A kind of high heat resistance organic flux and its application

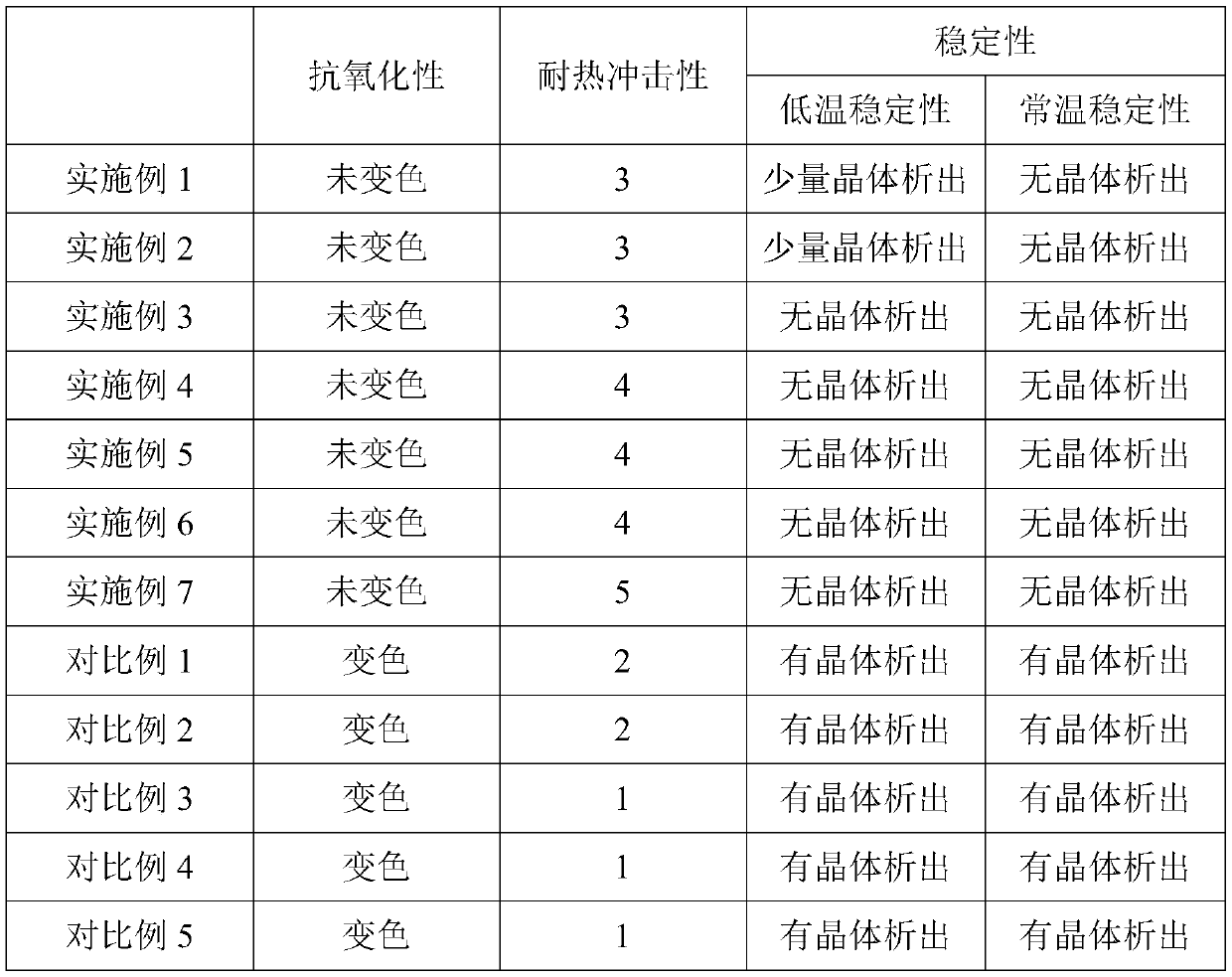

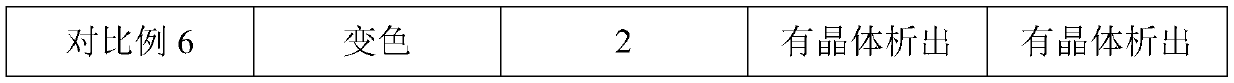

A solder-preserving agent, an organic technology, applied in the field of high heat-resistant organic solder-preserving agents, can solve the problems of discoloration or cracks, affecting the solderability and reliability of the copper surface, shortening the service life of the organic soldering agent, etc. The effect of good oxidation resistance and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] As a preferred technical solution of the present invention, the preparation method of the described imidazo[1,5-a]pyrido[2,3-E]pyrazinone at least comprises the following steps:

[0045] Dissolve 0.1 mmol of 3-fluoro-2-nitropyridine and 0.1 mmol of imidazole in 10 mL of acetonitrile, add 0.4 mmol of potassium carbonate, stir at room temperature for 72-96 h; neutralize with 1 mol / L hydrochloric acid After concentrating to pH=7, add 3mL of methanol and 50mgPd / C to the reaction liquid, and stir at room temperature for 2h with hydrogen gas, then add 1mL of 10% LiOH aqueous solution, stir at room temperature for 5h, after concentrating, add 2mL of DMF, stir to dissolve; 0.12mmol of N,N'-carbonyldiimidazole was dissolved in 1mL of DMF, then added dropwise to the reaction solution, heated to reflux for 1h, filtered and purified to obtain imidazo[1,5-a]pyrido[2,3-E] pyrazinone.

[0046] 3-Fluoro-2-nitropyridine, CAS: 54231-35-5, was purchased from Hangzhou Jieheng Chemical Co....

Embodiment 1

[0099] Example 1 provides a high heat-resistant organic solder flux, which includes at least the following components in parts by weight: 1 part of aryl-substituted imidazole, 0.1 part of imidazopyridopyrazinone, 10 parts of formic acid, 50 parts of propionic acid 1 part, 10 parts of 2-(2-methoxyethoxy) acetic acid, 1 part of metal compound, and 1000 parts of deionized water.

[0100] The aryl-substituted imidazole is 4-methyl-2,5-diphenylimidazole.

[0101] The imidazopyridopyrazinone is imidazo[1,5-a]pyrido[2,3-E]pyrazinone.

[0102] The preparation method of the imidazo[1,5-a]pyrido[2,3-E]pyrazinone at least comprises the following steps:

[0103] Dissolve 0.1 mmol of 3-fluoro-2-nitropyridine and 0.1 mmol of imidazole in 10 mL of acetonitrile, add 0.4 mmol of potassium carbonate, stir at room temperature for 72-96 h; neutralize with 1 mol / L hydrochloric acid After concentrating to pH=7, add 3mL of methanol and 50mgPd / C to the reaction liquid, and stir at room temperature ...

Embodiment 2

[0109] Example 2 provides a high heat-resistant organic solder flux, which includes at least the following components in parts by weight: 3 parts of aryl-substituted imidazole, 0.1 part of imidazopyridopyrazinone, 10 parts of formic acid, and 100 parts of propionic acid 1 part, 10 parts of 2-(2-methoxyethoxy) acetic acid, 1 part of metal compound, and 1000 parts of deionized water.

[0110] The aryl-substituted imidazole is 4-methyl-2,5-diphenylimidazole.

[0111] The imidazopyridopyrazinone is imidazo[1,5-a]pyrido[2,3-E]pyrazinone.

[0112] The metal compound is cuprous chloride.

[0113] The preparation method of the high heat-resistant organic solder flux is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com