Method for extracting copper for copper containing sulfurized ore

A mineral and sulfuric acid technology, applied in the field of copper extraction from copper-bearing sulfide minerals, can solve problems such as ineffectiveness, inability to handle copper concentrates alone, excess sulfuric acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

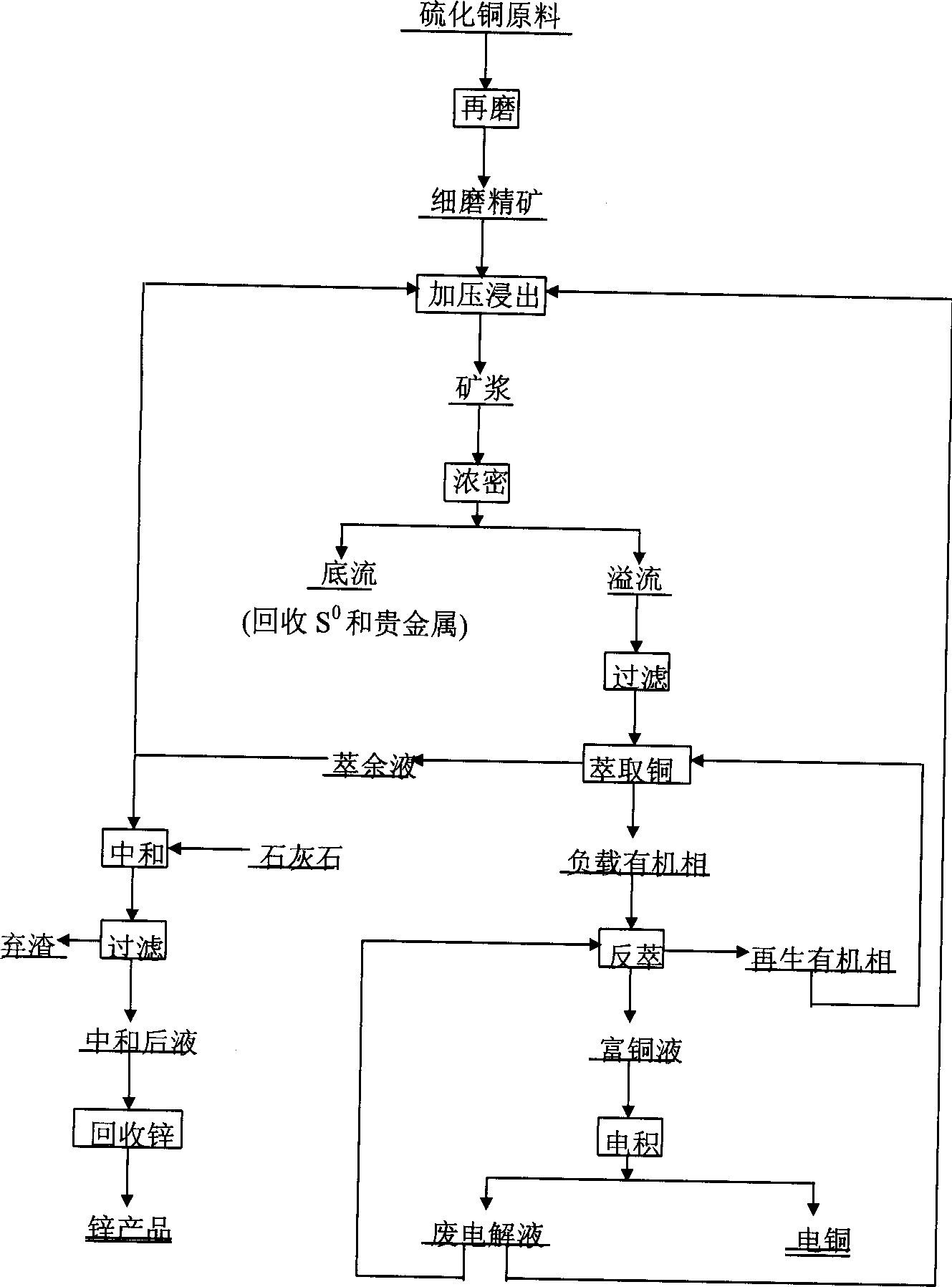

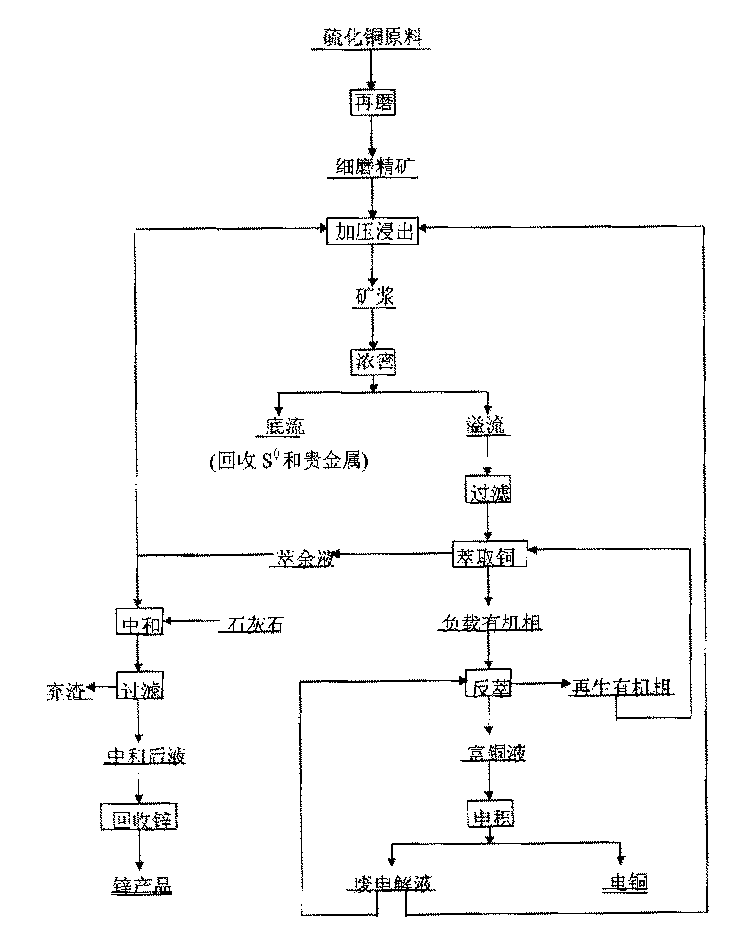

Image

Examples

example 1

[0048] Composition (%) of copper minerals used for leaching: Cu 10.58, Zn 2.57, Fe 31.93, S39.33.

[0049] Pressure leaching conditions are as follows: Grind the copper concentrate until the particle size is -44μm and account for more than 90%, take 200g ore sample, leaching temperature 110°C, oxygen partial pressure 100kPa, initial sulfuric acid concentration = 20g / l, [NaCl] = 85g / l, the liquid-solid ratio is 5 / 1, and the reaction time is 2 hours.

[0050] Leaching rate (%)

example 2

[0052] Composition (%) of copper minerals used for leaching: Cu 10.58, Zn 2.57, Fe 31.93, S39.33.

[0053] Pressure leaching conditions are as follows: Grind the copper concentrate until the particle size is -44μm and account for more than 90%, take 200g ore sample, leaching temperature 105°C, oxygen partial pressure 150kPa, initial sulfuric acid concentration = 25g / l, [NaCl] = 90g / l, the liquid-solid ratio is 5 / 1, and the reaction time is 2 hours.

[0054] Leaching rate (%)

example 3

[0056] Composition (%) of the leached copper concentrate used: Cu 25.82, Zn 2.91, Fe 29.10, S35.02.

[0057] Pressure leaching conditions are as follows: Grind the copper concentrate until the particle size is -44μm and account for more than 90%, take a 50g ore sample, leaching temperature 110°C, oxygen partial pressure 100kPa, initial sulfuric acid concentration = 60g / l, [NaCl] = 90g / l, the liquid-solid ratio is 5 / 1, and the reaction time is 2 hours.

[0058] Leaching rate (%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com