Method for preparing lithium iron phosphate and lithium nickel cobalt manganese oxide composite cathode material

A composite cathode material, lithium nickel cobalt manganate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor electrochemical performance, poor electronic conductivity, high temperature performance defects, etc., to improve overcharge and discharge performance. , Improve the cycle performance, the effect of no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

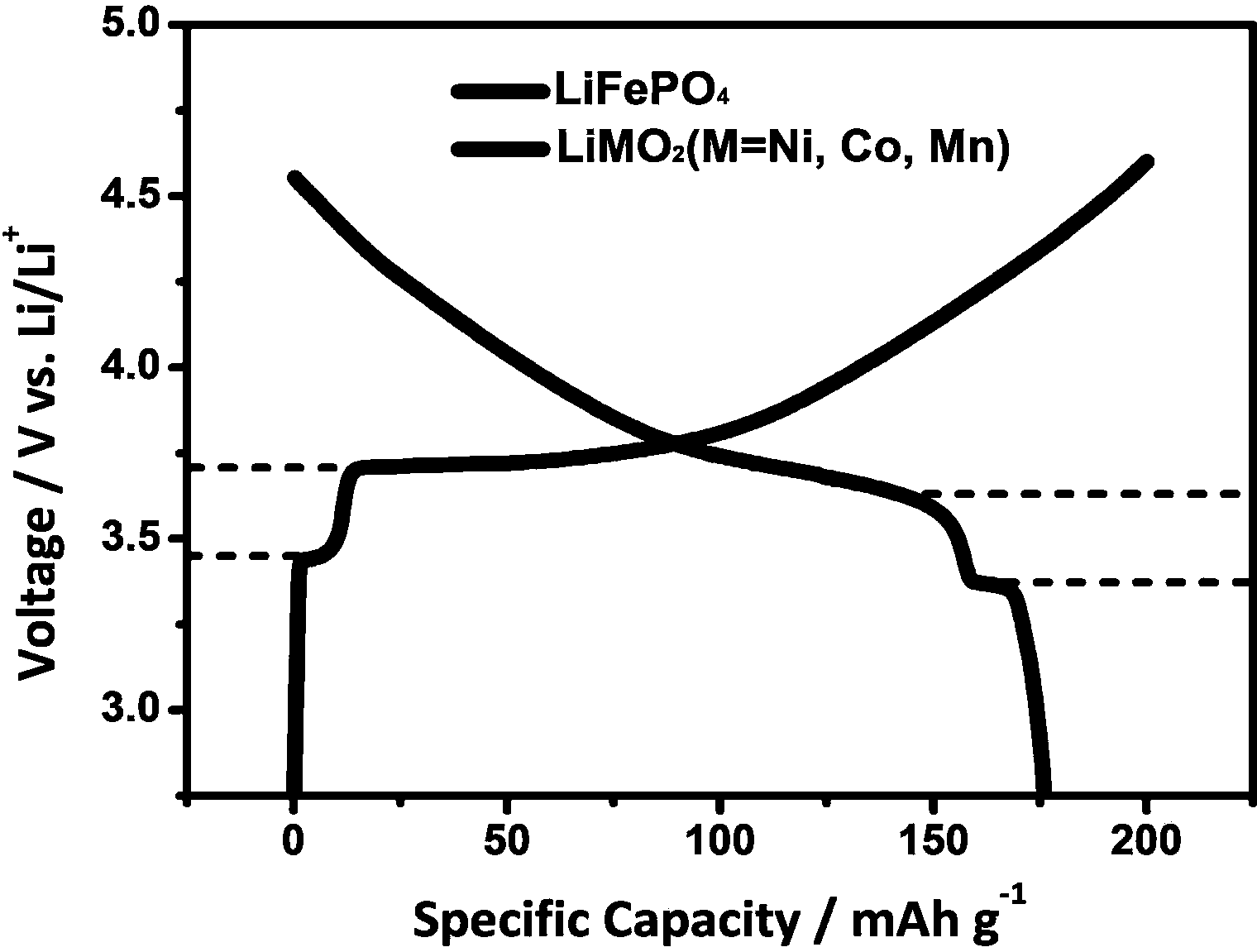

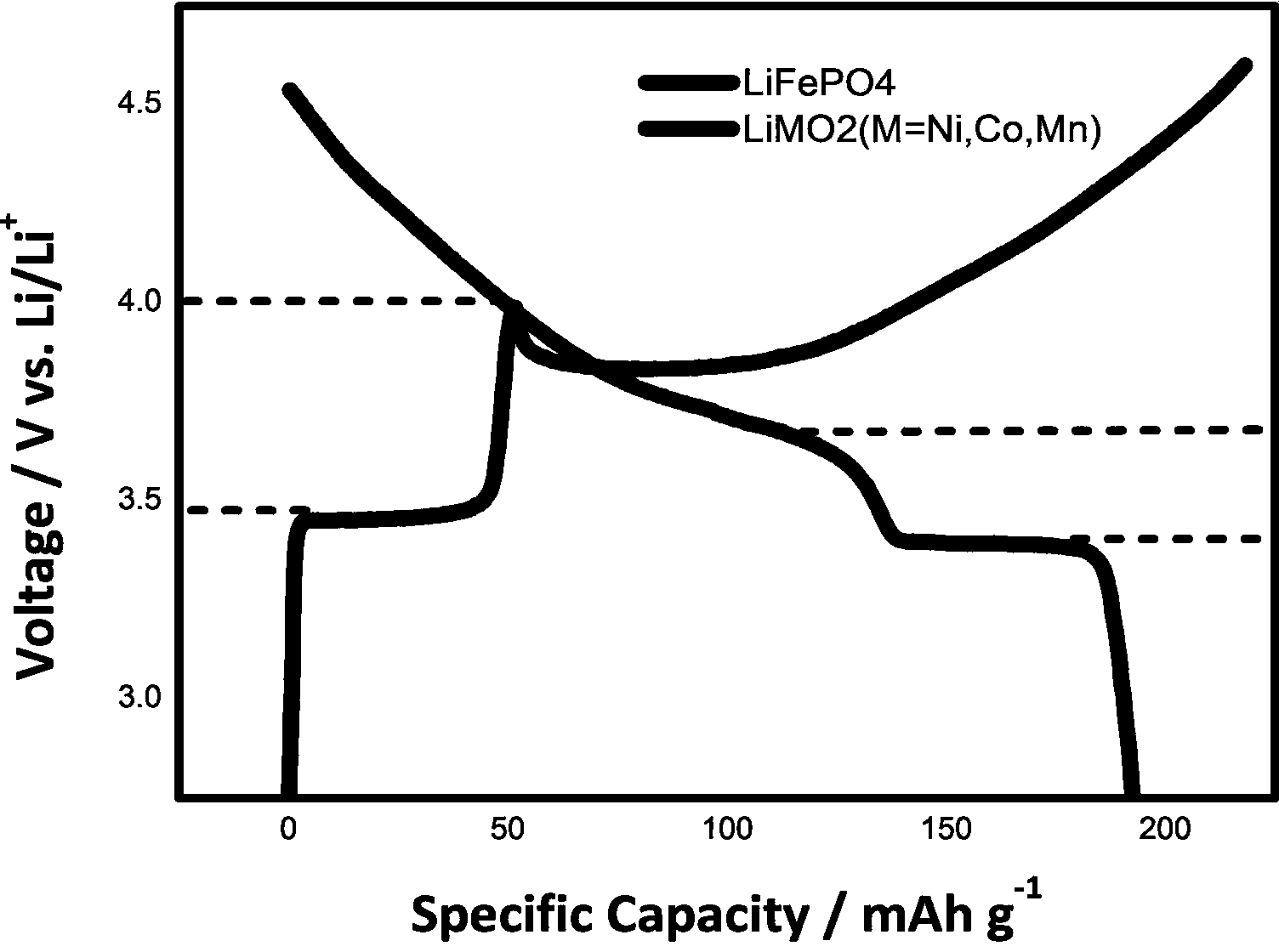

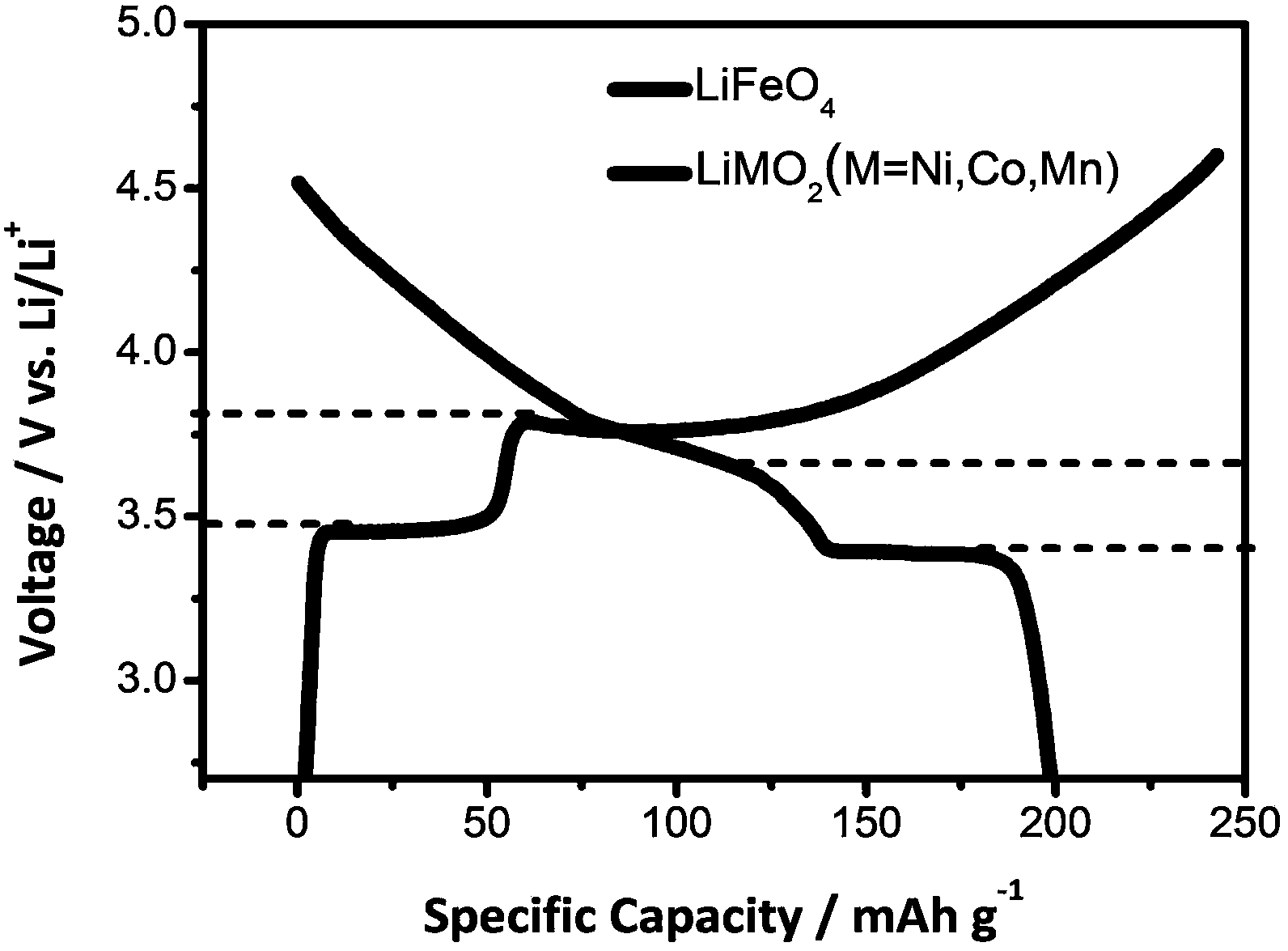

[0016] Using lithium iron phosphate and lithium nickel cobalt manganese oxide as positive electrode materials, the mass ratio of lithium iron phosphate to lithium nickel cobalt manganese oxide is 1:9, weigh 14.40g of lithium nickel cobalt manganese oxide and 1.60g of lithium iron phosphate and Mix 1.00g of acetylene black, dry ball mill for 30min, separate them after ball milling, then stir the two for pre-mixing, then add a certain amount of alcohol and stir evenly, then ball mill for 30min, then take out, dry and pulverize to obtain iron phosphate Composite cathode material of lithium and nickel-cobalt-lithium manganese oxide. Weigh 0.06g of binder PVDF, then add dropwise 0.9898g ~ 1.1589g of nitrogen methyl pyrrolidone to dissolve it into a solution with no bubbles, then weigh 0.54g of composite positive electrode material, add it to the solution, and stir The positive electrode slurry was made in two hours, and the slurry was evenly coated on the aluminum foil, dried to ma...

Embodiment example 2

[0018] Lithium iron phosphate and lithium nickel cobalt manganese oxide are used as positive electrode materials, and the ratio of lithium iron phosphate to lithium nickel cobalt manganese oxide is 2:8. The experimental steps are the same as the implementation case 1.

Embodiment example 3

[0020] Lithium iron phosphate and lithium nickel cobalt manganese oxide are used as positive electrode materials, the ratio of lithium iron phosphate to lithium nickel cobalt manganese oxide is 3:7, and the experimental steps are the same as the implementation case 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com