Method for separating copper and arsenic from black copper mud

A technology of black copper slime and rich copper, applied in the field of metallurgy, can solve problems such as low leaching rate, and achieve the effects of lowering leaching temperature, high efficiency and shortening leaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

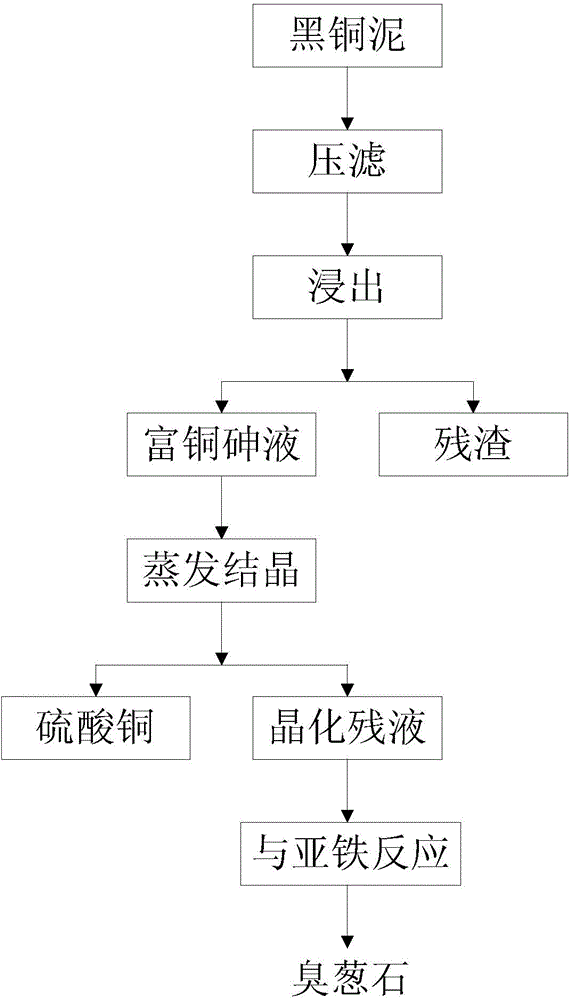

Image

Examples

Embodiment 1

[0042] The black copper slime is filtered by a filter press and is used for later use. The components of the filtered black copper slime include: 44.25wt% Cu, 22.37wt% As, 0.98wt% Sb, 1.28wt% Bi and the rest of Fe.

[0043] Add 200 g of filtered black copper mud to the reactor, then add 1500 mL of sulfuric acid solution with a concentration of 1.5 mol / L to the reactor, keep the temperature of the reactor at 55 ° C, and add 30 wt % peroxide dropwise at a constant speed to the reactor. Hydrogen solution 180mL, during the dropwise addition, the mixing system in the reactor was stirred at a stirring rate of 350r / min. After 1.5 hours, the hydrogen peroxide was added dropwise, and the mixed system in the reactor was separated from solid and liquid to obtain 2000 mL of copper-arsenic-rich liquid and residue. The content of Cu in the copper-arsenic rich solution is 0.044g / mL, and the content of As is 0.02g / mL. From this, it can be calculated that the leaching rates of copper and arse...

Embodiment 2

[0047] The black copper slime is filtered by a filter press and then used for later use. The components of the filtered black copper slime include: 48.75wt% Cu, 25.03wt% As, 0.81wt% Sb, 1.69wt% Bi and the balance Fe.

[0048] Add 200 g of filtered black copper mud to the reactor, then add 1200 mL of sulfuric acid solution with a concentration of 2 mol / L to the reactor, keep the temperature of the reactor at 60 ° C, and add 30 wt % hydrogen peroxide dropwise to the reactor at a constant speed Solution 120mL, during the dropwise addition, the mixing system in the reactor was stirred, and the stirring rate was 400r / min. After 1 hour, the dropwise addition of hydrogen peroxide was completed, and the mixed system in the reactor was subjected to solid-liquid separation to obtain 1500 mL of a copper-arsenic-rich liquid and a residue. The Cu content in the copper-arsenic-rich solution is 0.064g / mL, and the As content is 0.0309g / mL. From this, it can be calculated that the leaching ra...

Embodiment 3

[0052] The black copper slime is filtered through a filter press and used for later use. The filtered black copper slime includes: 53.29wt% Cu, 26.07wt% As, 0.71wt% Sb, 1.38wt% Bi and the balance Fe.

[0053] Add 200 g of filtered black copper mud to the reactor, then add 1000 mL of sulfuric acid solution with a concentration of 2.5 mol / L to the reactor, keep the temperature of the reactor at 65 ° C, and add 30 wt % peroxide dropwise to the reactor at a constant speed. Hydrogen solution 150mL, during the dropwise addition, the mixing system in the reactor was stirred, and the stirring rate was 300r / min. After 2 hours, the hydrogen peroxide was added dropwise, and the mixed system in the reactor was separated into solid and liquid to obtain 1200 mL of copper-arsenic-rich liquid and residue. The content of Cu in the copper-arsenic rich solution is 0.088g / mL, and the content of As is 0.04g / mL. From this, it can be calculated that the leaching rates of copper and arsenic in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com