Tail gas absorbing device in acetone cyanohydrin production

A tail gas absorption device, acetone cyanohydrin technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of increasing waste water volume and cost production, and achieve reduction of waste water volume, safety assurance, and economic benefits. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

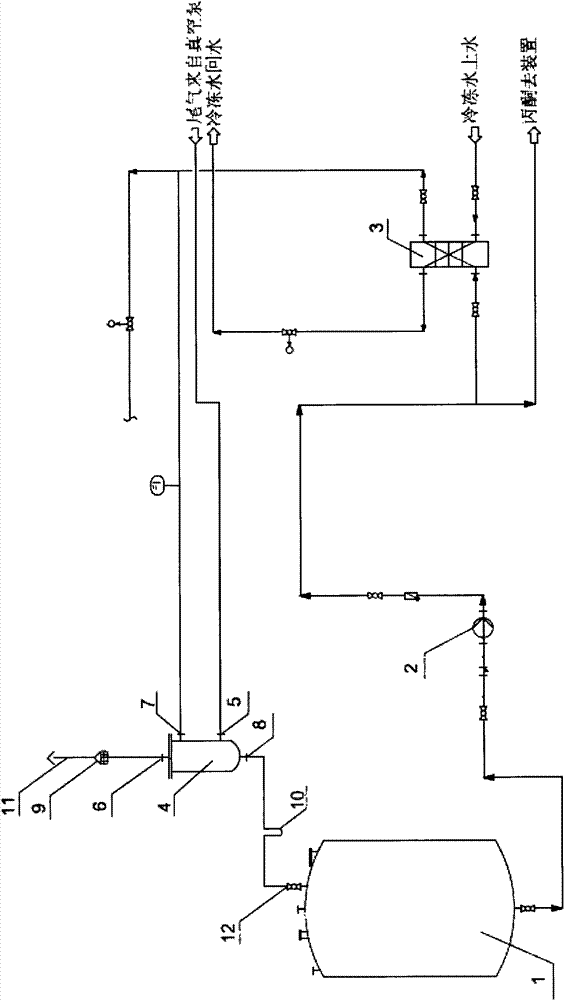

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

[0029] The present invention utilizes a 100,000-ton / year acetone cyanohydrin device in a certain place to improve, based on the existing acetone tank 1, acetone pump 2, and acetone cooler 3, and adding a tail gas absorption tower 4 to transform it.

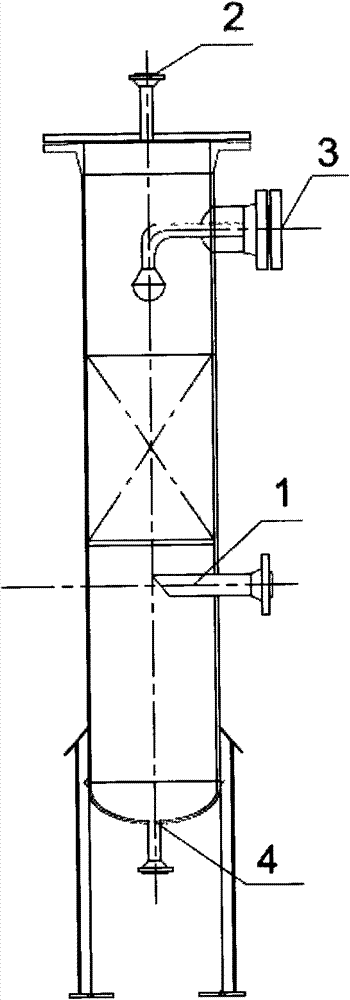

[0030] As shown in the figure, it includes acetone tank 1, acetone pump 2, acetone cooler 3, and an exhaust gas absorption tower 4. The exhaust gas absorption tower 4 is a packed tower, the filler adopts Pall ring packing, the equipment material is 316L, and the exhaust gas absorption tower 4 The upper part is provided with a flame arrester 9, the upper part of the flame arrester 9 is provided with an exhaust gas exhaust pipe 11, the lower part of the exhaust gas absorption tower 4 is provided with a liquid seal pipe 10, that is, a water seal 10, and the lower part of the liquid seal pipe 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com