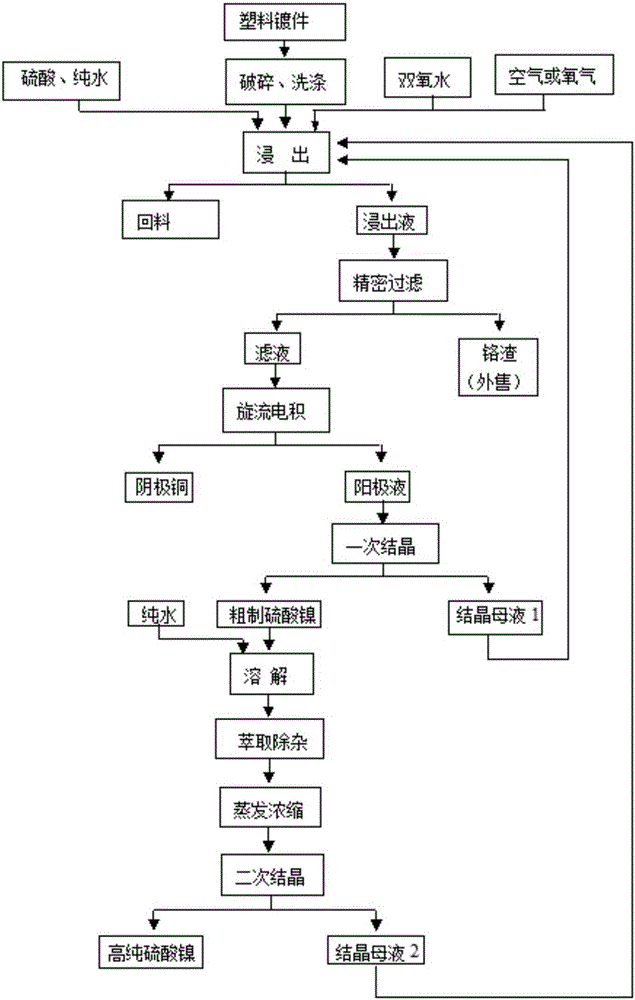

Method of recovering copper and nickel from plastic plated parts

A technology for recycling copper and plated parts, which is applied in the field of metallurgy, can solve the problems of incomplete crystal form, influence on nickel electrowinning, secondary pollution, etc., and achieve the effects of small influence, accelerated metal oxidation, and improved reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Weigh 1000 kg of the plastic plated parts after crushing and washing, wherein the contents of copper and nickel are 10% and 5% respectively. Add 1.8m into the reaction tank 3 Pure water, then slowly add 400kg of sulfuric acid with a mass concentration of 98%, and 50kg of hydrogen peroxide with a concentration of 20.2%. After 1 hour of reaction, turn on the circulation pump and the microbubble generator to blow in air and then leaching for 12 hours. The injection speed of the microbubble generator is 20m / s. After the reaction is completed, the leachate is filtered to obtain a leachate of 2.0m 3 It contains 49.5g / L copper, 24.7g / L nickel and 78.0g / L sulfuric acid. After the leaching solution is filtered by a precision filter, copper electrowinning is carried out in a cyclone electrolytic cell, and the output of cathode copper is 96.2kg. The anolyte contains 1.2g / L copper, 24.7g / L nickel, and 154.0g / L sulfuric acid; the anolyte is frozen to At -15°C, nickel was precipit...

Embodiment 2

[0050] Weigh 1000 kg of the plastic plated parts after crushing and washing, wherein the contents of copper and nickel are 10% and 5% respectively. Add 1.8m into the reaction tank 3 Pure water, then slowly add 400kg of sulfuric acid with a mass concentration of 98% and 50kg of hydrogen peroxide with a mass concentration of 25.0%, the leaching oxidant is hydrogen peroxide and oxygen, and the industrial pure oxygen is directly connected to the microbubble generator to make the oxygen bubble into the tank in the form of microbubbles Inside, the jet velocity of the microbubble generator is 20m / s. After 1 hour of reaction, turn on the circulation pump and the microbubble generator to blow in oxygen and then leaching for 8 hours. After the reaction is completed, the leachate is filtered to obtain a leachate of 2.0m 3 It contains 50.1g / L copper, 24.88g / L nickel and 76.0g / L sulfuric acid. The leaching solution was filtered by a precision filter and then used a cyclone electrolytic ...

Embodiment 3

[0052] Weigh 1000 kg of the plastic plated parts after crushing and washing, wherein the contents of copper and nickel are 10% and 5% respectively. Add 1.8m into the reaction tank 3 Pure water, then slowly add 400kg of sulfuric acid with a mass concentration of 98%, 50kg of 30.0% hydrogen peroxide, and after 1 hour of reaction, turn on the circulation pump and the microbubble generator to blow in air and then leaching for 12 hours. The injection speed of the microbubble generator is 15m / s. After the reaction is completed, the leachate is filtered to obtain a leachate of 2.0m 3 It contains 49.5g / L copper, 24.7g / L nickel and 78.0g / L sulfuric acid. The leaching solution was filtered by a precision filter and then put into the electrowinning tank for copper electrowinning to produce 93.2kg of cathode copper, 1.7g / L of copper, 24.51g / L of nickel, and 156.0g / L of sulfuric acid in the anolyte; the anolyte was frozen to At -15°C, nickel was precipitated in the form of nickel sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com