Method and system for preparing ferric chloride, electrodeposited copper and copper powder from copper-containing hydrochloric acid waste liquid

A technology of electrodepositing copper and ferric chloride, applied in iron halide, improvement of process efficiency, photographic process, etc., can solve the problems of polluted environment, waste liquid pollution, poor economic benefits, etc., and achieve good economic benefits and low price high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

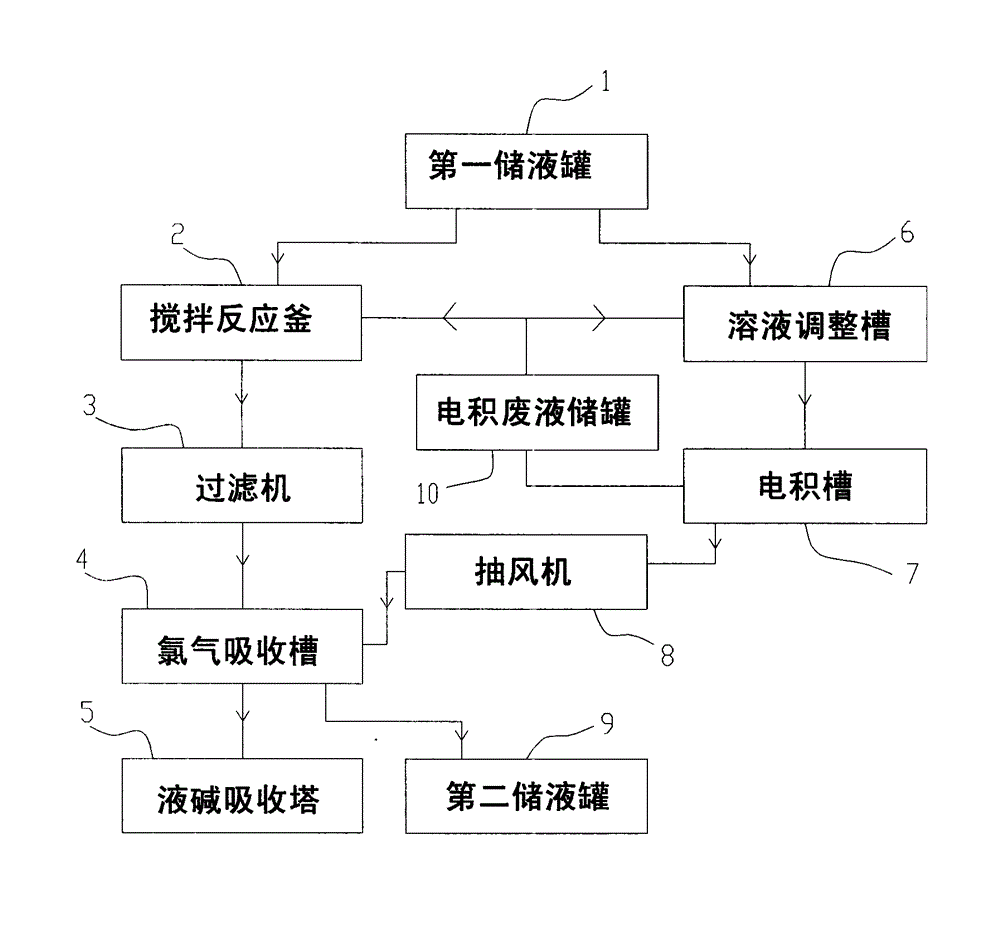

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] In order to enable the present invention to be described clearly and briefly, without repeating the details, the method and system provided by the present invention will be described simultaneously below. And the connection relationship of each component has been established by figure 1 It is clearly shown and described in the following process flow, and the connection relationship of each component will not be described in detail below.

[0039] application figure 1 In the system embodiment shown, the collected hydrochloric acid copper-containing waste liquid is stored in the first liquid storage tank 1, the waste liquid preferably contains 20-250 g / l of copper, and the concentration of free hydrochloric acid is generally 0.5-6 mol / l .

[0040] Pump part of the waste liquid into the stirred reactor 2, add iron powder accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com