A method for extracting manganese from manganese ore containing manganese silicate minerals

A technology of high silicomanganese ore and manganese silicate, applied in the direction of improving process efficiency, can solve the problems of limited improvement of manganese grade, etc., and achieve the effects of easy industrial implementation, short leaching time, and improved recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

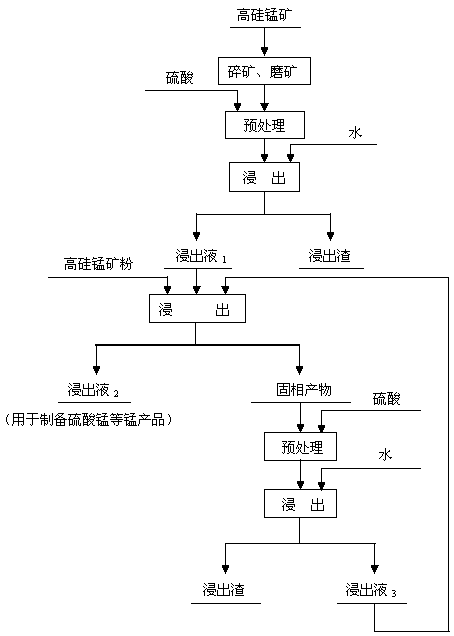

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Pretreatment and leaching

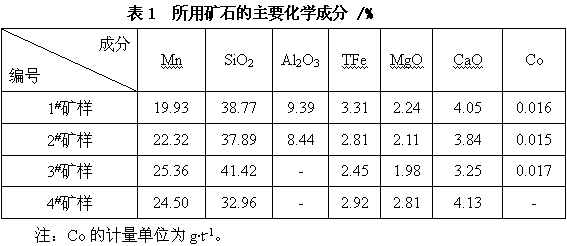

[0034] The high silicon manganese ore used in this example is 1 shown in table 1 # ore sample. 1 # The manganese mineral composition of the ore sample is 64% rhodochrosite, 35% manganese silicate, and 1% iron-manganese oxide.

[0035] A. Pretreatment: Grind the ore sample into -200 mesh ore powder accounting for 90%, add concentrated sulfuric acid to the ore powder, stir and mix evenly, and obtain the pretreated product; place the pretreated product in a heat preservation device (oven, box, etc.) type furnace or tunnel kiln), heat preservation and aging.

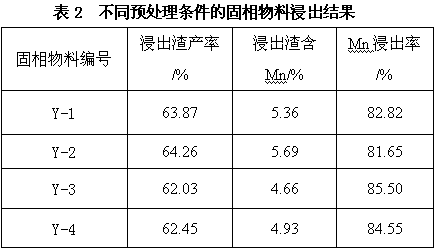

[0036] Silicomanganese (1 # The technical conditions for pretreatment of ore samples are as follows: the excess coefficient of concentrated sulfuric acid is 2.4 to 3.0, the pretreatment temperature is 135 to 165°C, and the pretreatment time is 60 to 100 minutes. The following four pretreatment products are obtained respectively:

[0037] Ⅰ. Put in 100.0g of mineral powder,...

Embodiment 2

[0044] Embodiment 2 Pretreatment and leaching

[0045] The silico-manganese ore that this example adopts is identical with embodiment 1, promptly 1 shown in table 1 # ore sample.

[0046] Under the conditions of concentrated sulfuric acid excess coefficient 2.7, pretreatment temperature 150°C, and aging for 80 minutes, put in 600.0 mineral powder for pretreatment, and then divide the pretreated product (1155.6g) into 6 equal parts for use.

[0047] The technical conditions for the leaching of the pretreated product are as follows: the leaching water-to-mineral ratio is 2.0-3.0, the leaching temperature is 20-70°C, and the leaching time is 20-50 minutes.

[0048] Ⅰ. Take 192.6g of the pretreated product, put it into 300mL of water, leaching at 20°C for 30min, separate the solid from the liquid, and dry the wet residue at 110°C to obtain 61.53g of leaching residue, leaching liquid 1 475mL, the solution contains Mn36.1g / L, H 2 SO 4 Content 82.6 / L. The leaching slag contains...

Embodiment 3

[0051] Example 3 Adding high silicon manganese ore powder for further leaching

[0052] due to leachate 1 H 2 SO 4 The content is relatively high (70~106g / L), so it can be added by adding rhodochrosite powder or high silicomanganese powder and H in the solution 2 SO 4 reaction, using sulfuric acid in solution. The reaction using rhodochrosite powder is relatively simple, so this method uses high-silico-manganese ore powder as a raw material for neutralization reaction as an example to illustrate.

[0053] The leach solution that embodiment 2 is obtained respectively according to I-III 1 After mixing (the mixture contains Mn40.2g / L, H 2 SO 4 content of 91.8g / L), add ore powder at a temperature of 70-90°C (according to 1.3-1.5 times the theoretical acid consumption of rhodochrosite in the ore), stir for 2-3 hours, and separate solid-liquid to obtain leachate 2 And solid phase leaching products (containing unleached manganese). Leachate 2 It is used to prepare manganese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com