Revolving furnace

A technology of rotary furnace and rotary drum, which is applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the problems of unsuitable for small and medium-scale production requirements, large occupied area, high manufacturing cost, etc., and achieve small occupied area and low labor cost. The effect of low strength and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

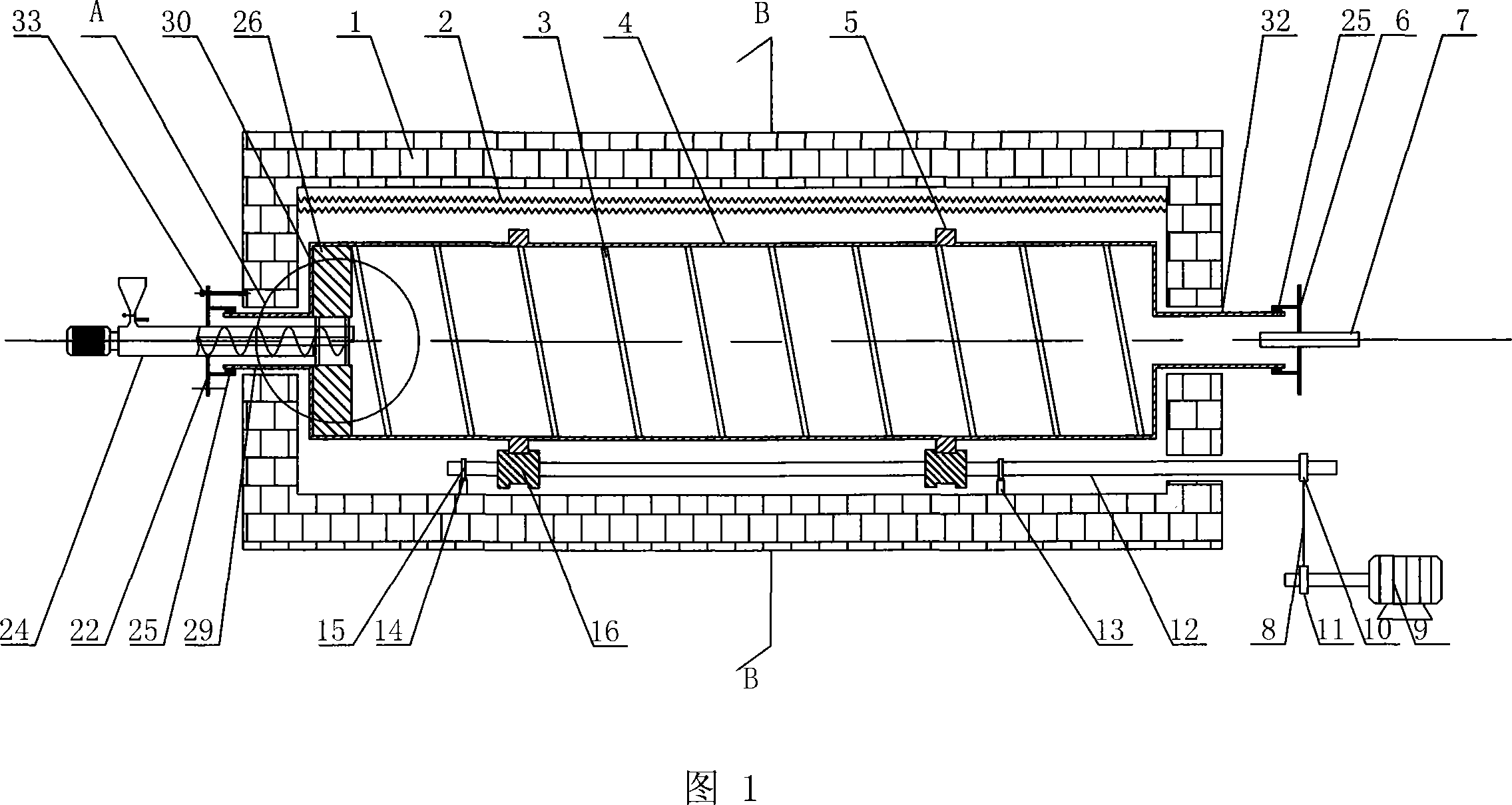

[0037] 1. Rotary furnace

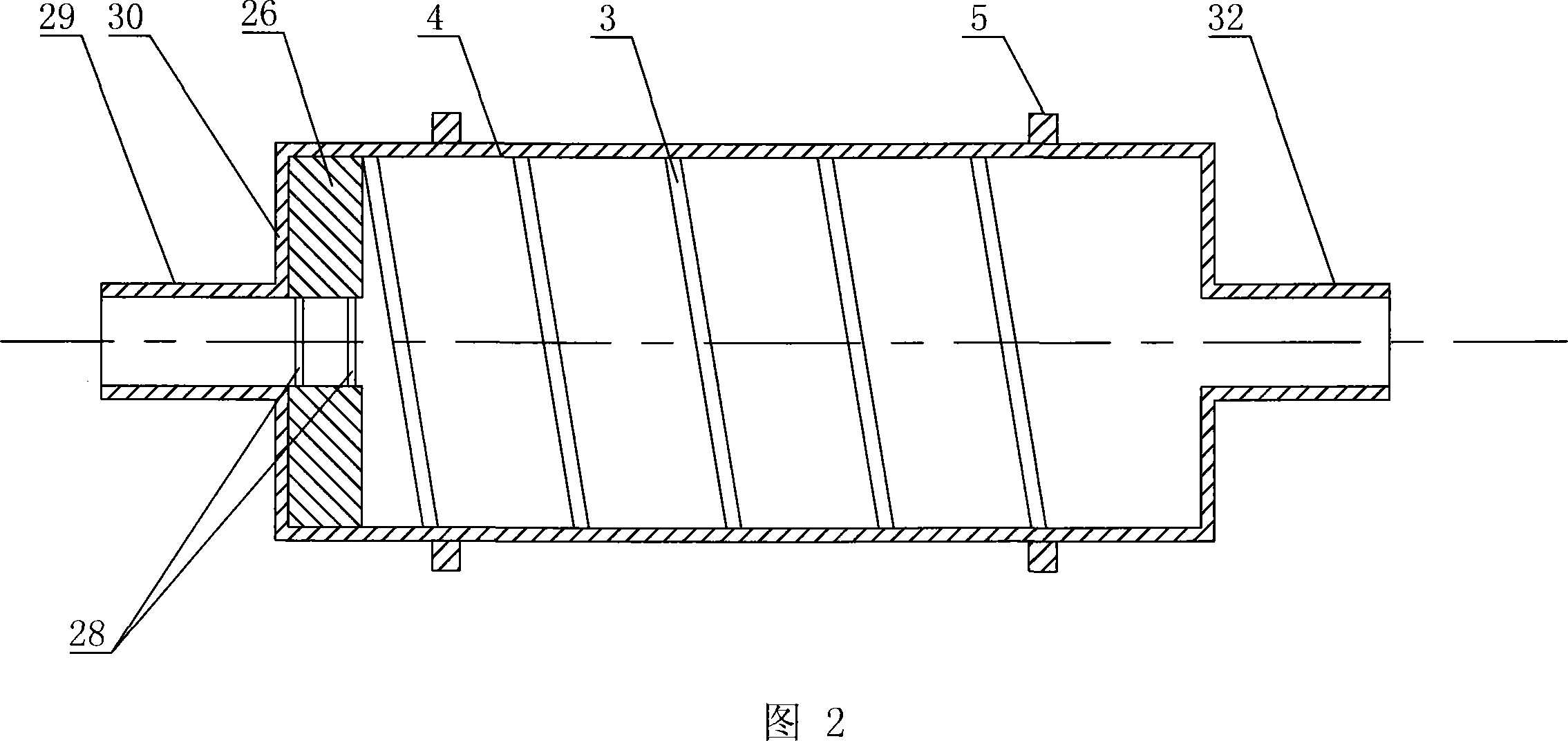

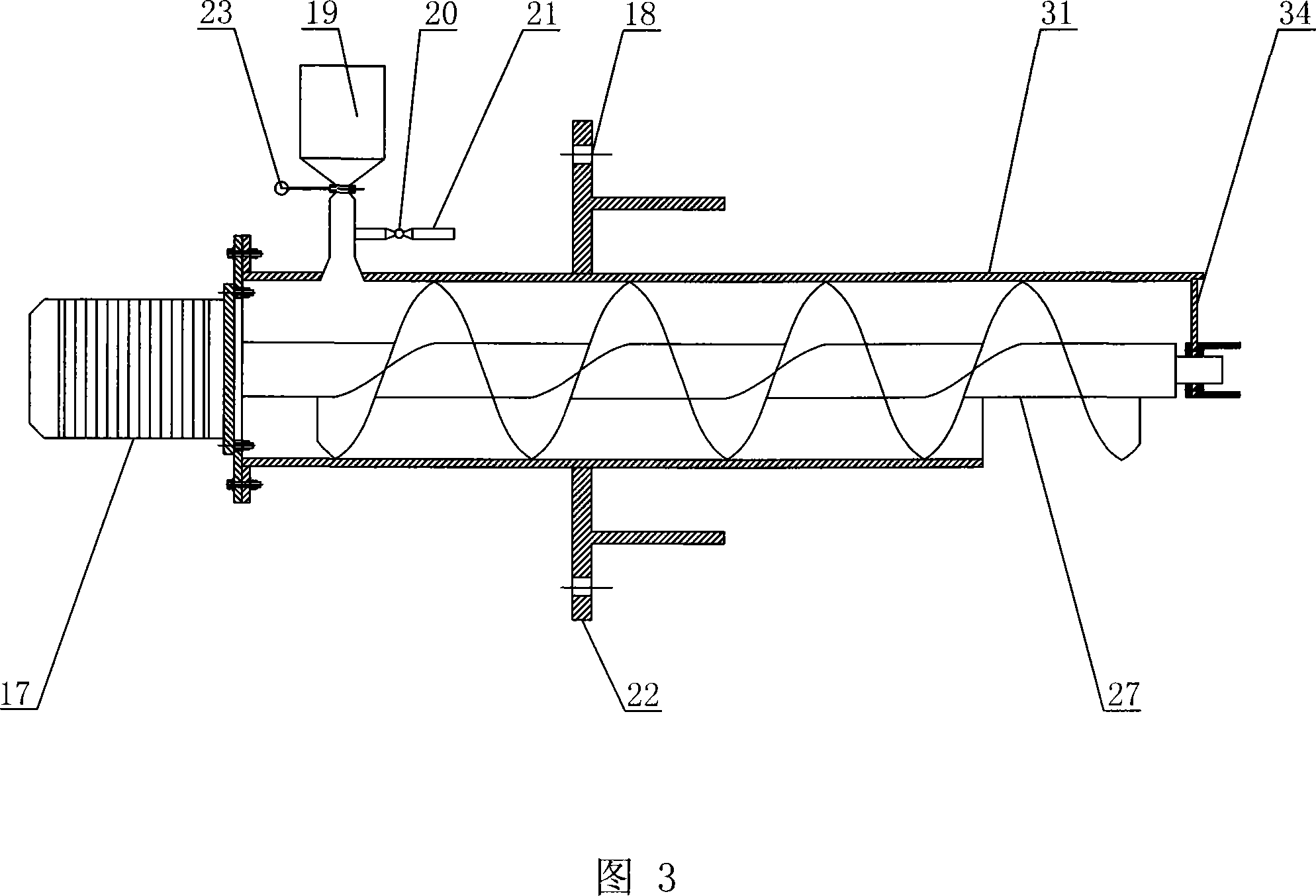

[0038] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, the present invention will be described in further detail.

[0039] The rotary furnace of the present invention is composed of furnace body 1, rotary drum 4, feeding and discharging device 24, power drive device and other parts:

[0040] A. Rotary drum

[0041]The rotary cylinder 4 is located inside the furnace body 1 , and the material inlet and outlet end and the waste gas outlet end of the rotary cylinder pass through the furnace body 1 . The inner wall of the rotary drum 4 is welded with spiral baffles 3 equidistantly distributed, and its height is 1 / 20 of the diameter of the rotary drum; two symmetrical discharge guide plates 26 are welded radially at the inlet and outlet of the rotary drum. The guide plate 26 is a rectangular plate, and the adjacent two sides are welded to the end surface 30 of the inlet and outlet of the rotary drum and the inner wall respectively, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com