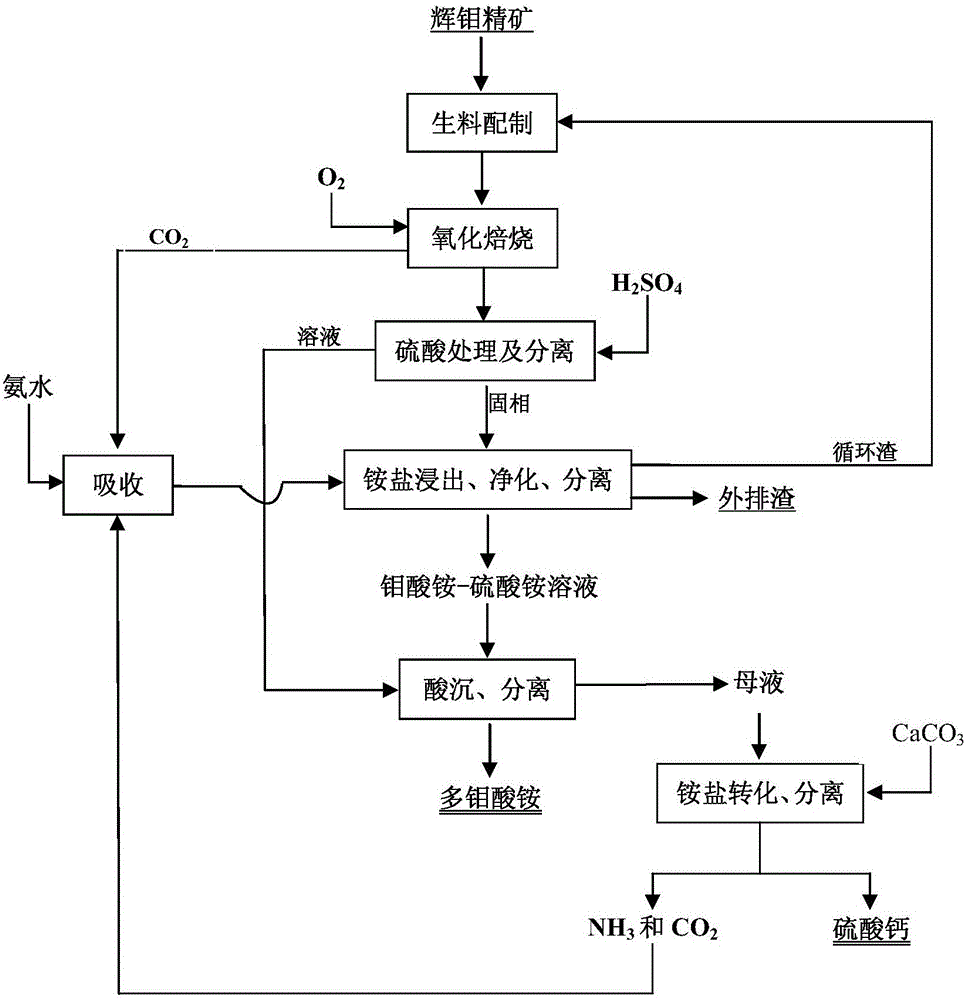

Clean metallurgic method for preparing ammonium molybdate from molybdenite concentrates

A technology of ammonium molybdate and concentrate, which is applied in the field of molybdenum smelting, can solve the problems of severe equipment corrosion, poor operating conditions, and volatilization loss, and achieve the effects of facilitating structural adjustment, reducing production costs, and reducing leaching temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

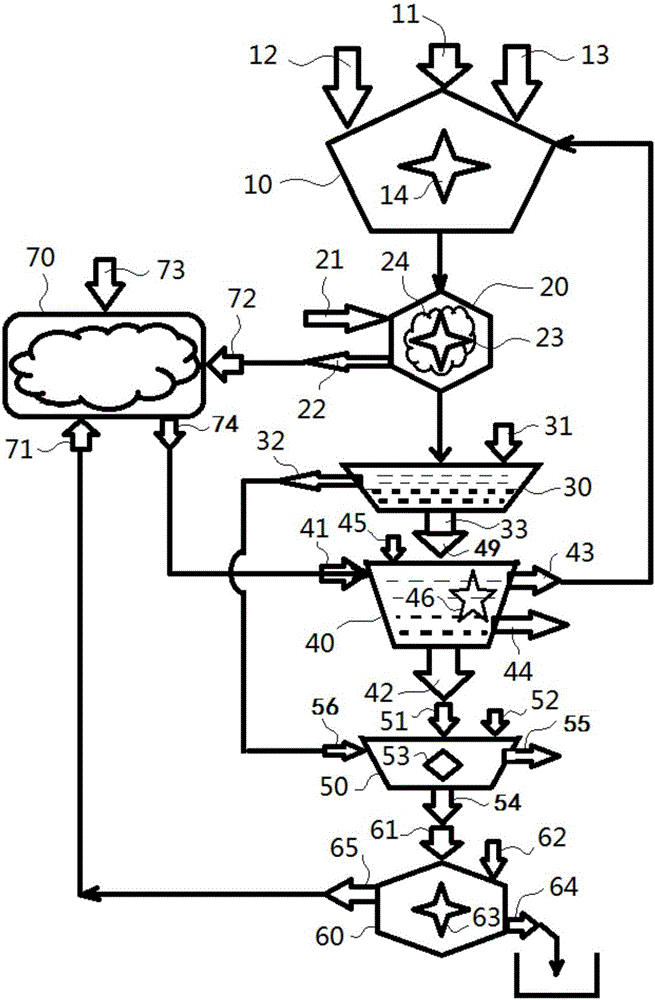

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1: by CaCO 3 / MoS 2 The molar ratio is 3.6. Calcium carbonate, molybdenite (40.33% by mass of Mo) and 3% calcium fluoride are ground and mixed to obtain raw meal. The particle size D90 of the raw meal is 110 μm. Then, the raw material is roasted at 600° C. for 2 hours in an oxygen-enriched atmosphere in a roasting furnace to obtain clinker. After the clinker is cooled to room temperature, it is ground with a vibrating mill, and the clinker particle size D90 is 130 μm. After the clinker is leached with water, solid-liquid separation is carried out, and rhenium is recovered from the leaching solution. Add the leaching residue after water immersion into a leaching tank with stirring, leaching with an ammonium carbonate solution with a concentration of 800g / L, and react at 100°C for 4 hours. After the reaction, the leached pulp is vacuum filtered, and the filter cake is washed three times with pure water. The leaching rate of molybdenum in molybdenite is 98.1...

Embodiment 2

[0060] Embodiment 2: by CaCO 3 / MoS 2 The molar ratio is 3.0. Calcium carbonate, molybdenite (40.33% by mass of Mo) and 2% calcium fluoride are ground and mixed to obtain raw meal. The particle size D90 of the raw meal is 100 μm. Then, the raw material is roasted at 600° C. for 0.5 hour in an oxygen-enriched atmosphere in a roasting furnace to obtain clinker. After the clinker is cooled to room temperature, it is finely ground with a vibration mill, and the clinker particle size D90 is 70 μm. After the clinker is leached with water, solid-liquid separation is carried out, and rhenium is recovered from the leaching solution. Add the leaching residue after water immersion into a stirring leaching tank, leaching with ammonium carbonate solution with a concentration of 300g / L, and react at 90°C for 6 hours. After the reaction, the leached pulp is vacuum filtered, and the filter cake is washed three times with pure water. The leaching rate of molybdenum in molybdenite is 75.61%...

Embodiment 3

[0061] Embodiment 3: by CaCO 3 / MoS 2 The molar ratio is 5.0, calcium carbonate, molybdenite (40.33% by mass of Mo) and 10% calcium fluoride are ground and mixed to obtain raw meal, and the particle size D90 of the raw meal is 80 μm. Then, the raw material is roasted at 400° C. for 6 hours in a roasting furnace with air flowing in to obtain clinker. After the clinker is cooled to room temperature, it is finely ground with a vibration mill, and the clinker particle size D90 is 70 μm. After the clinker is leached with water, solid-liquid separation is carried out, and rhenium is recovered from the leaching solution. Add the leaching residue after water immersion into the leaching equipment, which is a leaching tank with stirring, leaching with ammonium carbonate solution with a concentration of 800g / L, and react at 70°C for 8 hours. After the reaction, the leached pulp is vacuum filtered, and the filter cake is washed three times with pure water. The leaching rate of molybde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com