Multi-section forming reamer for processing automobile valve sleeve

A valve sleeve and reamer technology, applied in reamers, metal processing equipment, manufacturing tools, etc., can solve the problems of iron filings scratching the hole wall, edge wear, tool life reduction, etc., to facilitate chip removal and cooling of the blade mouth, to ensure concentricity requirements, and to improve the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

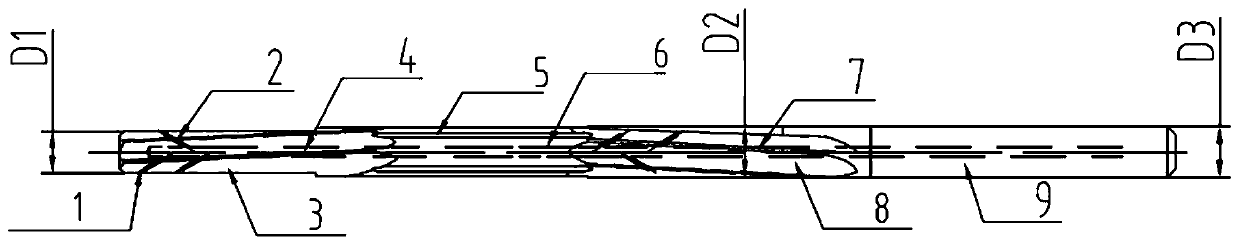

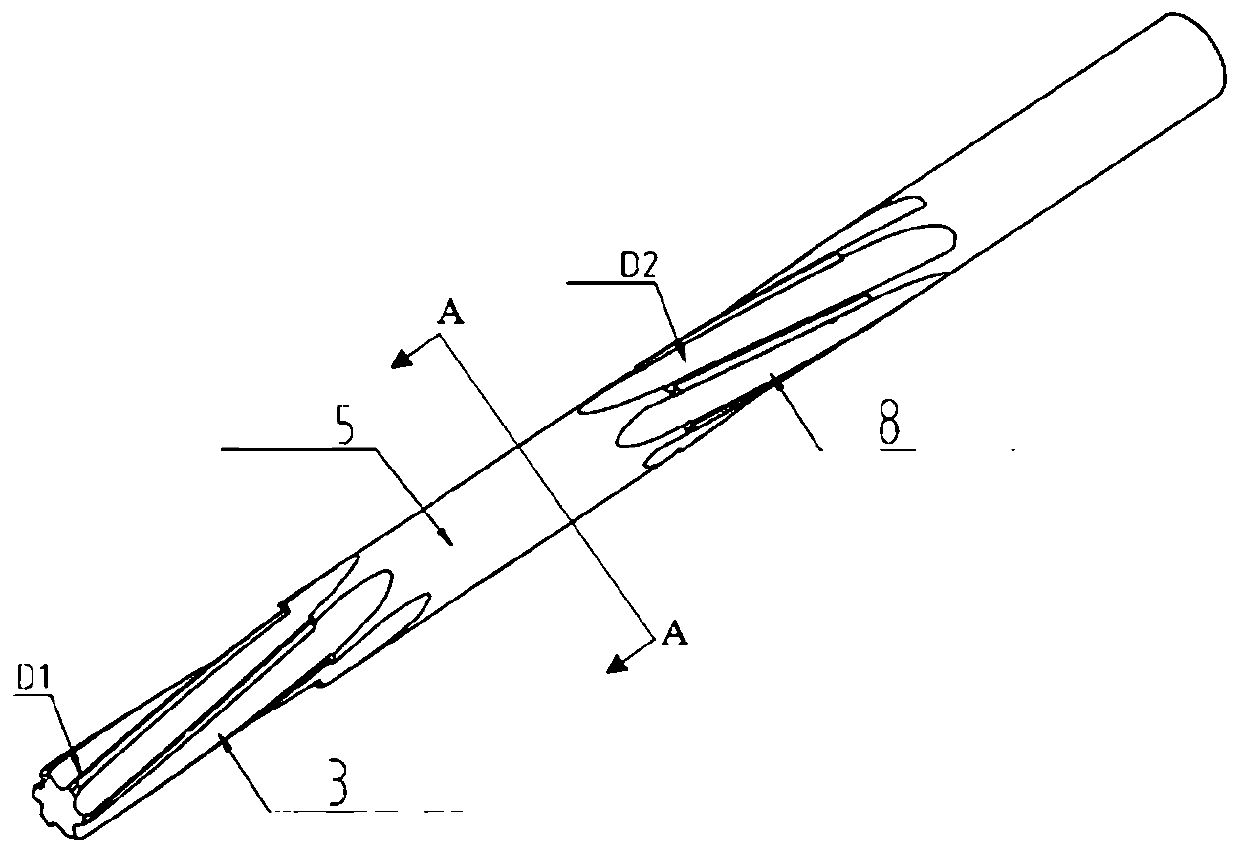

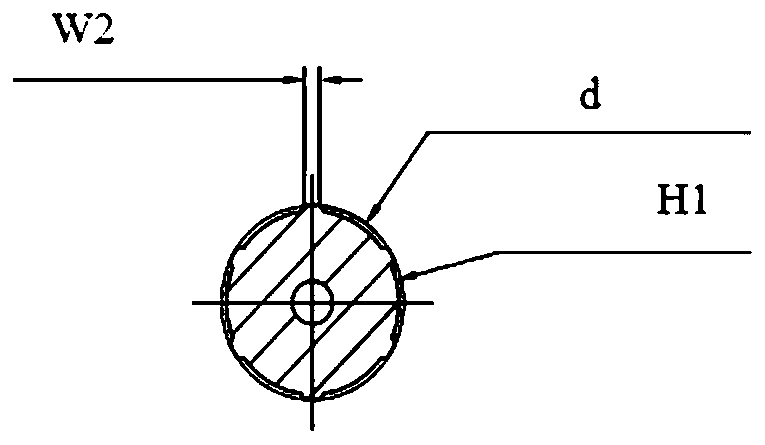

[0035] Such as Figure 1-11 As shown, a multi-section forming reamer for processing automobile valve sleeves includes a cutter body 1 and a handle 9. The cutter body 1 and the handle 9 are coaxial cylinders centered on a common axis 4, and the cutter body 1 has four sections. , are respectively: cylinder diameter D1, guide column 5, cylinder diameter D2 and tool holder 9 (cylindrical diameter D3), and there are two sections of chip removal grooves on the cutter body 1: left-handed knife groove 3 and right-handed knife groove 8, There is a forming chamfer at the front section of the head, and there are left peripheral cutting edge 2 and right peripheral cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com