Substrate processing apparatus and substrate processing method

a substrate processing and substrate technology, applied in the direction of liquid/solution decomposition chemical coating, manufacturing tools, coatings, etc., can solve the problems of defective processing in a local or global region of the substrate, the contact efficiency between the processing liquid and the substrate can decrease, and the defective processing becomes more marked, so as to achieve high yield and reduce the cost of electronic products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

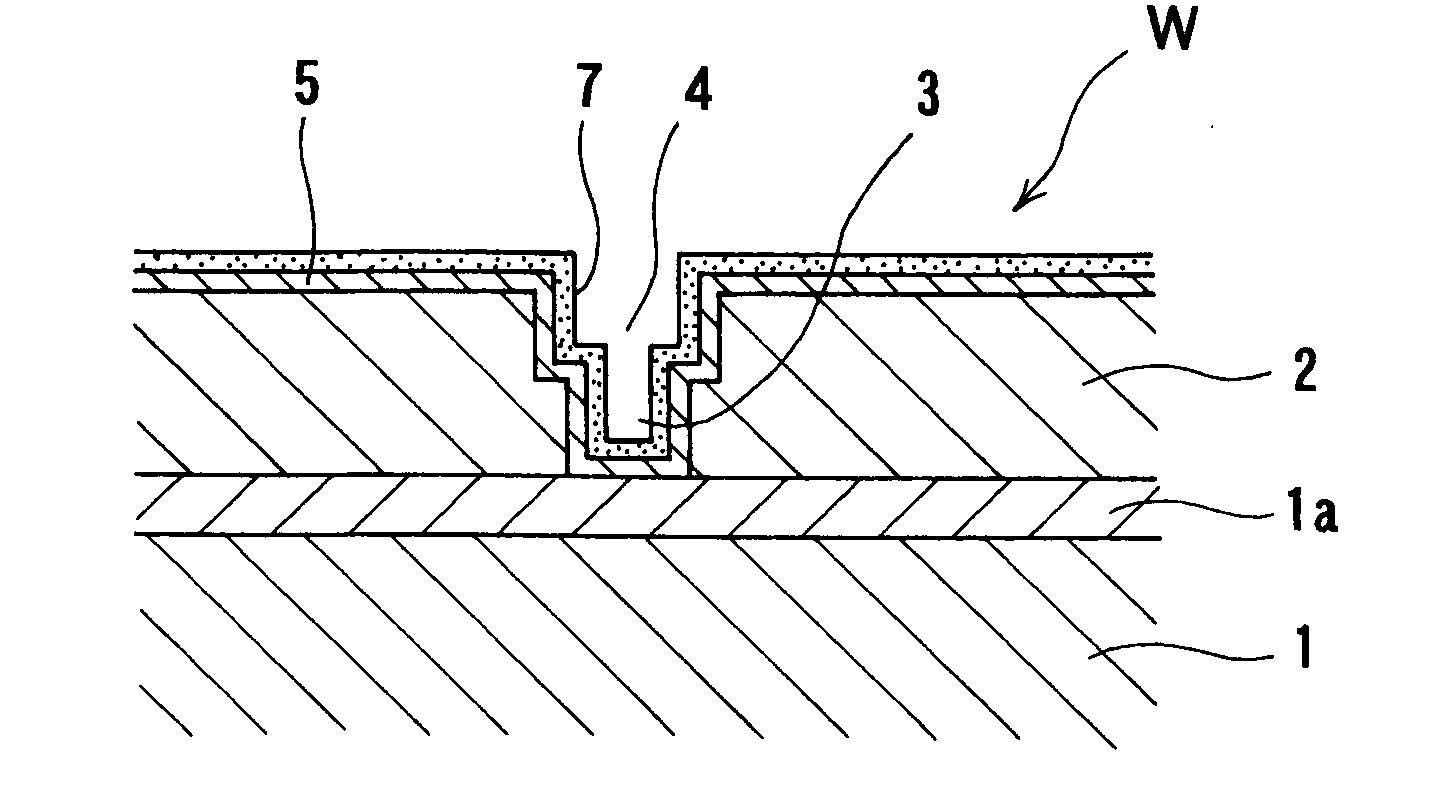

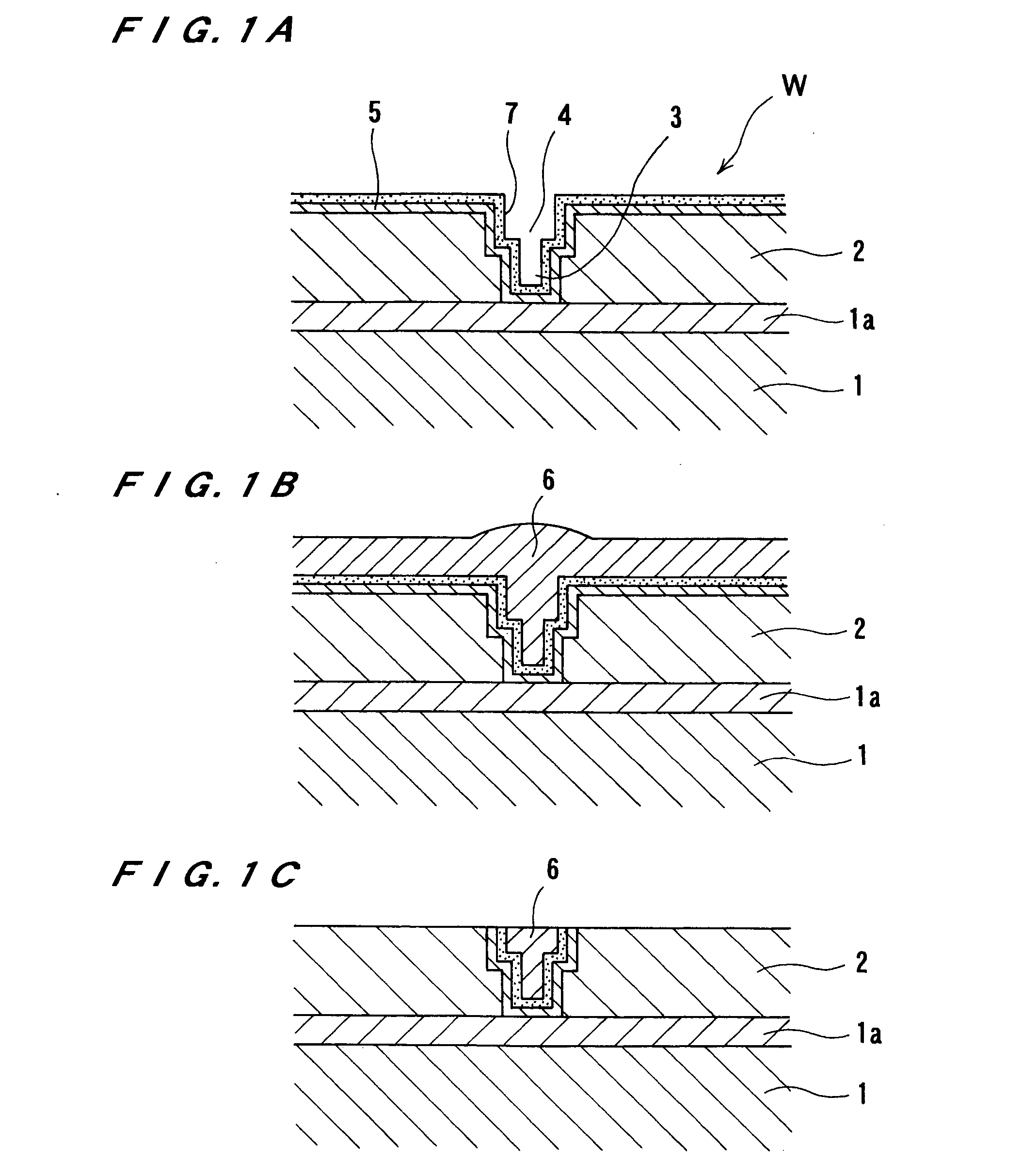

[0032] Preferred embodiments of the present invention will now be described with reference to the drawings.

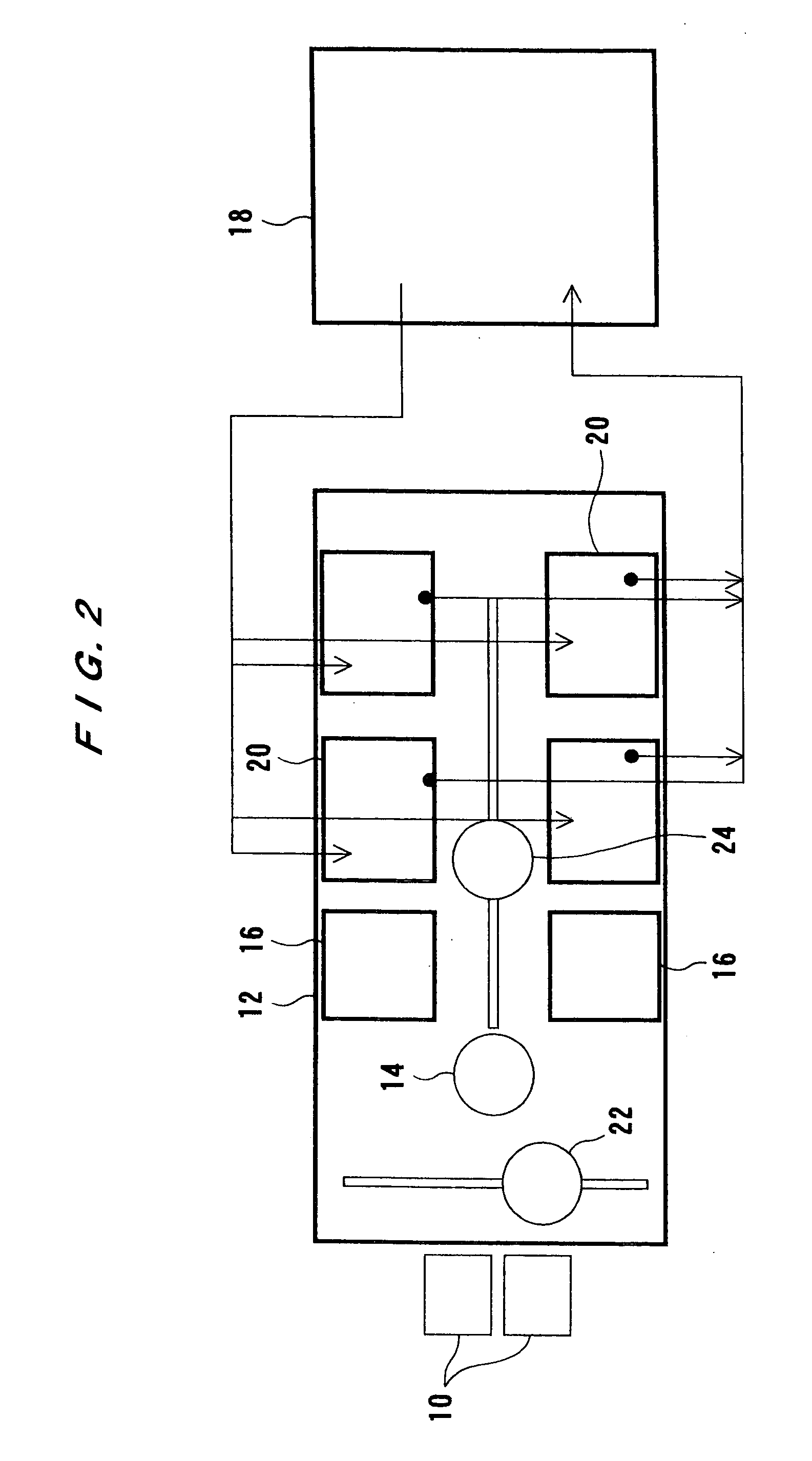

[0033]FIG. 3 shows a layout plan of a substrate processing apparatus, adapted to carry out electroplating, according to an embodiment of the present invention. The substrate processing apparatus, as with the substrate processing apparatus shown in FIG. 2, includes an apparatus frame 12. A substrate in a dry state is carried into the apparatus frame 12 from a substrate cassette 10; the substrate is processed inside the apparatus frame 12; and the substrate after processing, in a dry state, is taken out of the apparatus frame 12. Inside the apparatus frame 12 are disposed a stage 14, two post-cleaning apparatuses 16, four electroplating apparatuses 20 connected via piping to a plating solution supply / recovery apparatus 18, a first substrate transport robot 22 and a second substrate transport robot 24.

[0034] The substrate processing apparatus of this embodiment is also provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conductive | aaaaa | aaaaa |

| polarity | aaaaa | aaaaa |

| processing size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com