Laminated ceramic capacitor and manufacturing method thereof

A technology of ceramic capacitors and ceramic dielectrics, applied in capacitor manufacturing, multilayer capacitors, capacitors, etc., can solve the problems of reducing electrostatic capacitance and reducing the area of internal electrodes, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Prepare barium titanate-based dielectric ceramic powder as a capacitor material that exhibits X7R characteristics (the change rate of electrostatic capacitance within the temperature range of -55°C to +125°C at 25°C is within ±15%), and mixes it with poly Vinyl butyral, dioctyl phthalate, ethanol, etc. were mixed, and mixed with a disperser mill for 15 hours to obtain a ceramic slurry. The obtained ceramic slurry was coated on a strip-shaped PET film by a doctor blade method to form a ceramic green sheet with a thickness of 1.4 μm.

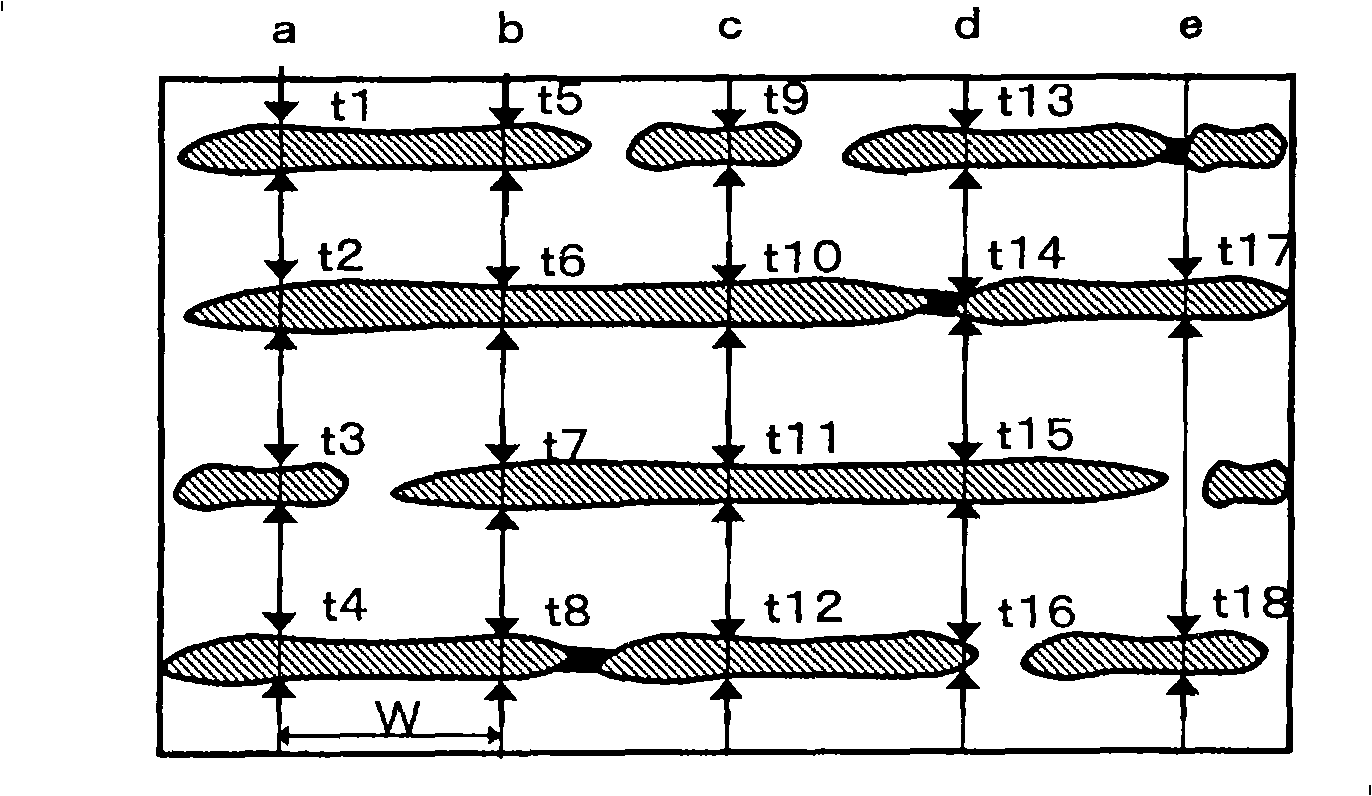

[0044] Ni powder in which CoO was coated on Ni particles with an arithmetic average particle diameter of 0.2 μm by spray pyrolysis was mixed with ethyl cellulose, terpineol, etc., to prepare a conductive paste for internal electrodes. Apply this conductive paste on the ceramic green sheet by screen printing method, within the range of 15cm x 15cm, in a roughly rectangular shape of 3.75mm x 0.75mm, a plurality of paste films with a thickness...

Embodiment 2

[0058]A laminated ceramic capacitor was formed in the same manner as in Example 1, except that Ni particles having an arithmetic average particle diameter of 0.2 μm were coated with a base metal by the method of adsorbing an acetylacetonate metal complex. The types of base metals to be coated are shown in Table 3.

[0059] 【table 3】

[0060]

[0061] For the obtained multilayer ceramic capacitor, the capacitance, the thickness of the internal electrode layer, the continuity of the internal electrode layer, and the average particle diameter of the metal particles constituting the internal electrode were measured in the same manner as in Example 1, as shown in Table 4.

[0062] 【Table 4】

[0063]

[0064] From the results in Table 4, it can be seen that the same effect can be obtained even if Mn, Fe, Cu, Nb, Ba, Ca, Sr, Ti, Zn, V, and rare earth metals other than Co are used as the base metal to coat Ni. .

[0065] From the above results, it can be seen that the multila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electrostatic capacitance | aaaaa | aaaaa |

| Electrostatic capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com