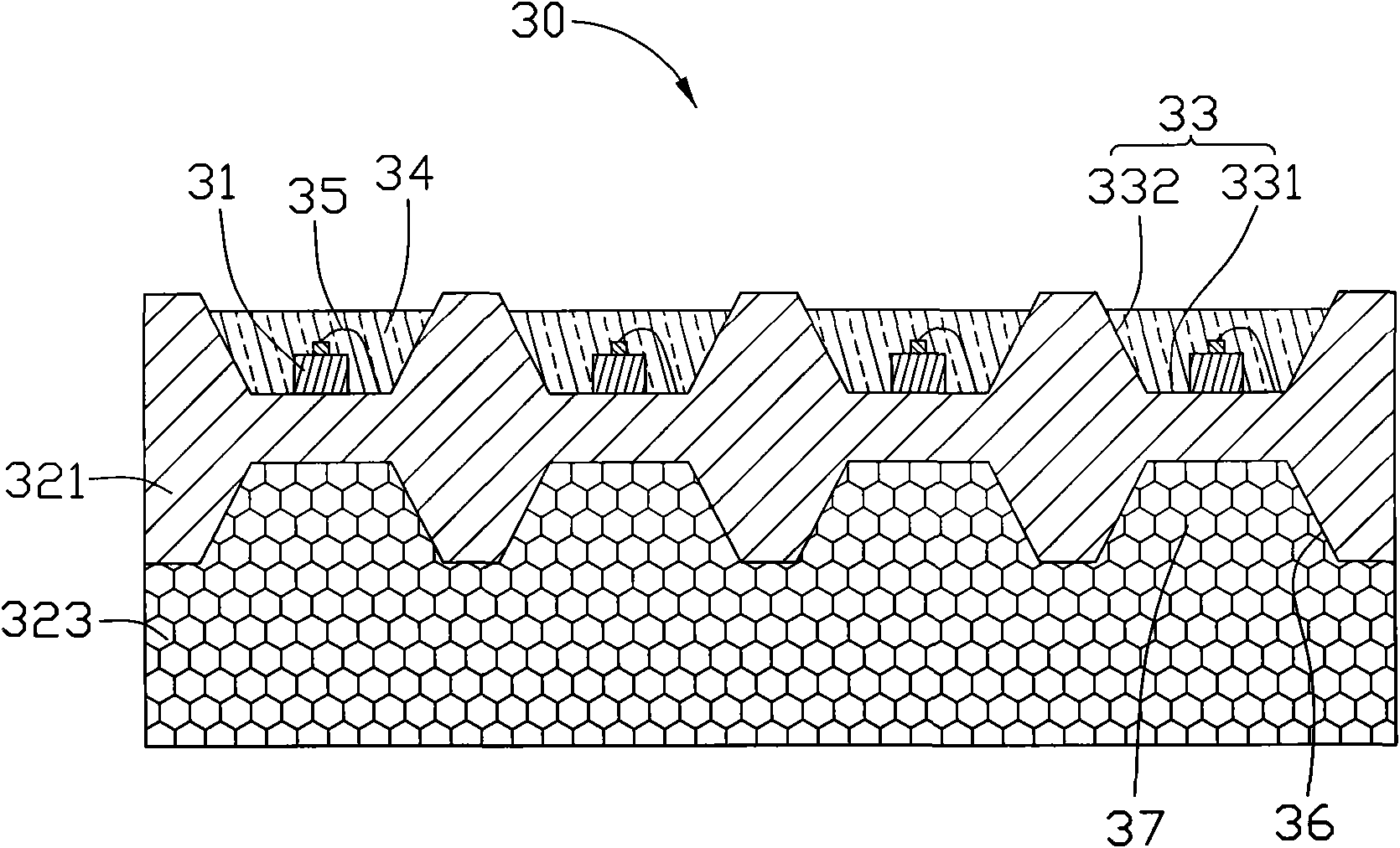

[0011] figure 2 Shown is a schematic diagram of the light emitting diode structure in an embodiment of the present invention. The light emitting diode structure 30 includes a base 321, a plurality of light emitting diode chips 31 on the base 321, packages 34 respectively fixing the light emitting diode chips 31 on the base 321, and a heat sink under the base. Board 323.

[0012] The upper surface of the base 321 is recessed downwards to form several bowl-shaped packaging cavities 33 . Each packaging cavity 33 has a horizontal bottom surface 331 and side surfaces 332 inclined upwards and outwards from the bottom surface 331 . The light-emitting diode chips 31 are arranged on the bottom surface 331 of the package cavity 33 in one-to-one correspondence, and are electrically connected to the conductive components (not shown) on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com