Method for controlling ammonia-process desulfurization aerosol discharge and dedicated absorption tower thereof

A desulfurization absorption tower and ammonia desulfurization technology are applied in the field of aerosol control in ammonia desulfurization flue gas desulfurization. Solve the problem of aerosol emission and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

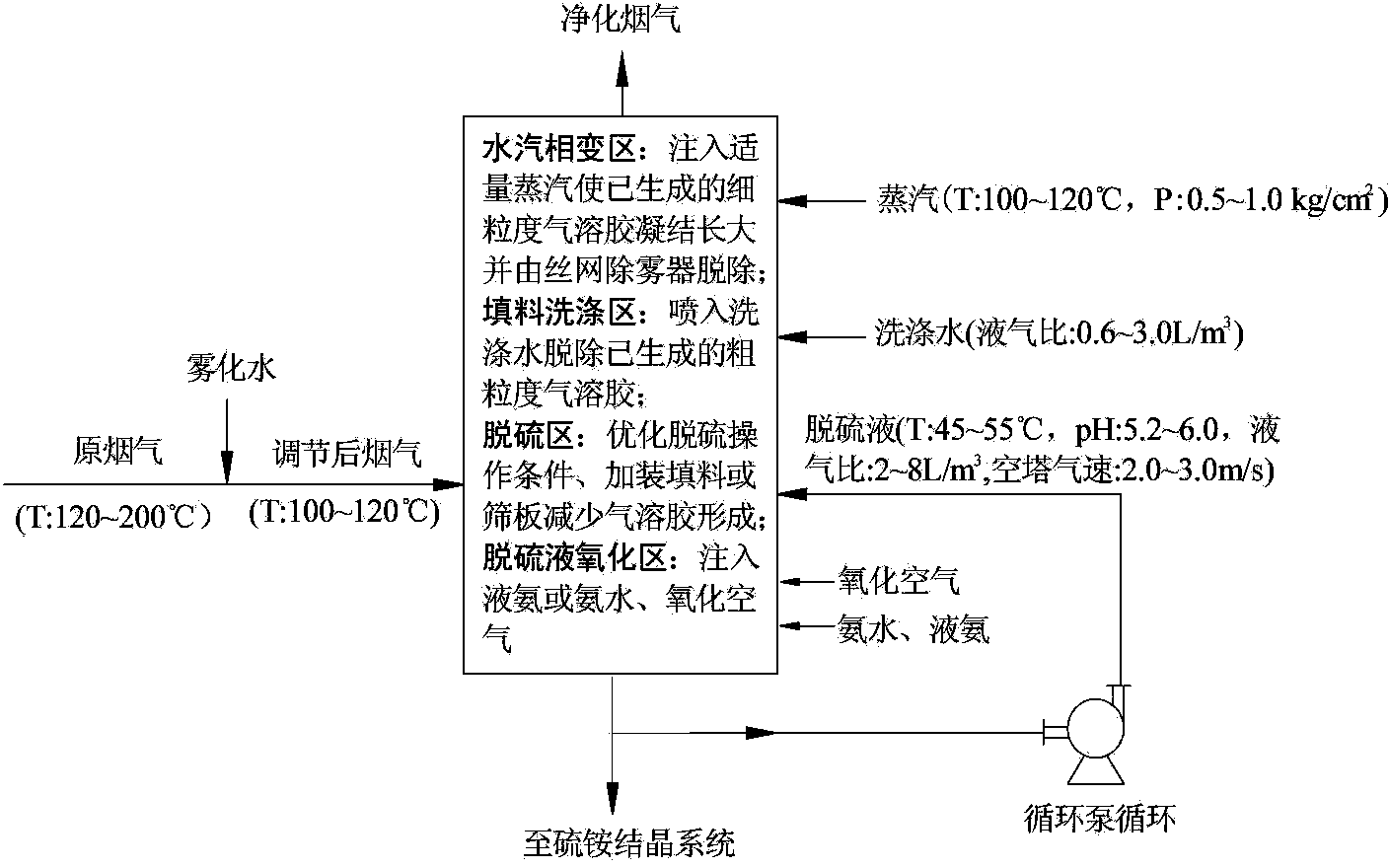

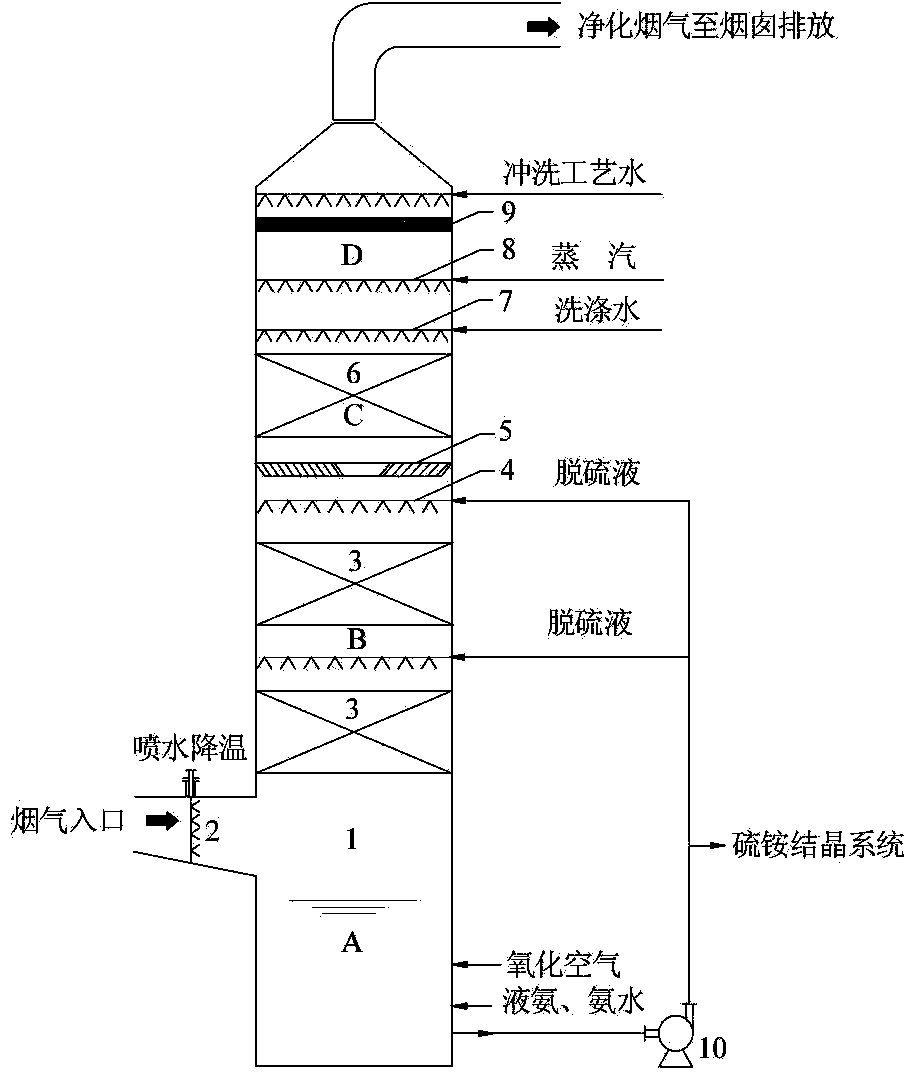

[0025] According to the present invention, a kind of control method of aerosol in flue gas desulfurization by ammonia process, its equipment and process are such as figure 2 The flue gas is cooled to 100-120 ℃ by the atomized water sprayed by the atomizing water nozzle 2, and then enters the desulfurization zone B of the desulfurization absorption tower 1, and the desulfurization liquid sprayed from the top to bottom by the desulfurization liquid nozzle 4. Countercurrent contact to absorb SO in flue gas 2 ; A 3-stage spray system is set up in desulfurization zone B, and each stage of the spray system is equipped with a layer of corrugated structured packing 3, and the specific surface area of the packing is 125m 2 / m 3 , the height of each layer is 1500mm; the air velocity of the superficial tower is 2.5m / s, and the operating liquid-gas ratio is 5L / Nm 3 , the pH of the desulfurization solution is 5.2 to 6.0, and the temperature of the desulfurization solution is 45 to 55°...

Embodiment 2

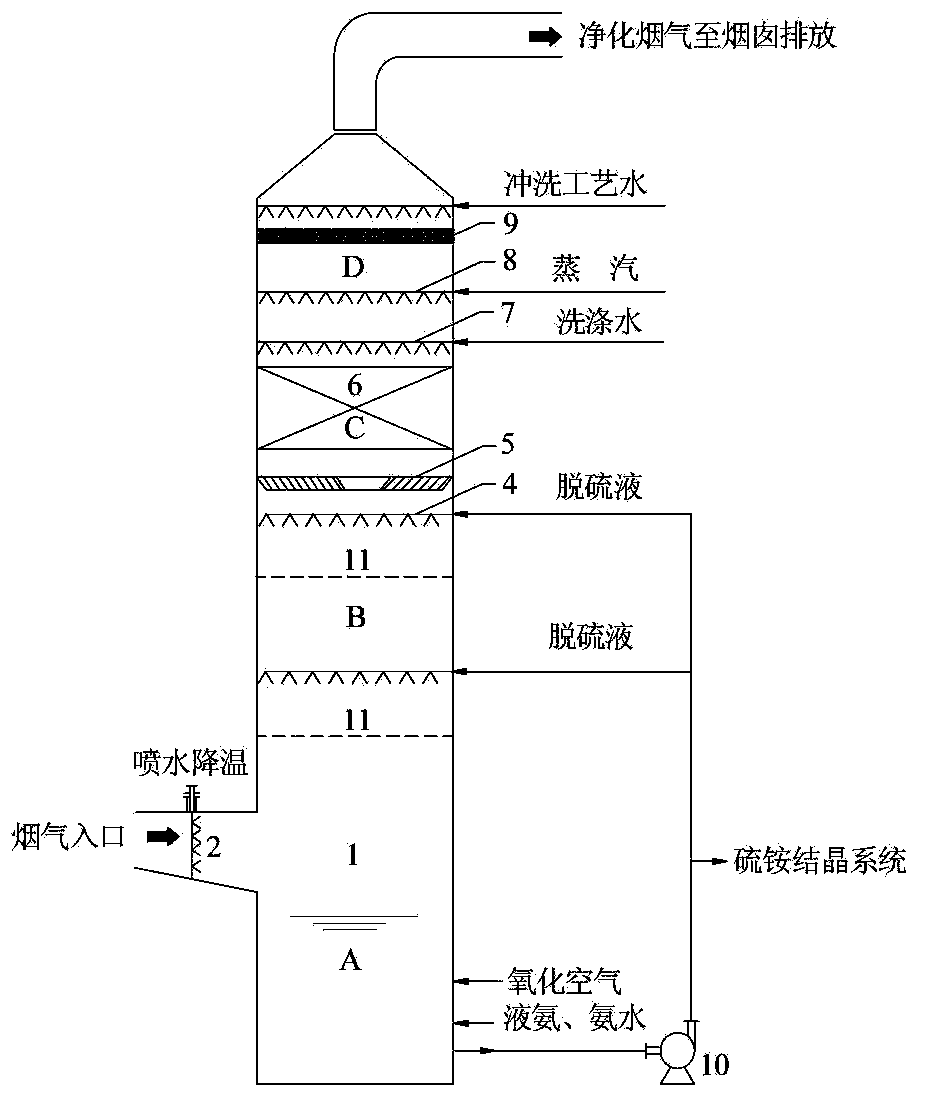

[0027] like image 3 As shown, the difference from Example 1 is that each level of spray system in desulfurization zone A is equipped with a non-overflow sieve plate 11, the sieve aperture is 10-12mm, and the opening rate is 10-15%, and the rest are the same as the embodiment. 1.

Embodiment 3

[0029] The flue gas is produced by a fully automatic coal-fired boiler with a flue gas volume of 150Nm 3 / h, the diameter of the desulfurization absorption tower is 150mm, the tower height is 4000mm, and there are two built-in sprays; each level of spray system is equipped with a layer of corrugated structured packing, and the specific surface area of the packing is 125m 2 / m 3 , the height of each layer is 300mm; the upper part of the desulfurization tower is provided with a packing washing area and a water-vapor phase change area, and two metal orifice corrugated structured packings are installed in the packing washing area, and the packing specific surface area is 250m 2 / m 3 , the total height of the packing layer is 300mm, and the outlet of the water vapor phase change zone is equipped with a DP type (high-efficiency) wire mesh demister, the height of the demister is 150mm, and the specific surface area of the demister is 625m. 2 / m 3 . The high-temperature coal-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| F | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com