Patents

Literature

152 results about "Blood oxygen pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PaO2 – Partial pressure of oxygen at sea level (765 mmHg) in arterial blood is between 75 mmHg and 100 mmHg. PvO2 – Oxygen tension in venous blood at sea level is between 30 mmHg and 40 mmHg.

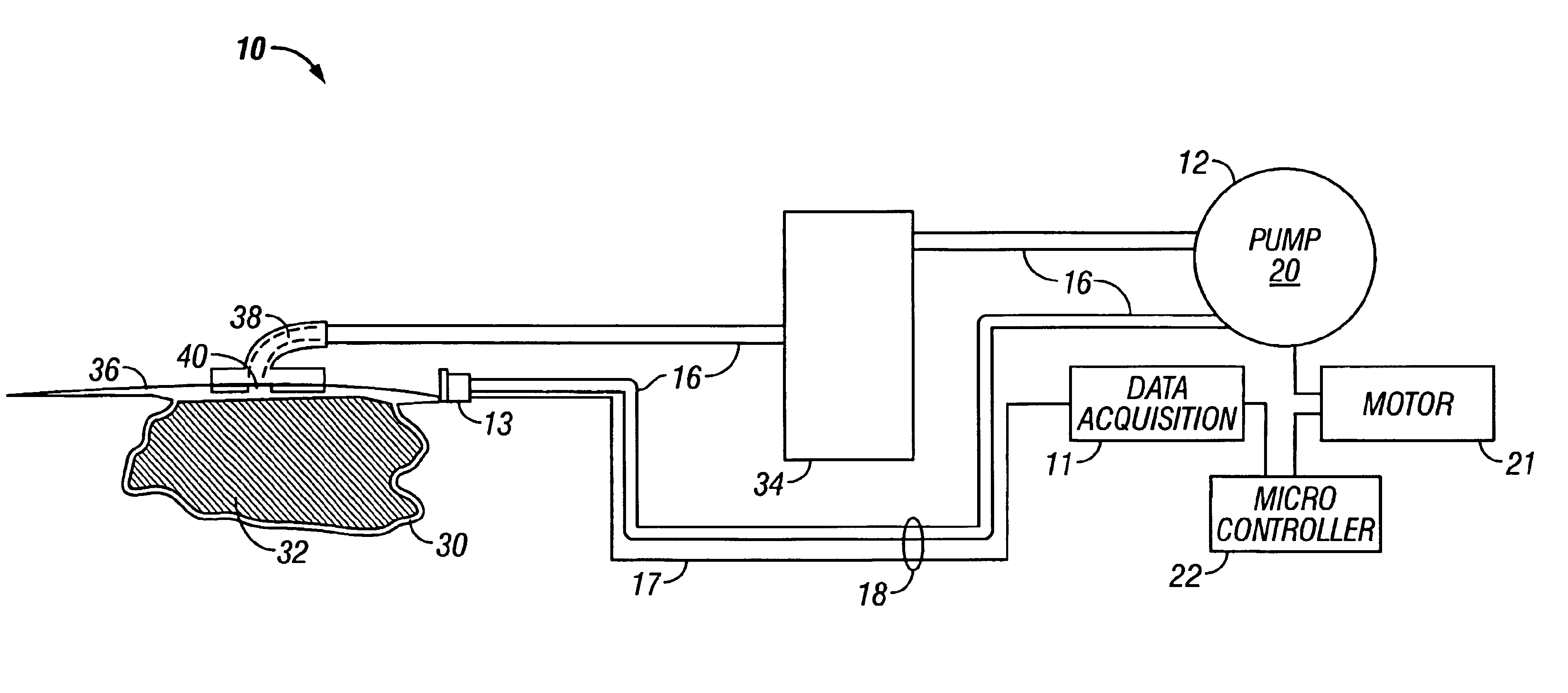

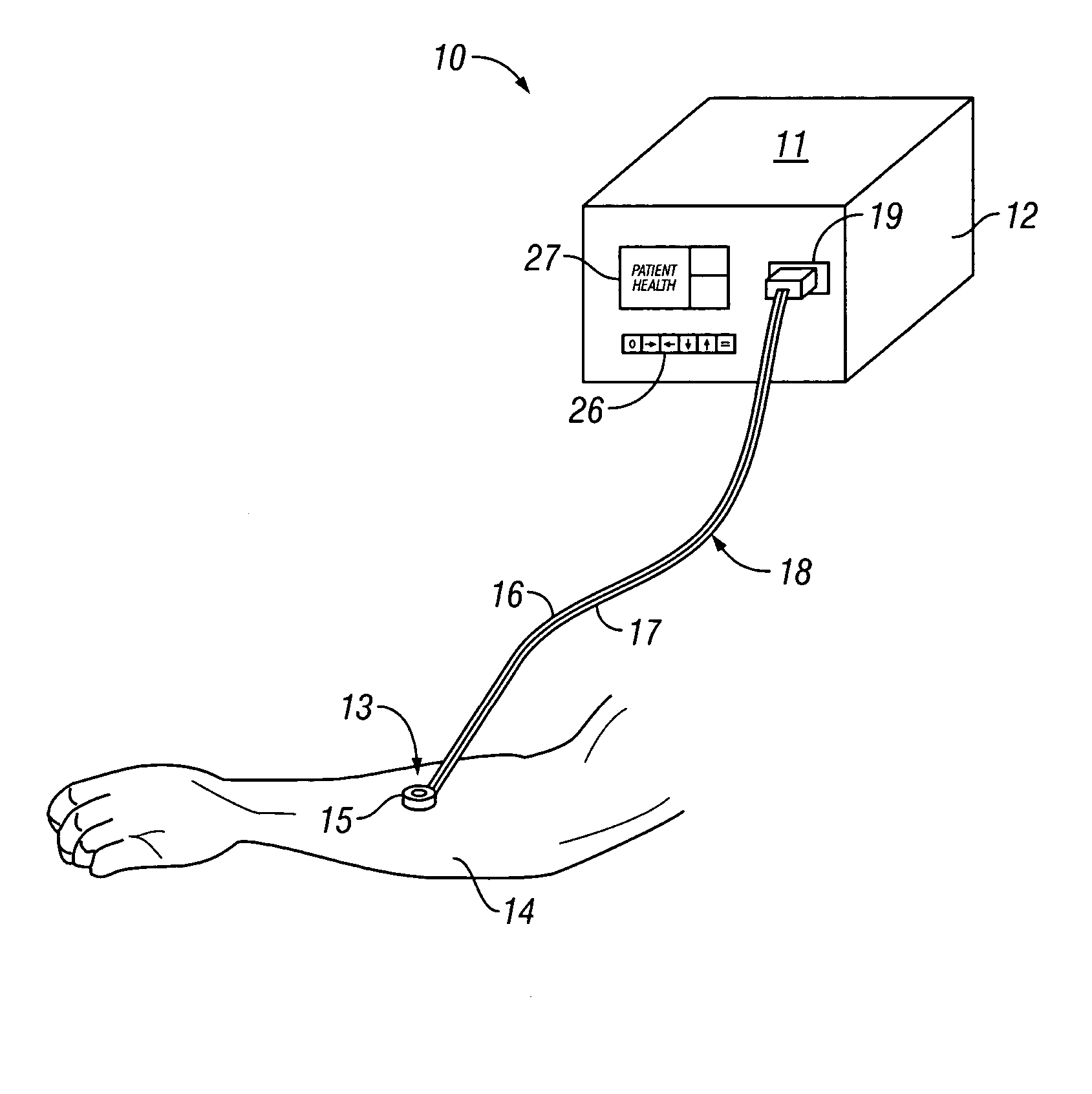

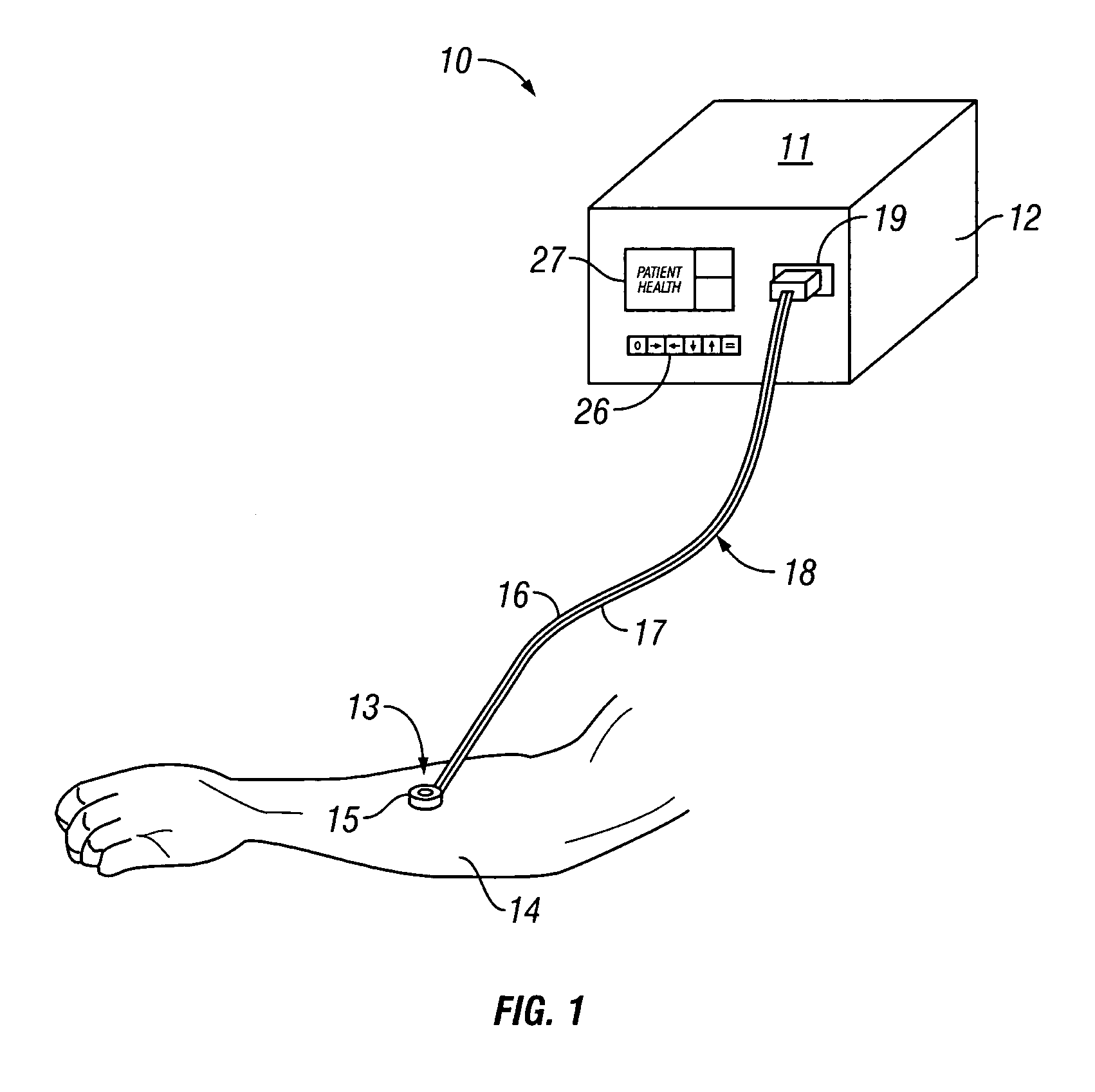

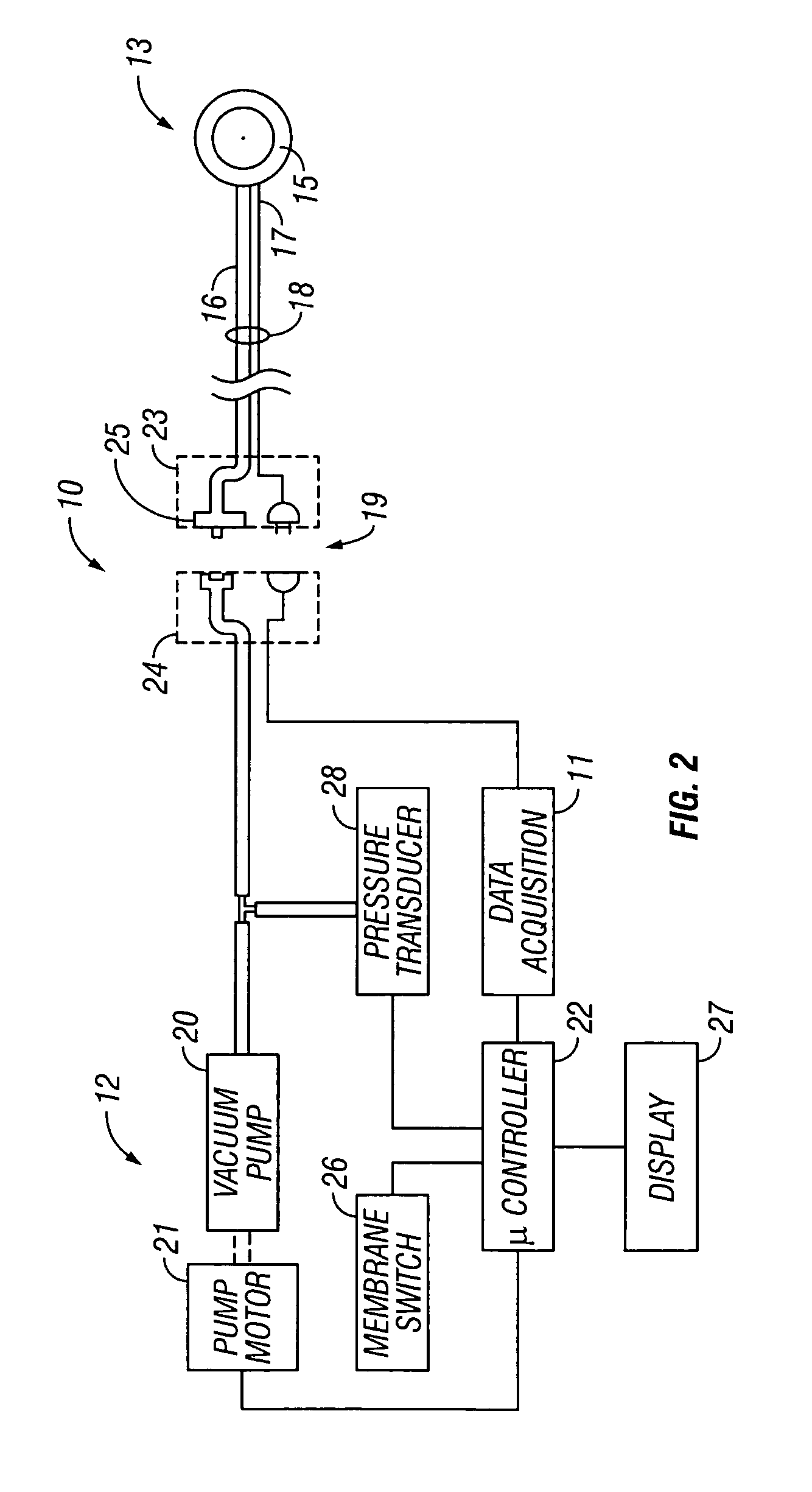

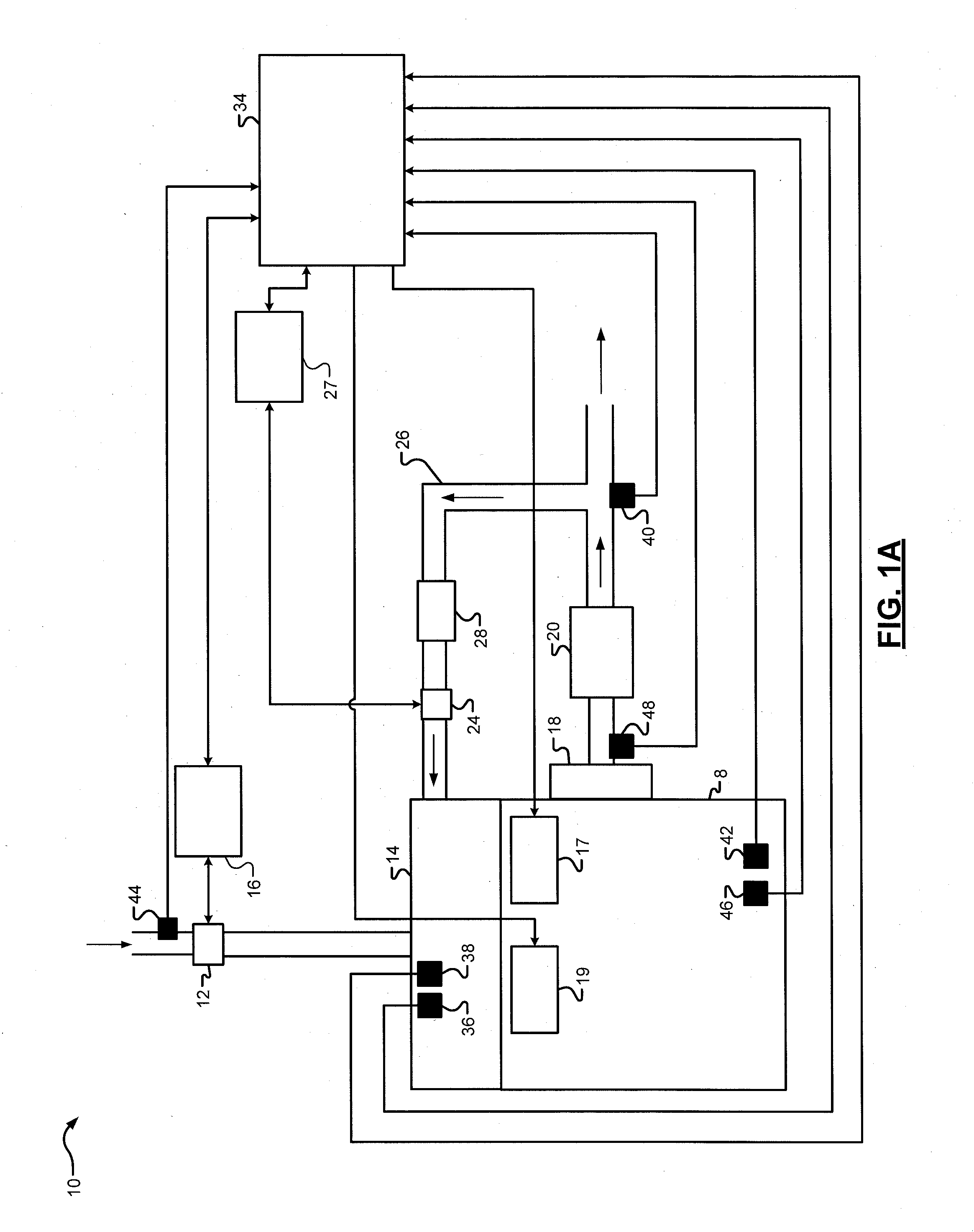

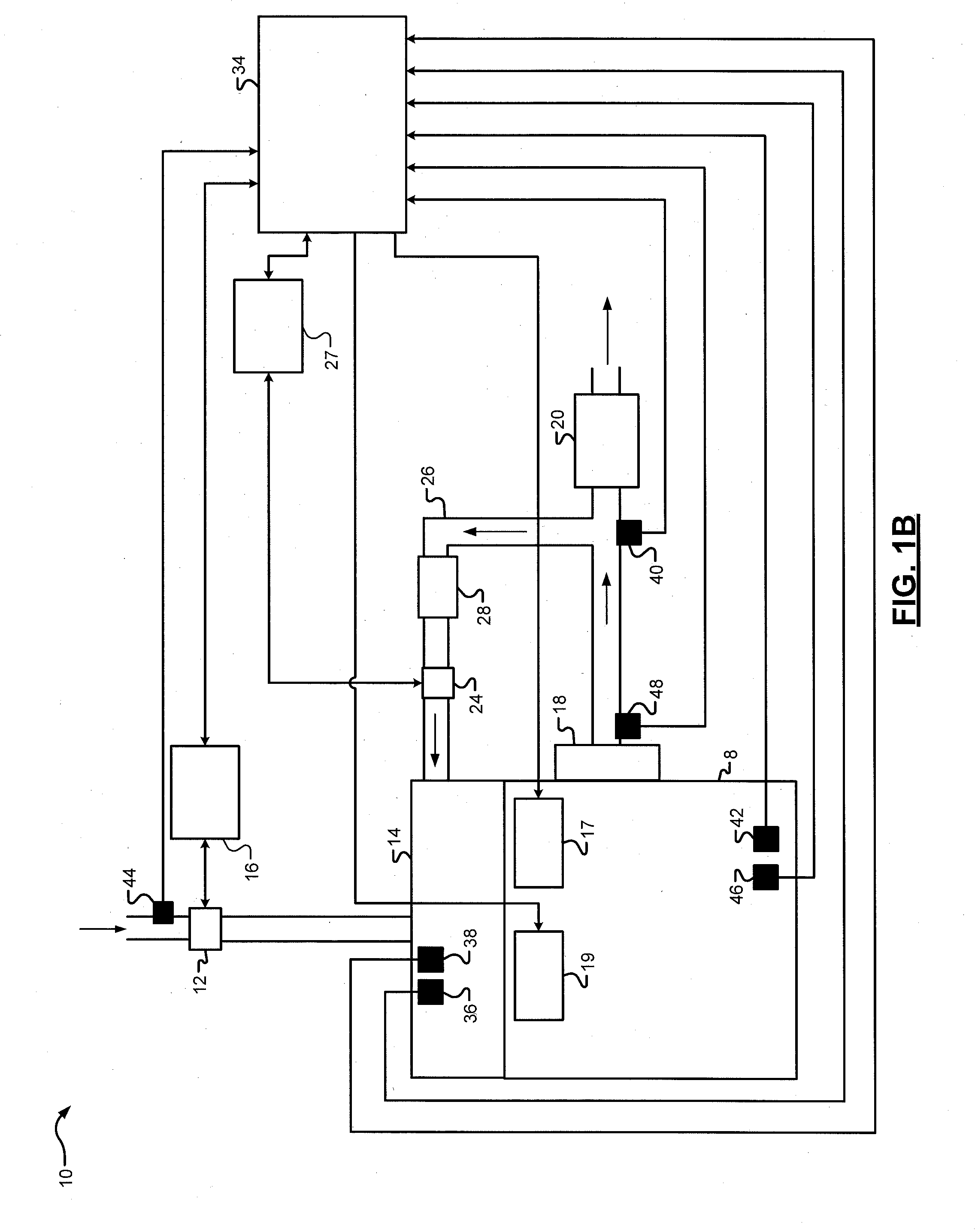

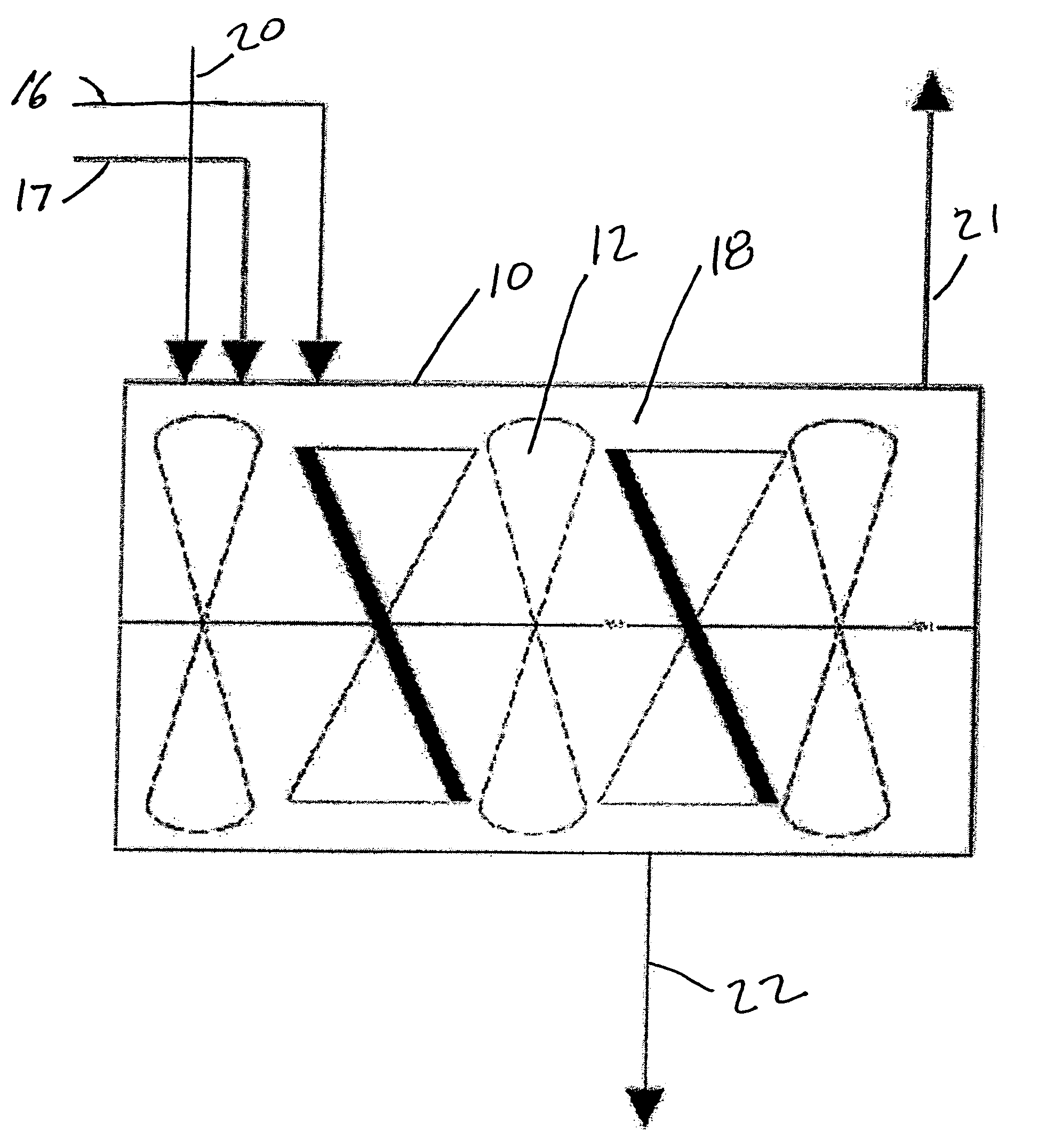

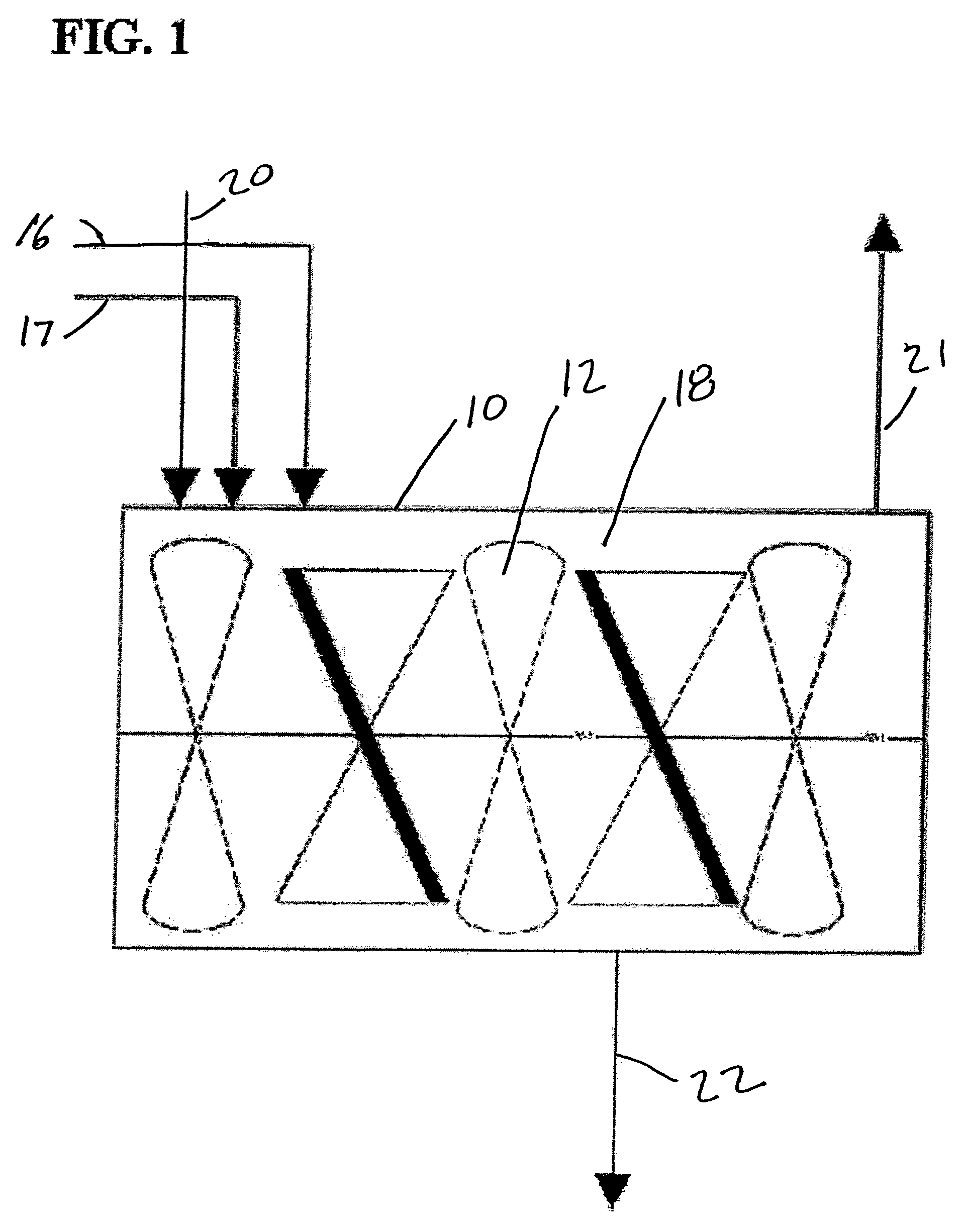

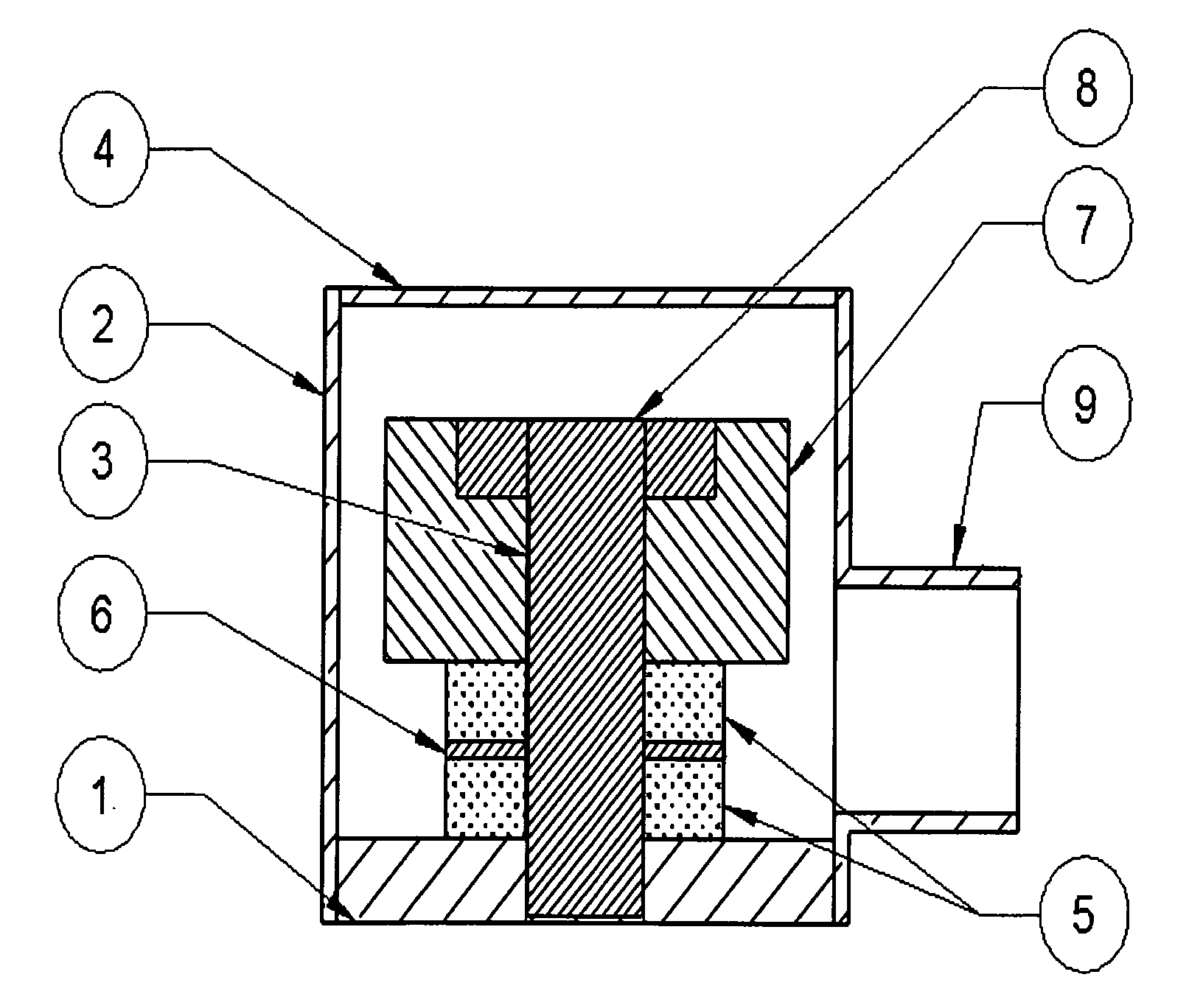

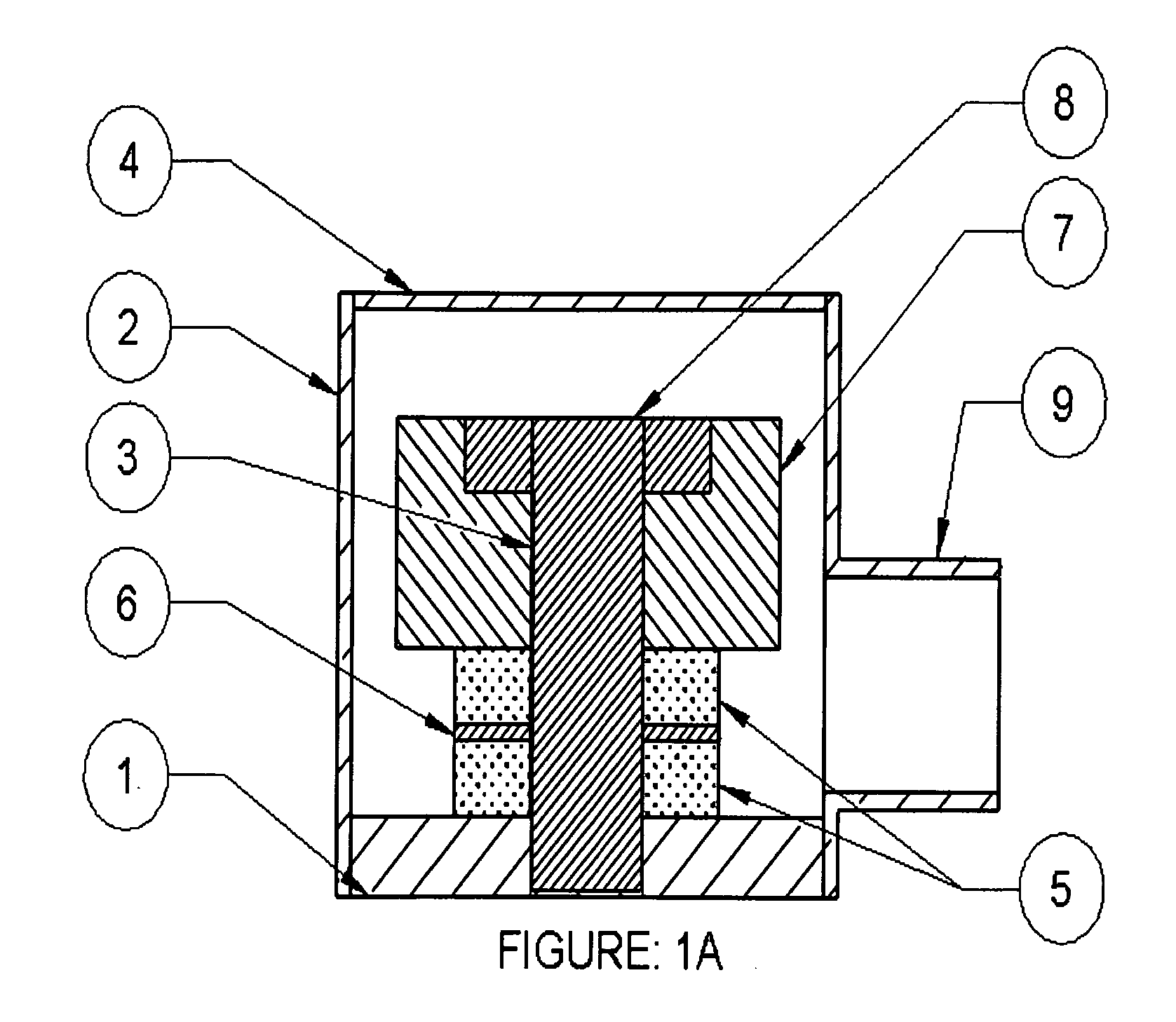

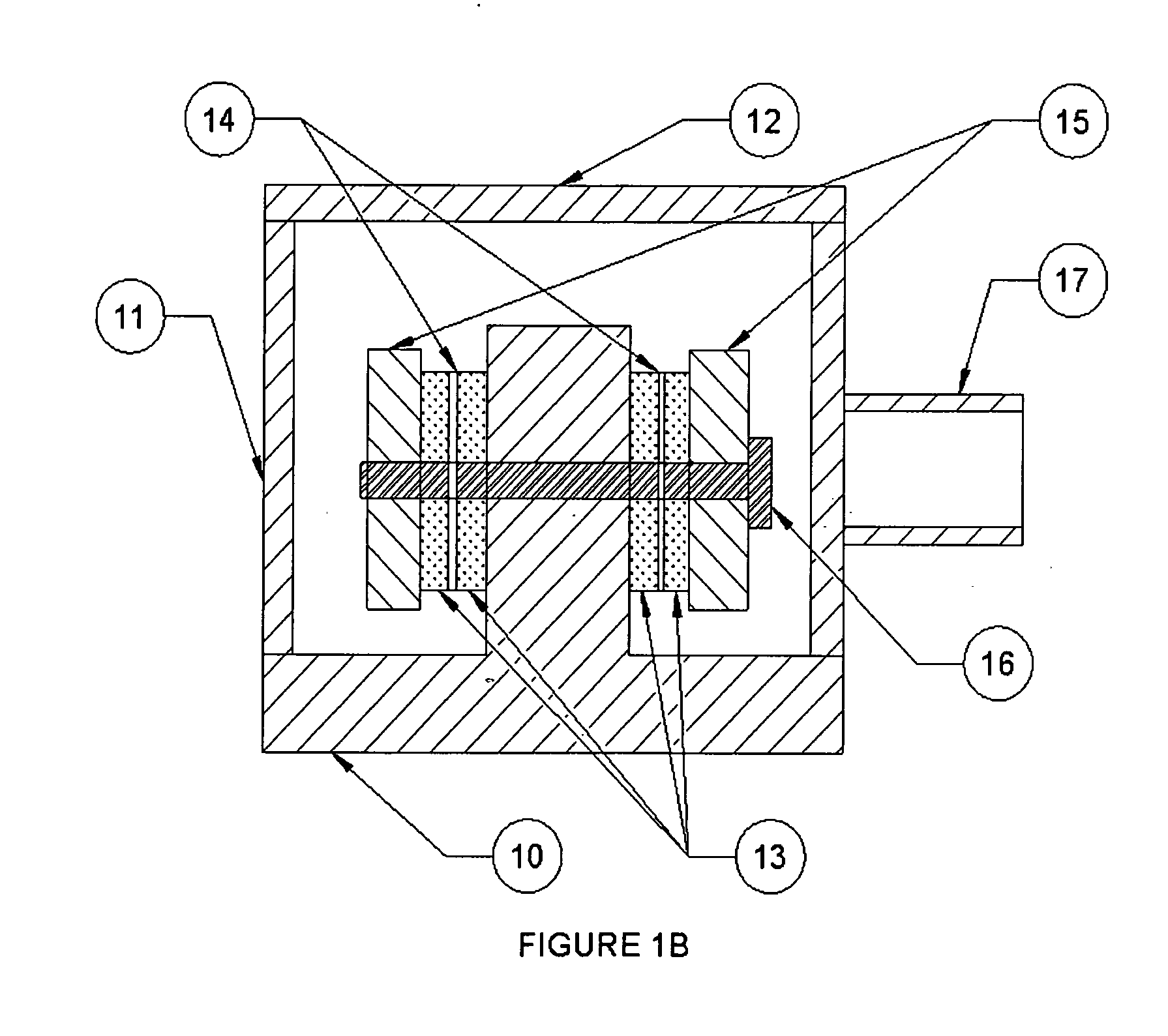

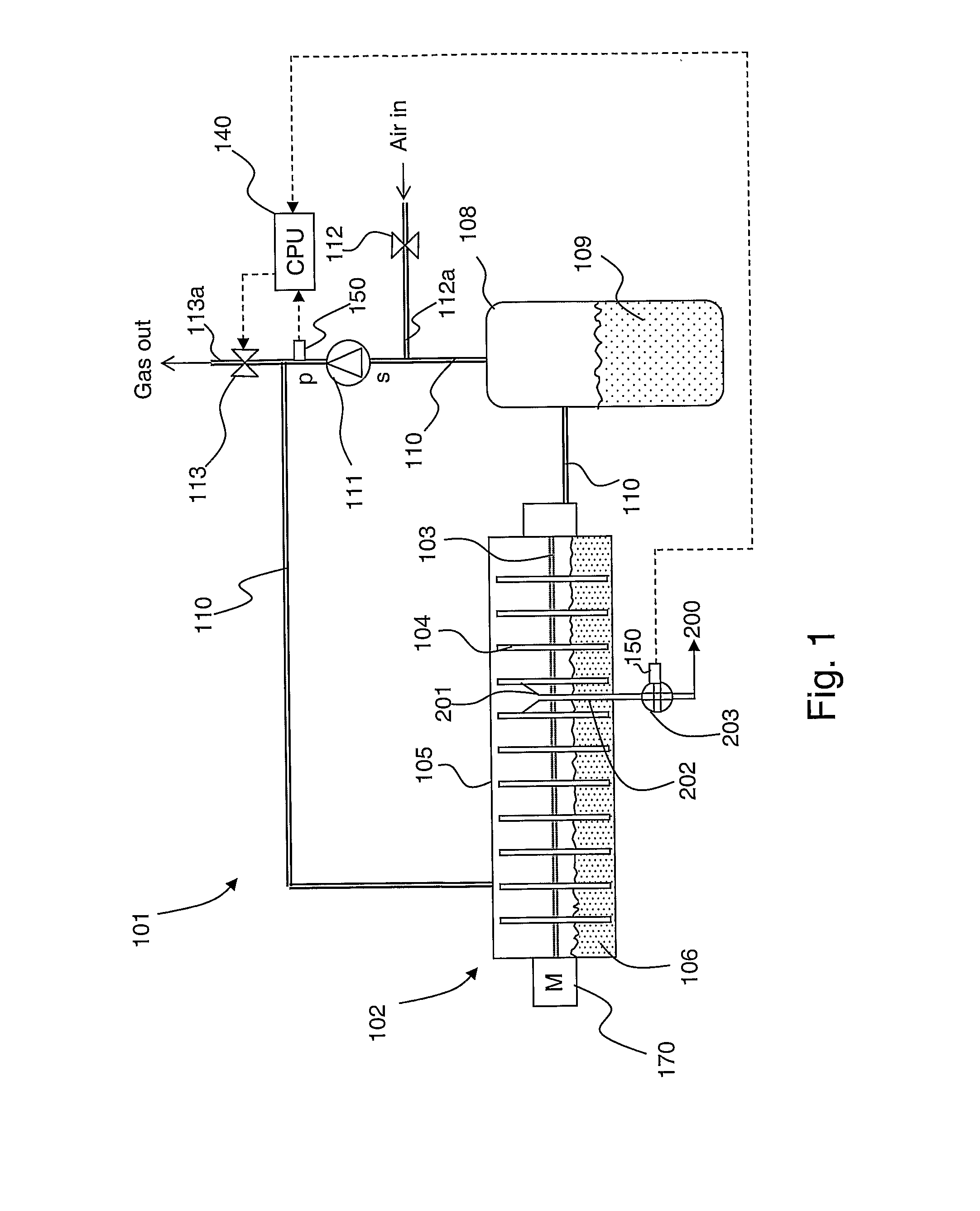

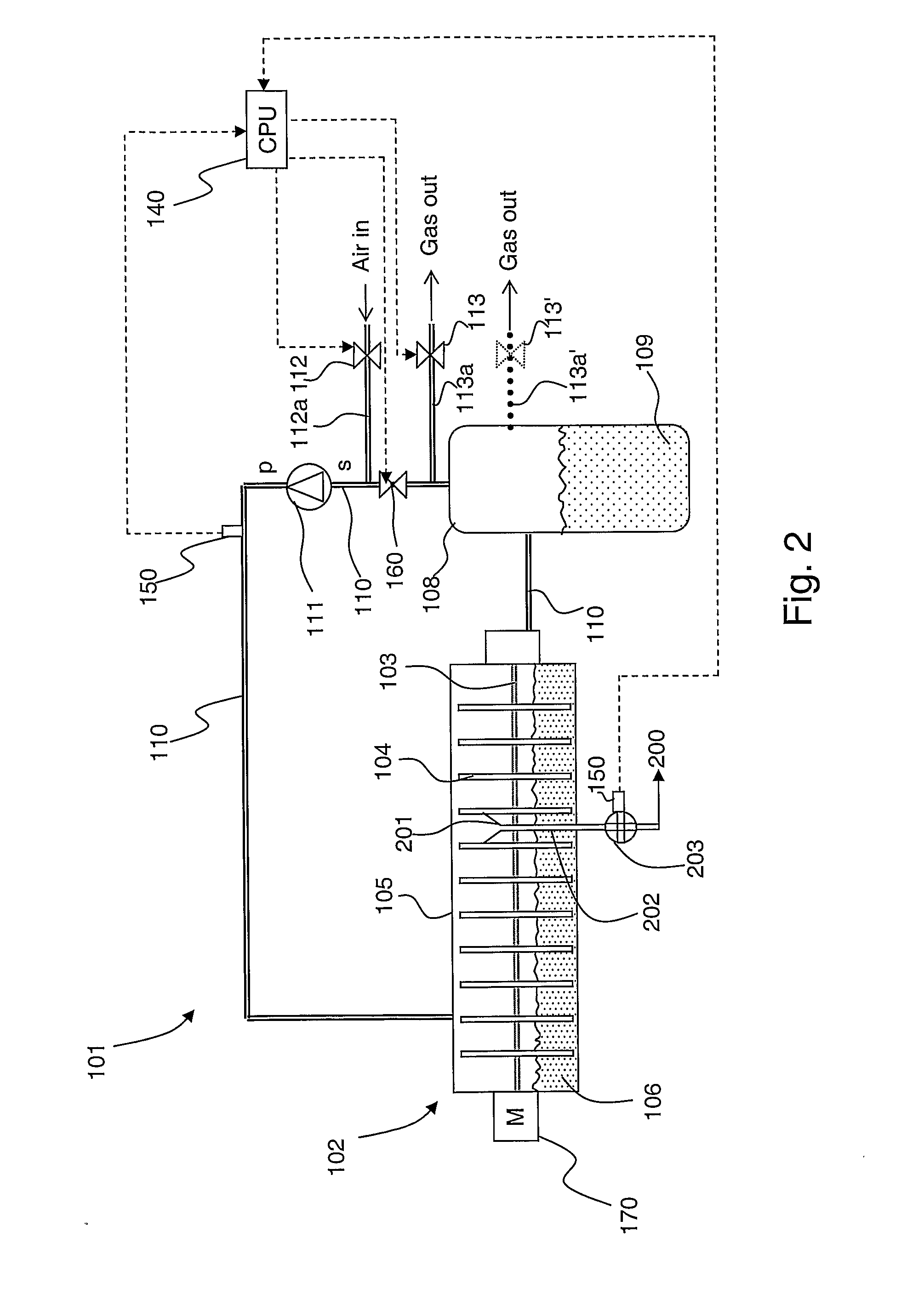

System for combined transcutaneous blood gas monitoring and vacuum assisted wound closure

InactiveUS6856821B2Eliminate opportunitySubstantial riskIntravenous devicesDiagnostic recording/measuringMicrocontrollerVacuum assisted

A method and apparatus for the transcutaneous monitoring of blood gases generally comprises a blood gas data acquisition device, a vacuum source and a blood gas transducer unit. The blood gas transducer unit is adapted for application to a patient's skin and administration of a local vacuum at the area of patient application. It further comprises an electrochemical blood gas transducer, well known to those of ordinary skill in the art, which is disposed entirely within the local vacuum at the area of patient application. The vacuum source is placed in fluid communication with the blood gas transducer unit, through a hydrophobic membrane filter for safety purposes, in order to induce a condition of hyperperfusion in the locality of the electrochemical blood gas transducer. Under the control of a microcontroller, or equivalent means, the blood gas acquisition device is then utilized to capture a measure of skin surface oxygen or carbon dioxide pressure. The microcontroller can then utilize this measure to arrive at an estimate of arterial partial pressure of oxygen or carbon dioxide, accordingly. Because vacuum induced perfusion produces the requisite condition of hyperperfusion without local heating and, therefore, without acceleration of the local metabolic function, the present invention results in more accurate than previously available estimates of partial pressure blood gas pressures and does so while eliminating a significant risk for injury to the patient.

Owner:KCI LICENSING INC

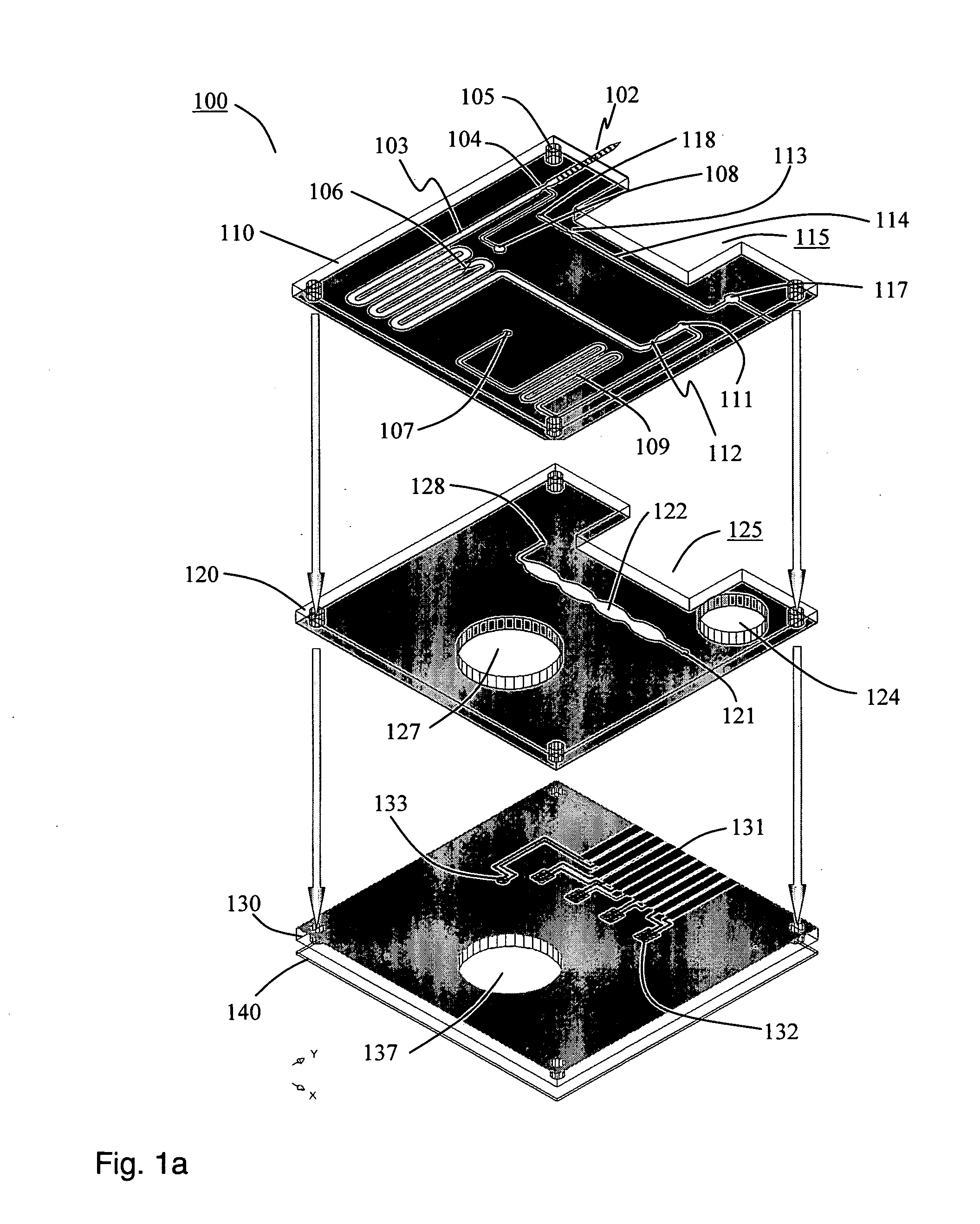

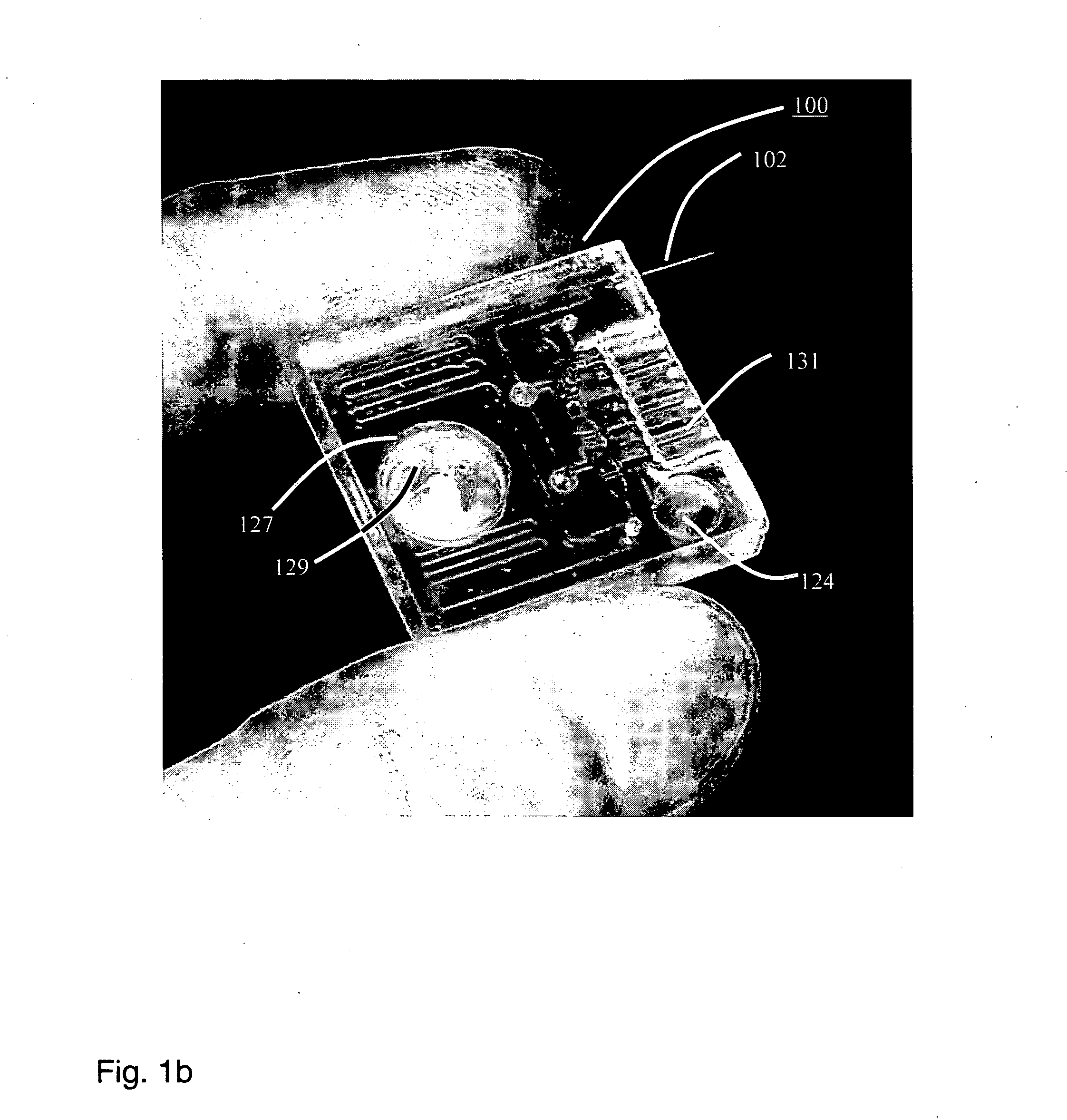

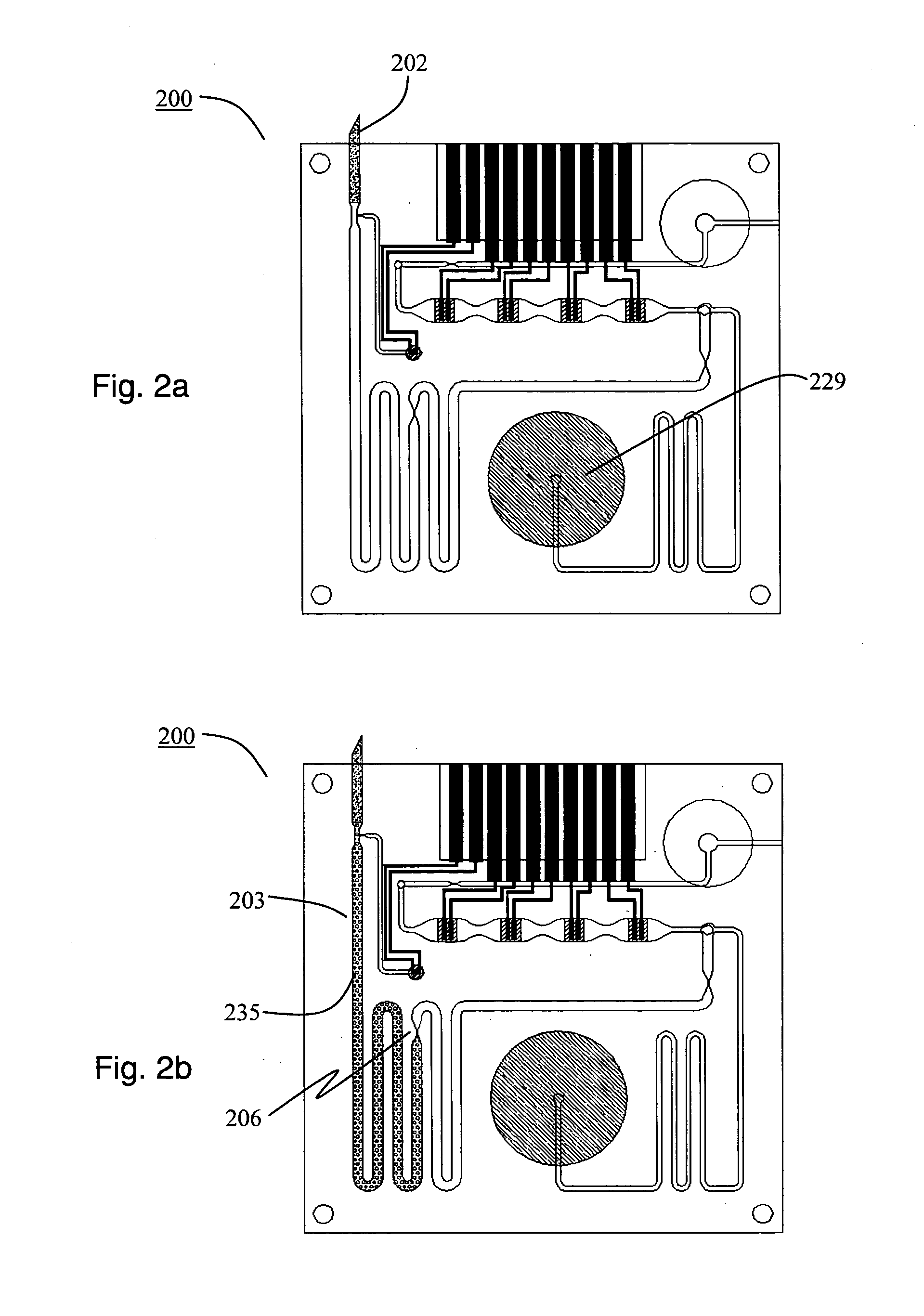

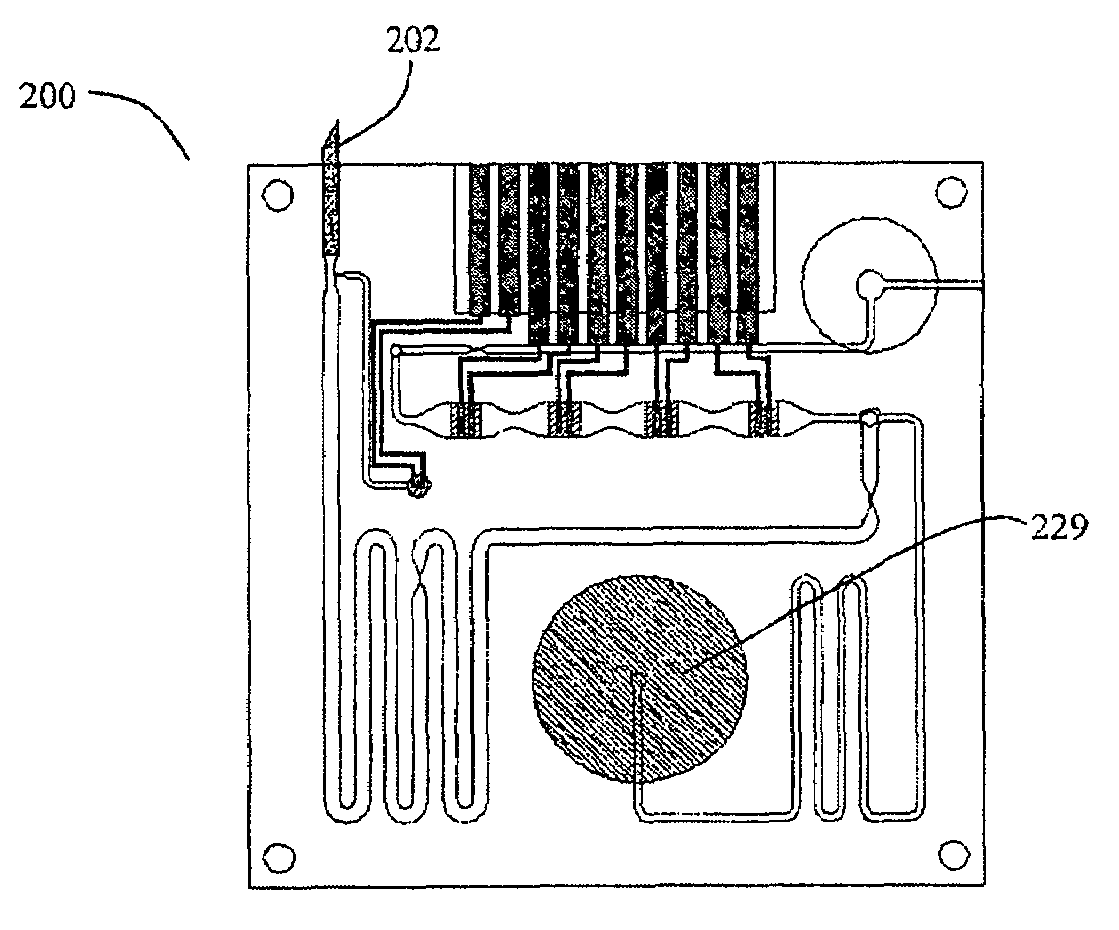

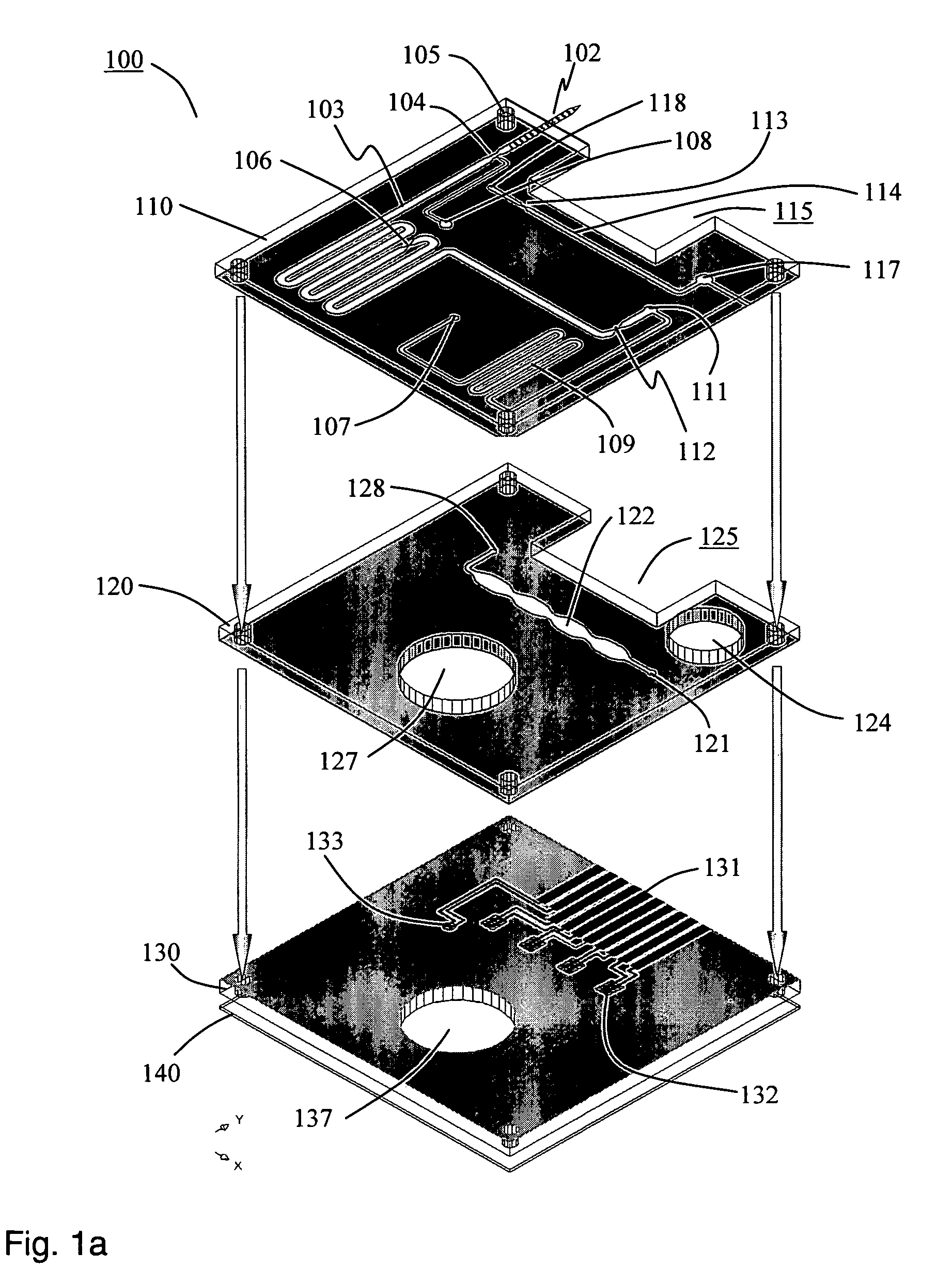

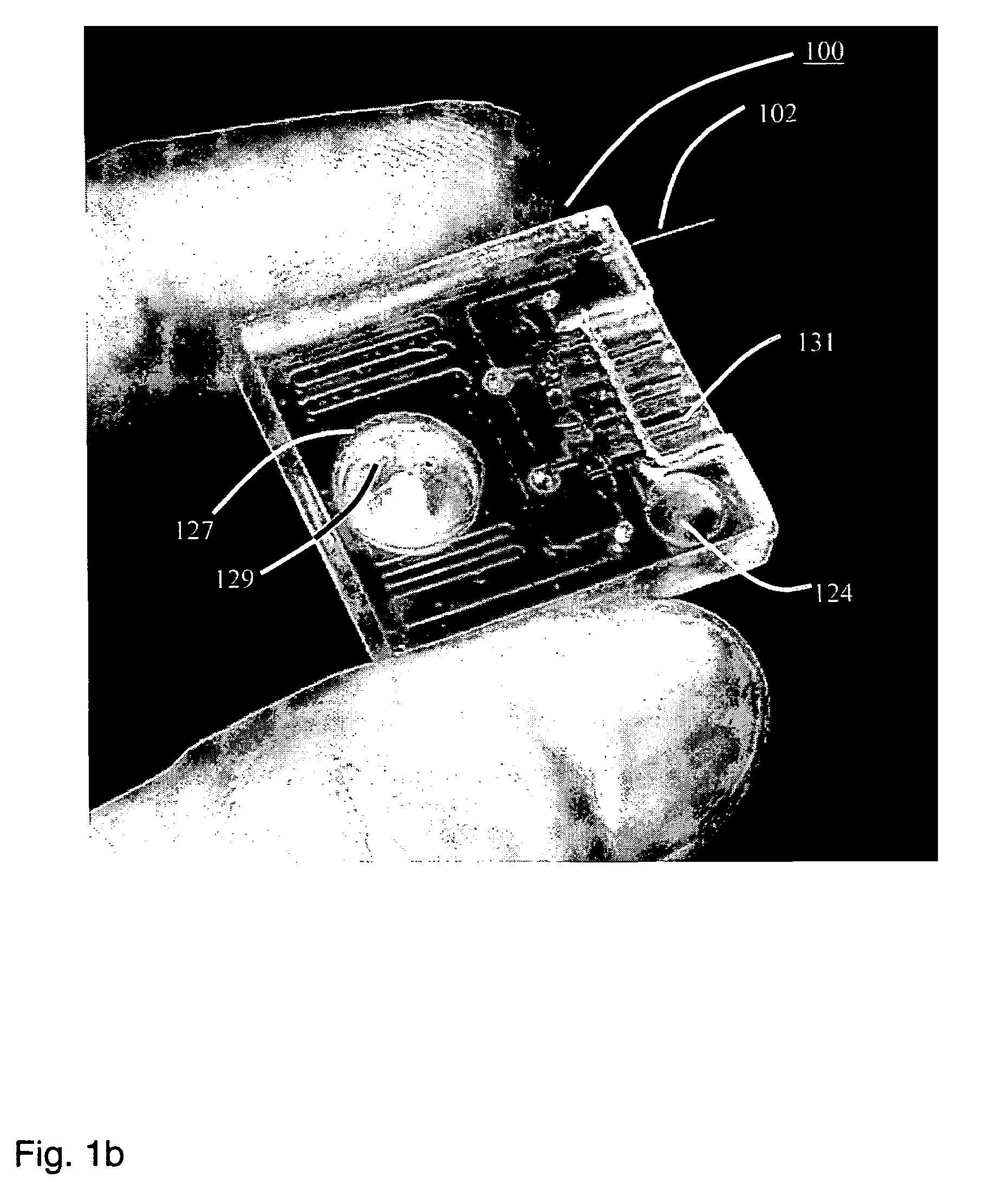

Smart disposable plastic lab-on-a-chip for point-of-care testing

InactiveUS20050130292A1None of measures has been particularly successfulRelieve painBioreactor/fermenter combinationsCombination devicesVenous bloodLab-on-a-chip

Disclosed herein is a fully-integrated, disposable biochip for point-of-care testing of clinically relevant parameters. Specifically, in accordance with an embodiment of the present invention, the biochip is designed for POCT (point-of-care-testing) of an array of metabolic parameters including partial pressure of oxygen, Glucose, and Lactate concentration from venous blood samples. The biochip is fabricated on a low-cost plastic substrate using mass manufacturing compatible fabrication processes. Furthermore, the biochip contains a fully-integrated metallic micro-needle for blood sampling. The biochip also uses smart passive microfluidics in conjunction with low-power functional on-chip pressure generators for microfluidic sequencing. The design, configuration, assembly and operation of the biochip are ideally suited for a disposable biochip specifically targeted towards POCT applications.

Owner:UNIVERSITY OF CINCINNATI

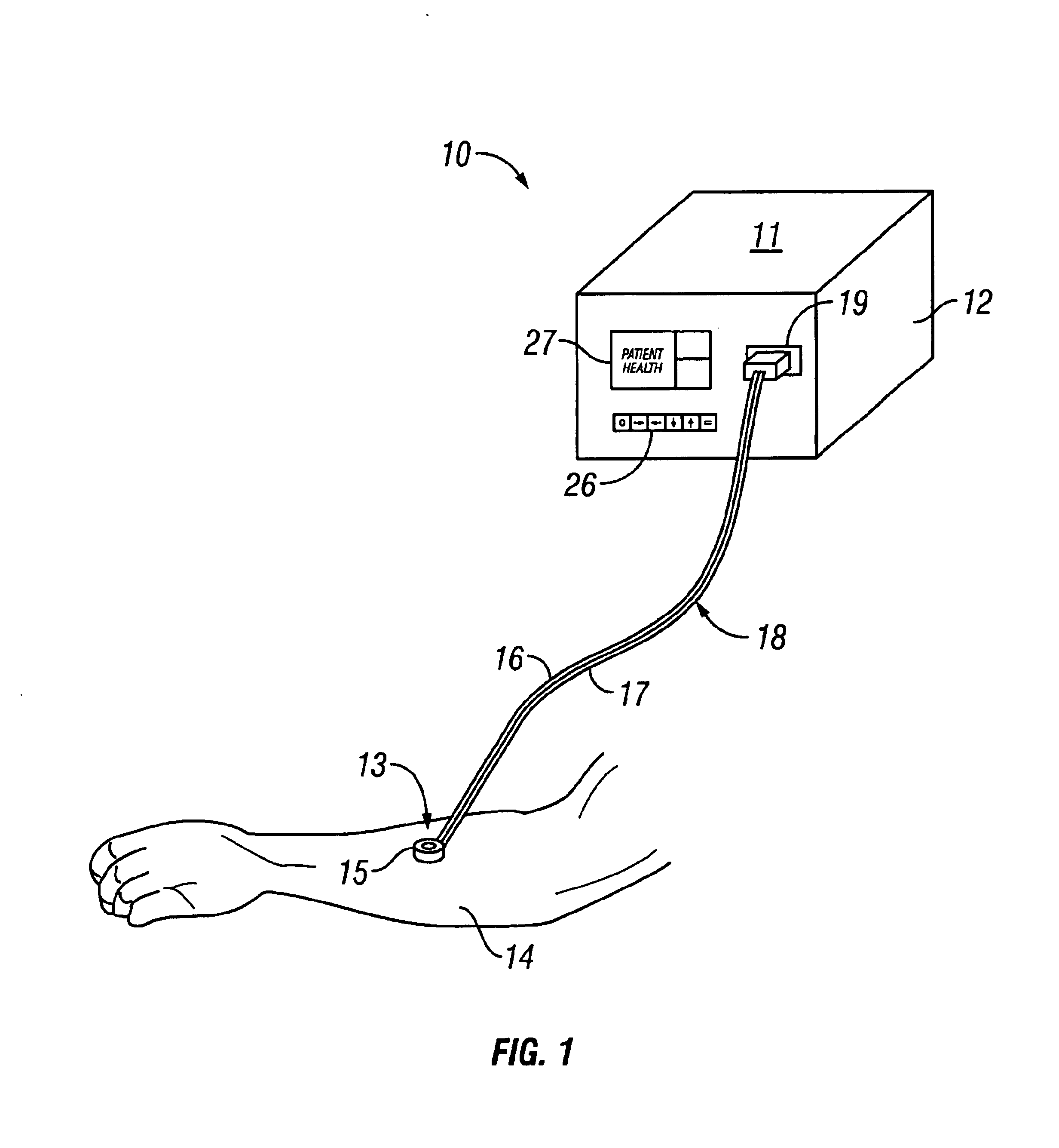

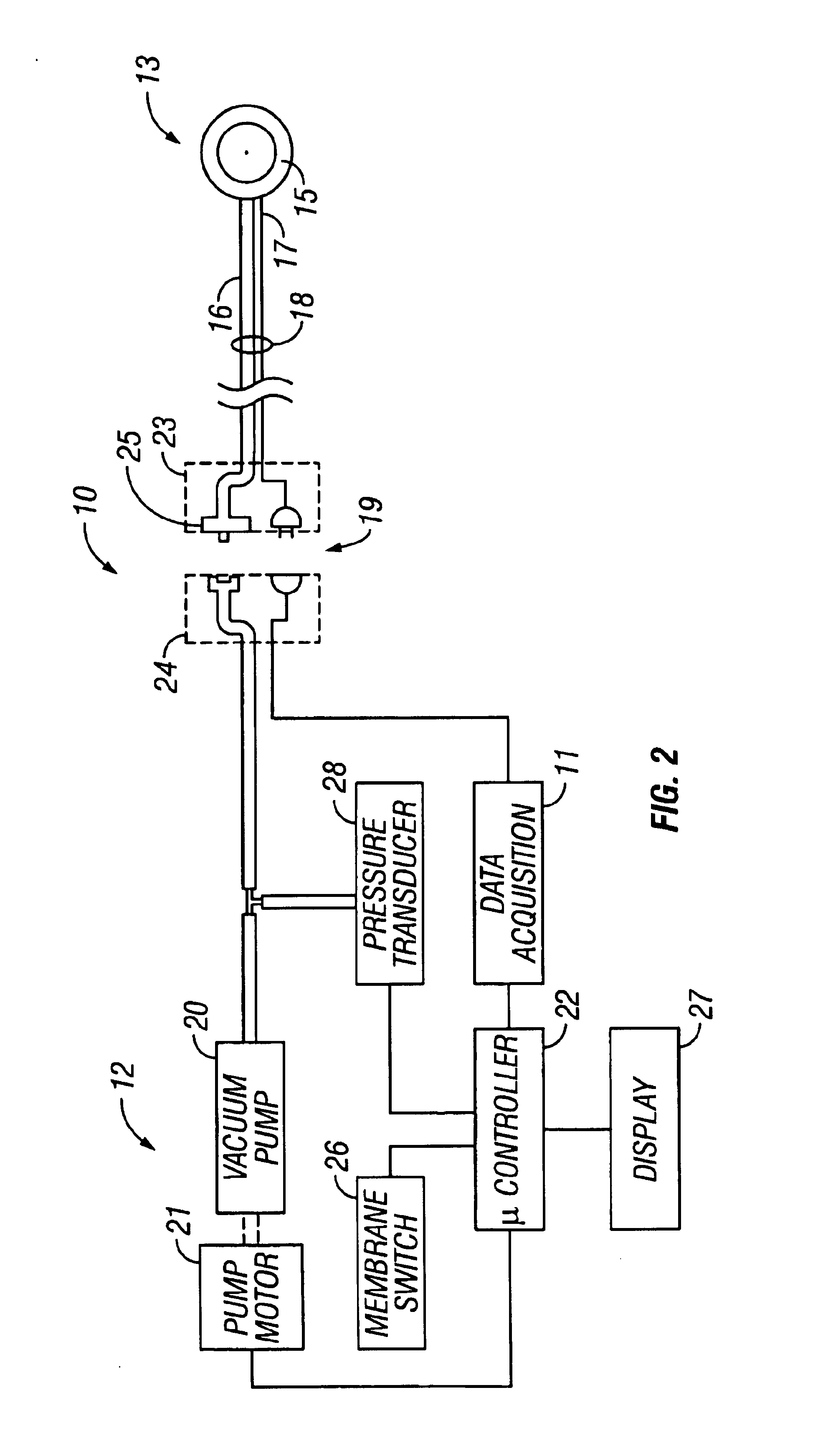

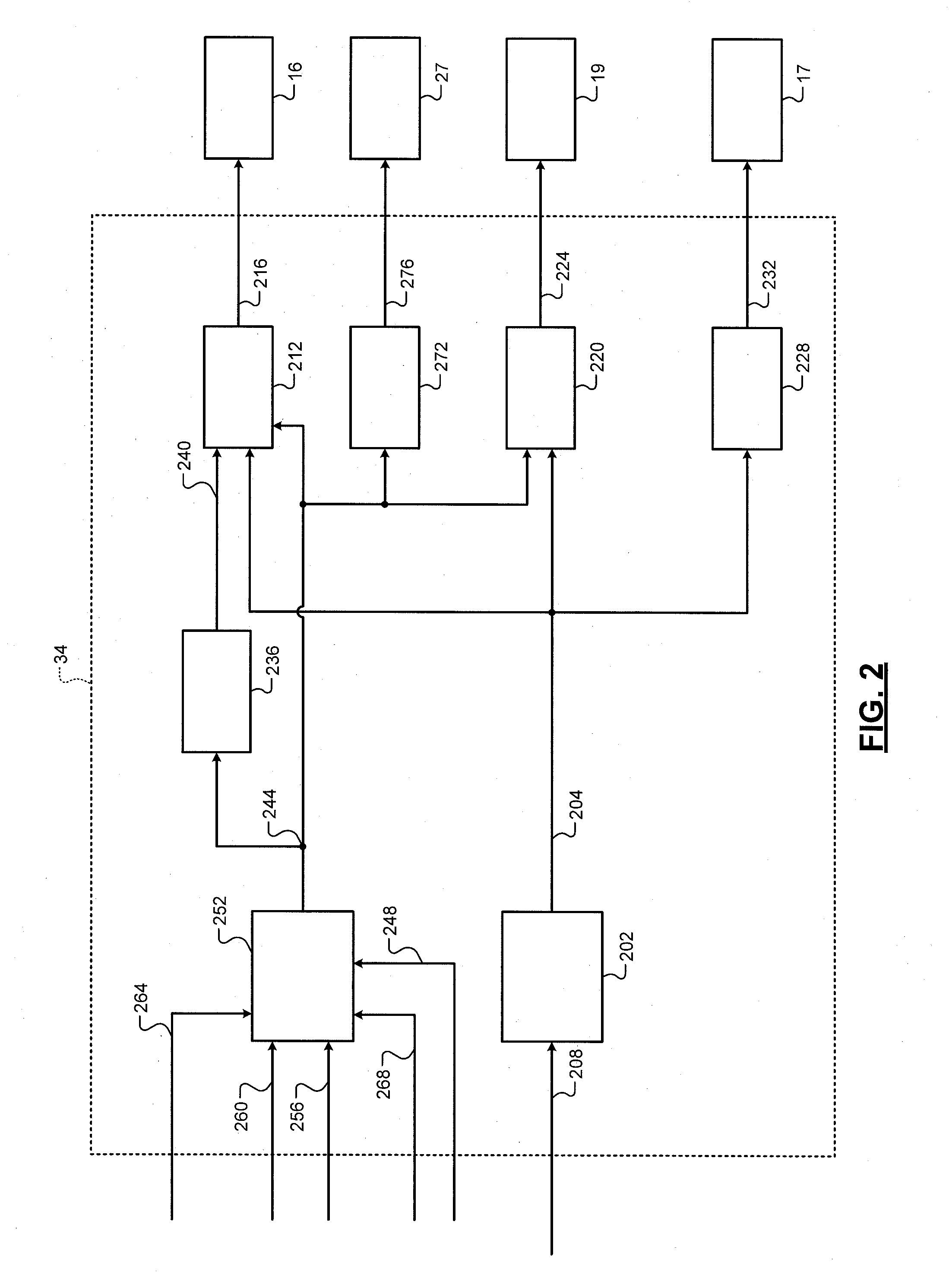

System for combined transcutaneous blood gas monitoring and negative pressure wound treatment

InactiveUS7524286B2Substantial riskAccurate estimateIntravenous devicesDiagnostic recording/measuringMicrocontrollerSignificant risk

Owner:KCI LICENSING INC

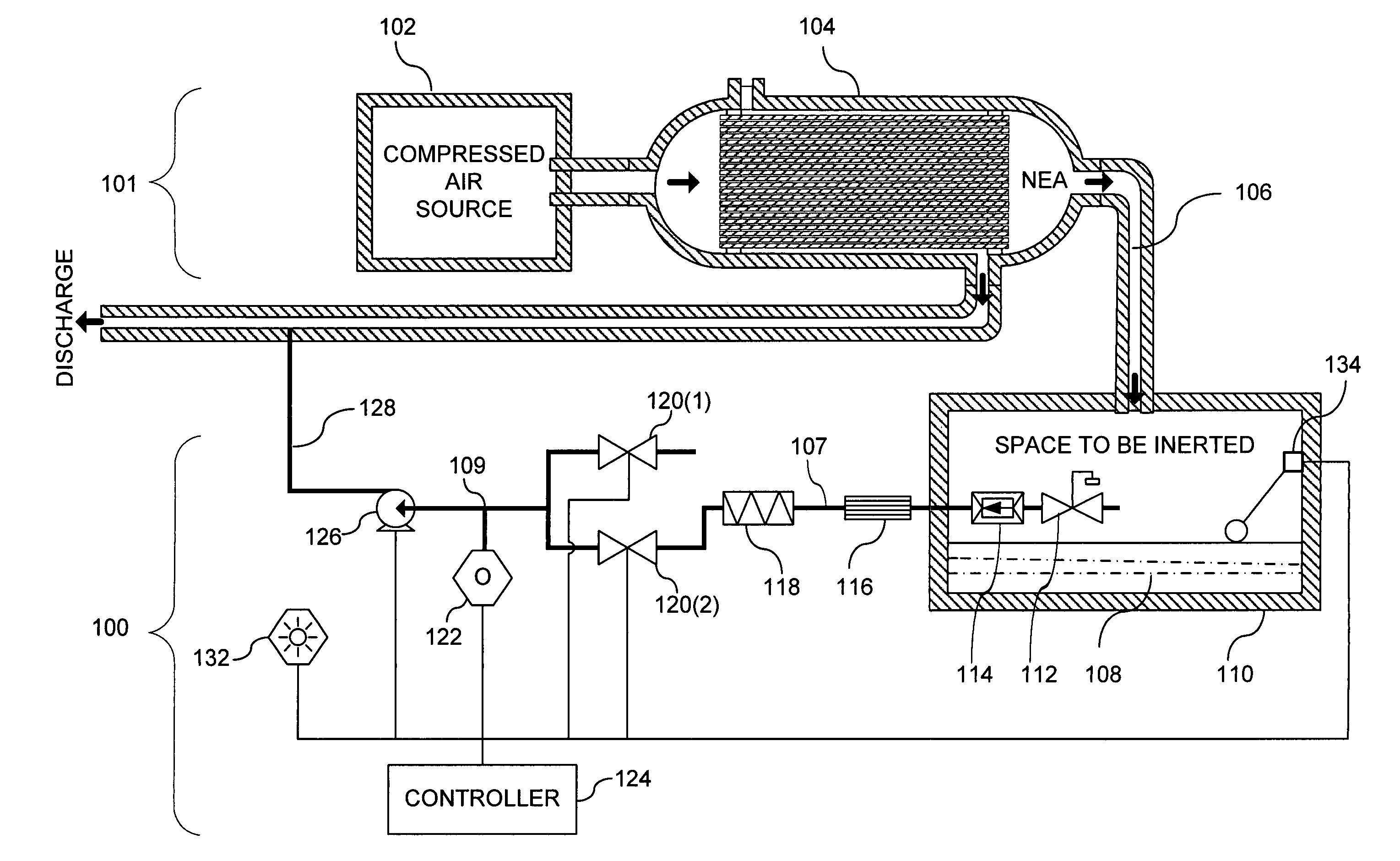

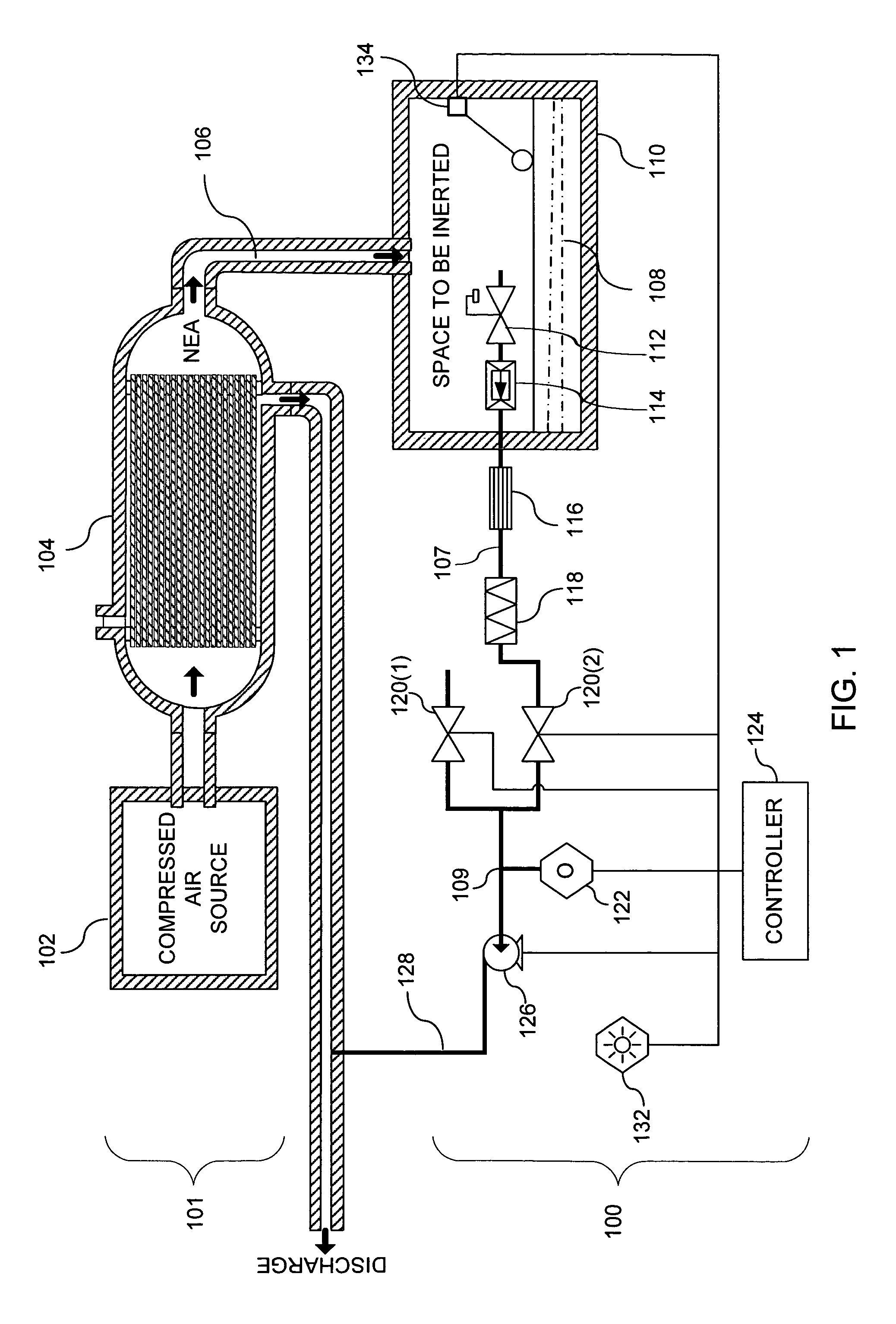

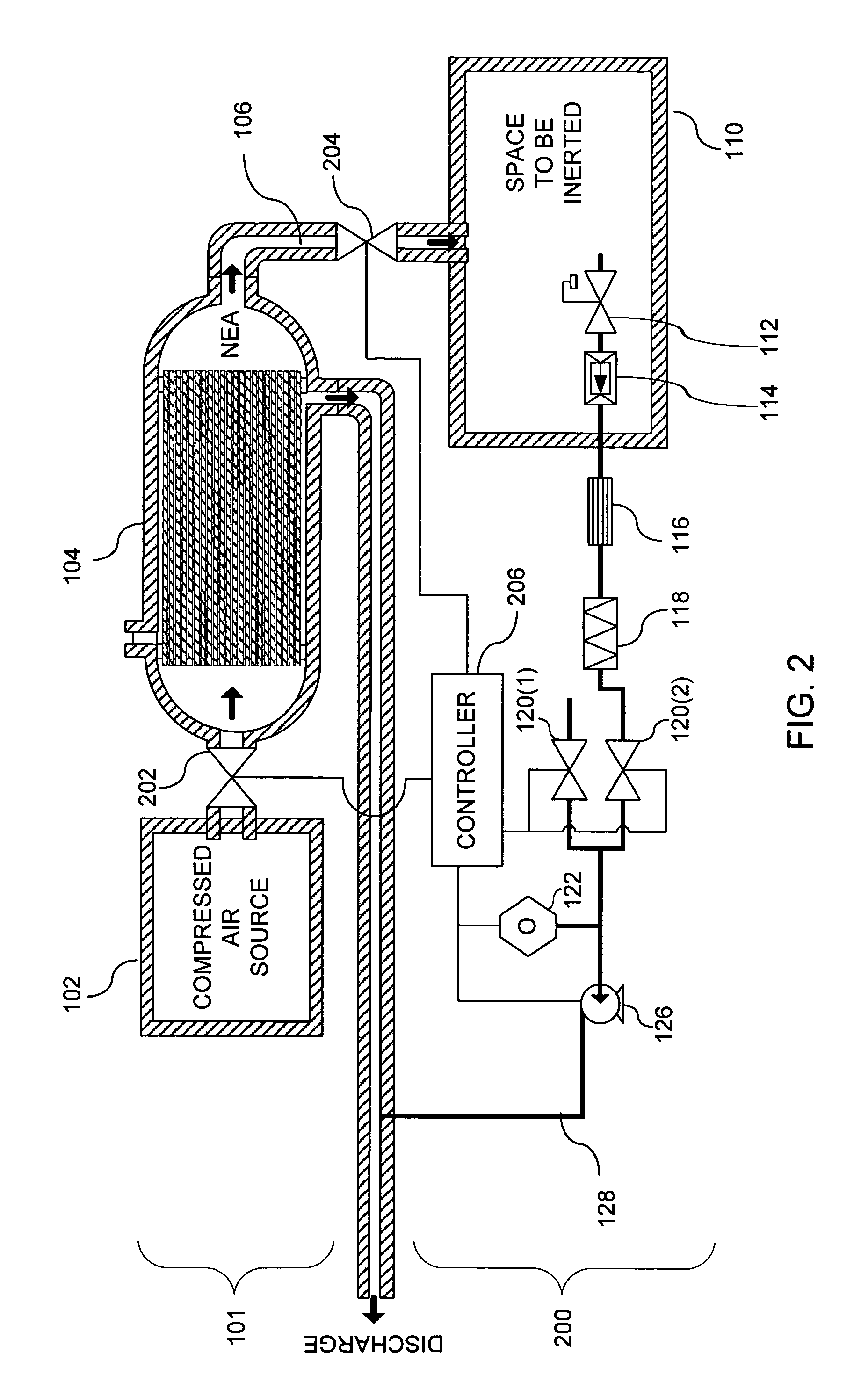

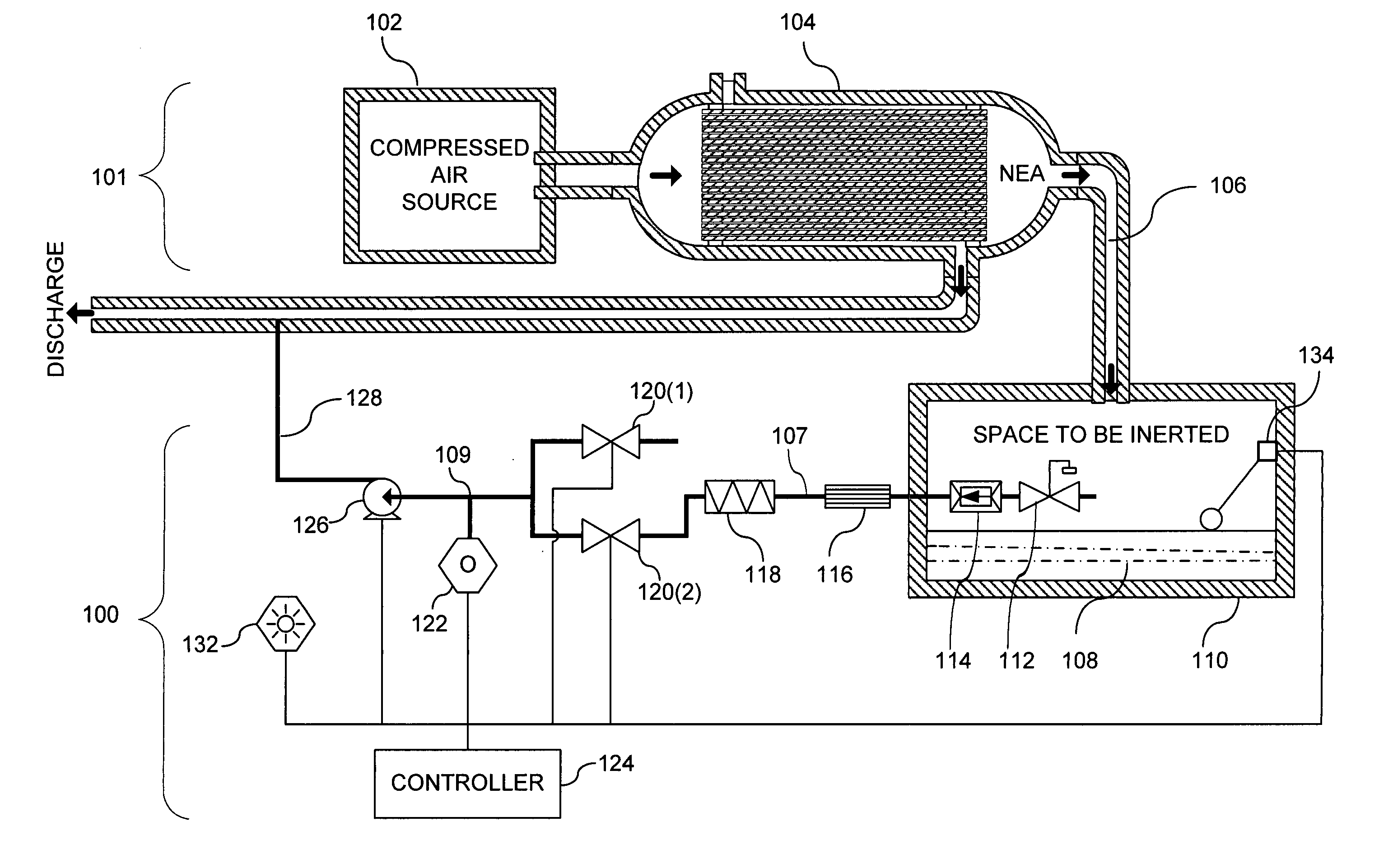

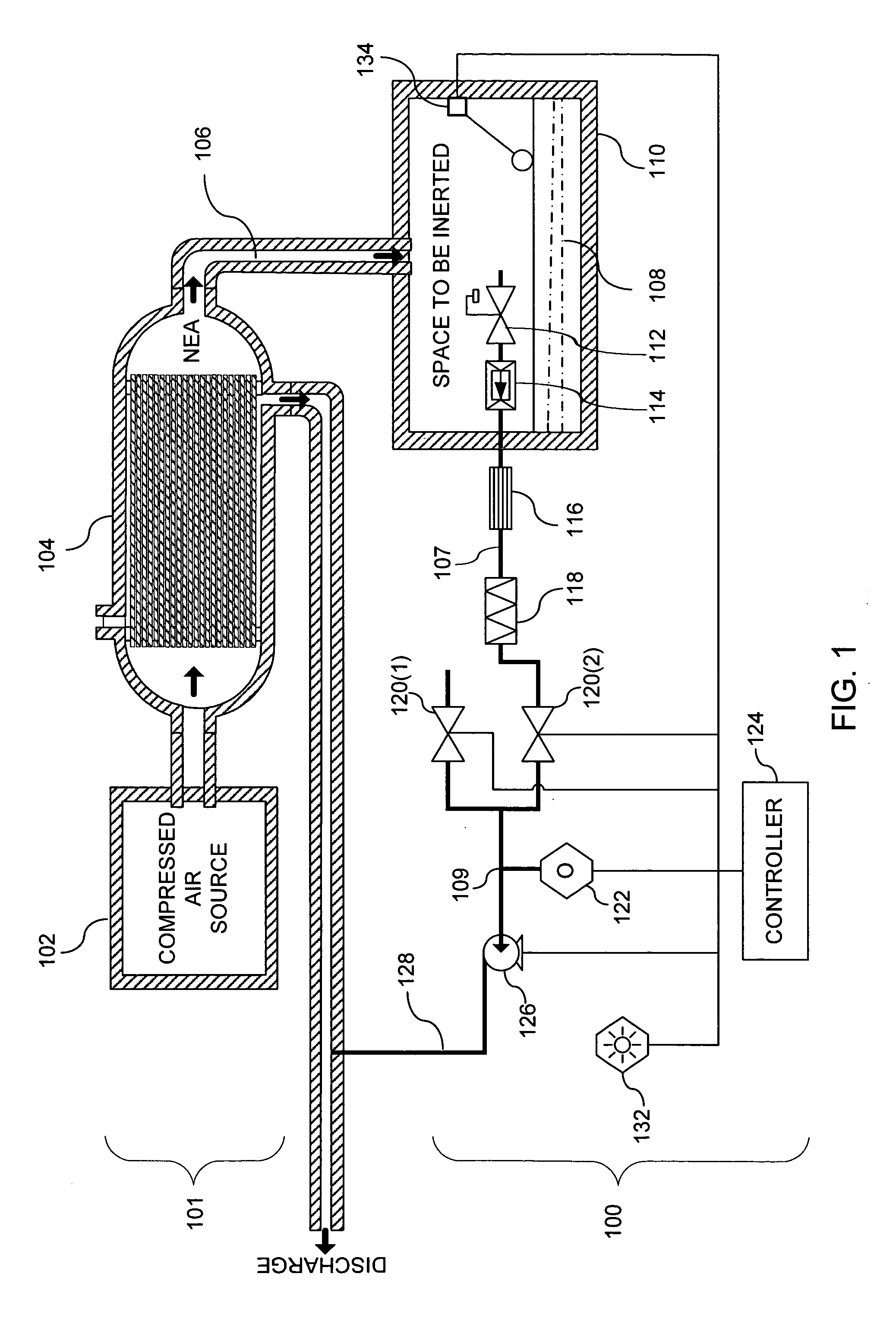

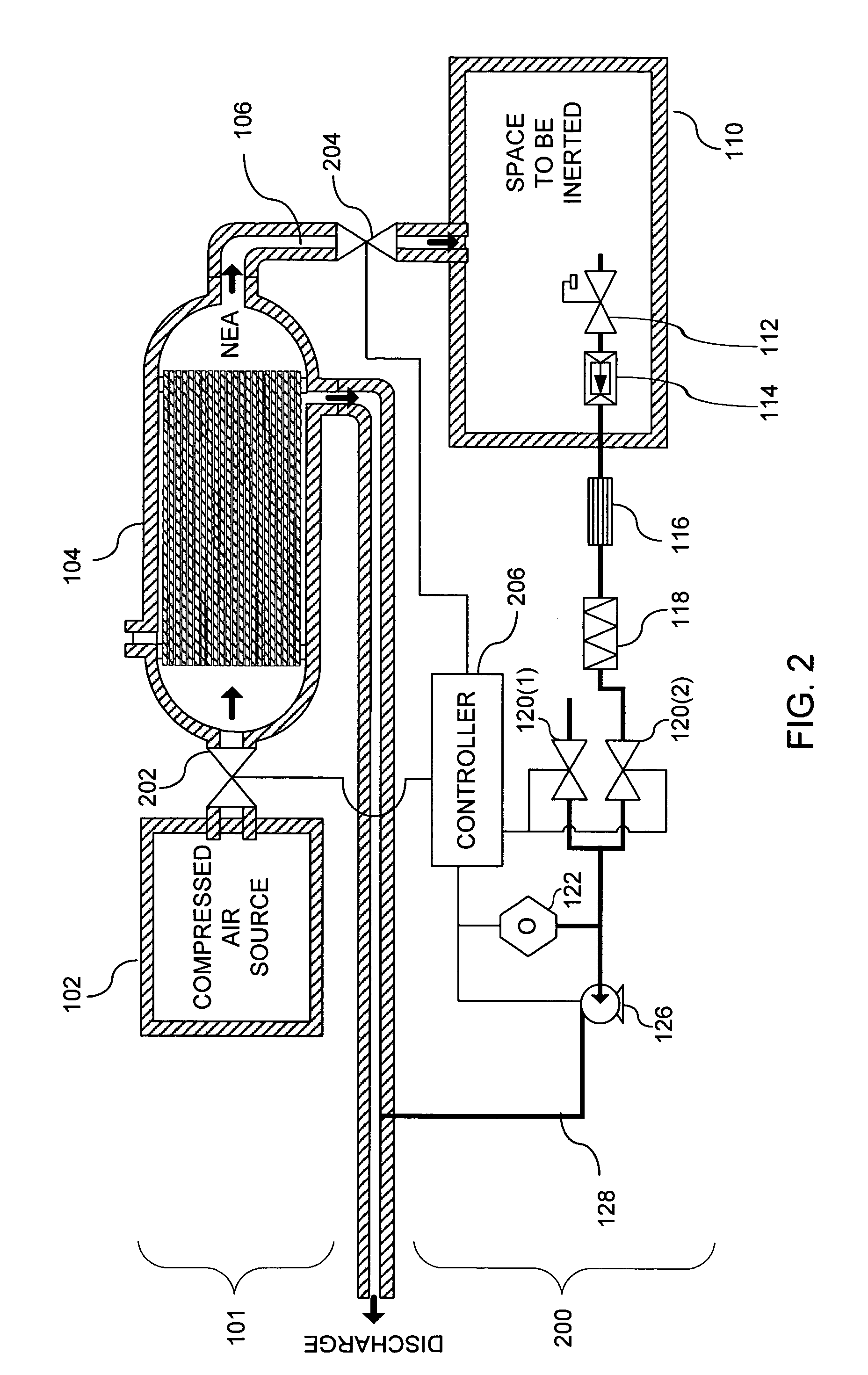

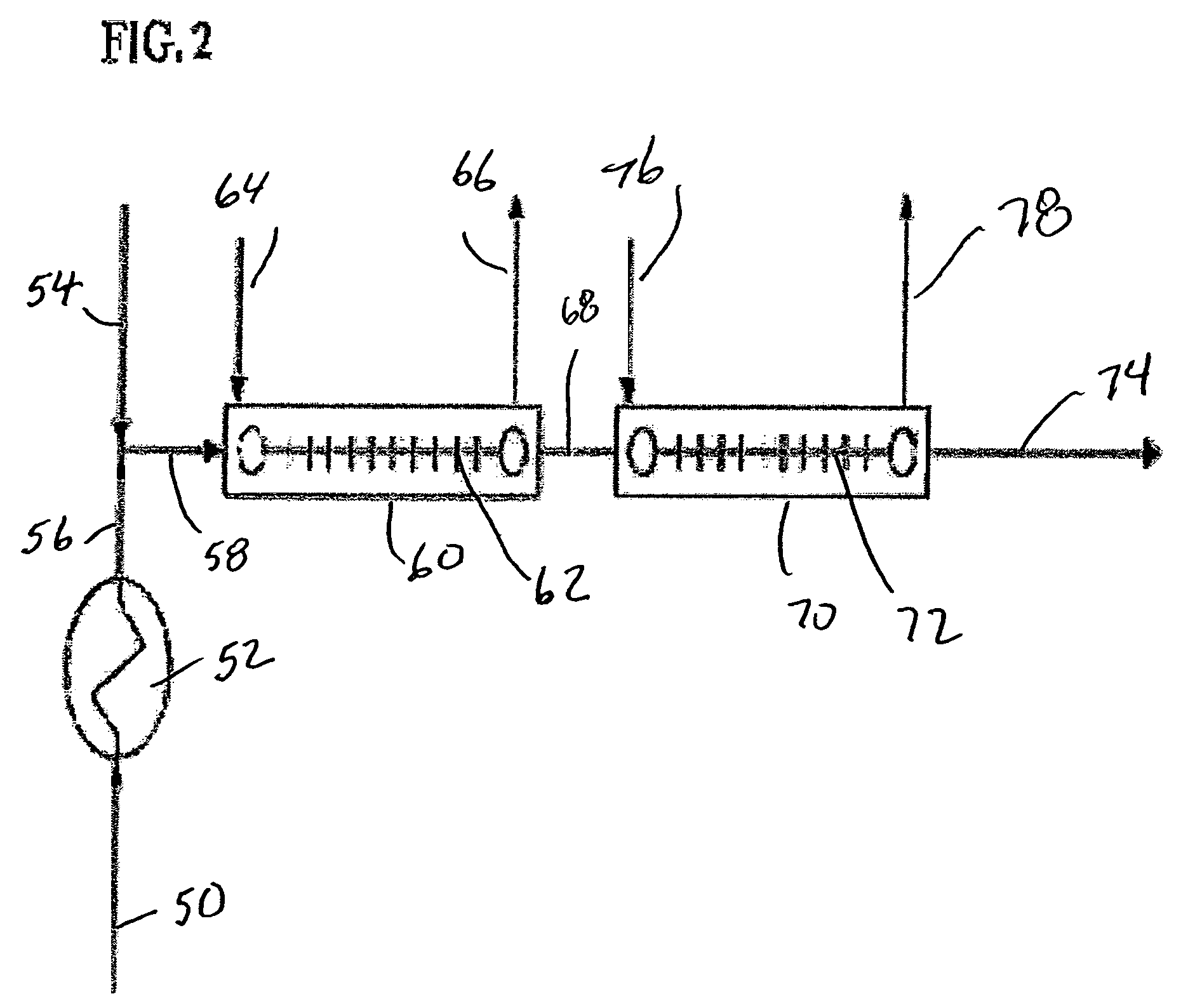

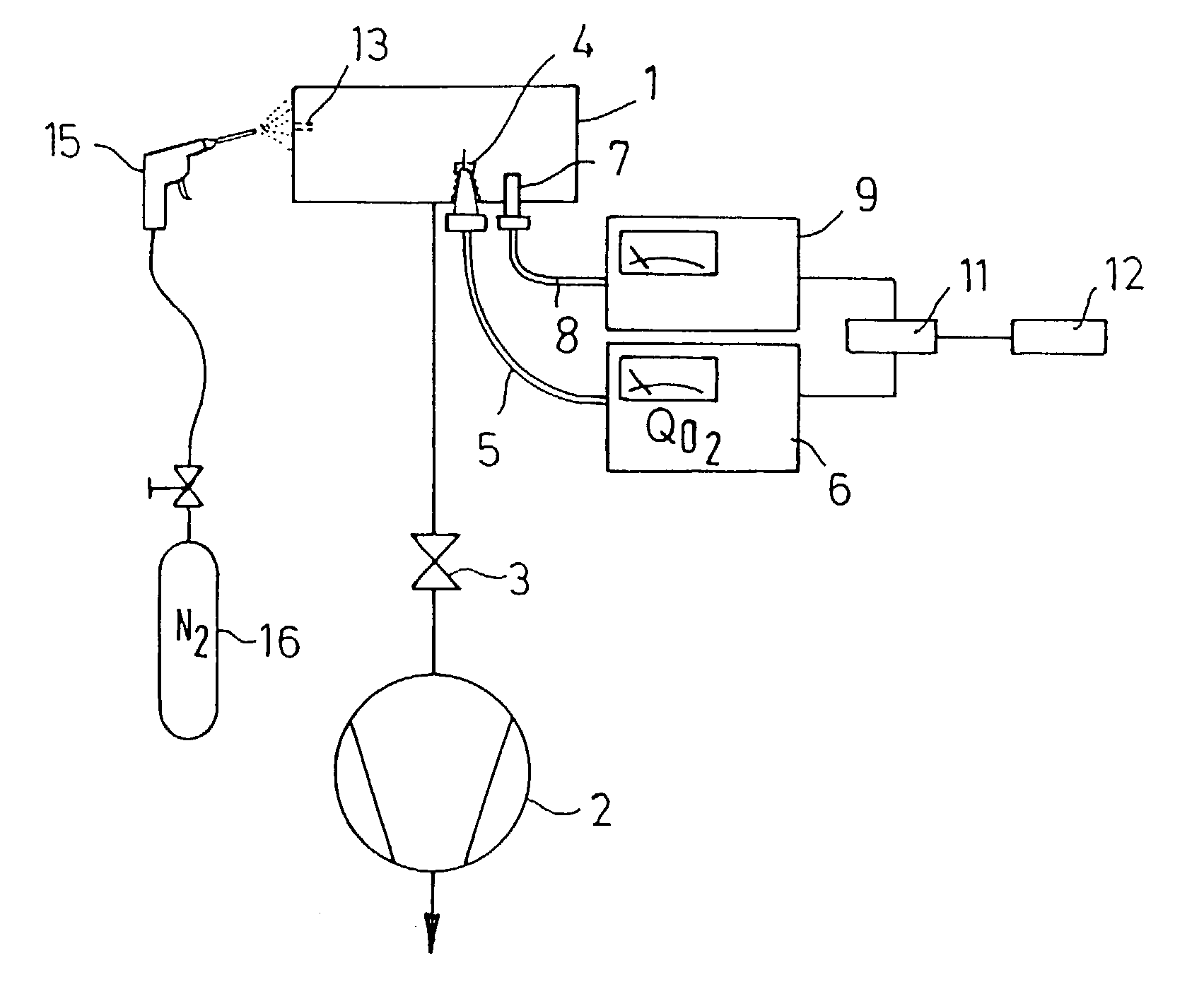

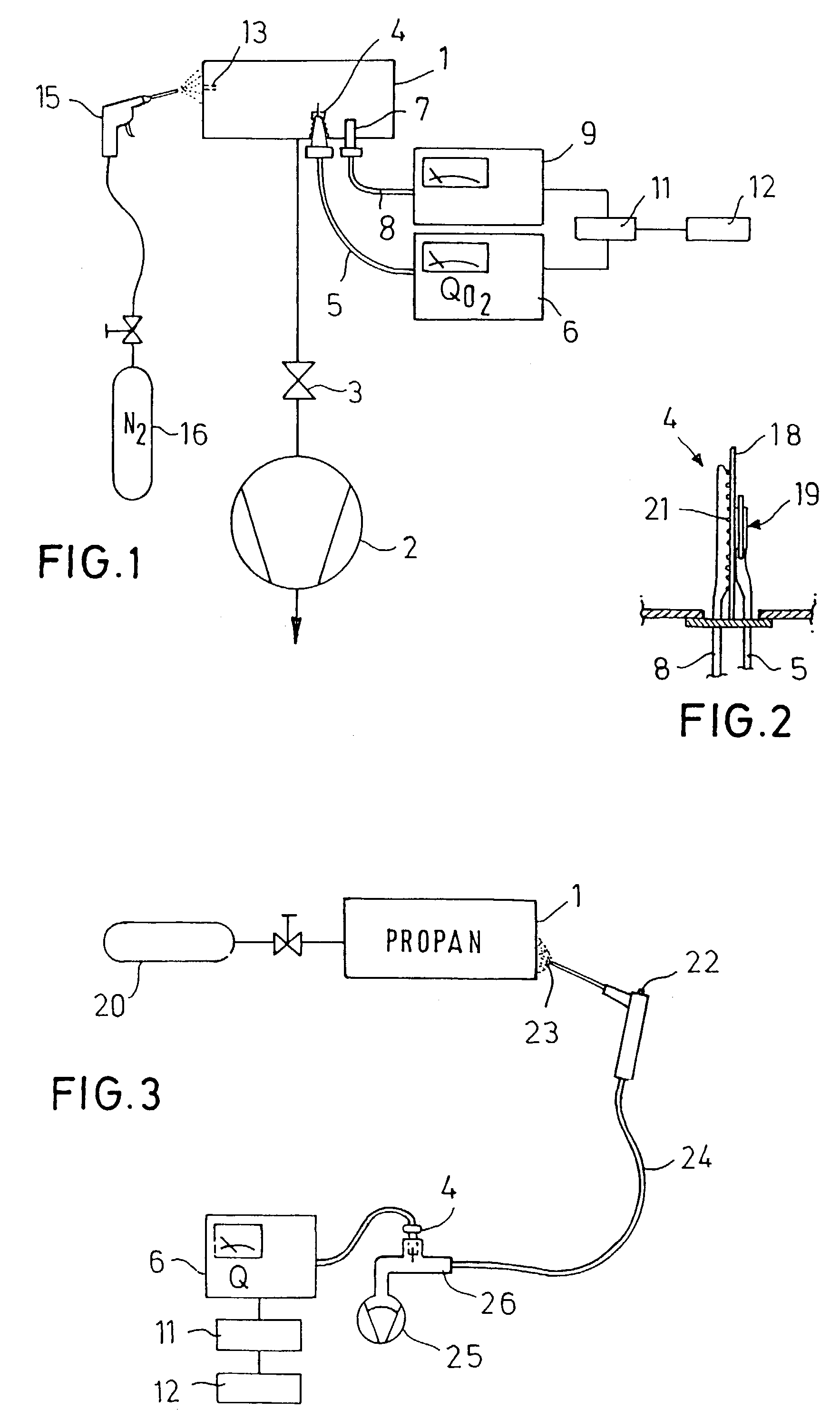

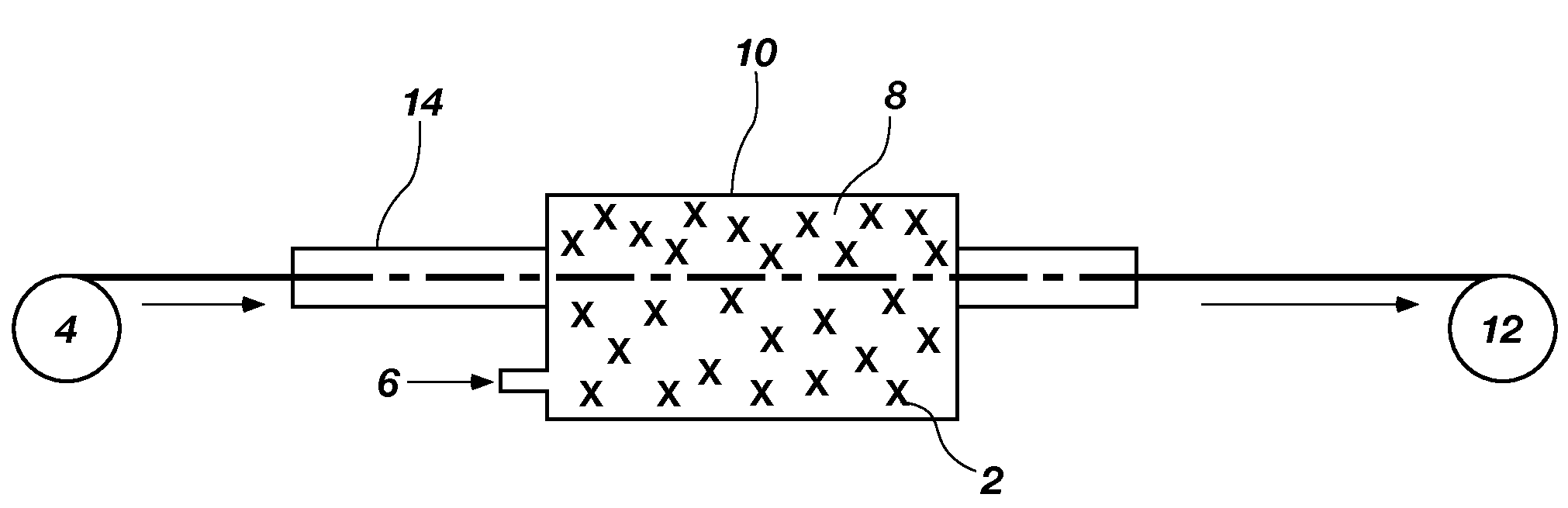

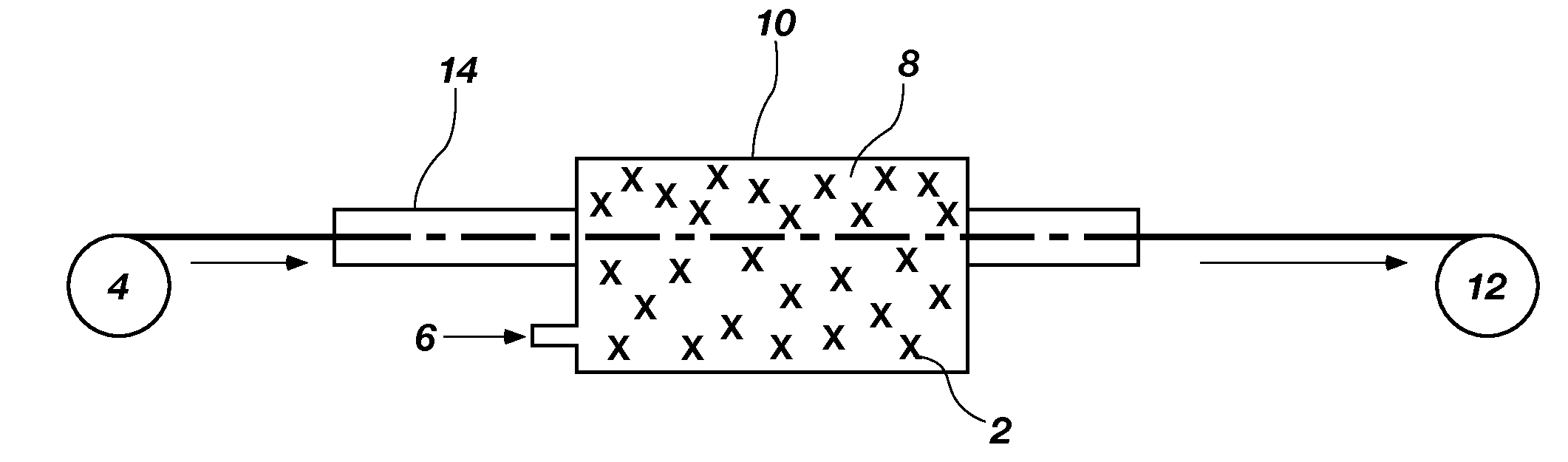

System and method for monitoring the performance of an inert gas distribution system

ActiveUS7013905B2Convenient verificationReduce misreadingAnalysing fluids using sonic/ultrasonic/infrasonic wavesValve arrangementsElectricityLine tubing

The gas monitoring system may include a gas line, an oxygen sensor, a filter, a pump, a indicator, and a controller. The gas line is configured to convey gas from a space configured to receive inert gas to a location remote from the space. The oxygen sensor is fluidly coupled to the gas line at the location. The oxygen sensor is configured to determine a partial pressure of oxygen present in the gas. The filter is fluidly coupled to the gas line between the space and the location. The filter is configured to remove combustible contaminants from the gas before it reaches the oxygen sensor. The controller is electrically coupled to the oxygen sensor and to the indicator. The controller is configured to activate the indicator when the partial pressure of oxygen exceeds a predetermined level.

Owner:PARKER INTANGIBLES LLC

System and method for monitoring the performance of an inert gas distribution system

ActiveUS20050229968A1Convenient verificationReducing false readingAnalysing fluids using sonic/ultrasonic/infrasonic wavesValve arrangementsElectricityOxygen sensor

The gas monitoring system may include a gas line, an oxygen sensor, a filter, a pump, a indicator, and a controller. The gas line is configured to convey gas from a space configured to receive inert gas to a location remote from the space. The oxygen sensor is fluidly coupled to the gas line at the location. The oxygen sensor is configured to determine a partial pressure of oxygen present in the gas. The filter is fluidly coupled to the gas line between the space and the location. The filter is configured to remove combustible contaminants from the gas before it reaches the oxygen sensor. The controller is electrically coupled to the oxygen sensor and to the indicator. The controller is configured to activate the indicator when the partial pressure of oxygen exceeds a predetermined level.

Owner:PARKER INTANGIBLES LLC

Smart disposable plastic lab-on-a-chip for point-of-care testing

InactiveUS7524464B2None of measures has been particularly successfulRelieve painBioreactor/fermenter combinationsCombination devicesVenous bloodLab-on-a-chip

Disclosed herein is a fully-integrated, disposable biochip for point-of-care testing of clinically relevant parameters. Specifically, in accordance with an embodiment of the present invention, the biochip is designed for POCT (point-of-care-testing) of an array of metabolic parameters including partial pressure of oxygen, Glucose, and Lactate concentration from venous blood samples. The biochip is fabricated on a low-cost plastic substrate using mass manufacturing compatible fabrication processes. Furthermore, the biochip contains a fully-integrated metallic micro-needle for blood sampling. The biochip also uses smart passive microfluidics in conjunction with low-power functional on-chip pressure generators for microfluidic sequencing. The design, configuration, assembly and operation of the biochip are ideally suited for a disposable biochip specifically targeted towards POCT applications.

Owner:UNIVERSITY OF CINCINNATI

Exhaust gas recirculation control systems and methods for low engine delta pressure conditions

A partial pressure determination module: determines a first partial pressure of oxygen in an intake manifold of an engine based on an output of a first oxygen sensor measuring oxygen in the intake manifold; and determines a second partial pressure of oxygen in an exhaust system based on an output of a second oxygen sensor measuring oxygen in the exhaust system. A concentration determination module: determines a concentration of oxygen in the intake manifold based on the first partial pressure and an intake manifold; and determines a concentration of oxygen in the exhaust system based on the second partial pressure. A flowrate determination module determines a mass flowrate of exhaust gas recirculation (EGR) based on the concentration of oxygen in the intake manifold and the concentration of oxygen in the exhaust system. An actuator control module controls an engine operating parameter based on the mass flowrate of EGR.

Owner:GM GLOBAL TECH OPERATIONS LLC

Calcium salt saponification of polyunsaturated oils

InactiveUS7098352B2Good storage stabilityImprove shelf life stabilityOrganic compound preparationFatty substance preservation using additivesCalcium hydroxideFatty acid glycerol esters

Methods for the preparation of storage-stable fatty acid calcium salt products by forming a reactive admixture of (a) an unsaturated fatty acid glyceride feedstock; and (b) from about 10% to about 30% of the total admixture weight of calcium hydroxide; and heating the admixture to a temperature at which the fatty acid glycerides saponify to form fatty acid calcium salts in an atmosphere in which the partial pressure of oxygen has been reduced by an amount effective to provide an improvement in storage stability. Storage stable calcium salts of unsaturated fatty acids prepared by the inventive method are also disclosed.

Owner:VIRTUS NUTRITION

Solid oxide fuel cell cathode material

InactiveCN1731607ASynthesis temperature is lowShort synthesis timeCell electrodesFuel cell detailsRare-earth elementAlkaline earth metal

Disclosed is a cathode material for solid oxidate fuel battery. The composition general formula of the invented cathode material is A1+xA1-xíõB1-yByíõO4í‚delta, wherein A is main group alkali earth metal, Aíõ is rare-earth element, B and B' are transient elements, and 0<x<1ú¼0<=y<=1ú¼delta<=0.17. The said cathode material has high oxygen-ion-electron mixing conductivity rate which is higher than perovskite structure cathode material's in the range of 10-5 to 1atm of partial pressure of oxygen. The inventive cathode material has the advantages of good heat stability, chemical resistance and oxidation catalytic reduction property.

Owner:HEILONGJIANG UNIV

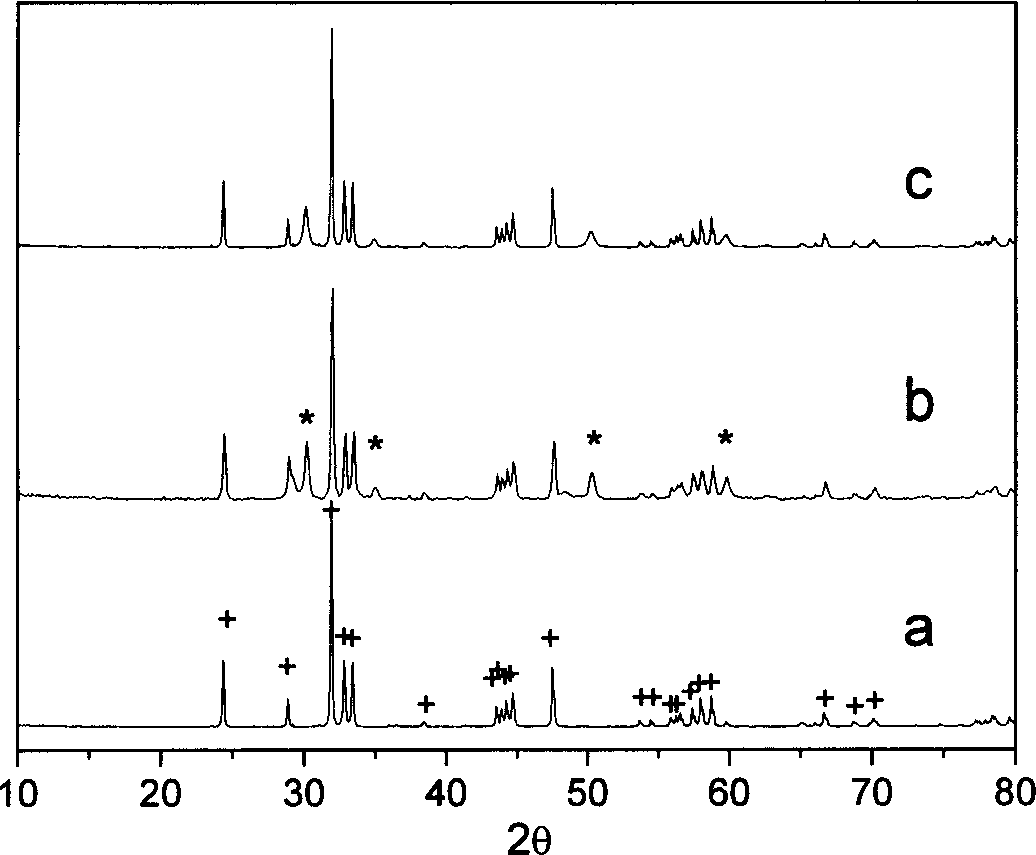

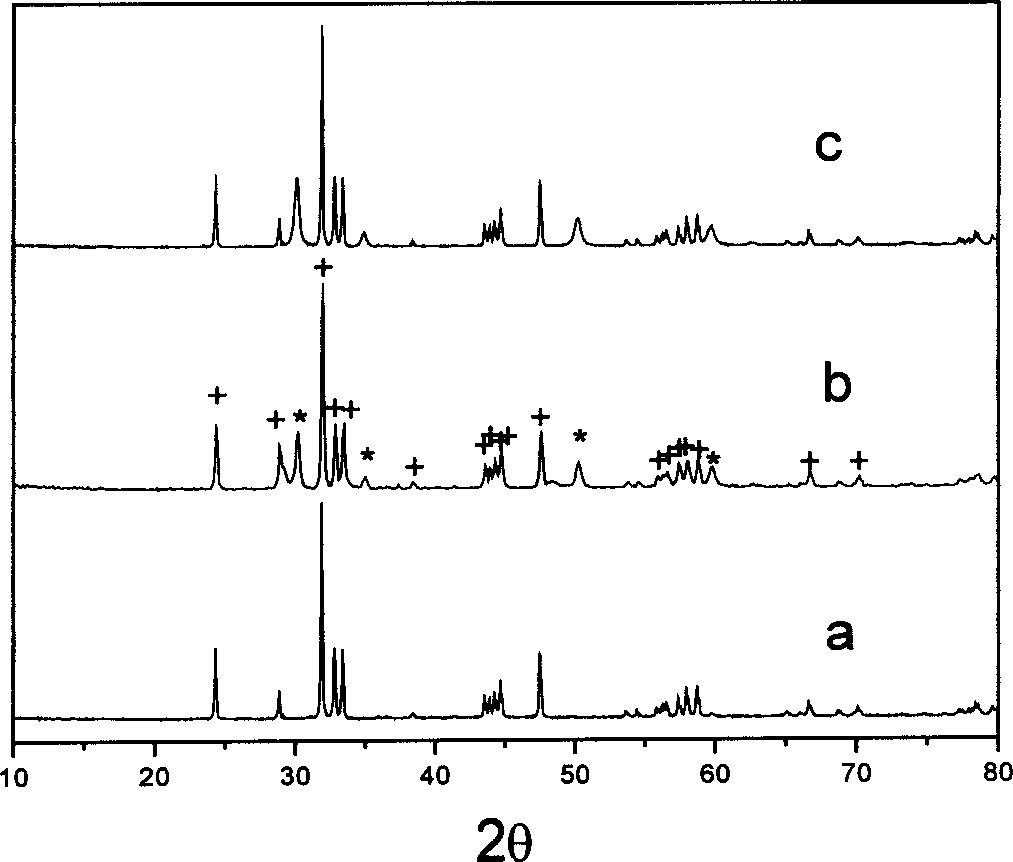

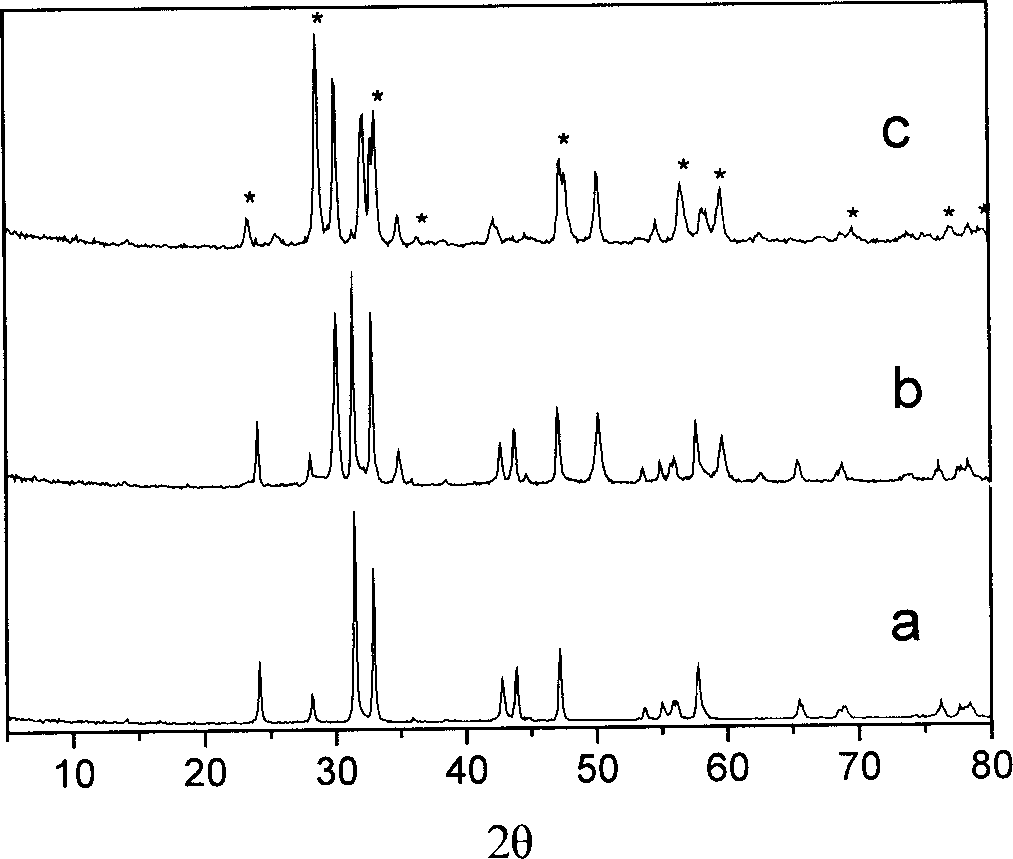

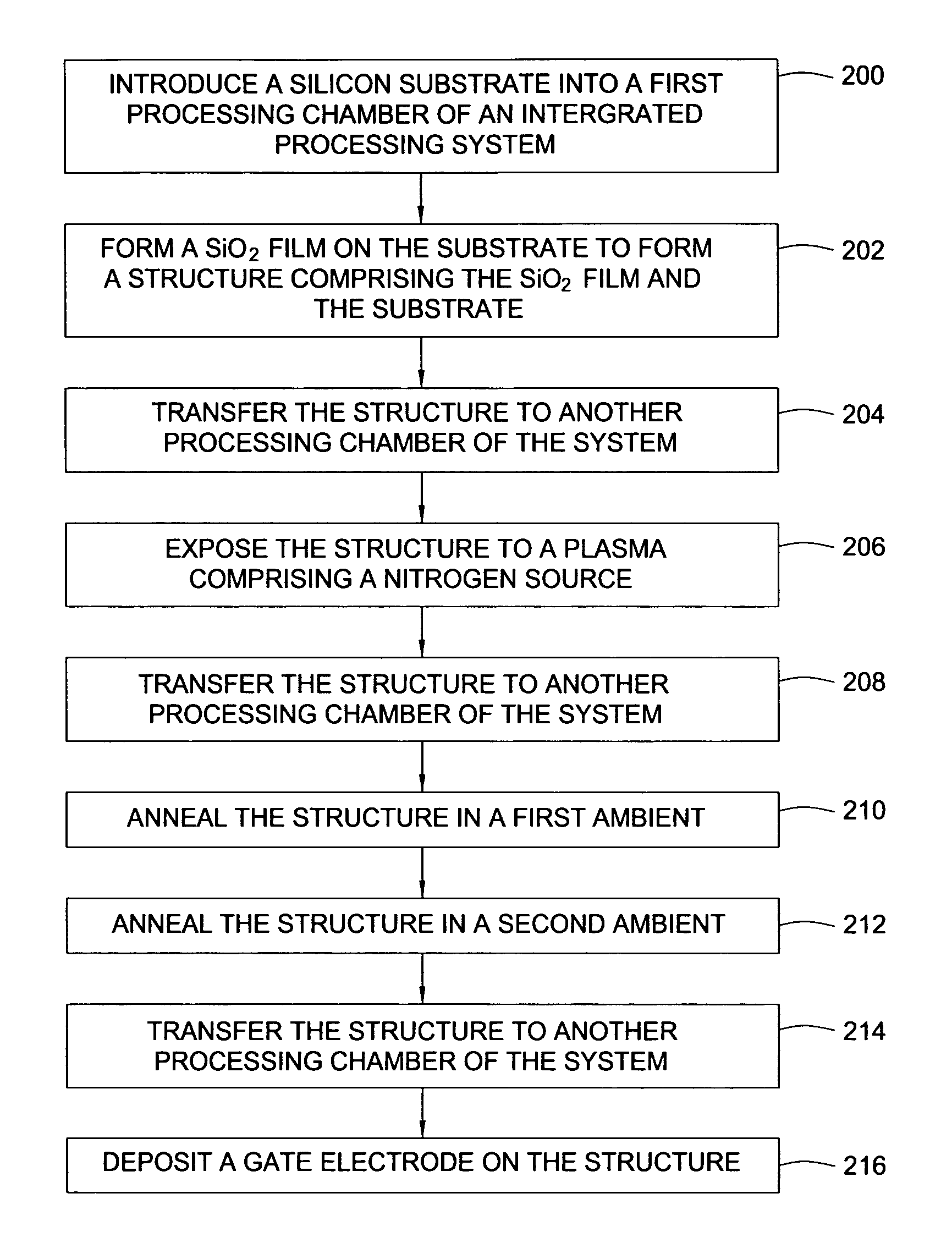

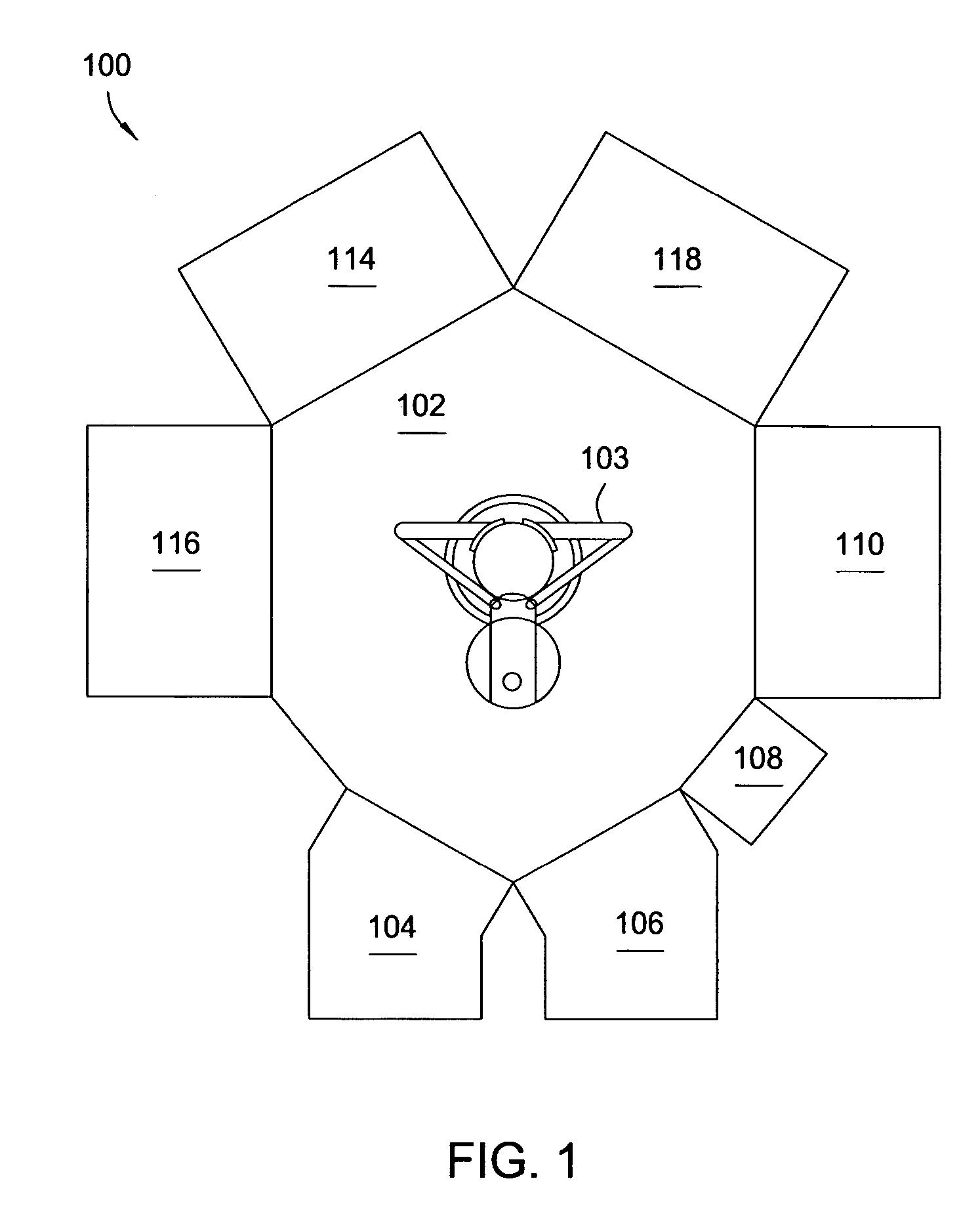

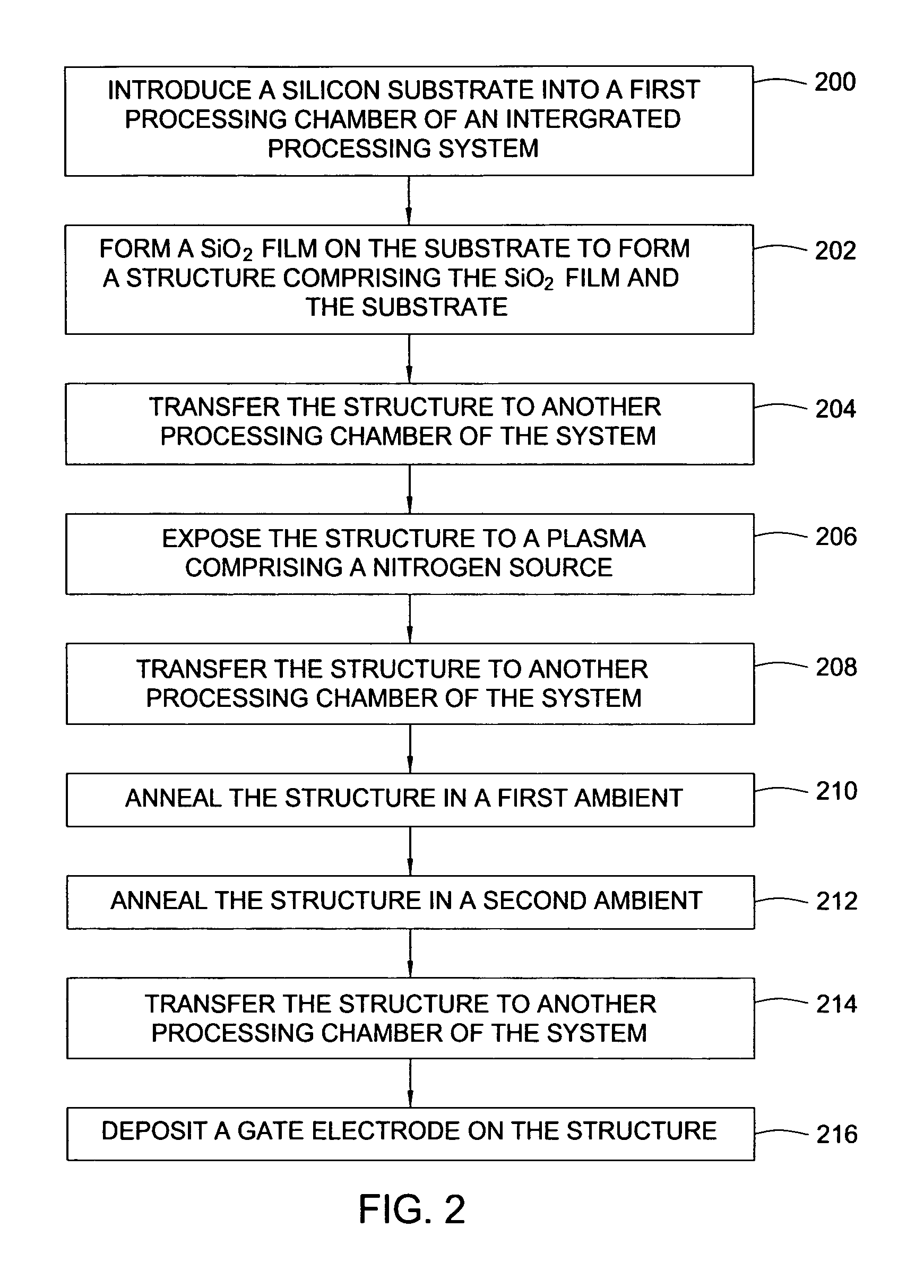

Manufacturing method for two-step post nitridation annealing of plasma nitrided gate dielectric

ActiveUS20060292844A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricNitrogen

A method of forming a silicon oxynitride gate dielectric. The method includes incorporating nitrogen into a dielectric film using a plasma nitridation process to form a silicon oxynitride film. The silicon oxynitride film is annealed in a first ambient. The first ambient comprises an inert ambient with a first partial pressure of oxygen at a first temperature. The silicon oxynitride film is then annealed in a second ambient comprising a second partial pressure of oxygen at a second temperature. The second partial pressure of oxygen is greater than the first partial pressure of oxygen.

Owner:APPLIED MATERIALS INC

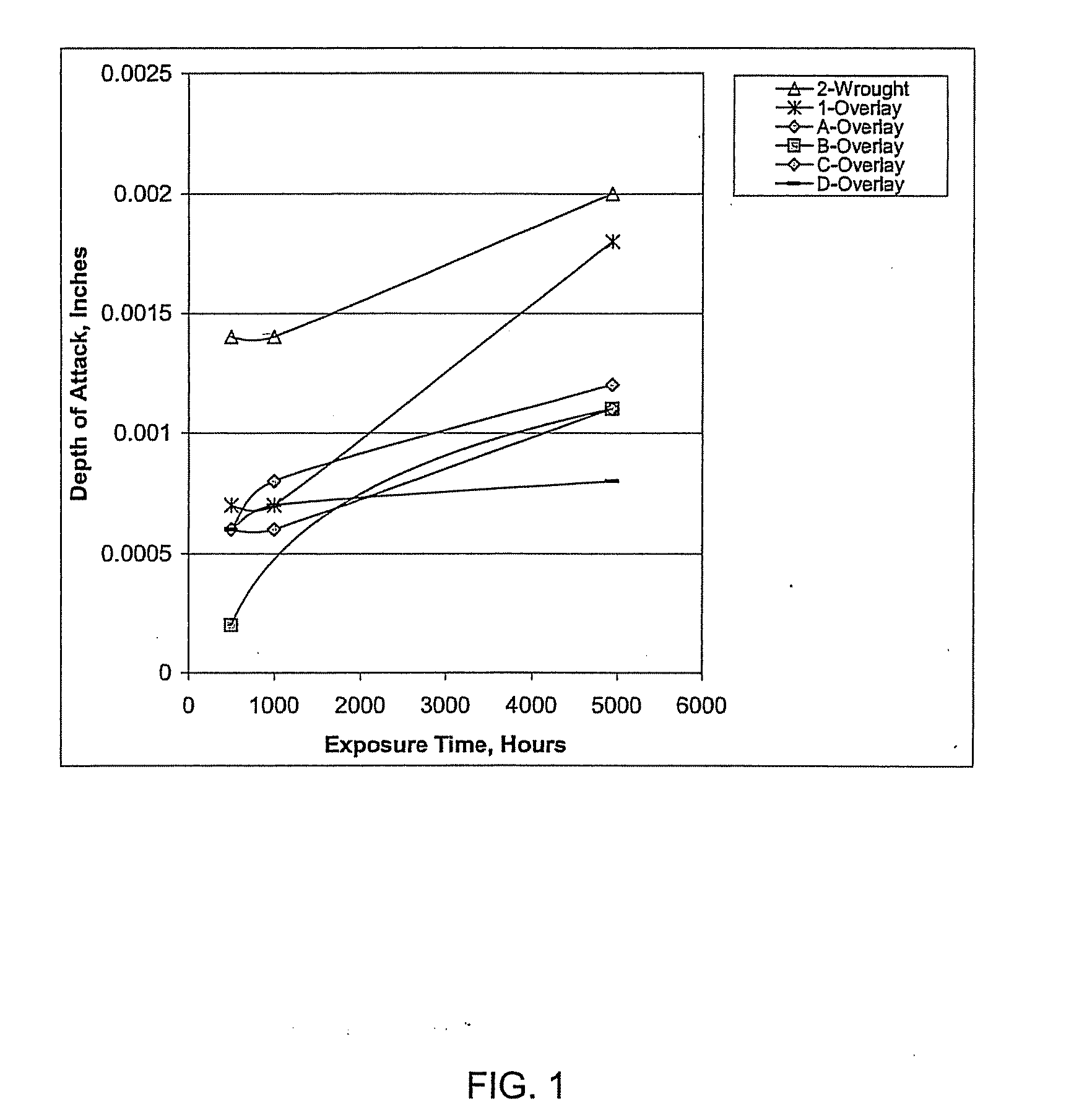

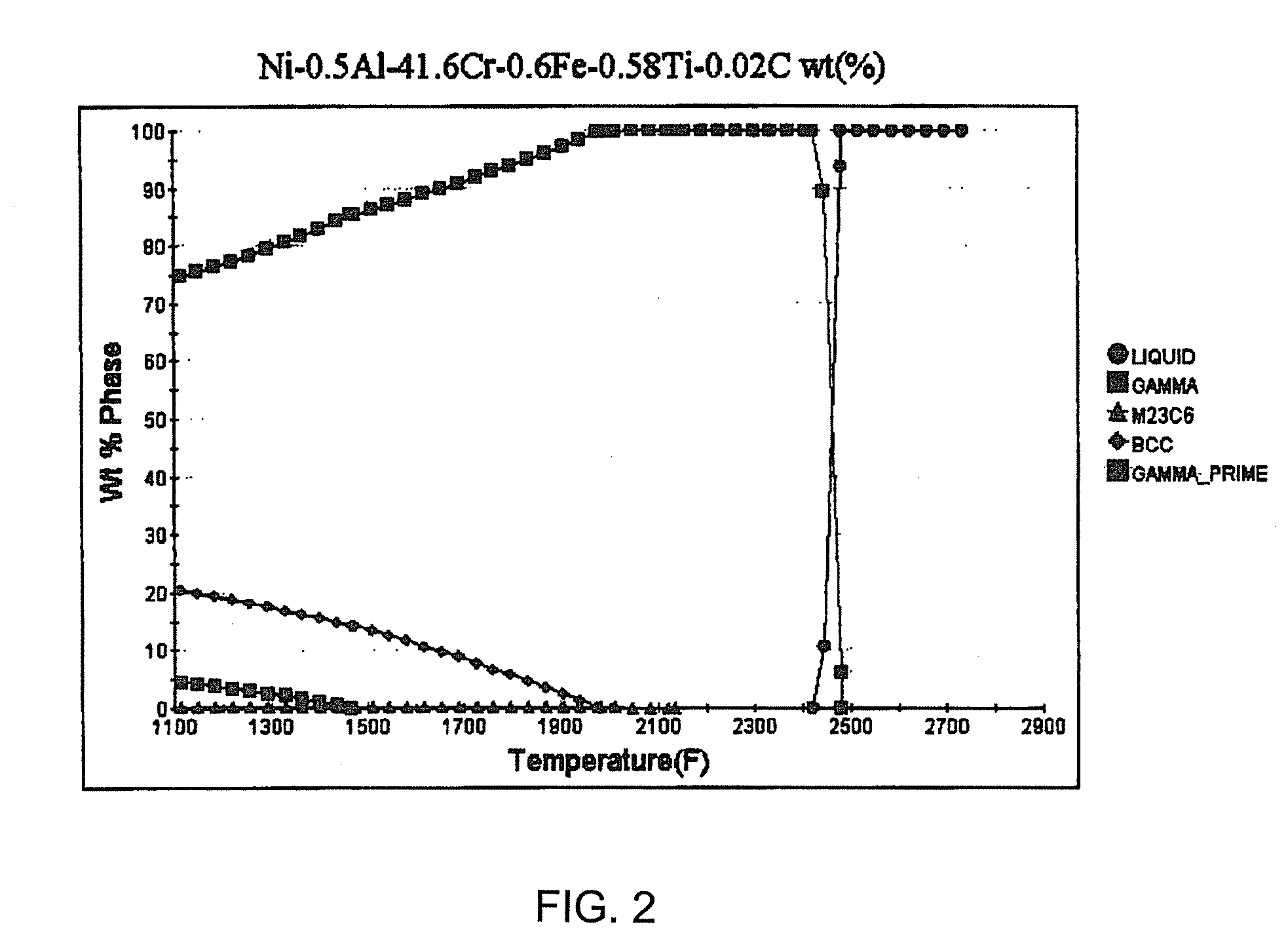

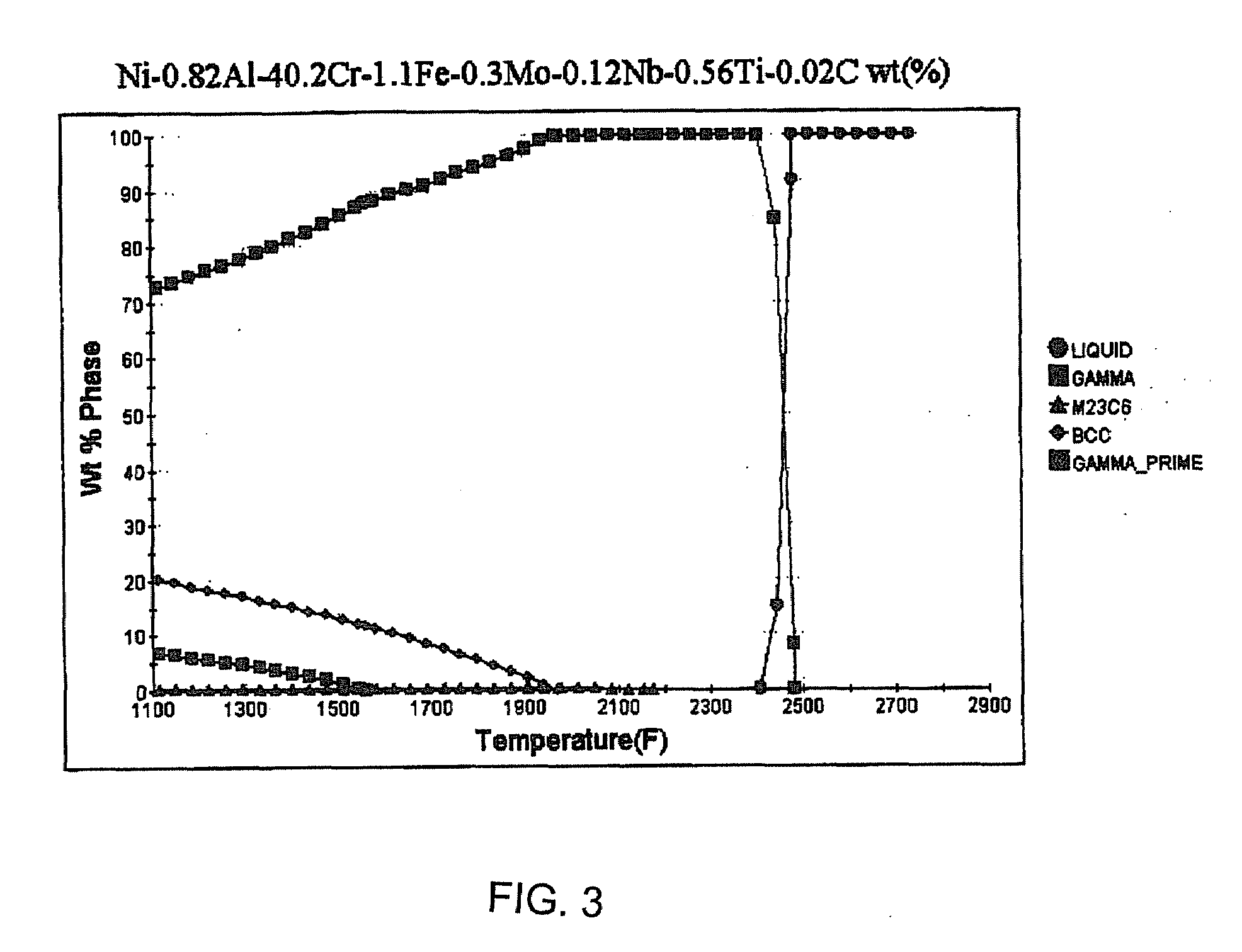

Filler Metal Composition and Method for Overlaying Low NOx Power Boiler Tubes

ActiveUS20080241580A1Solve the lack of corrosion resistanceEnvelopes/bags making machineryElectric discharge heatingAlloyOxygen

An alloy for use as a welding overlay for boiler tubes in a low NOx coal-fired boiler comprising in % by weight: 36 to 43% Cr, 0.2 to 5.0% Fe, 0-2.0% Nb, 0-1% Mo, 0.3 to 1% Ti, 0.5 to 2% Al, 0.005 to 0.05% C, 0.005 to 0.020% (Mg+Ca), 0-1% Mn, 0-0.5% Si, less than 0.01% S, balance substantially Ni and trace additions and impurities. The alloy provides exceptional coal ash corrosion resistance in low partial pressures of oxygen. The alloy also increases in hardness and in thermal conductivity at service temperature over time. The increased hardness improves erosion resistance of the tubes while the increased thermal conductivity improves the thermal efficiency of the boiler and its power generation capabilities.

Owner:HUNTINGTON ALLOYS CORP (US)

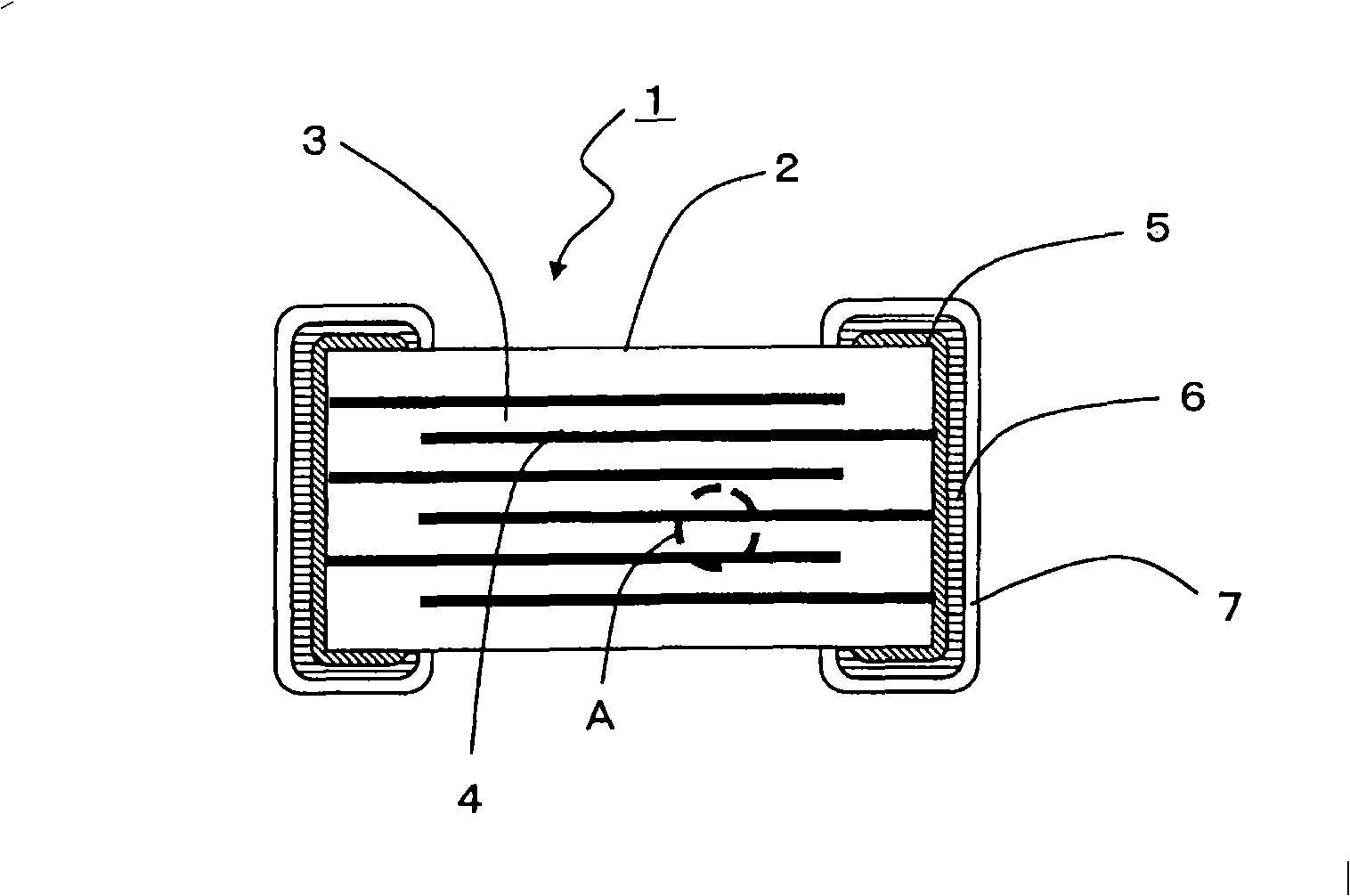

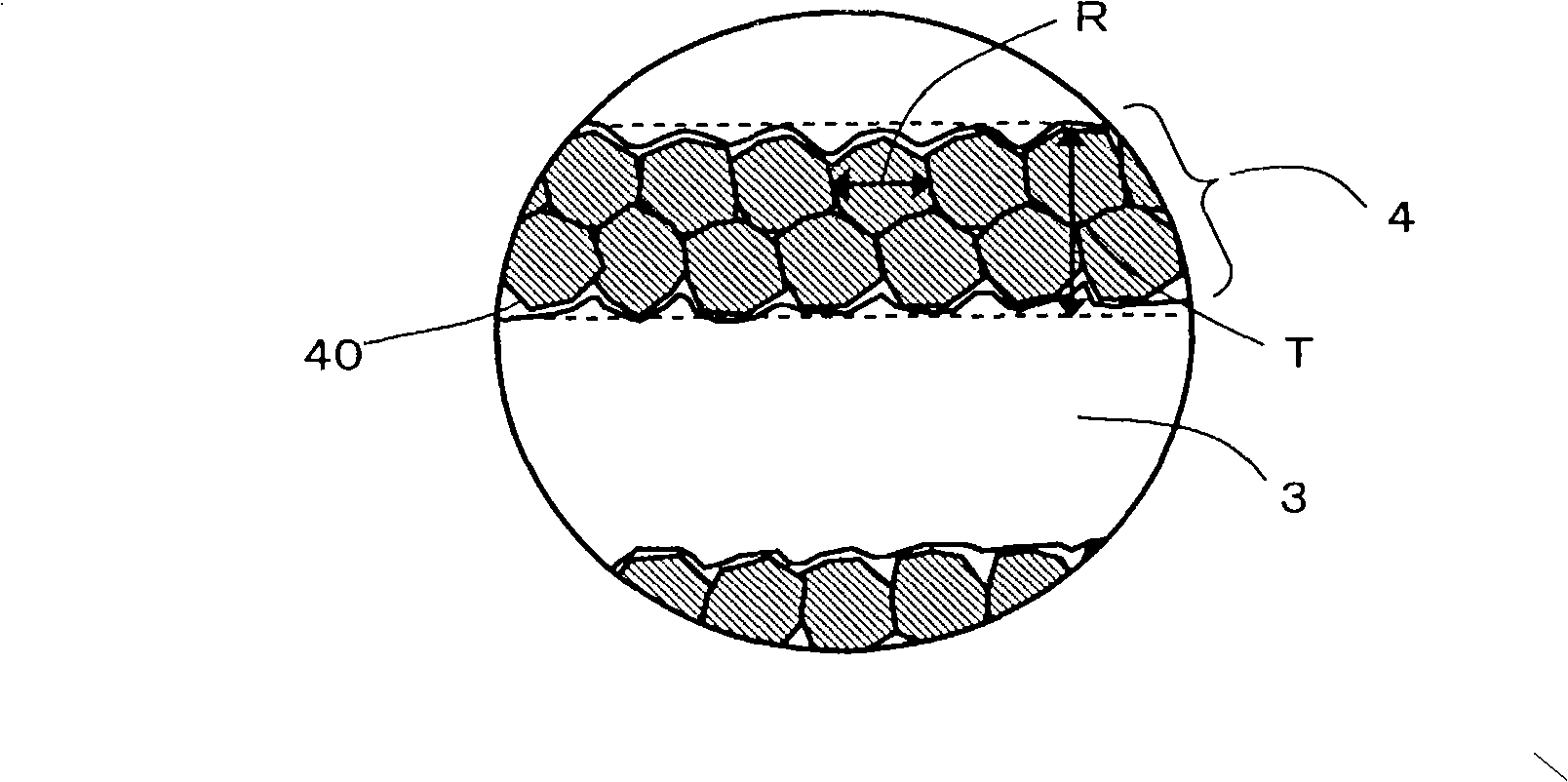

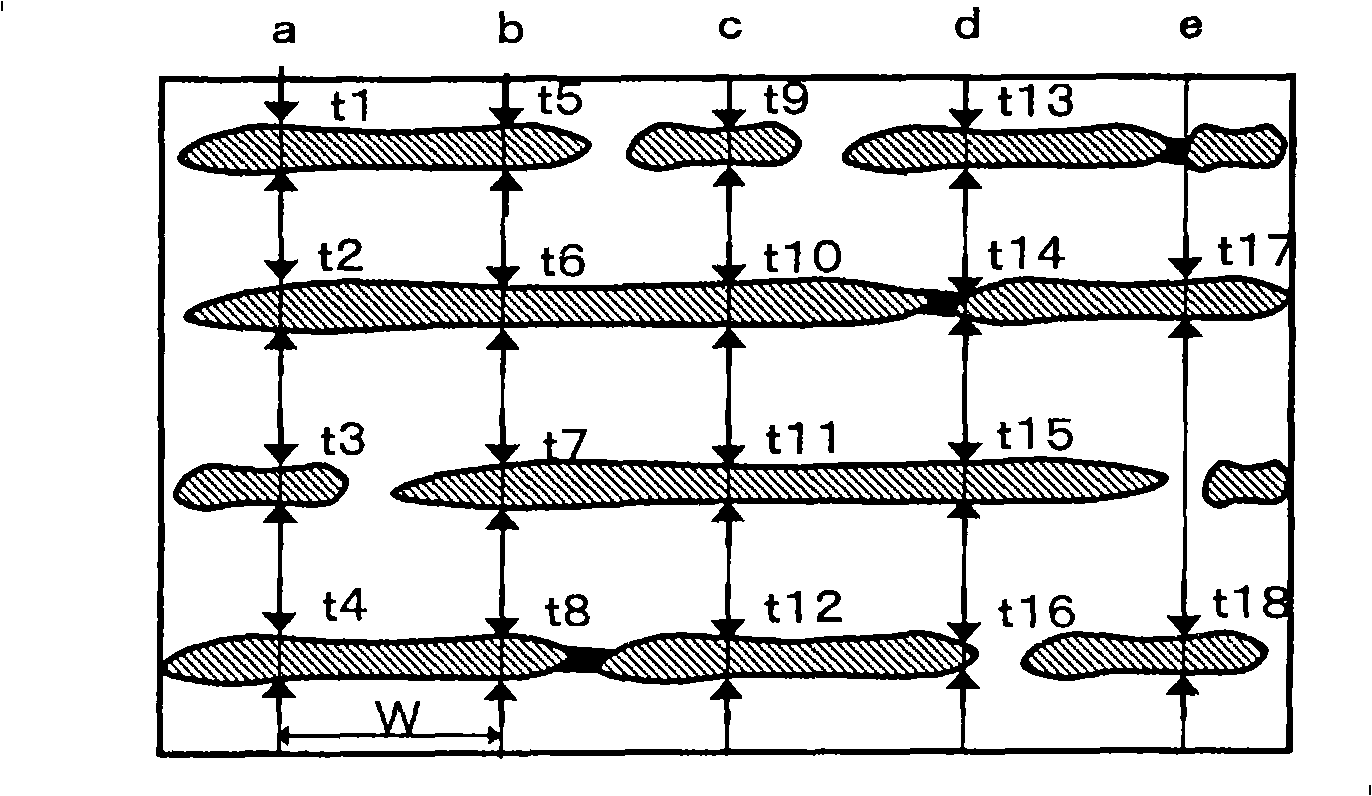

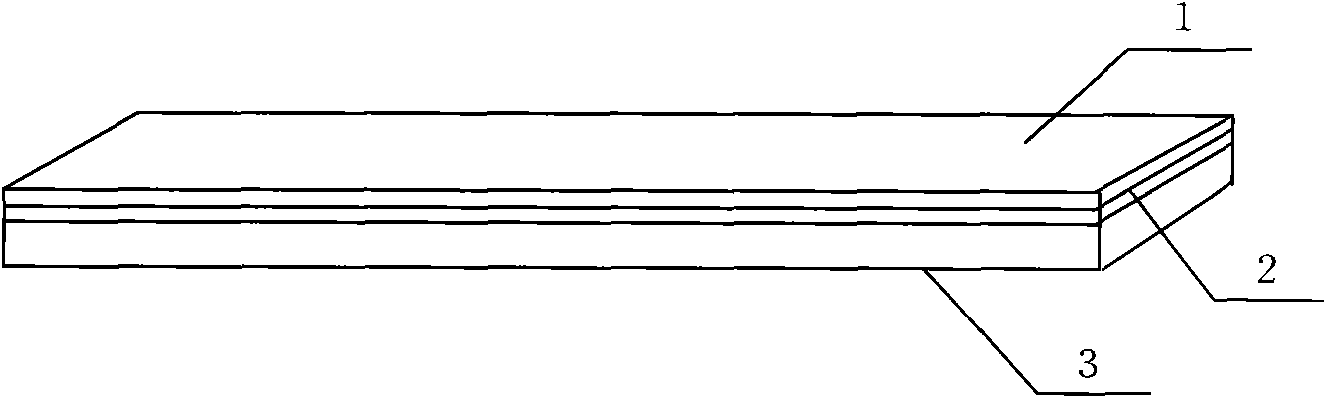

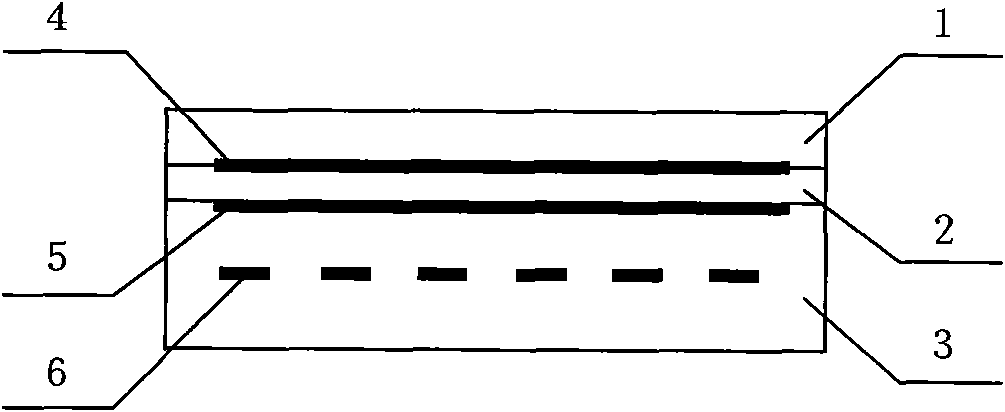

Laminated ceramic capacitor and manufacturing method thereof

ActiveCN101354962ALow costImprove continuityFixed capacitor electrodesFixed capacitor dielectricConductive pasteCeramic capacitor

The purpose of the invention is to obtain a laminated ceramic capacitor of the internal electrode with great continuity with a low cost. The internal electrode layer (4) of the laminated ceramic capacitor (1) is composed of the metal particles (40); the metal particles (40) processes the solution for the thickness (T) of the average granule diameter less than the inner electrode layer (4) in the direction of the particle diameter (R) parallel to the direction of the internal electrode layer (4); the internal electrode layer can be formed by the conductive paste with the conductive powder, which is obtained by the heat process in the reductive atmosphere in the 10-14-10-18 atm partial pressure of oxygen. The conductive powder is covered with the base metal particles selected from the Mn, Co, Fe, Cu, Nb, Ba, Ca, Sr, Ti, Zn and tombar thite or the oxidant particles on the Ni metal particles.

Owner:TAIYO YUDEN KK

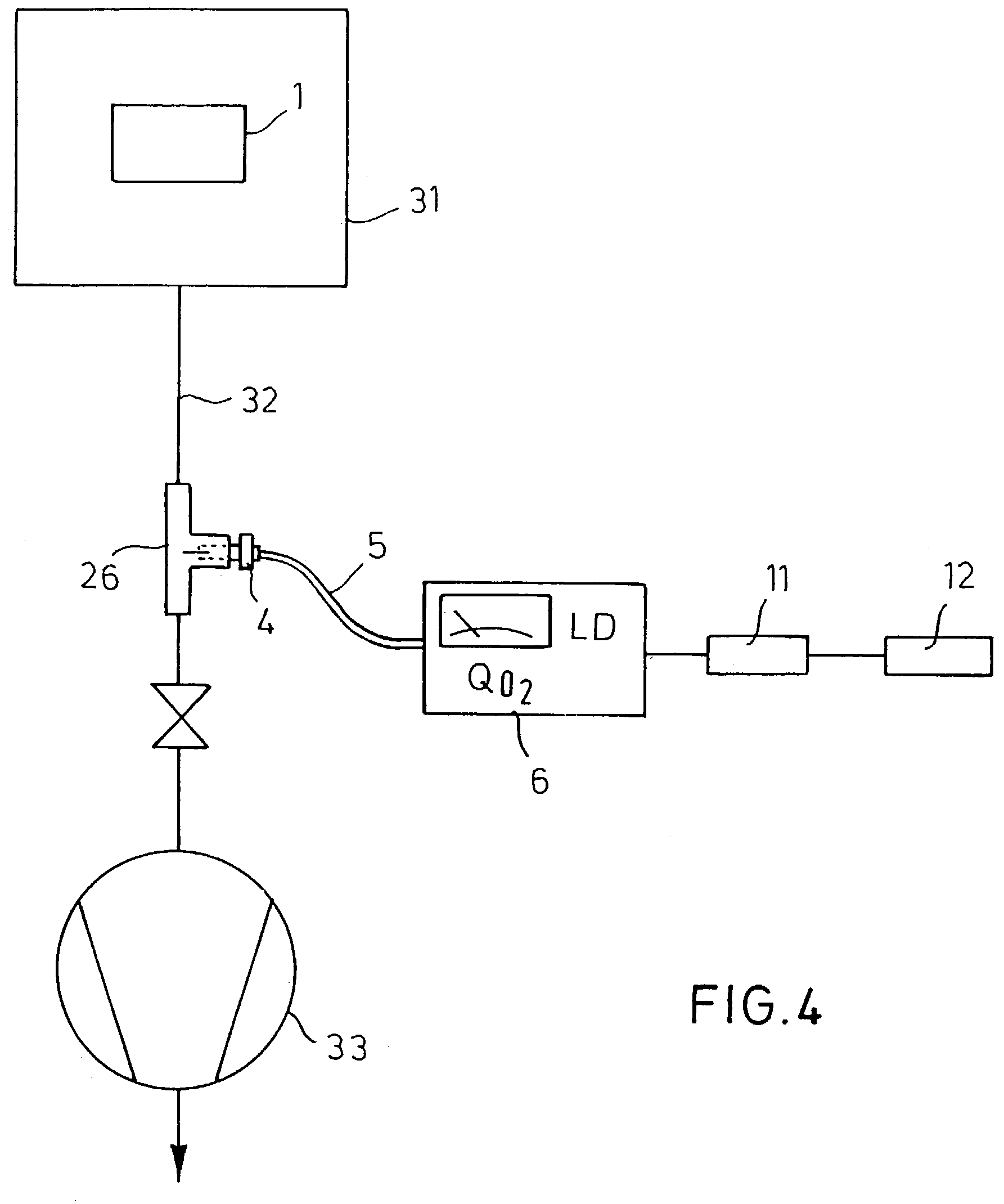

Method for detecting and localizing leaks and suitable device for carrying out the method

InactiveUS7156976B2Detection of fluid at leakage pointMeasurement of fluid loss/gain rateOxygen sensorEngineering

The invention relates to a method and a device for detecting leaks in the wall of a test object, container or similar, by measuring and evaluating changes that occur in a partial gas pressure. The invention aims to simplify the detection of leaks. To this end, changes that occur in partial pressures of oxygen are detected and evaluated using an oxygen sensor (4).

Owner:INFICON GMBH

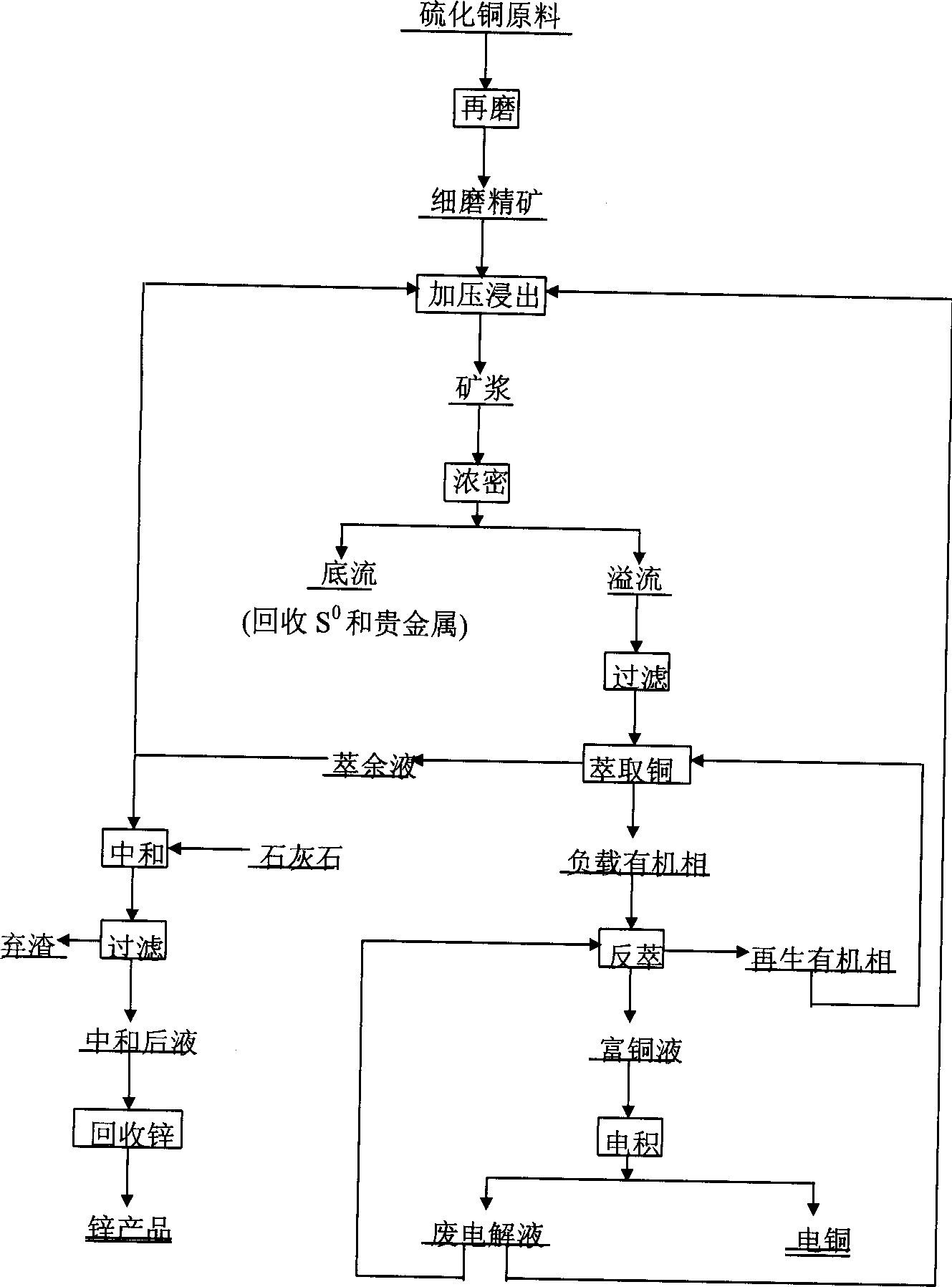

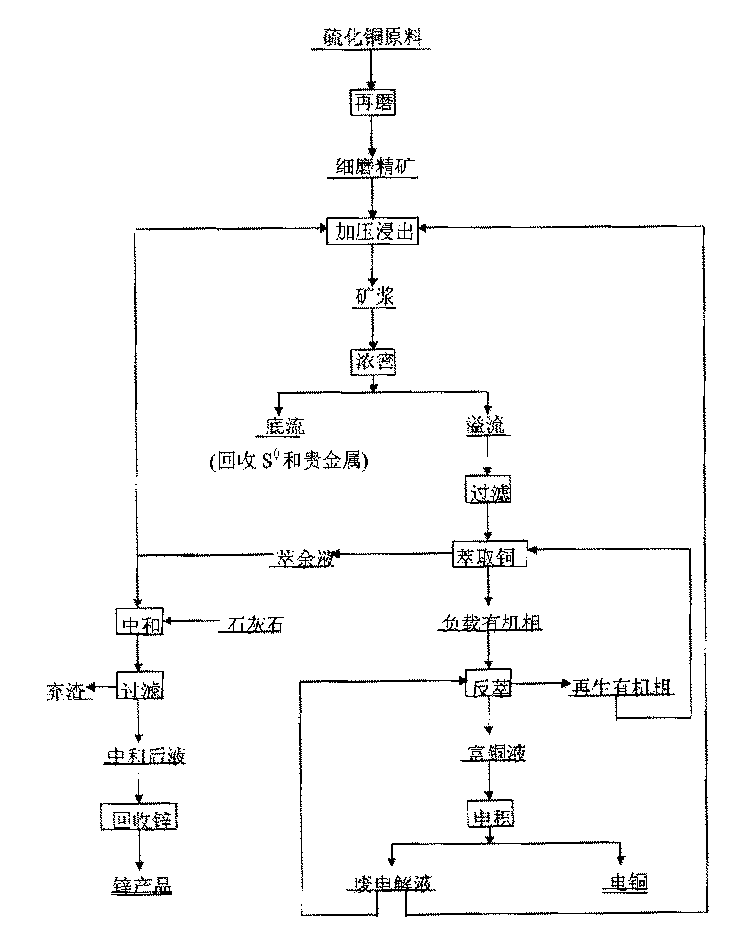

Method for extracting copper for copper containing sulfurized ore

InactiveCN1358871ALow leaching temperatureRelieve pressureProcess efficiency improvementSlagSulfide minerals

The method for extracting copper from copper-bearing sulfide mineral is characterized by leaching copper-bearing mineral under the condition of introduction of oxygen and in the presence of sulfuric acid and chlorine ion, the liquid-solid ratio of leaching-out liquor is 1-8:1, primary concentration of sulfuric acid is 5-70 g / L, leaching total pressure is 200-1000 kPa, partial pressure of oxygen is 100-800 kPa, temp. is 100-130 deg.C and time is 1-4 hr. The leaching temp. and pressure of said method are low, its selectivity is good, the pyrite can not be oxidated, and the harmful impurity, for example arsenic, can be solidifed in arsenic-ion slag, so that it is a process friendly to environment.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Accelerometer for high temperature applications

ActiveUS20120204644A1Improve performanceDelay agingPiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesAccelerometerAlloy

This invention is for a hermetic piezoelectric accelerometer sensor that can operates at high temperatures without the degradation observed on the piezoelectric elements, due to Oxygen depletion of the piezoelectric materials, when they are exposed to high temperatures, in reducing atmospheres, or low partial Oxygen pressure, inside a sealed housing. When a piezoelectric element loses Oxygen, becomes more electrically conductive, and this severe loss in resistivity, exacerbated with the increase of the temperature, makes the sensor inoperable, unreliable, or with permanent damage. The accelerometer of this invention operates effectively over a wide range of temperatures, including high temperatures above 1600° F., depending of the piezoelectric element used on the construction. The housing of the accelerometer uses a small section of metal made with Silver (or Silver alloys) to allow Oxygen diffusion through the metal, when it is exposed to high temperature. This permits that the construction of the accelerometer housing, can be sealed hermetically; and the piezoelectric elements of the sensor have increased lifetime, with enough partial pressure of Oxygen inside the housing.

Owner:DYTRAN INSTR

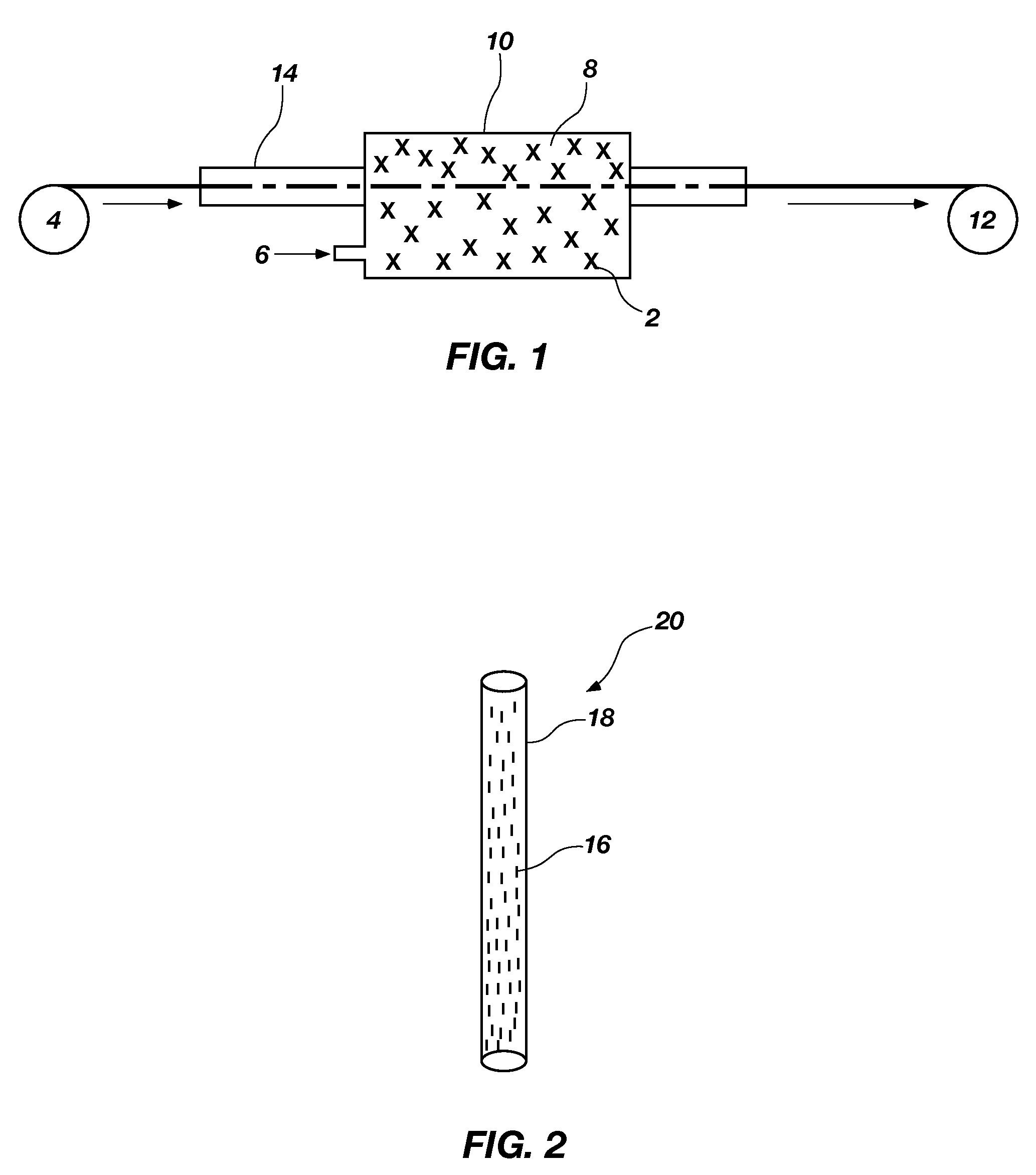

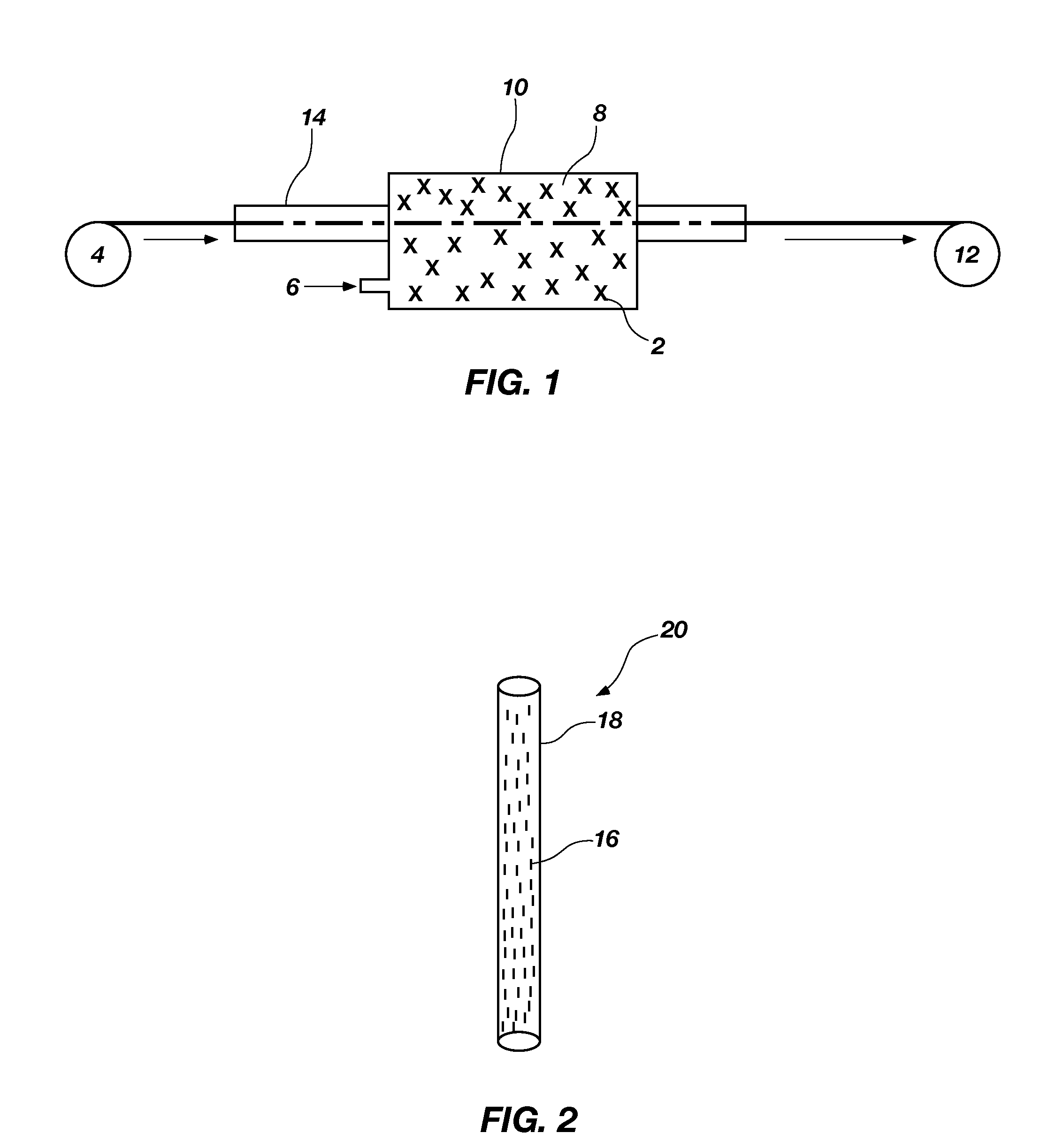

Silicon carbide fibers and articles including same

Methods of producing silicon carbide fibers. The method comprises reacting a continuous carbon fiber material and a silicon-containing gas in a reaction chamber at a temperature ranging from approximately 1500° C. to approximately 2000° C. A partial pressure of oxygen in the reaction chamber is maintained at less than approximately 1.01×102 Pascal to produce continuous alpha silicon carbide fibers. Continuous alpha silicon carbide fibers and articles formed from the continuous alpha silicon carbide fibers are also disclosed.

Owner:ADVANCED CERAMIC FIBERS

Methods of producing silicon carbide fibers, silicon carbide fibers, and articles including same

ActiveUS20120088088A1Production economyMaterial nanotechnologyLiquid surface applicatorsCarbon fibersSic fiber

Methods of producing silicon carbide fibers. The method comprises reacting a continuous carbon fiber material and a silicon-containing gas in a reaction chamber at a temperature ranging from approximately 1500° C. to approximately 2000° C. A partial pressure of oxygen in the reaction chamber is maintained at less than approximately 1.01×102 Pascal to produce continuous alpha silicon carbide fibers. Continuous alpha silicon carbide fibers and articles formed from the continuous alpha silicon carbide fibers are also disclosed.

Owner:ADVANCED CERAMIC FIBERS

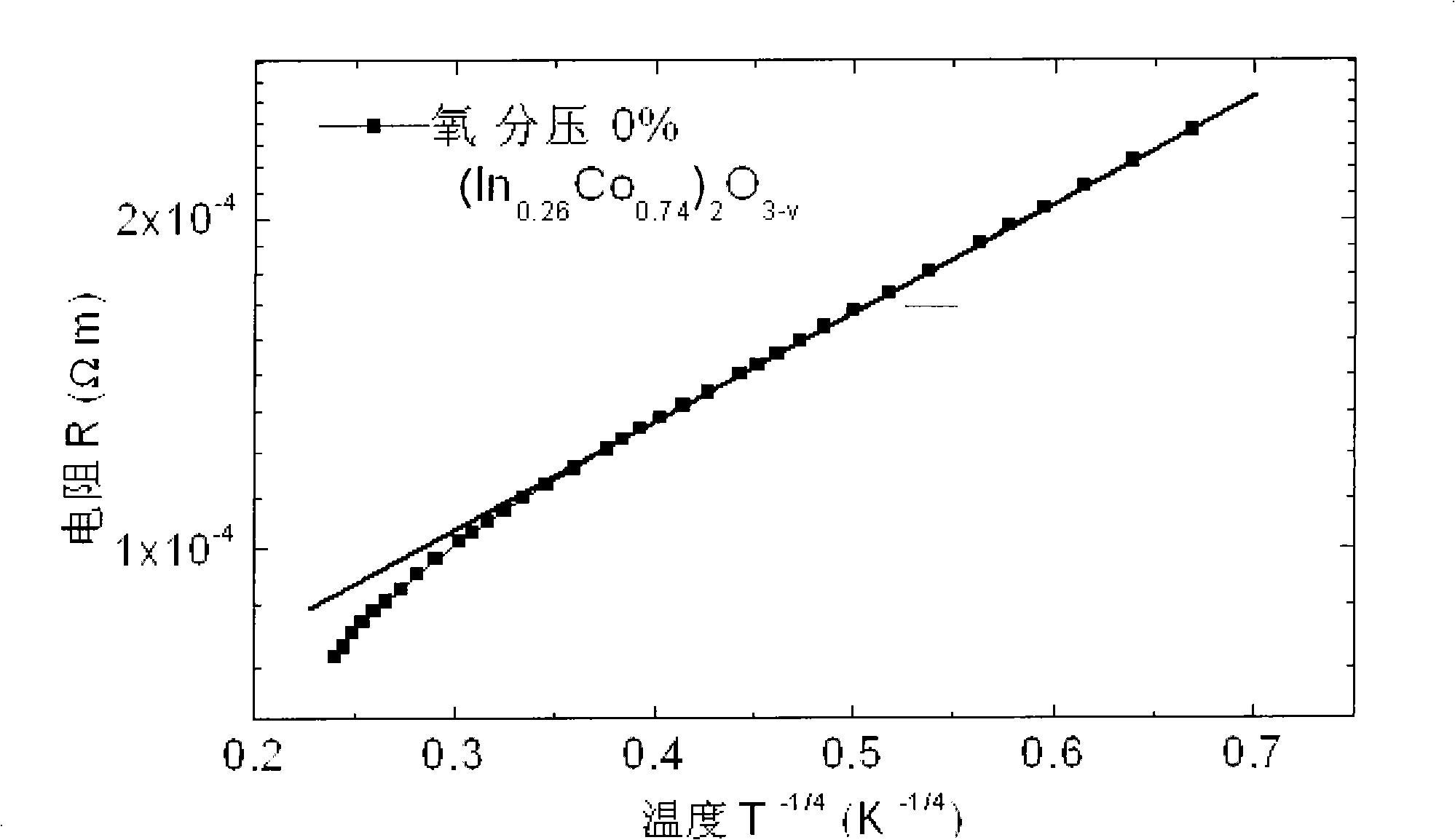

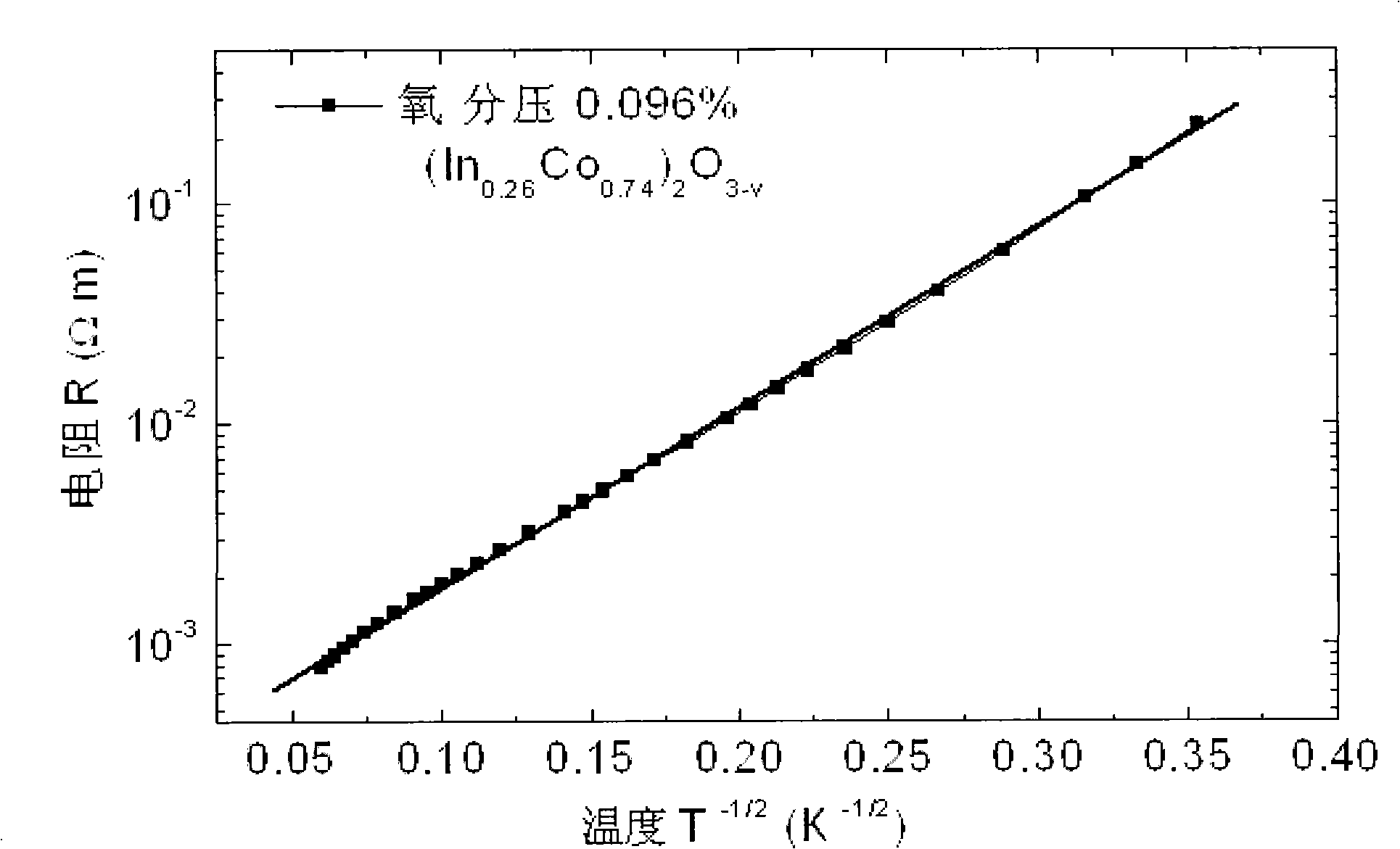

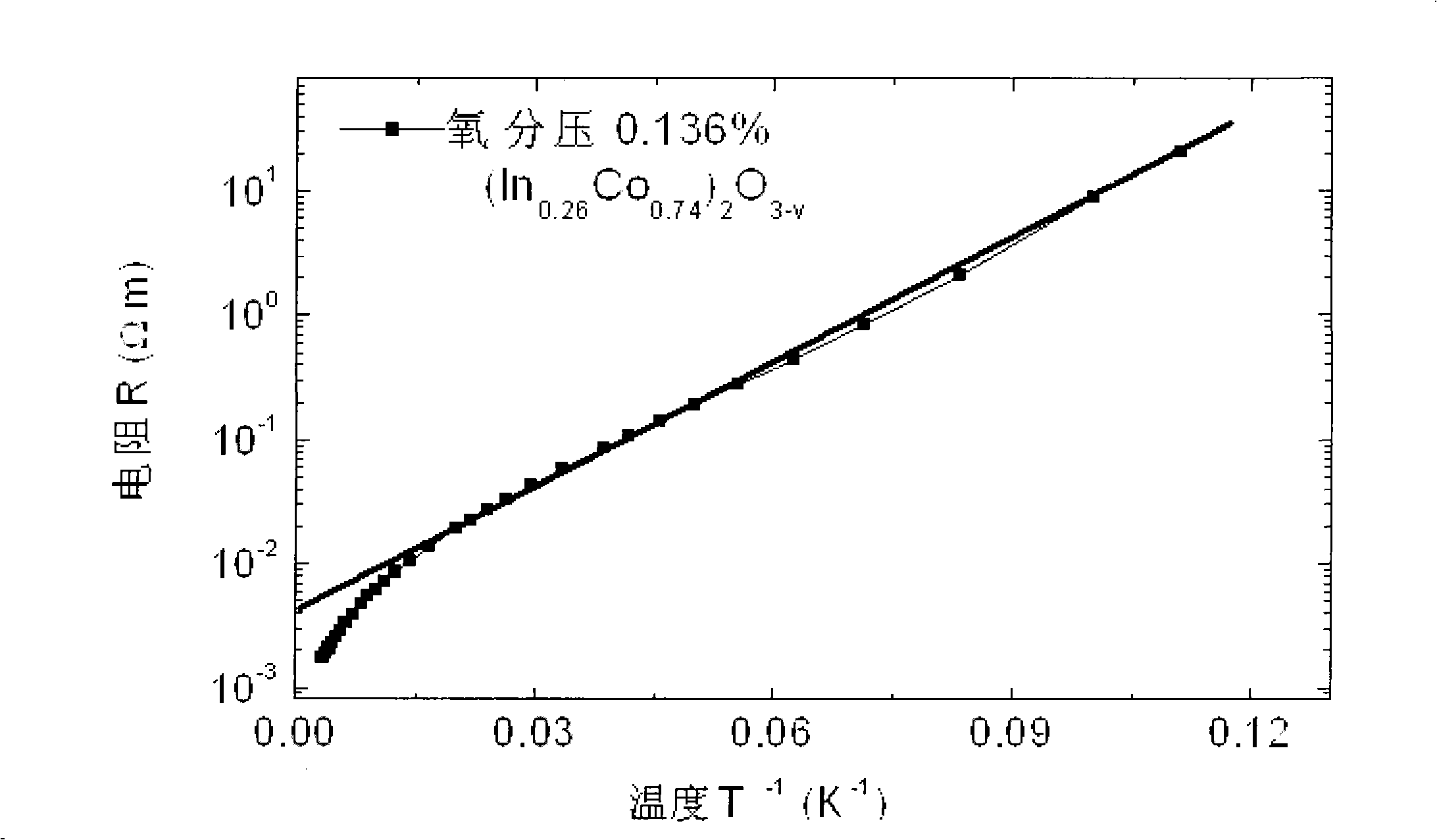

Oxidate magnetic semiconductor thin film capable of regulating electric transport property and method of preparing the same

InactiveCN101256869AImprove magnetismHigh curie temperatureInorganic material magnetismCathode sputtering applicationOxygen vacancyHigh resistivity

The present invention provides oxide magnetic semiconductor film with adjustable electronic transport properties and manufacture method thereof, which belongs to information technology rotating electron material field. The series oxide magnetic semiconductor film displays common electric transport property: material with low electric resistivity being Mott range transition resistor, material with middle electric resistivity being hard Efros range transition resistor, material with high electric resistivity being hardgap resistor. The super thin iron magneto- metallic layer and the wide forbidden region oxide semiconductor layer are alternating deposited on substrate by using the method of magnetron sputtering or pulsed laser depositing through accurate control partial pressure of oxygen in film preparation process to regulate electric transport property of material. Electric transport property of oxide magnetic semiconductor film is only related to concentration of oxygen vacancy in material.

Owner:SHANDONG UNIV

Process for producing an oxide

Provided is a process for producing an oxide which includes an electrically conductive mayenite type compound and has an electron density of at least 1 * 1018 / cm3, starting from a combination of a calcium compound and aluminium compound, or a compound which includes calcium and aluminium with a molar ratio of calcium oxide and aluminium oxide as equivlent oxides in the range 9:10 to 14:5, wherein the process for producing an oxide includes a step of heating and holding the starting material at 900-1300 DEG C to produce a calcined powder which includes at least one oxide selected from a group comprising calcium aluminate, calcium oxide and aluminium oxide, and a step of heating and holding the aforementioned calcined powder at least 1200 DEG C and less than 1415 DEG C, in a reducing atmosphere in an atmosphere of an inert gas with a partial pressure of oxygen of no more than 1000 Pa or in a vacuum atmosphere.

Owner:ASAHI GLASS CO LTD

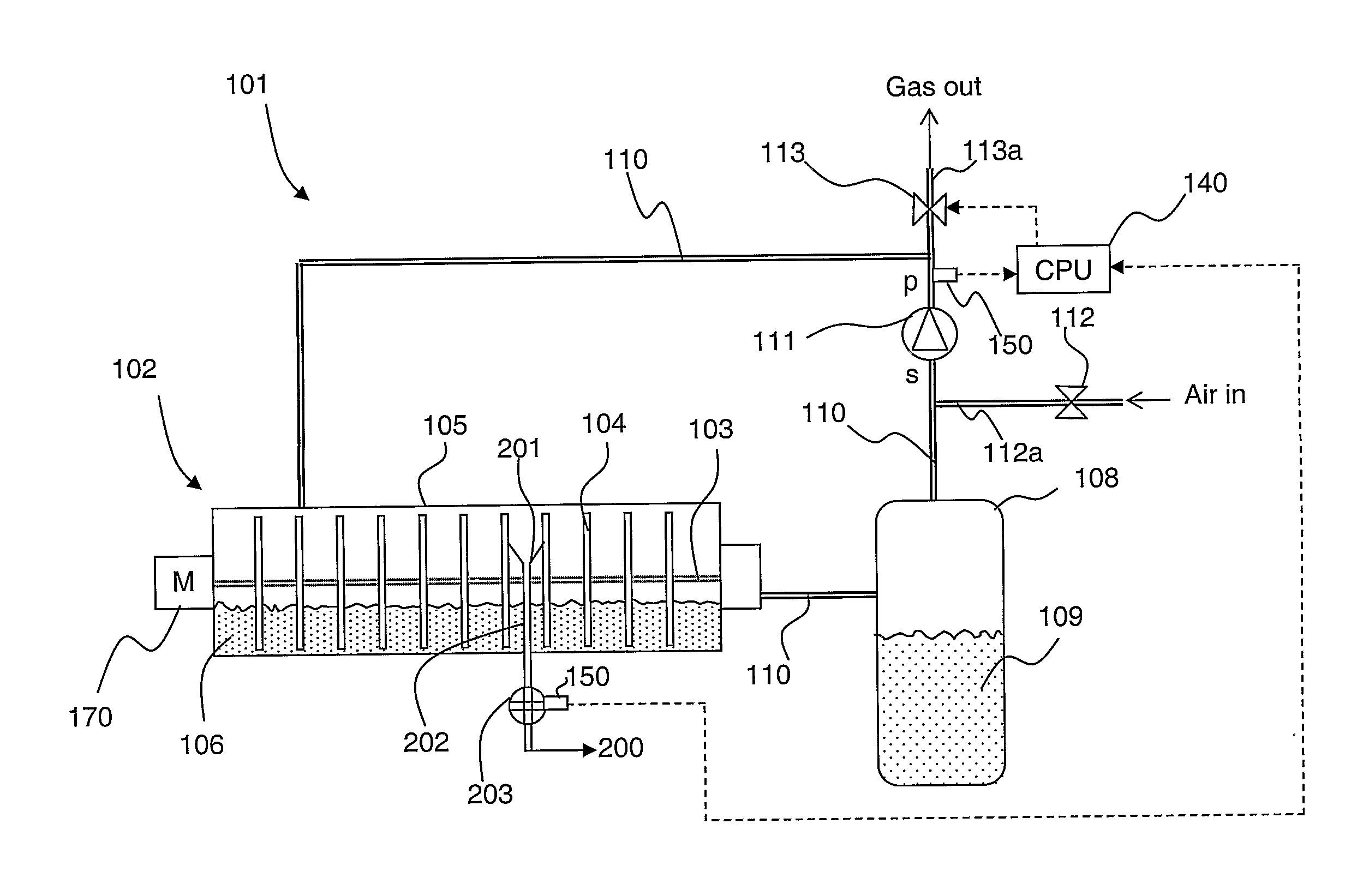

Method and Device for Washing of Lime Mud

InactiveUS20070221345A1Use minimizedPromote oxidationWater/sewage treatmentLoose filtering material filtersGas phaseFresh air

The method and an arrangement are for dewatering and washing lime slurry before the dewatered lime mud is passed to a lime mud kiln. The lime slurry is dewatered in a pressurized lime mud filter of disc or drum type. The pressurized lime mud filter is pressurized through a compressor drawing on its suction side (s) gas phase from the filtrate tank and pressurizing on the pressurized side (p) of the compressor the pressure vessel on the lime mud side of the filter. A certain pre-determined amount of gas phase in the gas circulation system is vented and an equivalent pre-determined amount of fresh air is added to the recycled gas phase with the aim of maintaining the partial pressure of oxygen gas above a certain minimum level.

Owner:METABO PAPER SWEDEN

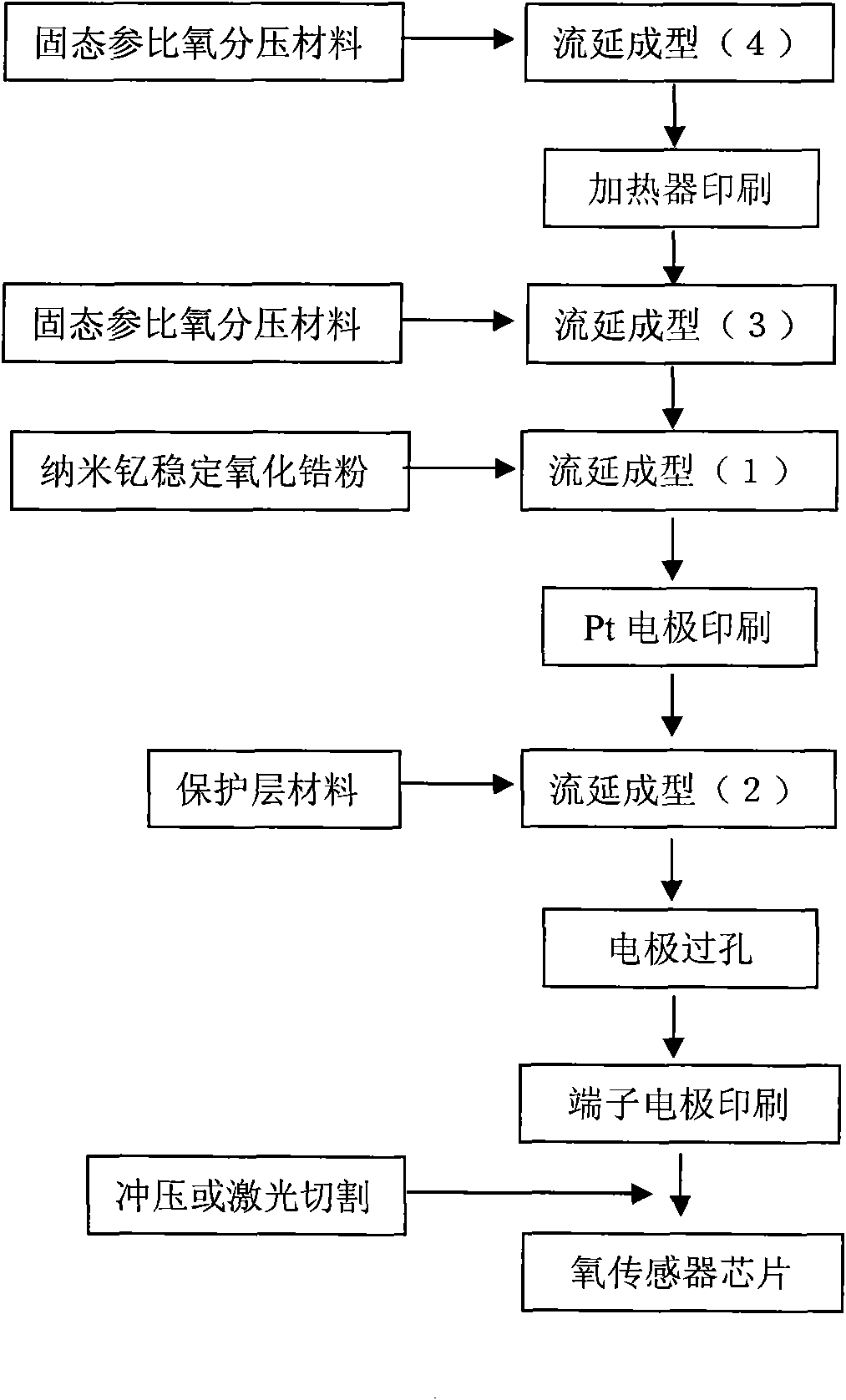

ZrO2 oxygen sensor for solid state reference partial pressure of oxygen and manufacture method thereof

The invention relates to a slice type oxygen sensor used for air-fuel delivery ratio control of a vehicle engine and a manufacture method thereof. The manufacture method comprises the following steps: slurry made of yttrium stabilization zirconia powder forms a slice blank through a casting technology; Pt electrodes which have certain gaps are respectively manufactured in silk screens at both sides of the slice blank; a solid state oxygen partial pressure reference slice is prepared on the yttrium stabilization zirconia slice blank through a secondary casting technology; an RuO material heater is printed in a silk screen in the middle of a secondary casting layer, and the thickness of the layer is of 6 to 7 times of a yttrium stabilization zirconia layer; a porous protective layer is formed at the side of an outer electrode on the yttrium stabilization zirconia slice blank in a curtain coating mode; finally, a prefabricated substrate blank is punched into a strip shape according to a required size, an electrode connecting hole is manufactured, and vacuum sintering is carried out in the program temperature rising process with the temperature of as high as 1600 DEG C to manufacture a sensor chip. The method fully utilizes the curtain coating technology of ceramic slice type materials and the silk screen printing technology of slurry electrodes, and has the advantages of less production technology links, high product consistency, high yield and low cost.

Owner:JILIN UNIV +1

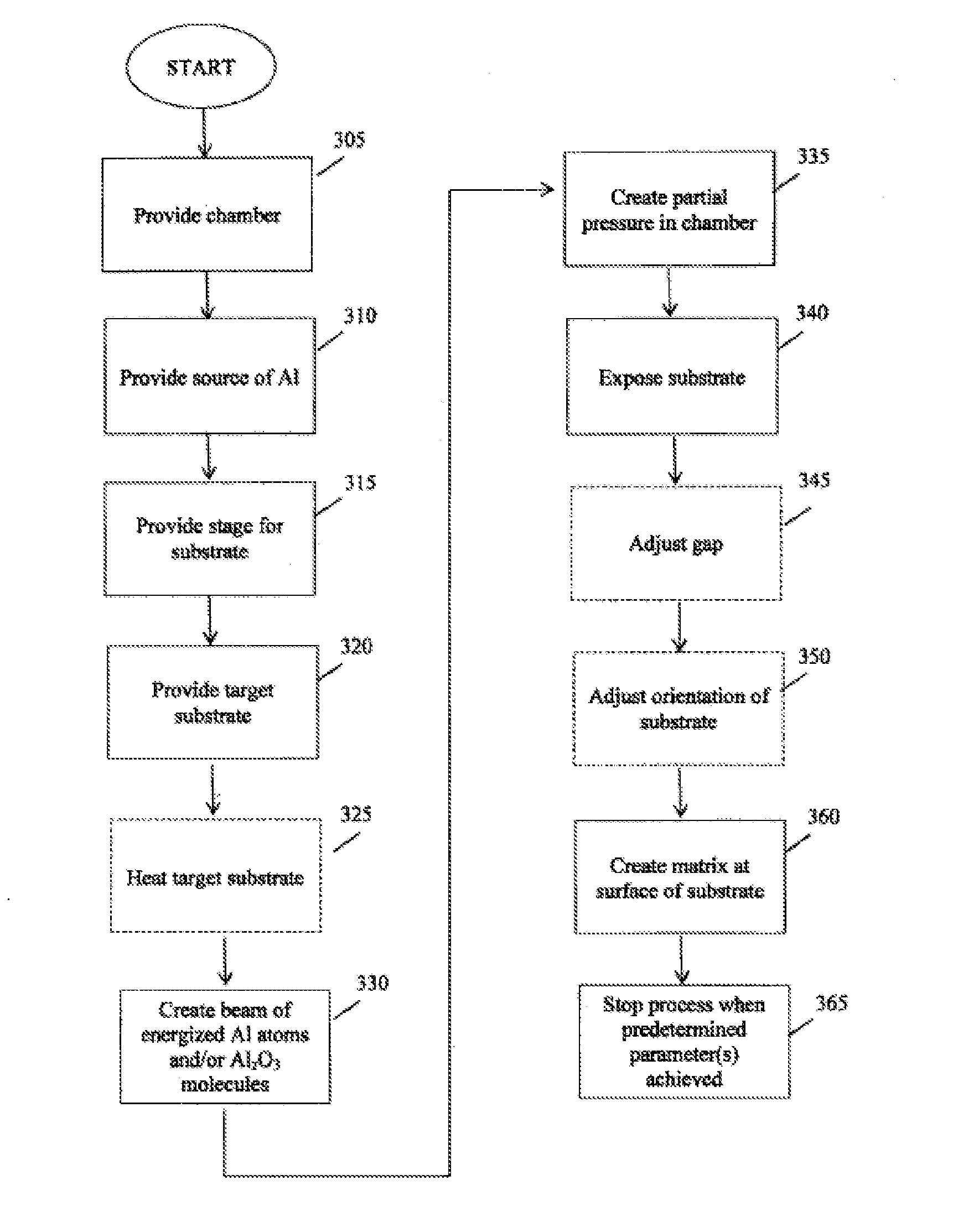

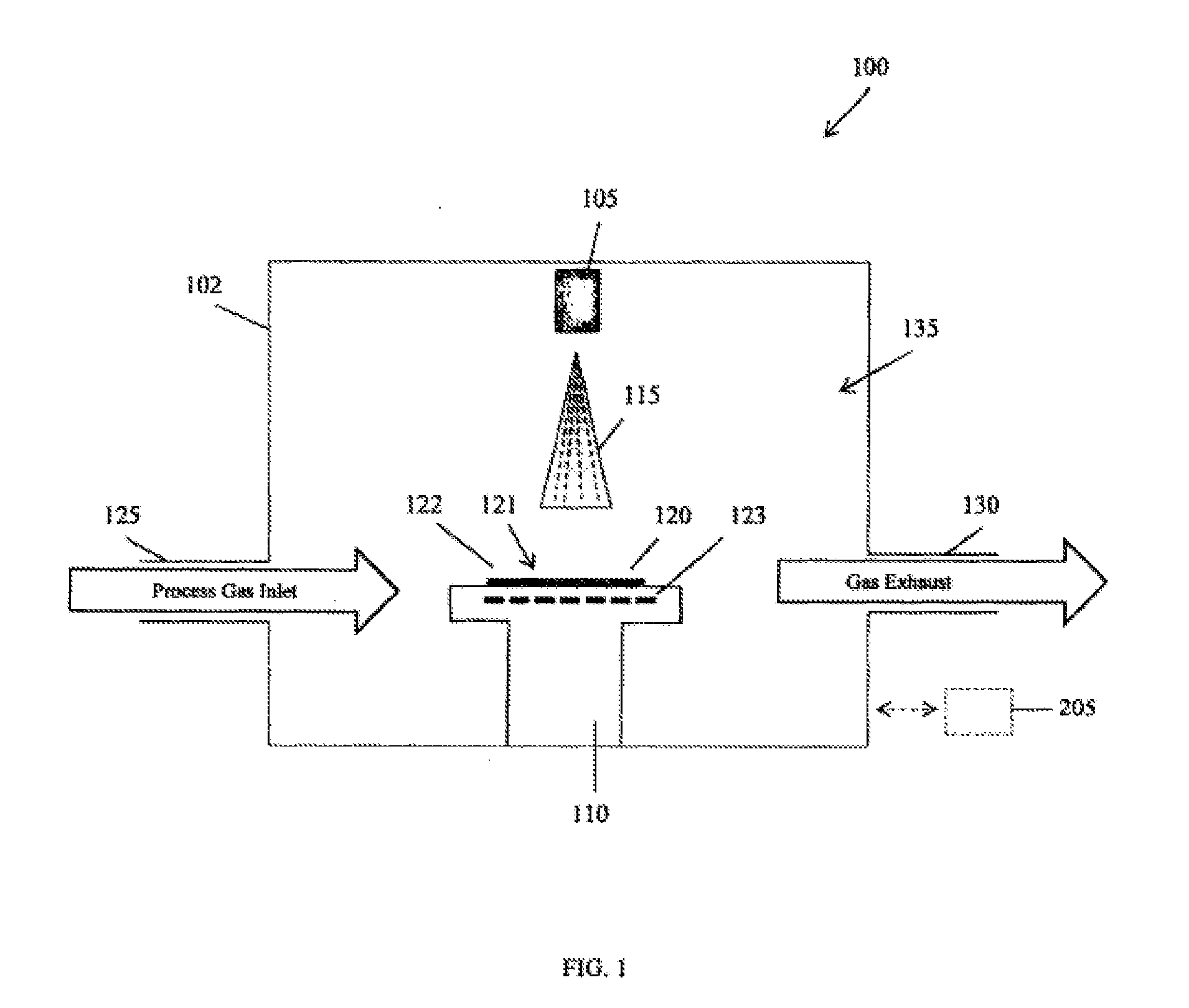

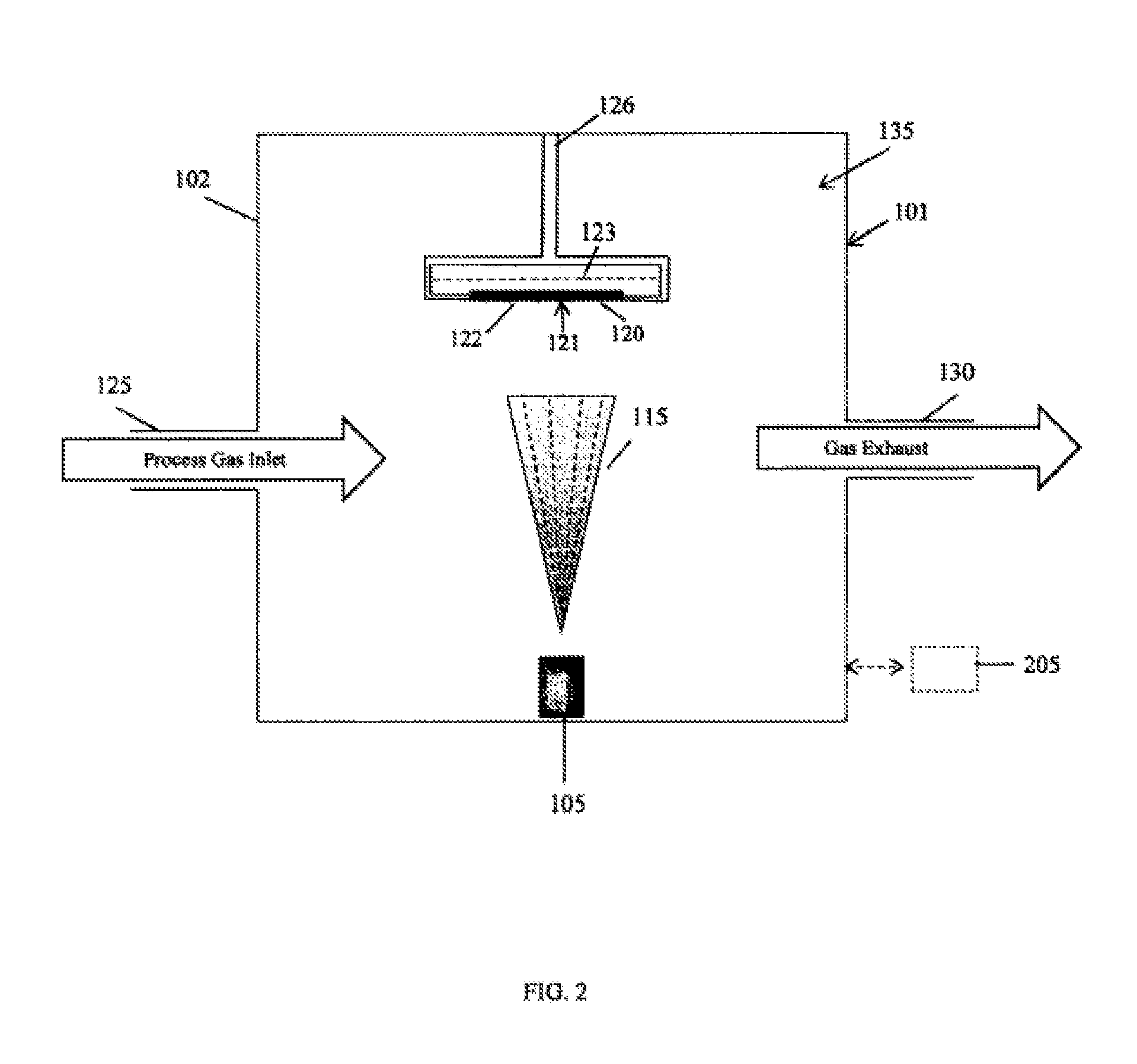

Method of growing aluminum oxide onto substrates by use of an aluminum source in an environment containing partial pressure of oxygen to create transparent, scratch-resistant windows

A system and process for inter alia coating a substrate such as glass substrate with a layer of aluminum oxide to create a scratch-resistant and shatter-resistant matrix comprised of a thin scratch-resistant aluminum oxide film deposited on one or more sides of a transparent and shatter-resistant substrate for use in consumer and mobile devices such as watch crystals, cell phones, tablet computers, personal computers and the like. The system and process may include a sputtering technique. The system and process may produce a thin window that has a thickness of about 2 mm or less, and the matrix (i.e., the combination of the aluminum oxide film and transparent substrate) may have a shatter resistance with a Young's Modulus value that is less than that of sapphire, i.e., less than about 350 gigapascals (GPa). The thin window has superior shatter-resistant characteristics.

Owner:RUBICON TECHNOLOGY

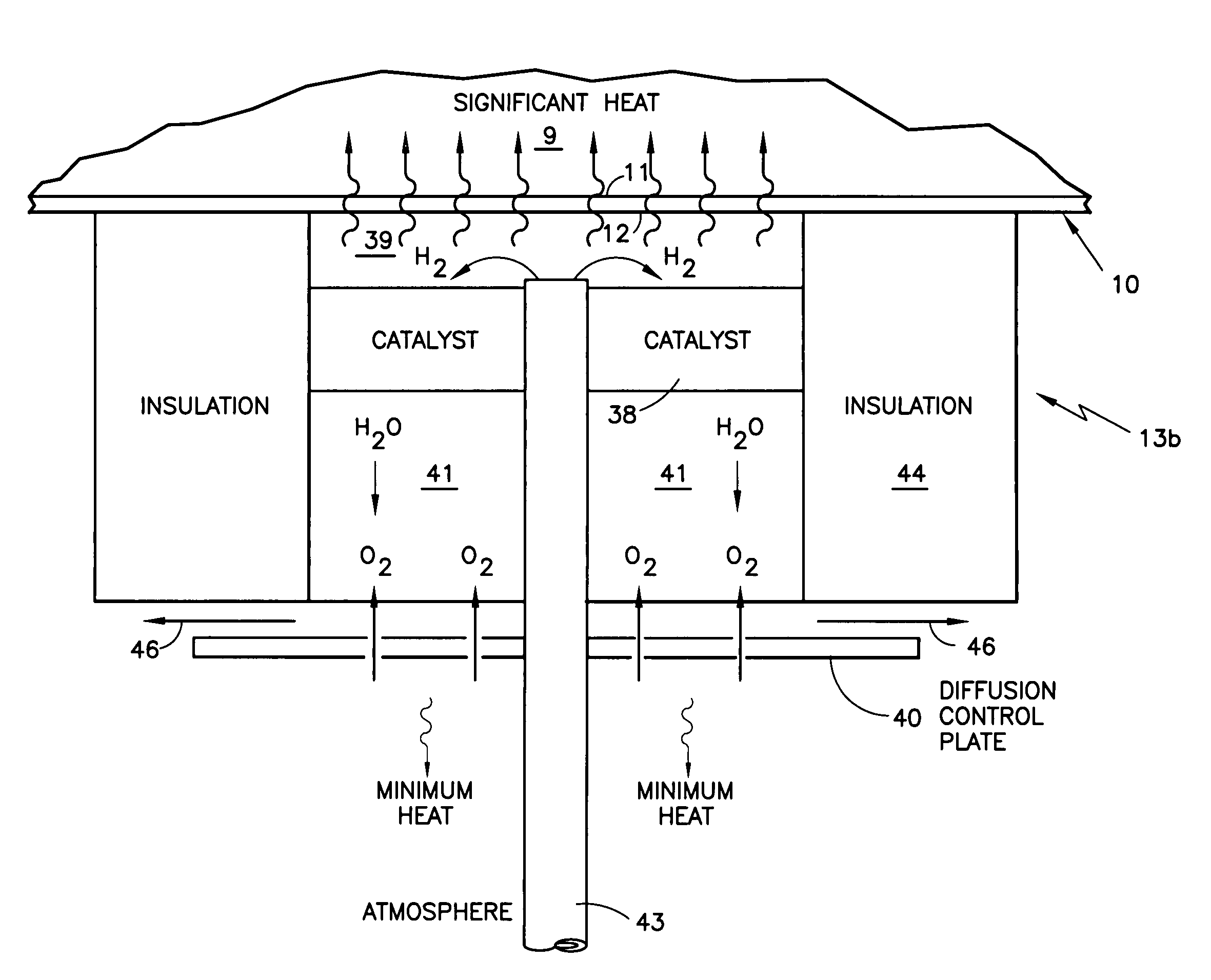

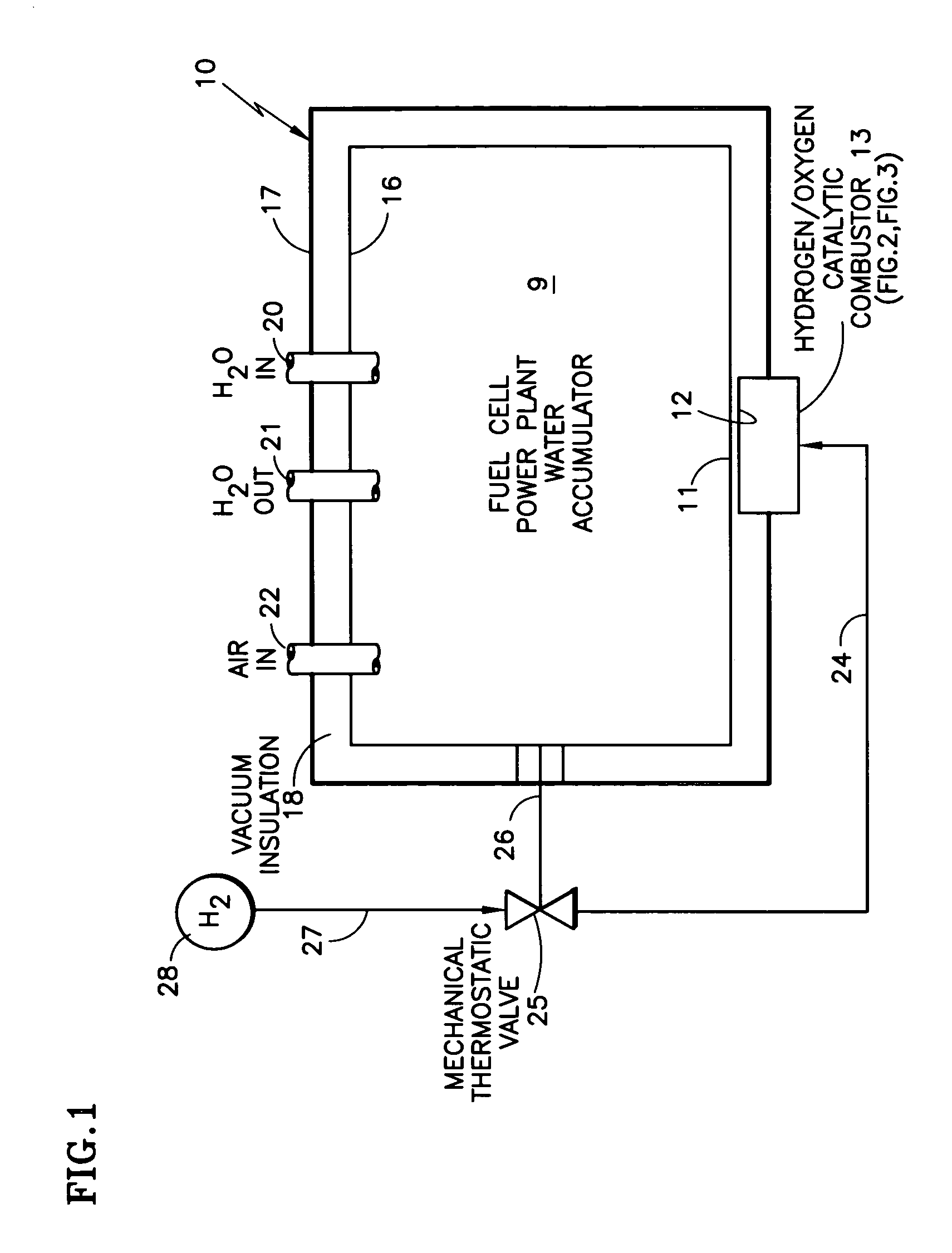

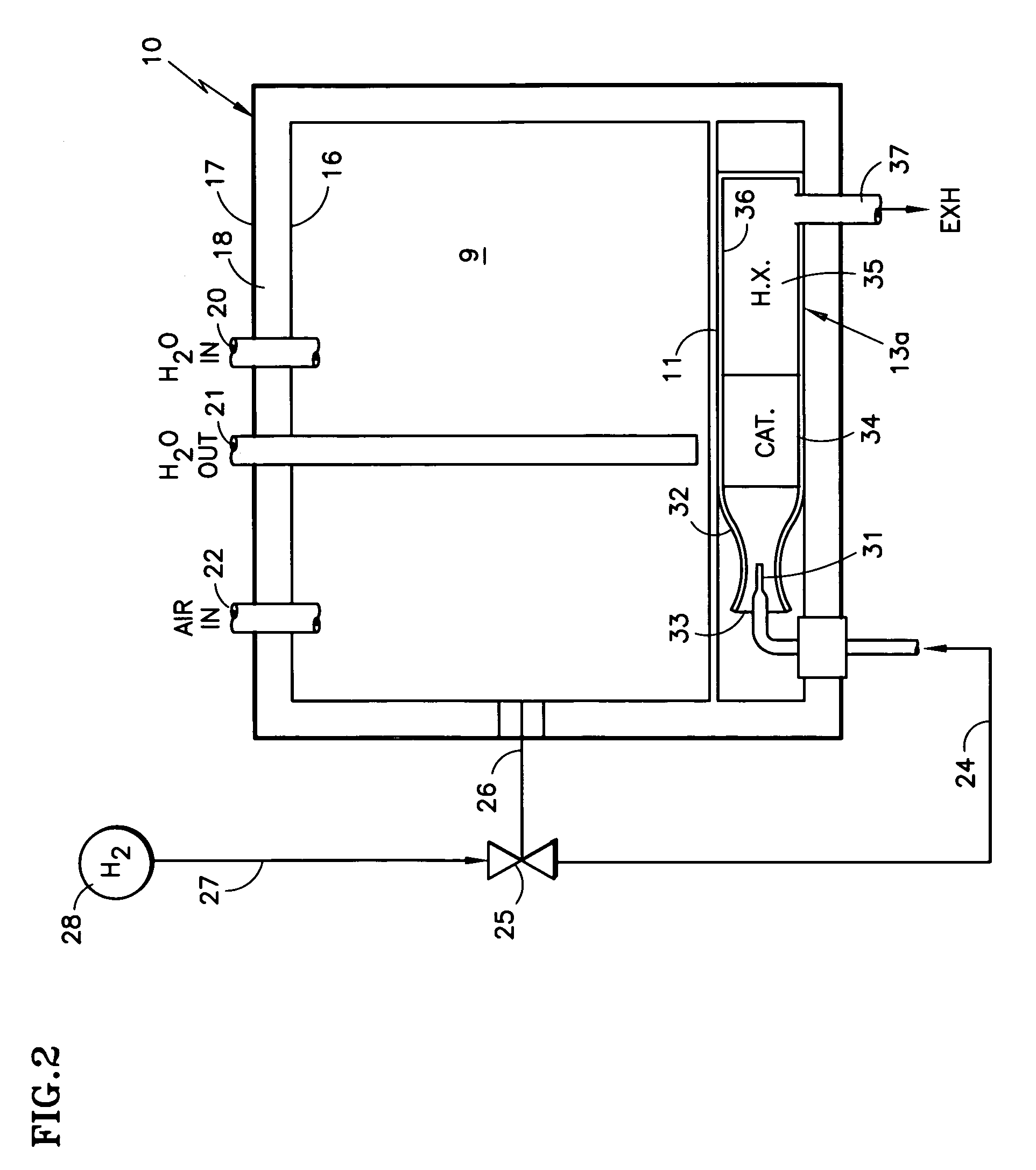

Catalytic combustors keeping contained medium warm in response to hydrostatic valve

ActiveUS7410619B2Improve efficiencyEfficient combustionExhaust apparatusFuel cell auxillariesAtmospheric airWater vapor

The medium (9), such as water, of a container (10), such as a fuel cell accumulator, is kept above freezing by a hydrogen / oxygen catalytic combustor (13) fed hydrogen from a source comprising a mechanical thermostatic valve (25) in thermal communication (26) with the container (10) and connected to a hydrogen supply (28). The combustor may comprise an ejector (32) having hydrogen through its primary inlet (31) drawing air through a secondary inlet (33). The combustor may comprise a diffusion combustor having a catalyst (38) spaced from a heating surface (30) and a diffusion control plate (40) low partial pressure of oxygen at the catalyst causing diffusion through the barrier. Water vapor from combustion condenses on a surface (146) and is led by hydrophilic woven carbon paper (126) to wicking material (133), which has smaller pores than the carbon paper, which leads the water downwardly, through a disk (140) and plugs (147) to atmospheric air. The noble metal catalyst mixture includes TEFLON® to permit water generated by combustion to flow by gravity out of the catalyst.

Owner:AUDI AG

Cordyceps sinensis dew beverage with anti-fatigue function and preparation thereof

The invention relates to cordyceps beverage with the function of anti-fatigue and a preparation method thereof. The beverage mainly contains 15-30 percent of cordyceps fermentation liquid, 1-10 percent of extracted rhodiola, 0.1-1.5 percent of medlar polysaccharide powder, 0.5-3.0 percent of honey, 5-15 percent of sucrose, 0.1-1.0 percent of sea buckthorn fruit powder, 0.01-0.2 percent of flavoring and the rest is purified water. The cordyceps beverage with the function of anti-fatigue has the advantages of specific flavor and the performances of anti-fatigue, hypoxia resistance and immunity improvement. At the same time, the beverage can improve the short time memory of moderate plateau people and the level of partial pressure of oxygen in blood, lower the frontload and the afterload of hearts, improve the function of hearts, increase the content of oxygen in blood effectively, reduce the lactic acid level in blood, lead healthy men to work efficiently and permanently with abundant spirit, enhance the function of heart and cardiovascular and improve sexual function. And the beverage is especially suitable for the crowds working in front of computers for a long time.

Owner:QINGHAI XUEYULONG BIOLOGICAL TECH

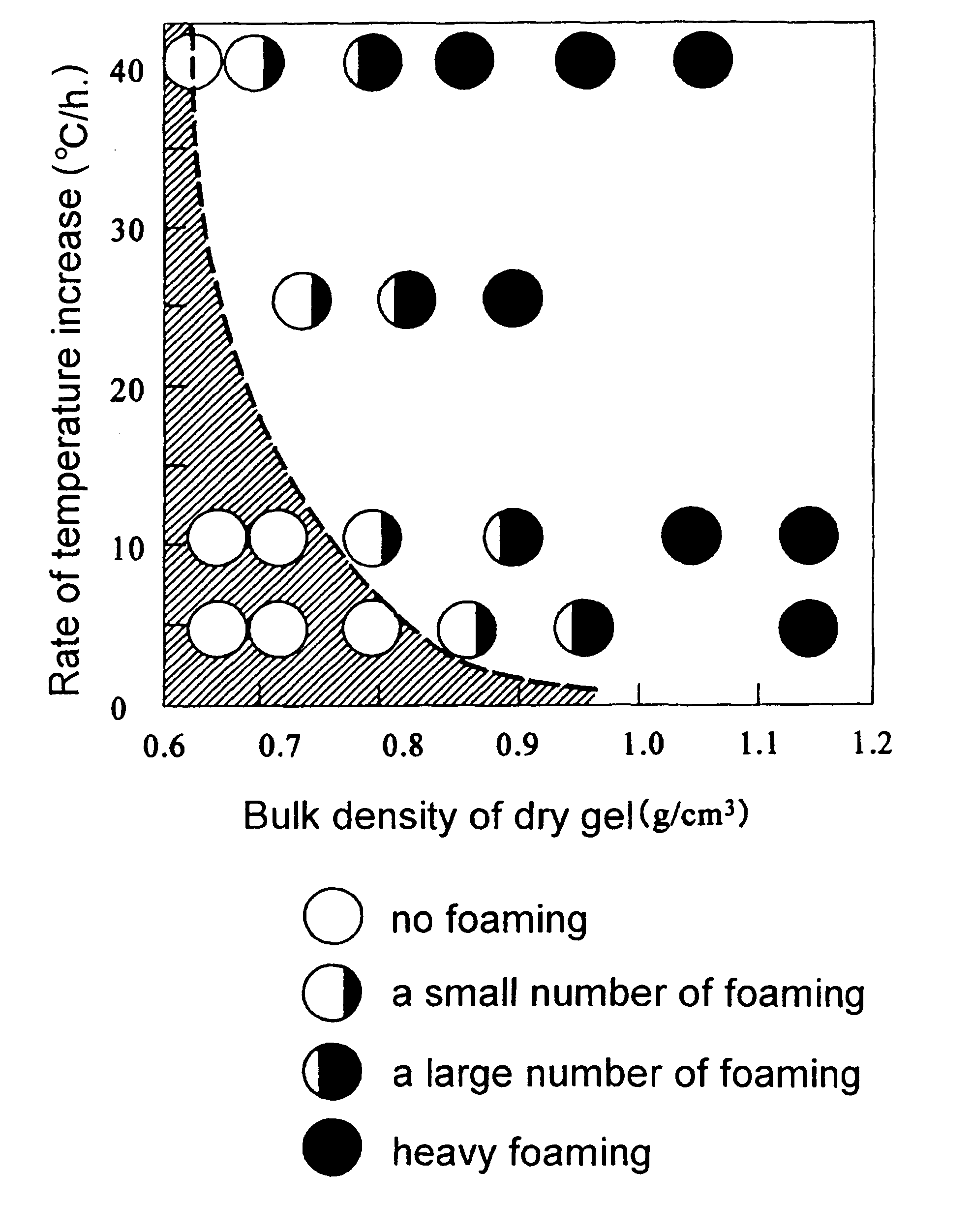

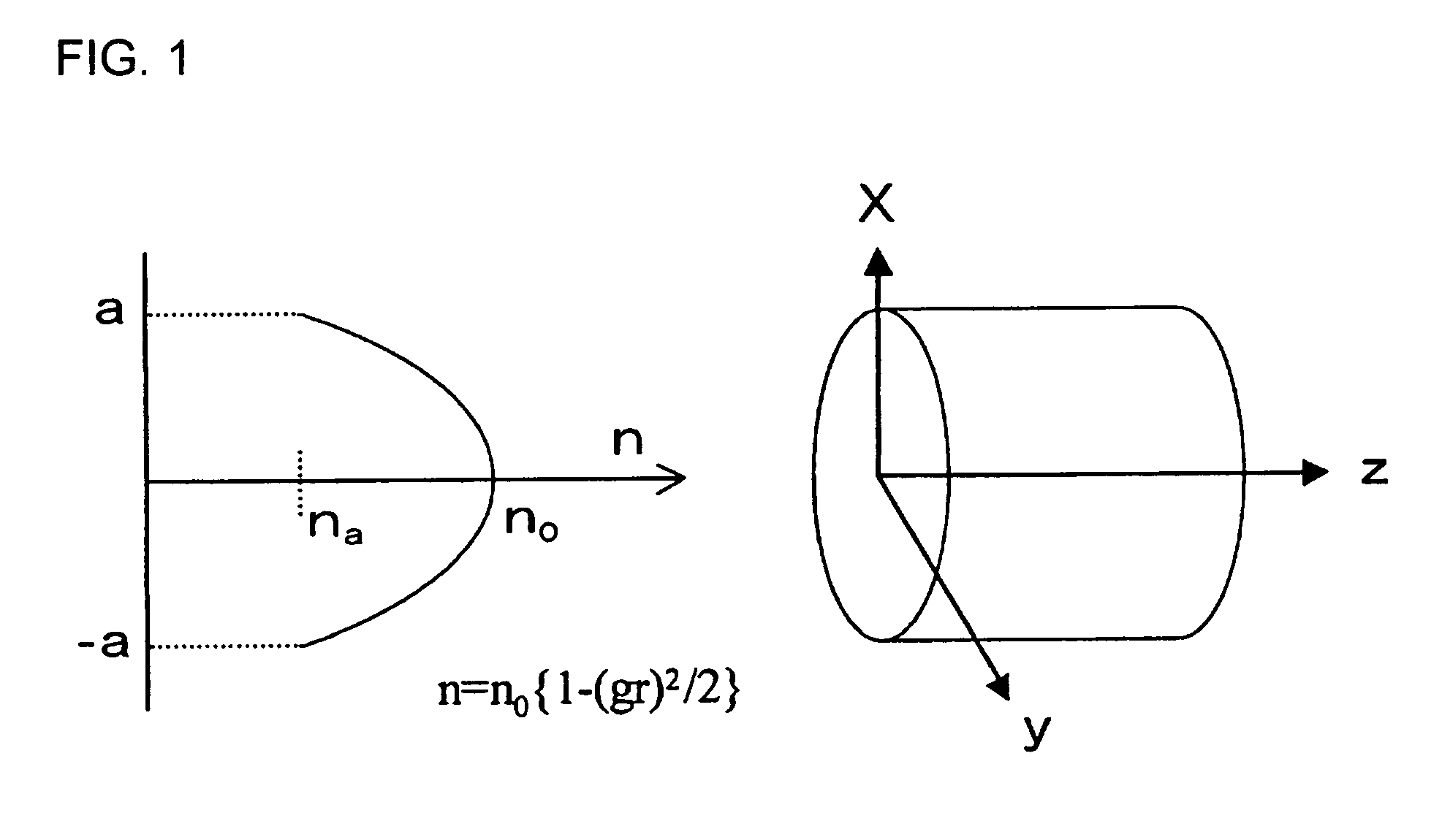

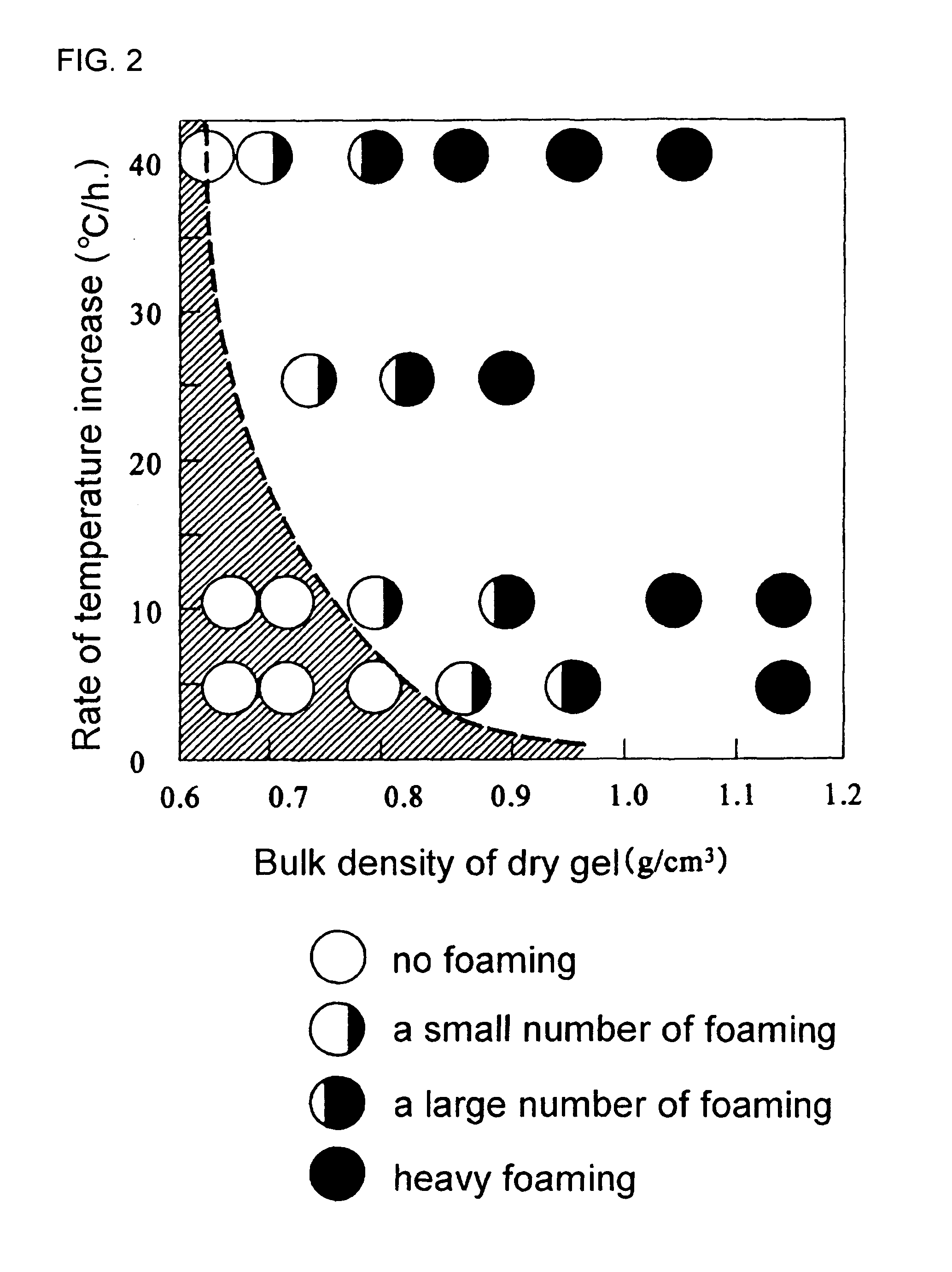

Method for manufacturing grin lens and grin lens

ActiveUS20070160854A1Easy and efficient to manufactureIncrease the number ofGlass/slag layered productsGlass reforming apparatusRefractive indexVolumetric Mass Density

A method for manufacturing a GRIN lens includes the steps of forming a wet gel provided with a concentration distribution having a different concentration of a refractive index distribution imparting metal that differs in concentration in a radial direction, drying the wet gel to form a dry gel having a bulk specific gravity ρ (g / cm3), sintering the dry gel to form a GRIN lens base material and stretching the GRIN lens base material while heating. The method is characterized in that, in the step of sintering the dry gel, partial pressures of oxygen during sintering at 800° C. or higher are 10−1 Pa or lower and also the relation between a rate of temperature increase ν (° C. / hr) and a bulk density ρ of the dry gel during sintering at 1,000 to 1,150° C. is defined by ν≦105*EXP (−12ρ). As a result of this, the GRIN lens, which has a large numerical aperture and a small diameter, can stably and easily be manufactured.

Owner:TOYO SEIKAN GRP HLDG LTD

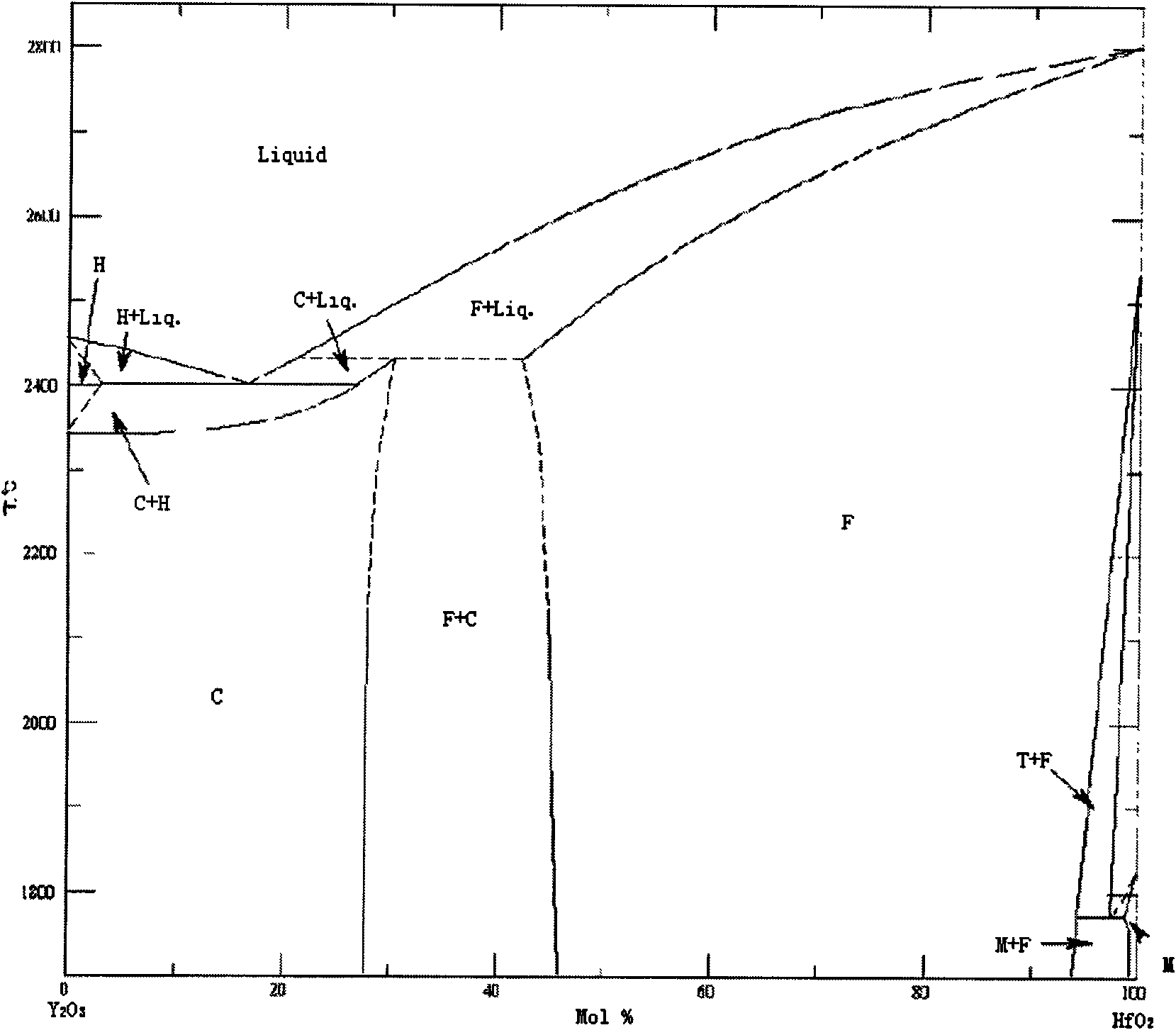

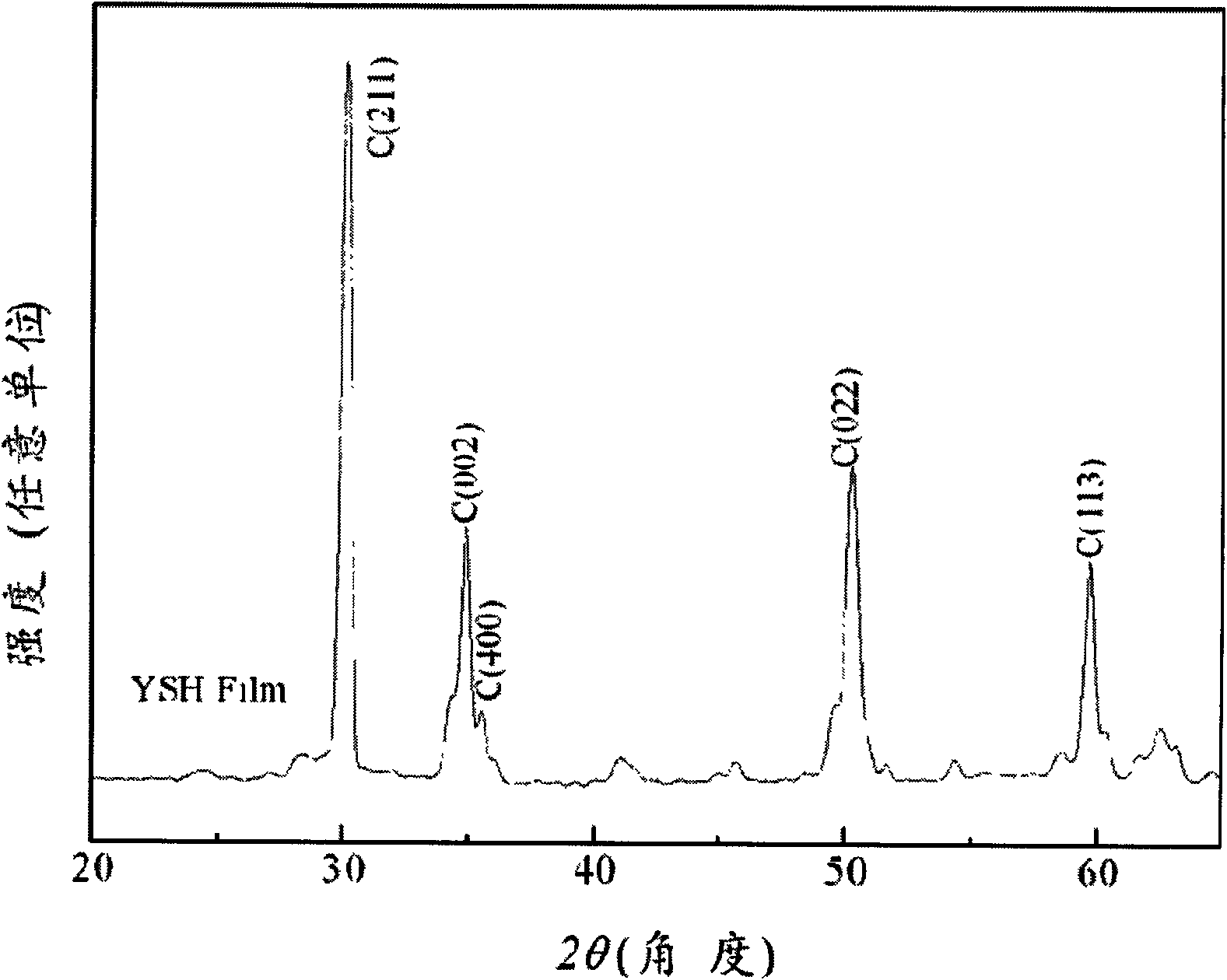

Gate dielectric material cubical phase HfO2 film and preparation method thereof

InactiveCN101660128AHigh dielectric constantMeeting the requirements of the semiconductor industryVacuum evaporation coatingSputtering coatingGate dielectricSolid reaction

The invention relates to a gate dielectric material cubical phase HfO2 film and a preparation method thereof. A stable cubical phase HfO2 film is obtained by doping Y2O3, and the molar percentage of the doping amount of the Y2O3 is between 0 and 28. The HfO2 is in a cubical phase at normal temperature, and the dielectric constant is 27.2. The gate dielectric material cubical phase HfO2 film is prepared by using the cubical phase HfO2 ceramic target material stabilized by the Y2O3 by a pulse laser deposition technique under the conditions of high vacuum and low partial pressure of oxygen. The invention uses the method of pulse laser deposition, uses the metal oxide Y2O3 and the HfO2 as raw materials and uses the binary phase diagram of the two materials as a basis to obtain the cubical phase HfO2 which is stable at normal temperature by the high-temperature solid phase reaction at normal temperature, thereby remarkably improving the dielectric constant of the HfO2 at normal temperatureand preparing and obtaining a YSH film, the EOT value of which is less than 1.5 nm. The invention provides new vitality for the application of the HfO2 which is the most potential gate dielectric material in the future.

Owner:NANJING UNIV

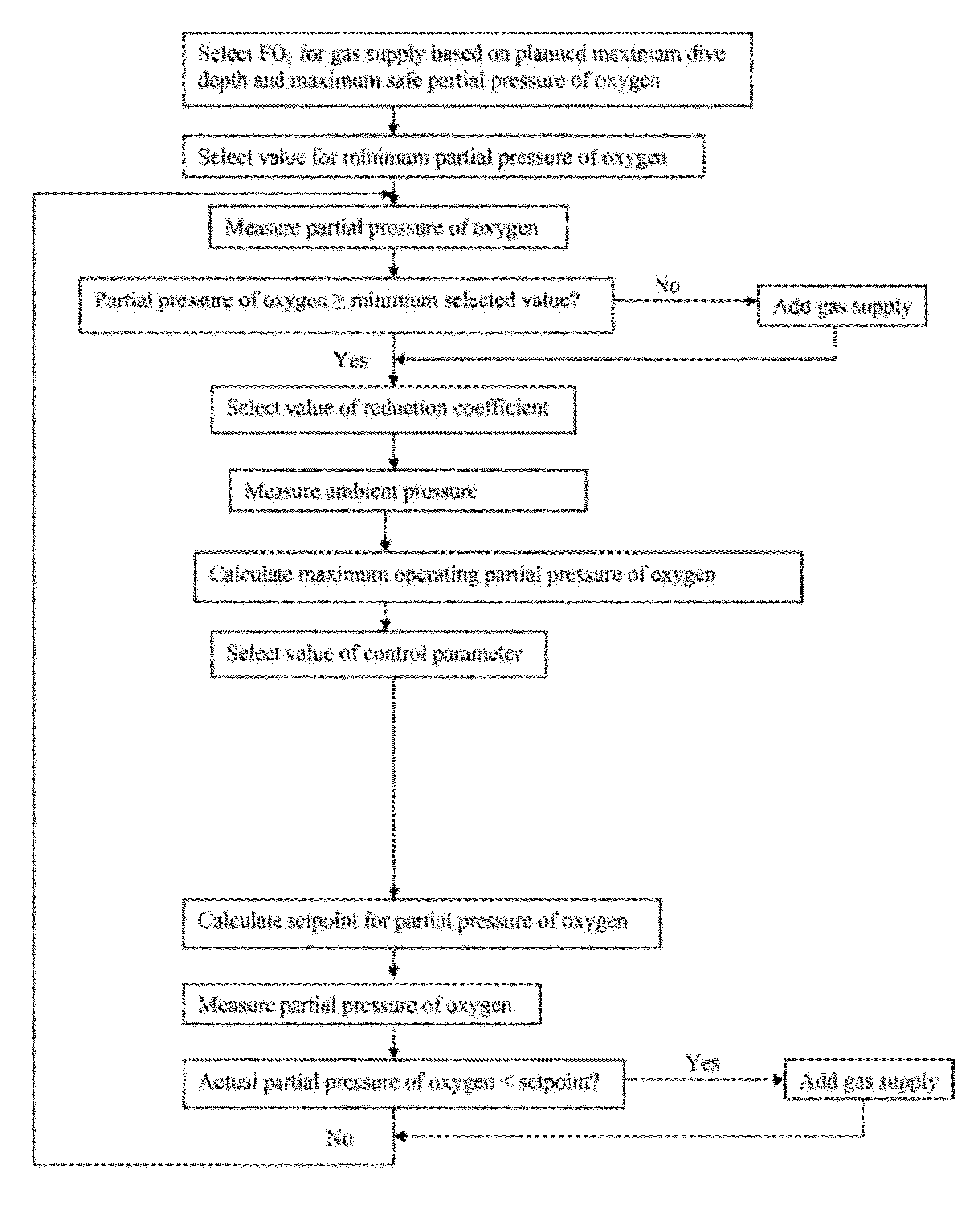

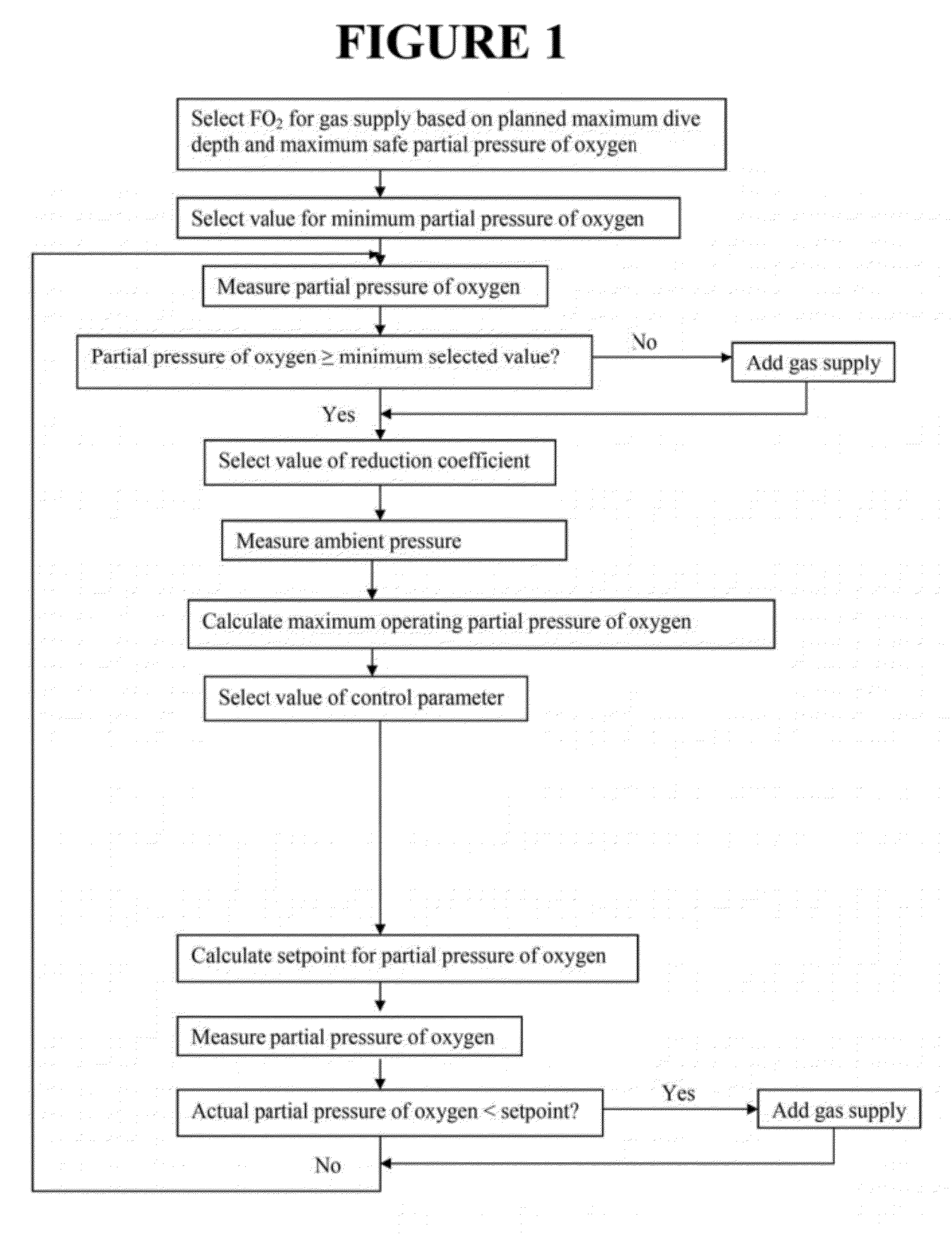

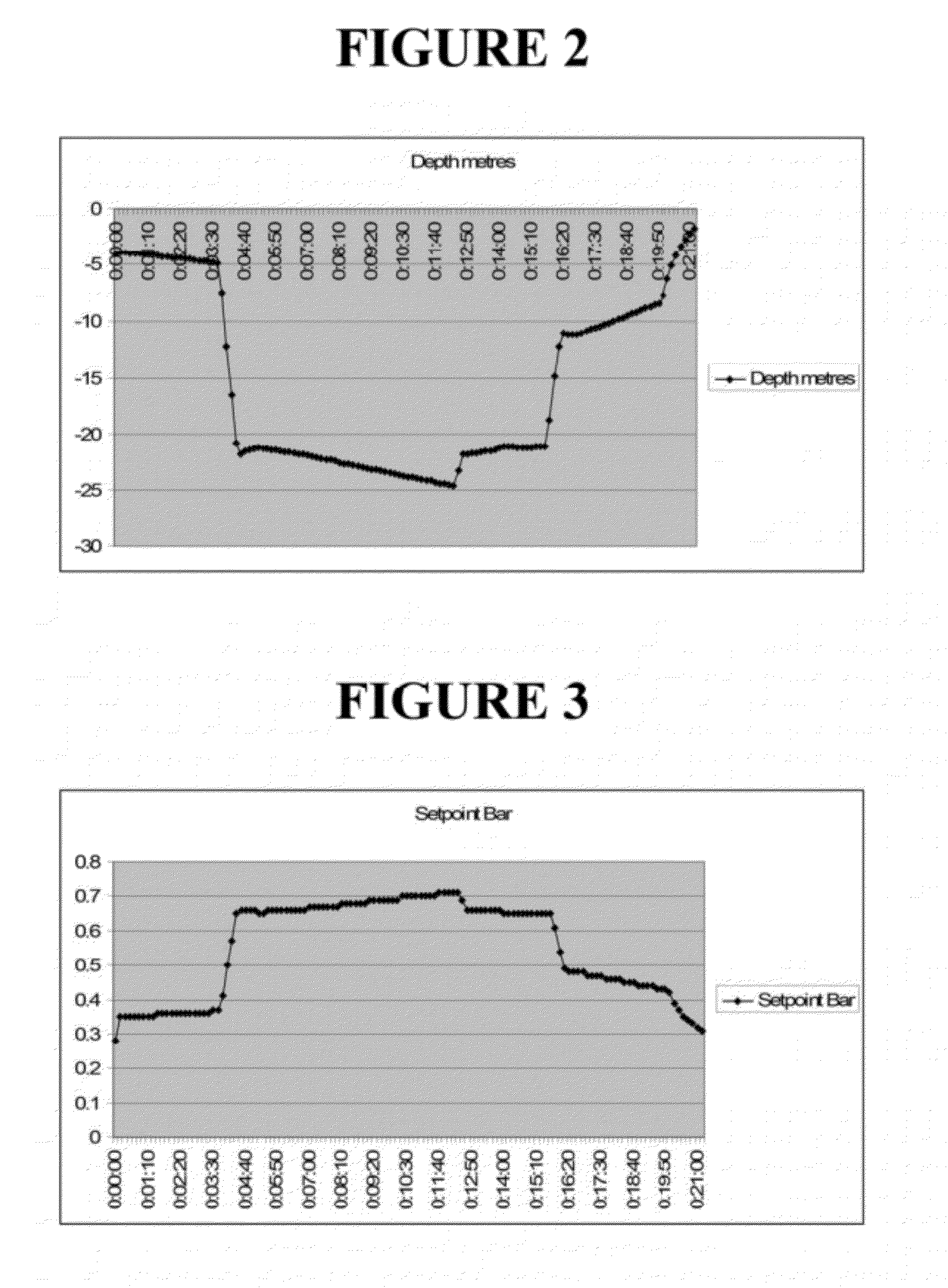

Rebreather Control Parameter System and Dive Resource Management System

ActiveUS20120048273A1Minimizing decompression timeMinimizing gas ventingTime indicationSynchronous motors for clocksAutomatic controlResource Management System

A method and apparatus for automatically controlling partial pressure of oxygen in the breathing loop of a rebreather diving system. A diver may adjustably select a control parameter to maintain partial pressure of oxygen at a setpoint that varies with ambient pressure and is within a range between a maximum safe partial pressure of oxygen at depth and a minimum safe partial pressure of oxygen for the purpose of biasing the performance of the rebreather either towards minimizing gas venting from the rebreather breathing loop or minimizing decompression time. A method and apparatus for managing and monitoring the use of dive resources in comparison with a target dive time specified by the diver, calculating and indicating remaining dive time based on dive resource values and calculating and indicating dive resource values required to meet preselected dive resource end values and dive requirements.

Owner:GURR KEVIN +1

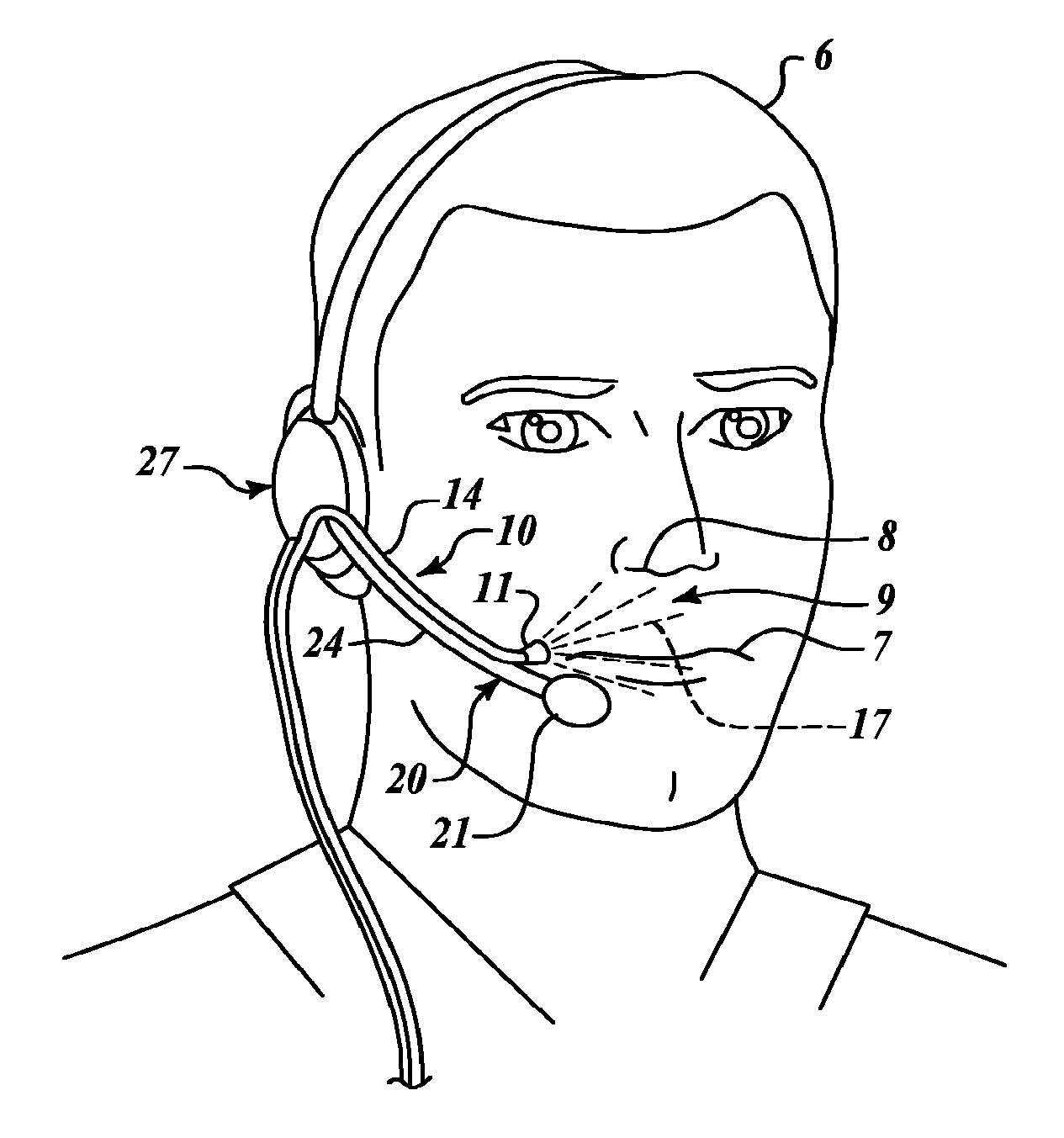

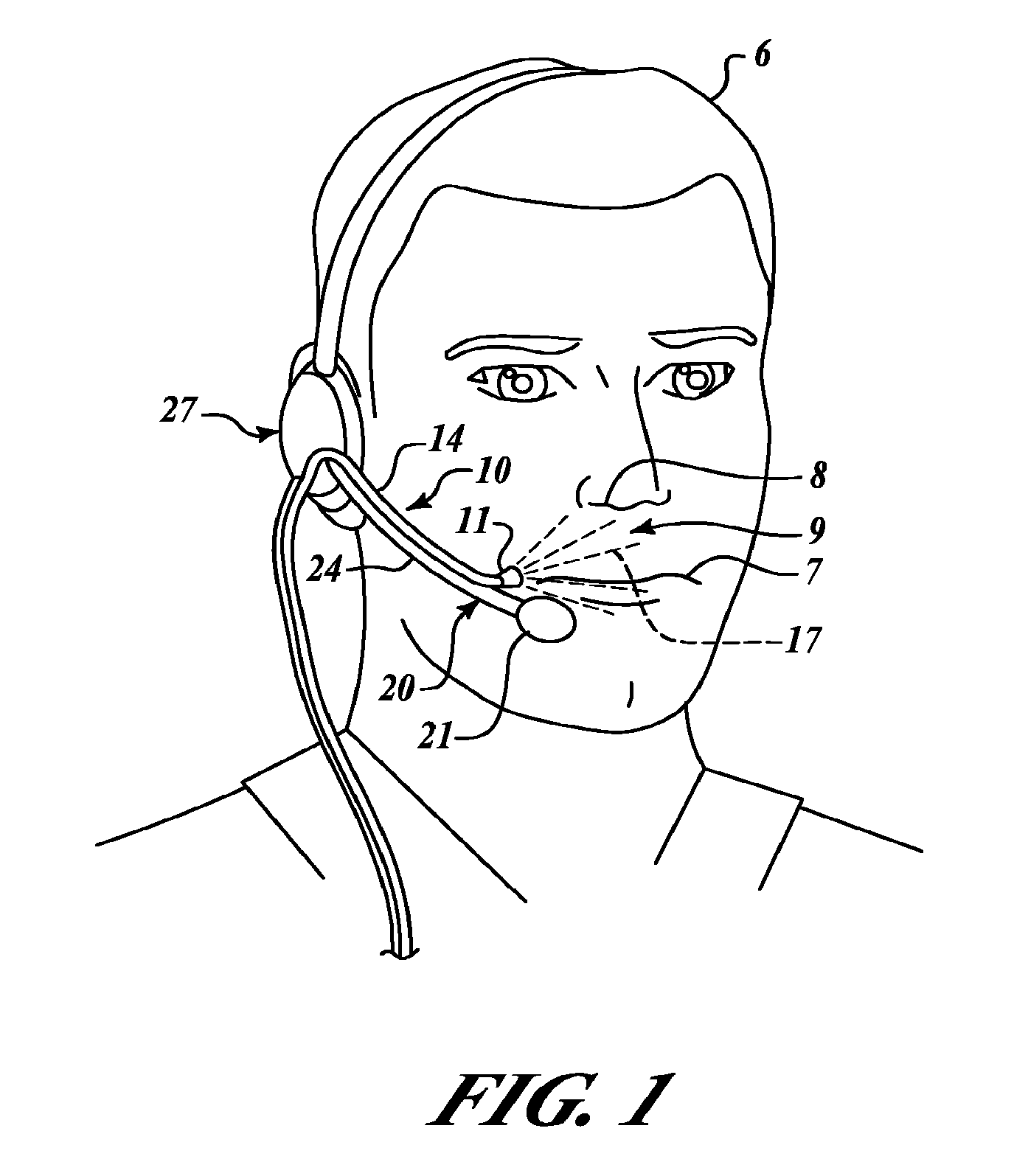

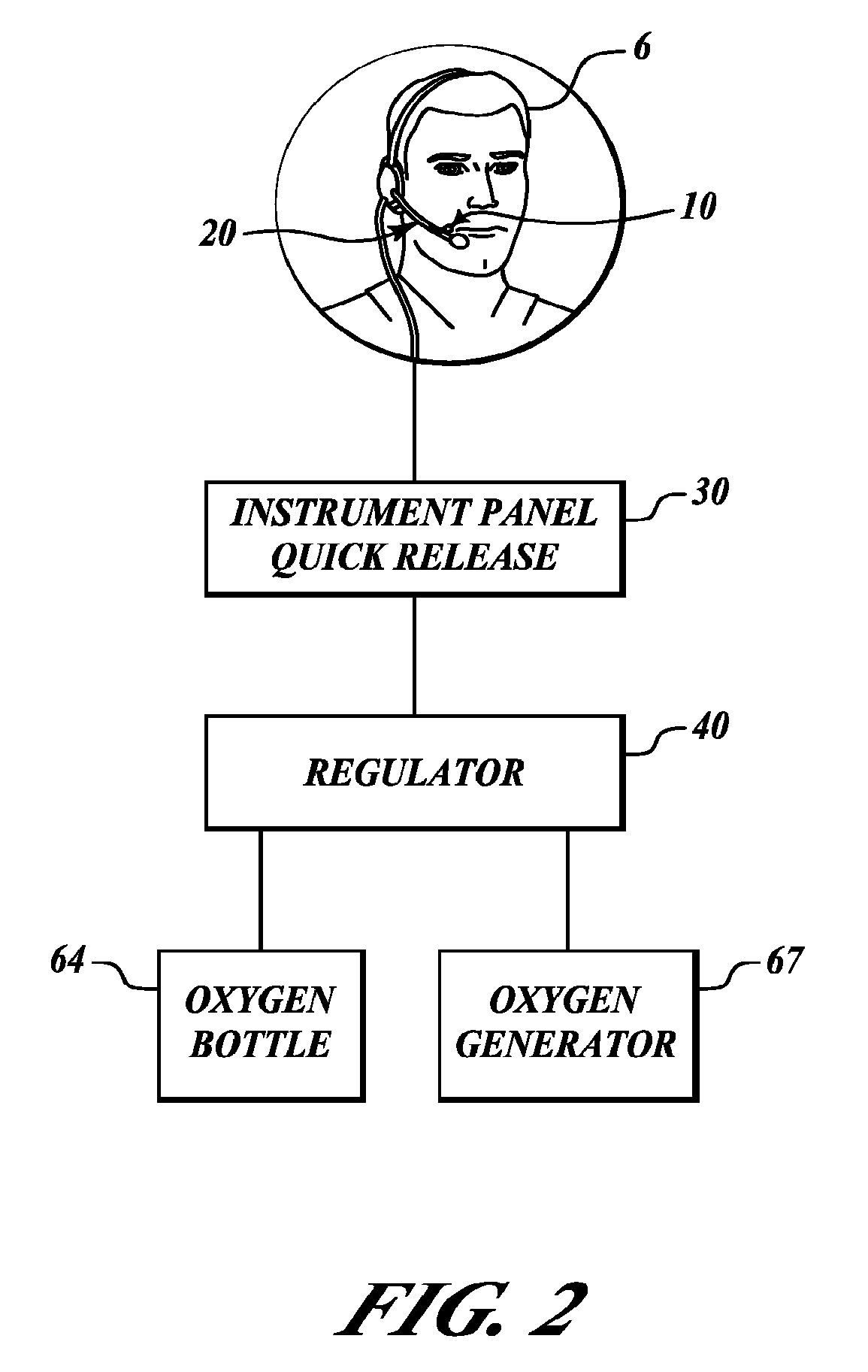

Aviator emergency oxygen system

A method, a system, and an oxygen delivery boomlet are configured to provide an additional partial pressure of oxygen to an aviator. The boomlet includes a conduit configured to receive an oxygen flow from a positive pressure oxygen source. A nozzle is in communicative connection with the conduit such that the oxygen flow the conduit receives is conducted to the nozzle. The nozzle is configured to direct the conducted flow of oxygen to an interpalatine region of the aviator. The boomlet is configured for attachment to a microphone boom.

Owner:NEVADA AVIATION SAFETY CONSULTANTS

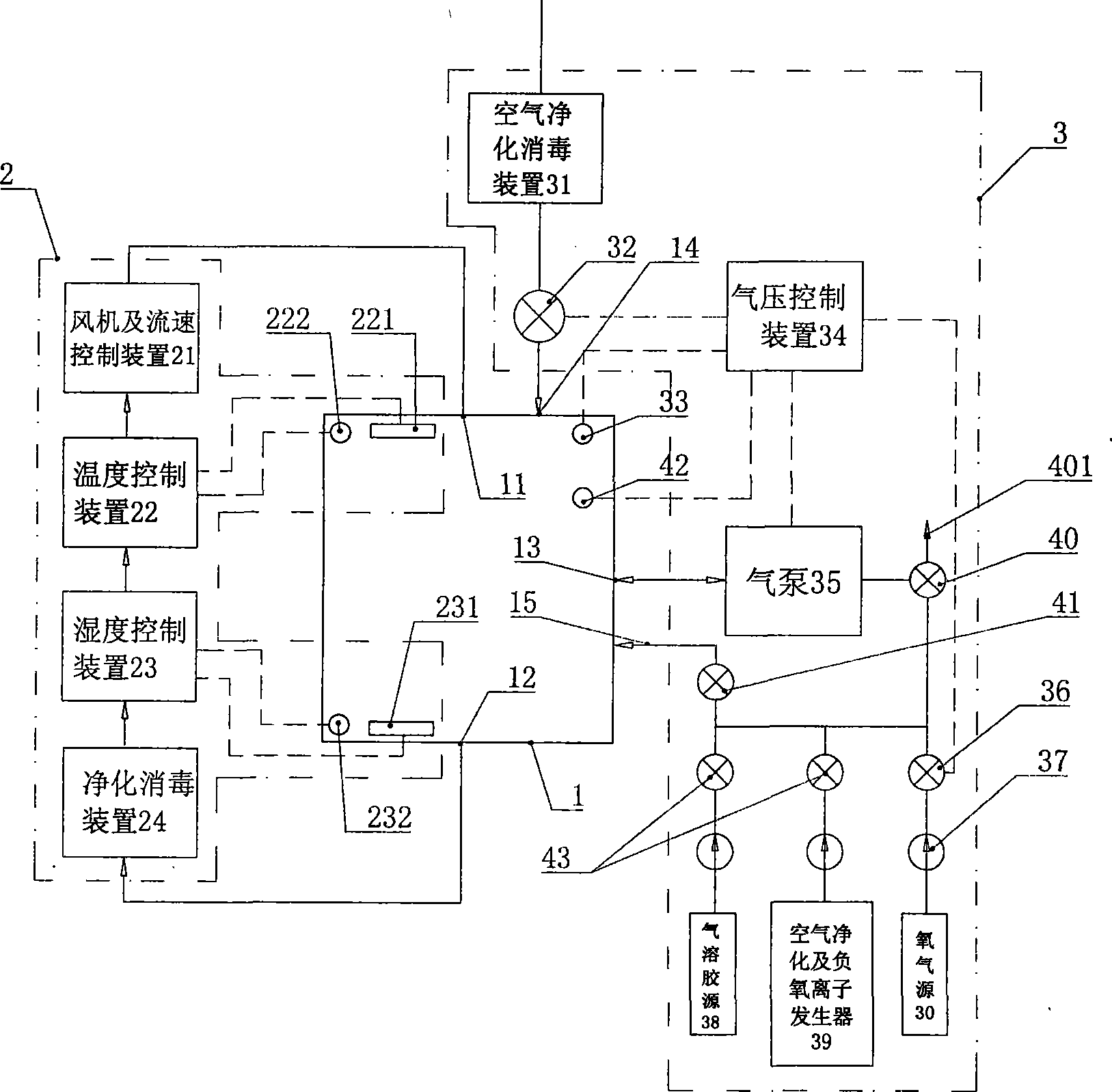

Biological internal environment conditioning device and use method thereof

ActiveCN101380263ASmooth blood circulationVaporization point loweredBreathing protectionTreatment roomsVolumetric Mass DensityEngineering

The invention discloses a biological internal environment conditioning device and a using method thereof. The biological internal environment conditioning device includes a conditioning chamber, an internal circulating system and an external circulating system; a temperature-humidity adjusting device is arranged in the conditioning chamber; the internal circulating system builds and maintains a stated internal environment for the inside of the conditioning chamber by the temperature-humidity adjusting device; the external circulating system prepares a certain gas components for the inside of the conditioning device and controls the pressure of the inside of the conditioning chamber. In the invention, a gas therapy device utilizes the changes of a plurality of factors like air density, temperature, humidity and partial pressure of oxygen to lead the blood circulating system of a human body to be unobstructed and to release the acid volatilizable matters in the blood from a dredged sweat duct, thus achieving the goals of dredging blood, exhausting acid and removing toxin.

Owner:姜林

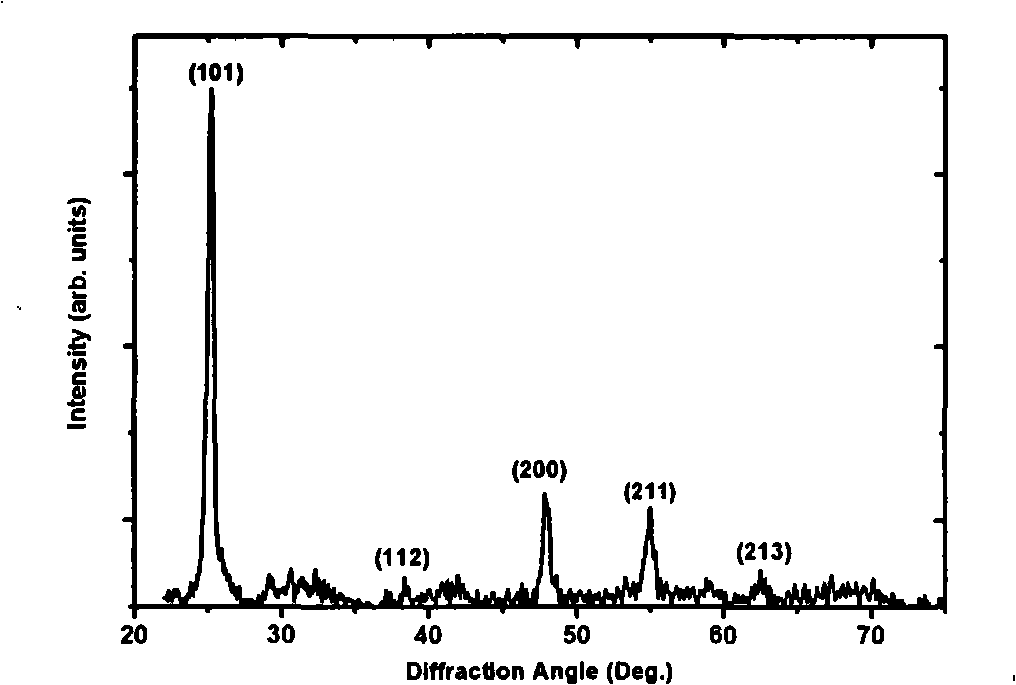

A dye sensitized solar battery anode and its making method

InactiveCN101261901AImprove bindingObvious characteristics of easy industrializationLight-sensitive devicesElectrode manufacturing processesIntermediate frequencyLong axis

The invention belongs to the field of dye sensitization solar cell materials and relates to an anodic film of the dye sensitization solar cell (DSSC) and the preparation method. The anode is (101) preferentially-growing anatase crystallographic form TiO2 porous membrane; the cross section of a TiO2 grain is oval with a long axis of about 100-145nm and a short axis of about 30-50nm; pores are distributed among the columnar grains of TiO2 and the aperture is between 2-100nm. The TiO2 anodic film is manufactured by adopting an intermediate frequency (40KHz) or radio frequency (13.56MHz) reaction magnetron sputtering method: Titanium is taken as a target and O2 and Argon are taken as discharge gases, the substrate is conductive glass or flexible conductive substrate; the substrate temperature is kept under 120 DEG C during the deposition process. The (101) preferentially-growing anatase film is prepared by adjusting the overall sputtering pressure and the partial pressure of oxygen and controlling the bias voltage; the film is led to have porous structure by controlling the deposition rate and the included angle between the substrate and the target face. The preparation method is especially suitable for the preparation of the flexible DSSC TiO2 anodic film.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com