Ultrasonic inserting cutting tool for processing curve outline of honeycomb core

A technology of curved contour and honeycomb core, applied in the direction of tools for lathes, tools for planers/slotters, manufacturing tools, etc., can solve the problems of difficult curve contour processing, deformation of honeycomb cores, overcuts, etc., to reduce processing Defects, friction reduction, damage reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

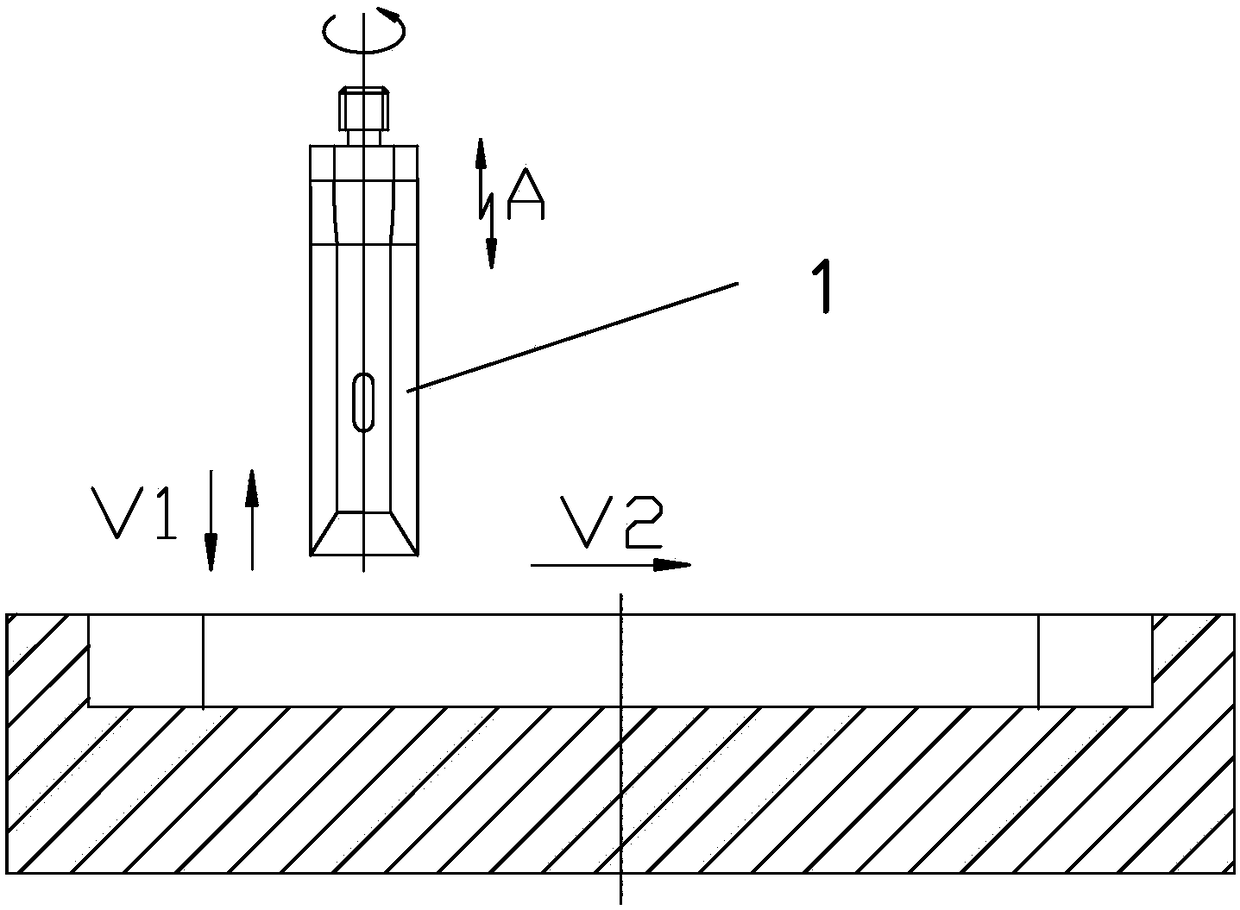

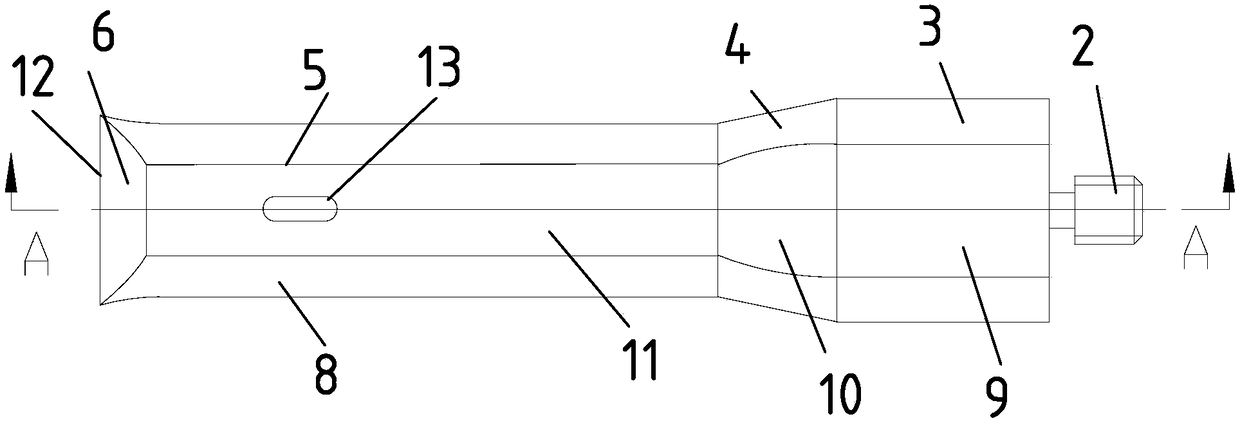

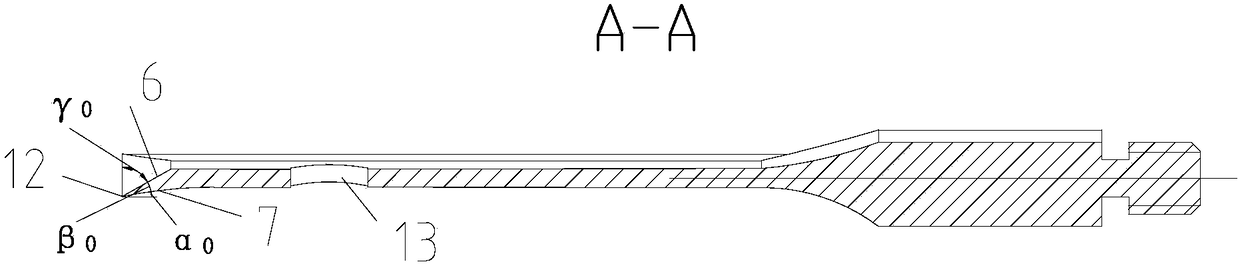

[0047] Such as Figure 2-Figure 7 As shown, an ultrasonic plunge-cutting tool 1 for honeycomb core curve profile processing includes sequentially connected threaded sections 2, rigidity enhancement blocks 3, trapezoidal platform transition blocks 4 and thin sheet-shaped open blades 5, the threaded section 2. The axes of the rigidity enhancement block 3, the trapezoidal platform transition block 4 and the sheet-shaped open blade body 5 are all located on the axis of the ultrasonic plunge-cutting tool 1 for honeycomb core curve contour processing;

[0048] The large end of the trapezoidal platform transition block 4 is connected to the front end of the rigidity enhancement block 3, and the large end of the trapezoidal platform transition block 4 is consistent with the size of the front end of the stiffness enhancement block 3. The small end of the trapezoidal platform transition block 4 is connected with the rear end of the thin sheet-shaped open blade body 5, the small end of t...

Embodiment 2

[0061] Such as Figure 8-Figure 11As shown, an ultrasonic plunger cutting tool 1 for honeycomb core curve profile processing, the fan ring arc face rake surface 6, the fan ring arc surface flank 7, the thin open blade body 5 The outer surface of the blade and the arc-shaped blade guide groove 11 approach to a plane.

[0062] Such as Figure 10 As shown, when processing the outer curve profile of the honeycomb core, the ultrasonic plunging tool 1 used for the processing of the honeycomb core curve profile generates longitudinal vibration under the action of ultrasound, and performs horizontal coordinates on the safety plane according to the processing curve profile path 14 Adjust, and adjust the angle of rotation around its own axis, so that the approximate plane where the cutting arc bottom edge is located is tangent to the processing curve contour path 14 of the required plunge-cutting process, and then the tool is fed axially as a whole to perform plunge-cutting, through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com