Gate dielectric material cubical phase HfO2 film and preparation method thereof

A gate dielectric, cubic phase technology, applied in the field of microelectronic materials, can solve problems such as EOT increase, and achieve the effect of increasing dielectric constant and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

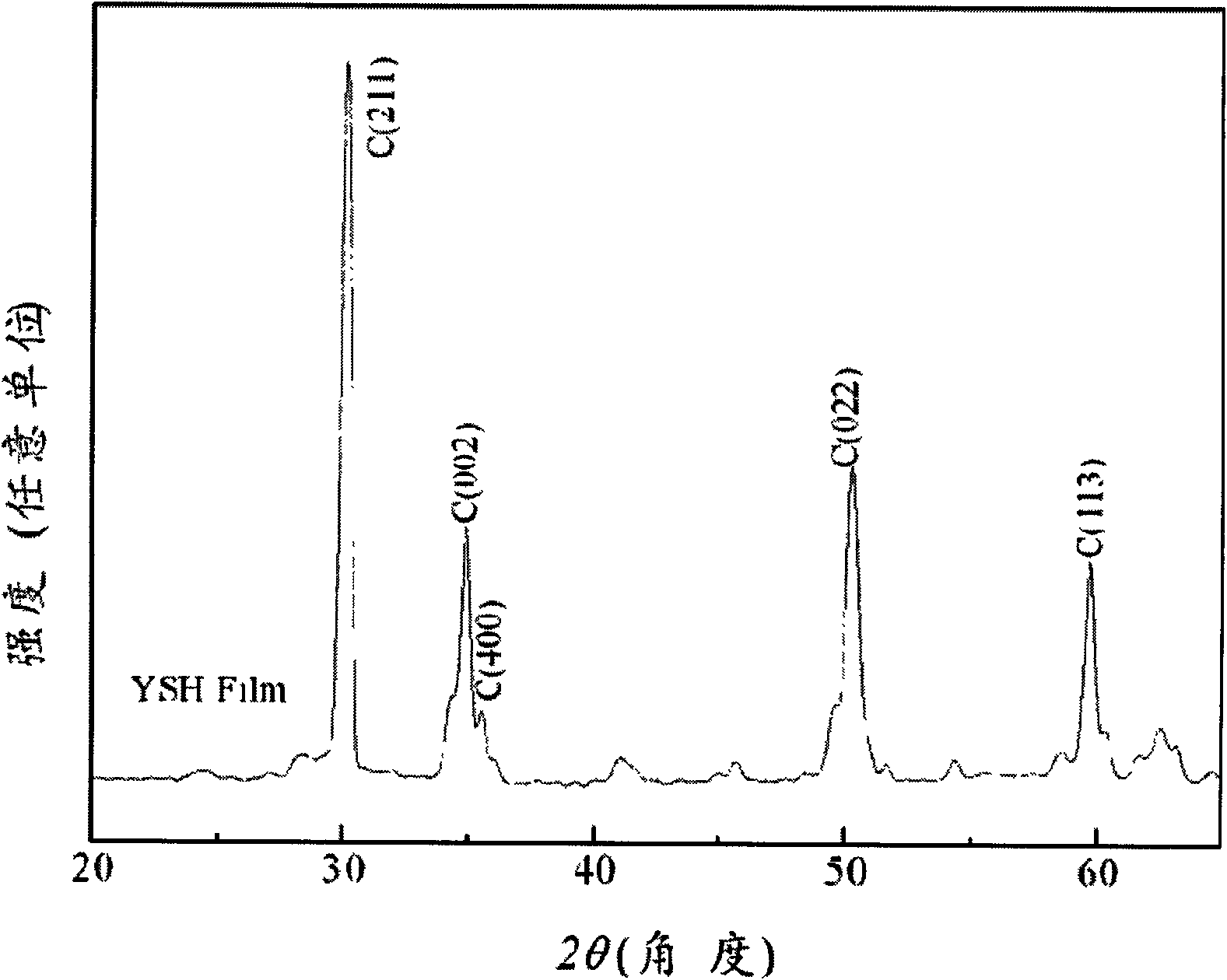

[0035] In the present invention, under high vacuum and low oxygen partial pressure conditions, an ultra-thin film with a thickness of about 5nm is made on a silicon substrate. The film is amorphous, and its dielectric constant varies with Y 2 o 3 There will be a small change in the amount of doping.

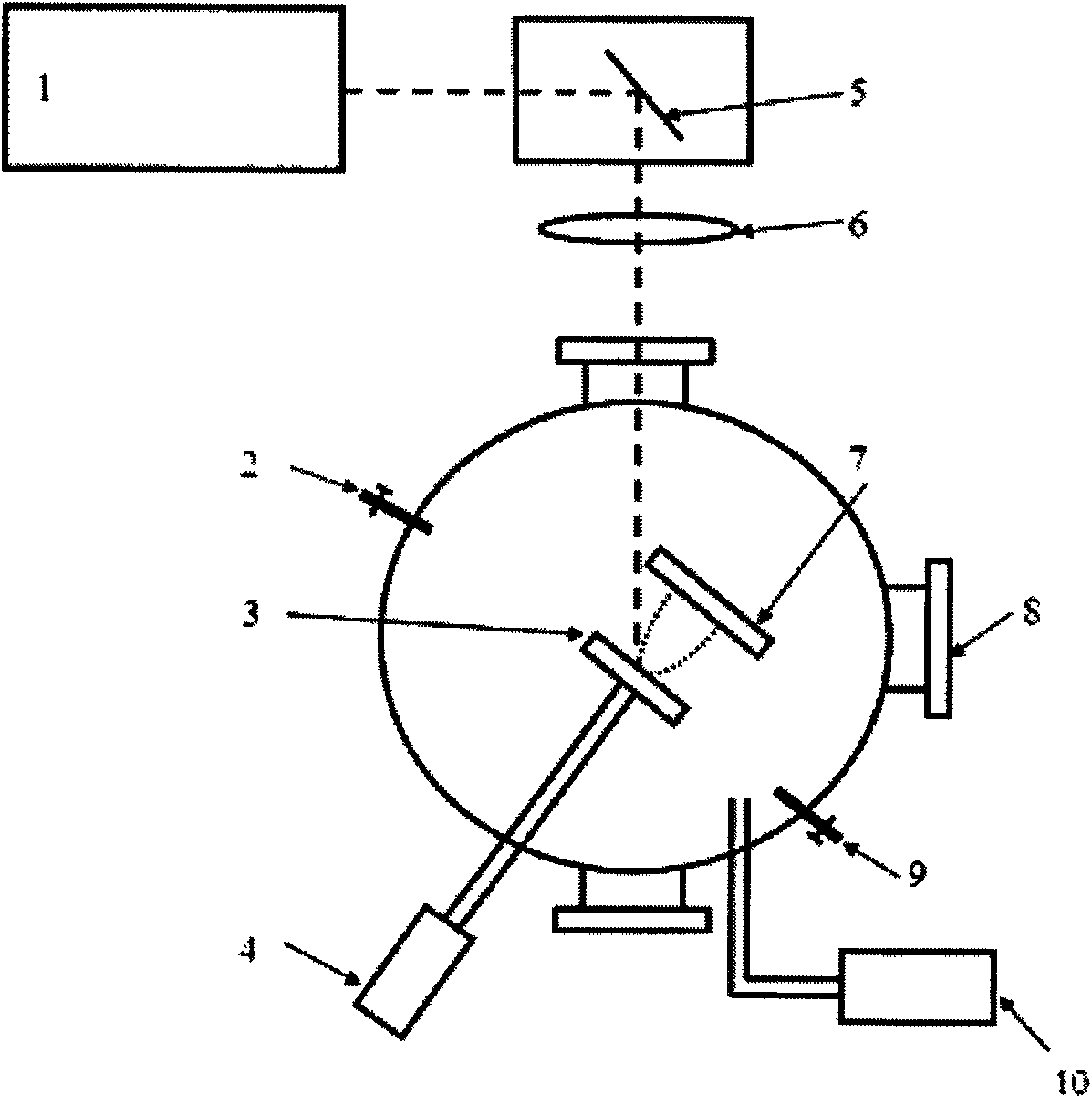

[0036] Such as figure 1 , the growth system of the present invention uses a pulsed laser deposition system, such as figure 1 , including excimer laser 1; inlet valve 2; target 3; motor 4; mirror 5; focusing lens 6; substrate table 7; observation port 8; air release valve 9; mechanical pump and molecular pump 10, pulse laser The deposition system is a prior art and will not be described in detail.

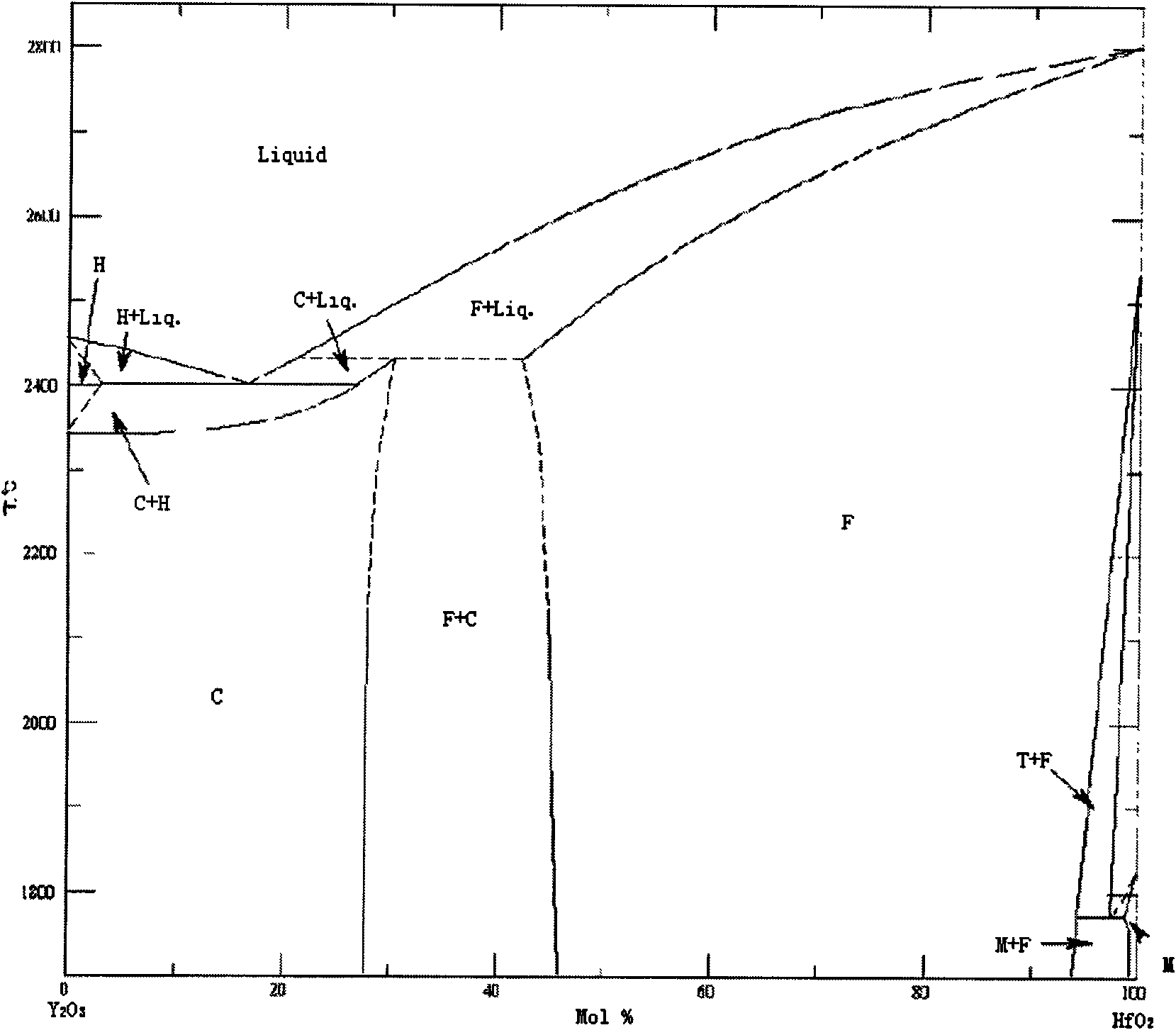

[0037] to prepare Y 2 o 3 Take a YSH film with a molar ratio of 6% as an example, and its preparation steps are as follows:

[0038] (1) Preparation of YSH ceramic target: pure Y 2 o 3 and HfO 2 The powder is mixed according to the molar ratio of 6:94, fully milled by a ball m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com