Solid oxide fuel cell cathode material

A fuel cell cathode and solid oxide technology, which is applied to fuel cell components, battery electrodes, circuits, etc., can solve problems such as the inability to meet the basic requirements of intermediate temperature oxide fuel cell cathode materials, and reduce synthesis time and synthesis The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

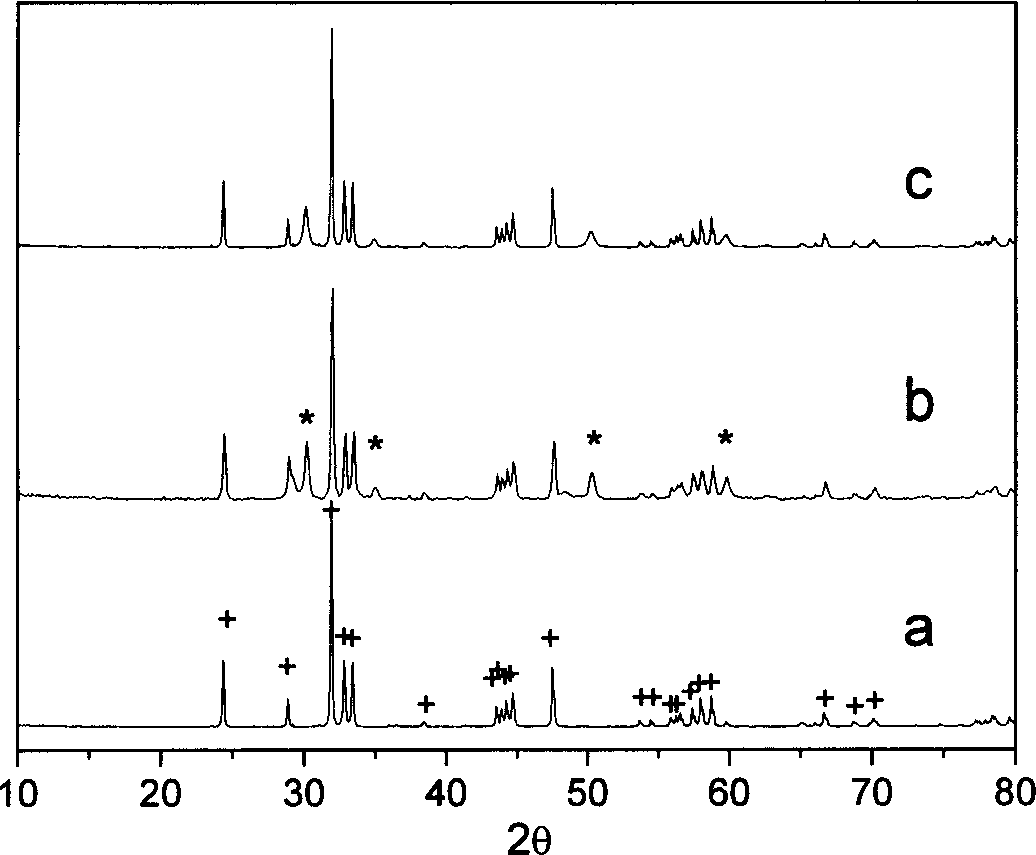

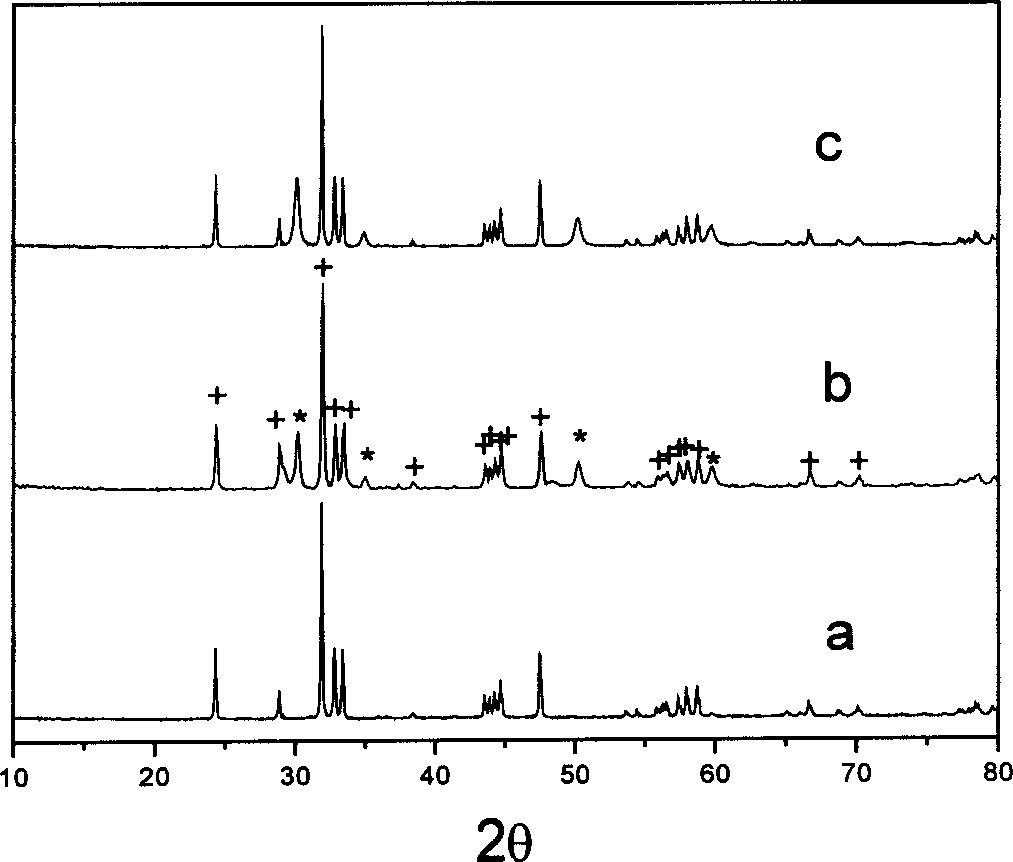

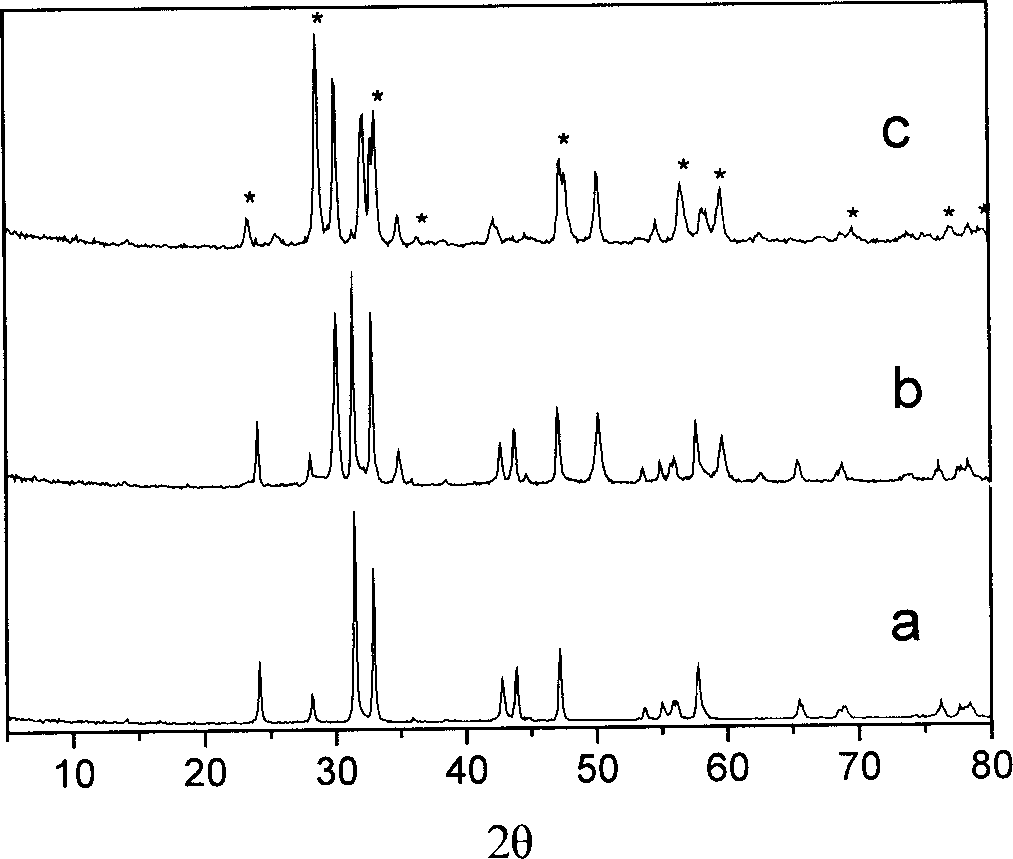

Image

Examples

specific Embodiment approach 1

[0013]Specific embodiment 1: The general composition formula of the solid oxide fuel cell cathode material in this embodiment is A 1+x A' 1-x B 1-y B' y o 4±δ , where A is the main group of alkaline earth metals, A' is a rare earth element, B and B' are transition group metal elements, 0<x<1, 0≤y≤1, δ≤0.17.

[0014] A and A' in this embodiment represent alkaline earth elements (Ca, Sr, or Ba, etc.) and rare earth elements (La, Ce, Pr, Nd, Pm, Sm, Eu, or Gd, etc.) in the periodic table, respectively. B and B' are transition group metal elements (Cr, Mn, Fe, Co, Ni, Cu, Zn, Mo, W, V, Nb or Ta, etc.).

specific Embodiment approach 2

[0015] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that when A is Sr, A' is Sm, B is Ni, B' is Co, and δ=0, the solid oxide fuel cell cathode material The structural formula is Sr 1-x SM 1+x Ni 1-y co y o 4 .

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment two is that when x=0.5 and y=0, the structural formula of the solid oxide fuel cell cathode material is Sr 0.5 SM 1.5 NiO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com