A dye sensitized solar battery anode and its making method

A technology for solar cells and dye sensitization, applied in the field of dye-sensitized solar cells, can solve the problem of not clearly clarifying the grain size, orientation and porosity characteristics of thin films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

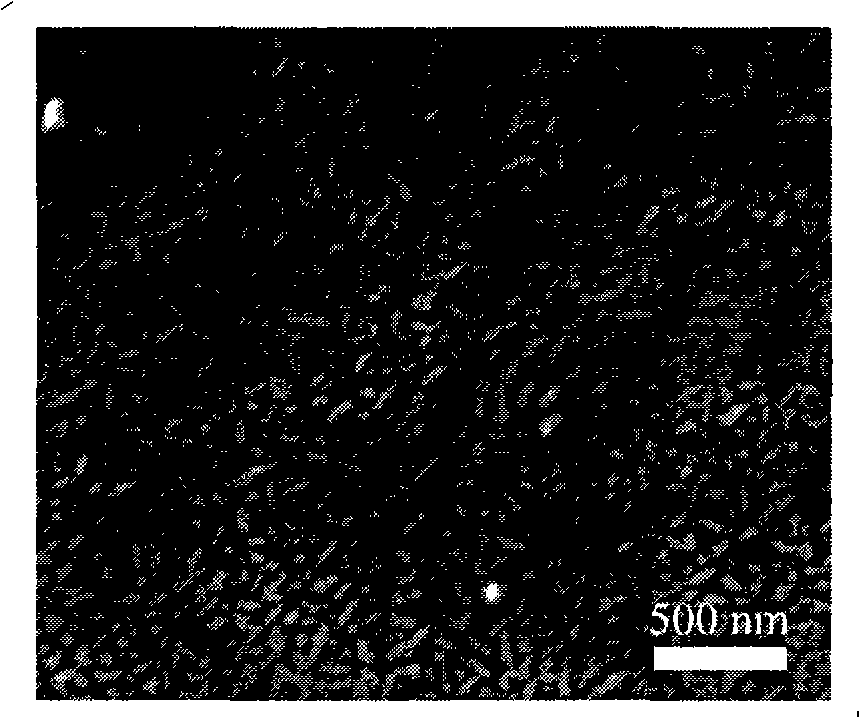

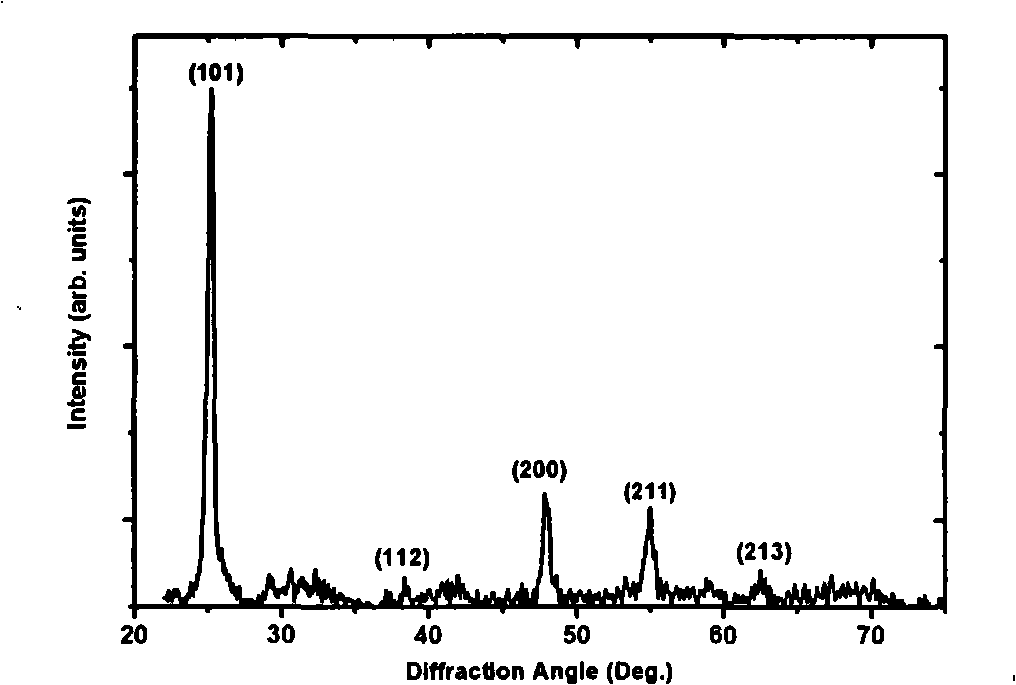

[0016] Embodiment 1, have (101) preferred growth nano anatase TiO 2 Preparation method of thin film anode

[0017] Substrates used to prepare thin films were ultrasonically cleaned in acetone and absolute ethanol solutions for 15 minutes, then rinsed with deionized water, and dried for later use. A titanium target with a purity of 99.9% is fixed on a magnetron cathode target holder, and a substrate for preparing a thin film after cleaning and drying is fixed on a sample base of a vacuum chamber of a magnetron sputtering system. The magnetic field strength in the sputtering area on the target surface is about 300 Gauss, the distance from the target surface to the substrate is 60mm, and the angle between the sample surface and the normal of the target surface is 30°. Bake the vacuum chamber before preparation, and wait for the background vacuum to 1×10 -3 After Pa, argon gas was introduced to 1Pa, and then the target was cleaned by sputtering. After the titanium target is cle...

Embodiment 2

[0019] Embodiment 2, preparation dye-sensitized solar cell

[0020] The film was heated to 100°C for 10 min and then soaked in 30 mM N719 dye to sensitize at room temperature for 24 hours. Combine the above electrode with Pt counter, LiI and I 2 acetonitrile solution to assemble dye-sensitized solar cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com