ZrO2 oxygen sensor for solid state reference partial pressure of oxygen and manufacture method thereof

A technology of an oxygen sensor and a manufacturing method, which is applied in the directions of instruments, scientific instruments, analytical materials, etc., can solve the problems of strict requirements on the alignment accuracy of electrode vias, difficult sealing of reference air channels, and increased manufacturing costs, and achieves convenient Screen printing and process turnover, simple structure, high production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

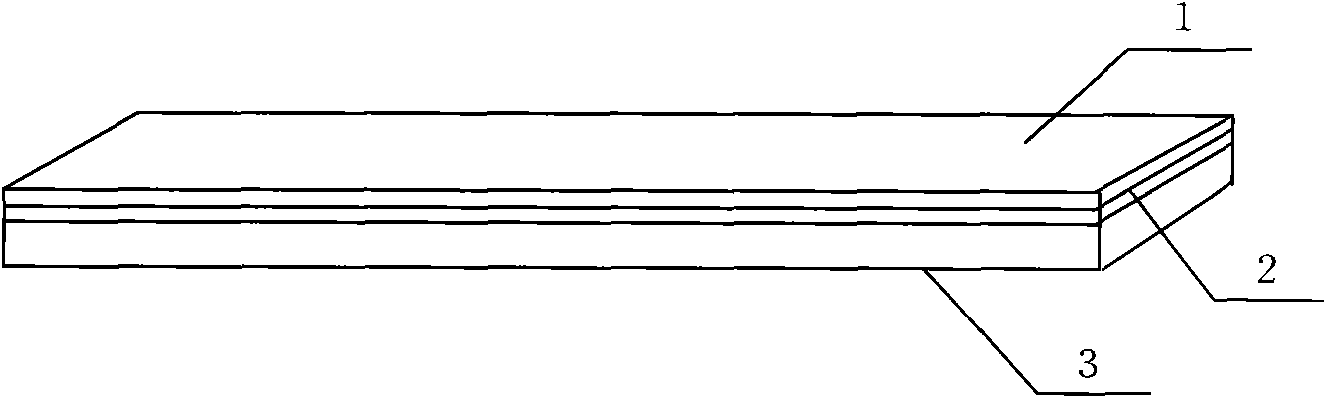

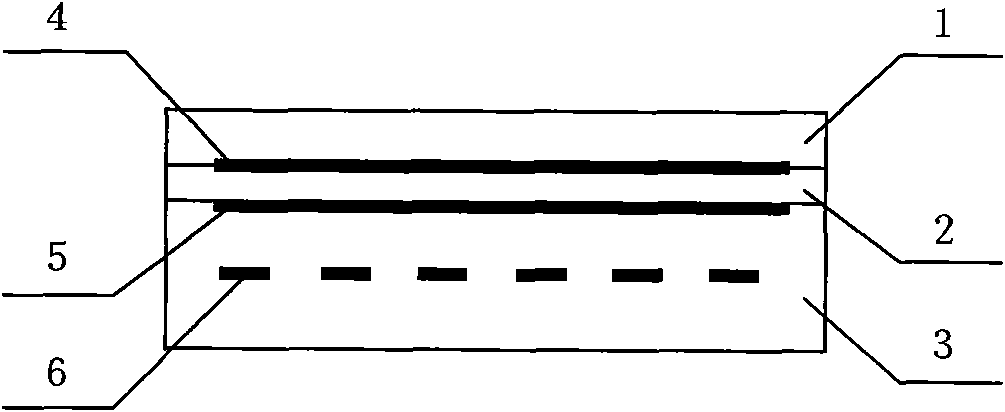

[0022] Further illustrate the specific content of the present invention below in conjunction with accompanying drawing

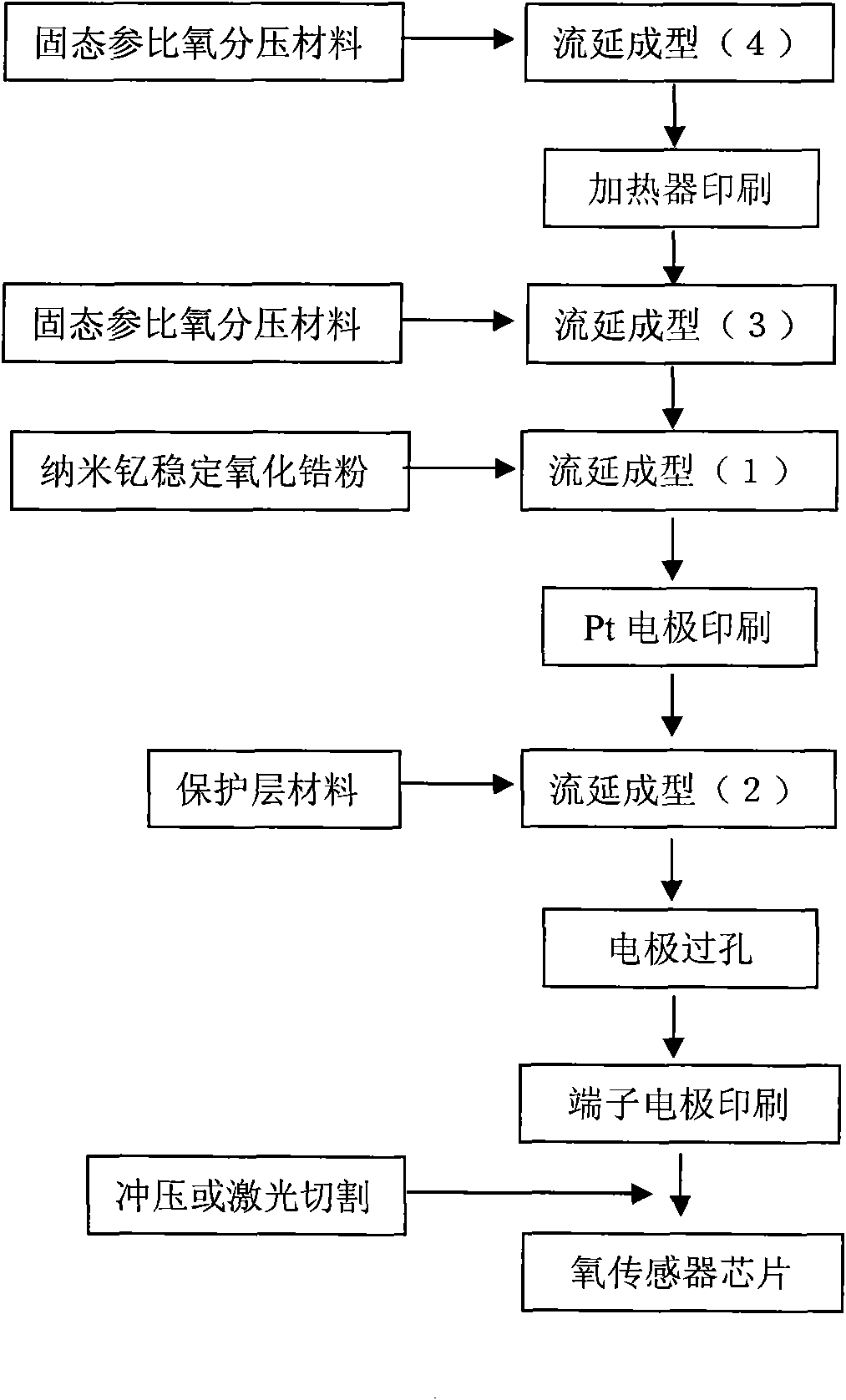

[0023] The present invention adopts multi-layer casting, one-time sintering process, and the method for concrete implementation is:

[0024] 1. Preparation of cast slurry:

[0025] First, yttrium-stabilized zirconia, solid reference oxygen partial pressure material, and protective material powder were vacuum-dried at 125°C for 4 hours, and organic solvent and trihexanolamine solution were added, and after fully grinding, polyvinyl alcohol and lipid were added to plasticize The agent was continuously ground for 12 hours, and after filtration, air bubbles were removed under vacuum conditions to complete the preparation of three casting slurries.

[0026] 2. Preparation of yttrium stabilized zirconia cast layer:

[0027] Measure and adjust the gap between the scraper of the tape casting machine and the marble substrate through the grating ruler. In order to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com