Multi-shaft rotary creel, sample warper and warping method

A rotary creel technology, applied to warping machines, creels, manufacturing tools, etc., can solve uneven tension, uneven yarn tension, uneven distance or angle between the bobbin and the yarn guide at the front end of the yarn guide Uniformity and other issues to achieve the effect of improving the degree of freedom and preventing uneven tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The examples shown in the drawings are merely examples, and various modifications other than those shown in the drawings are possible as long as they do not deviate from the technical idea of the present invention.

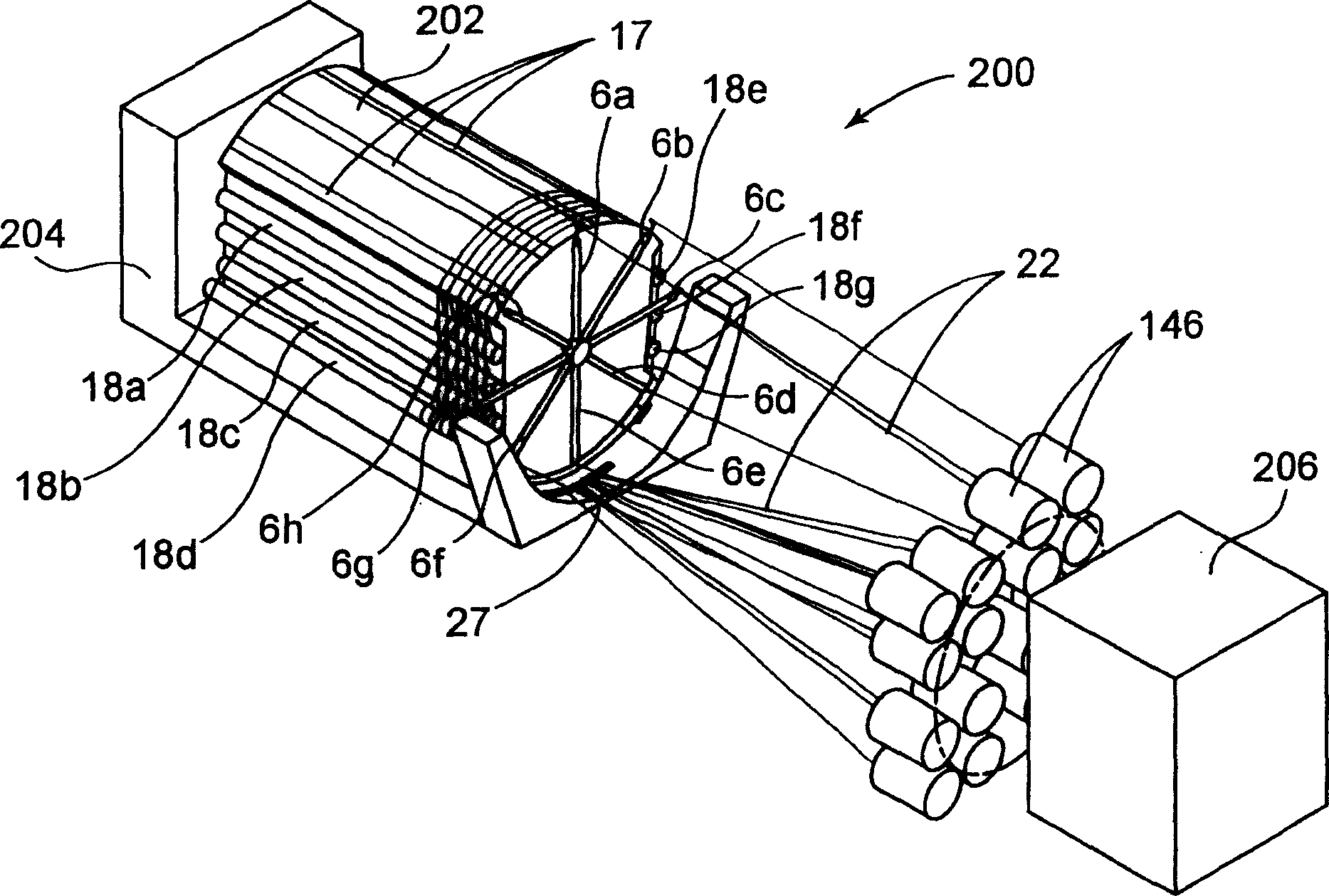

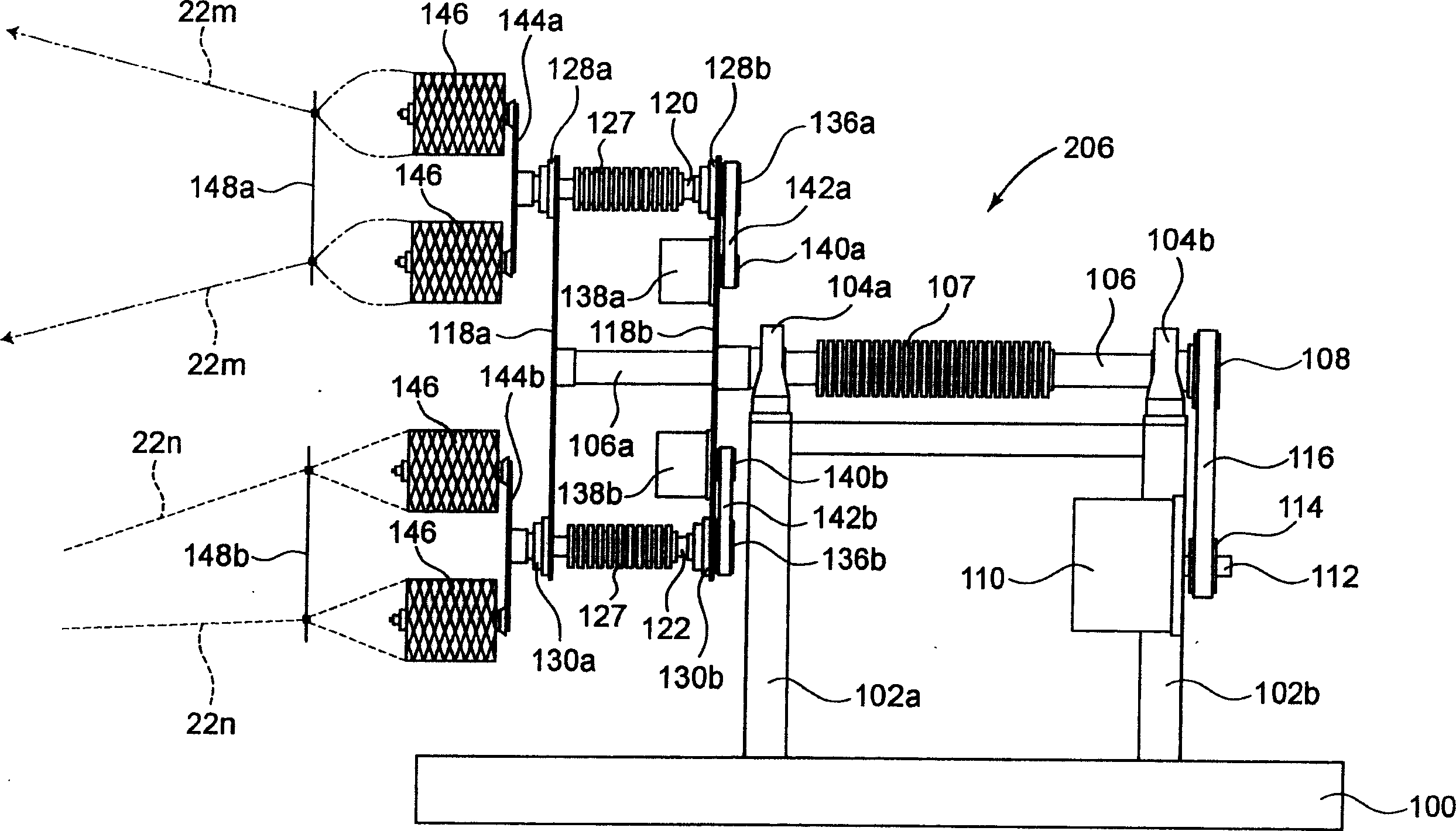

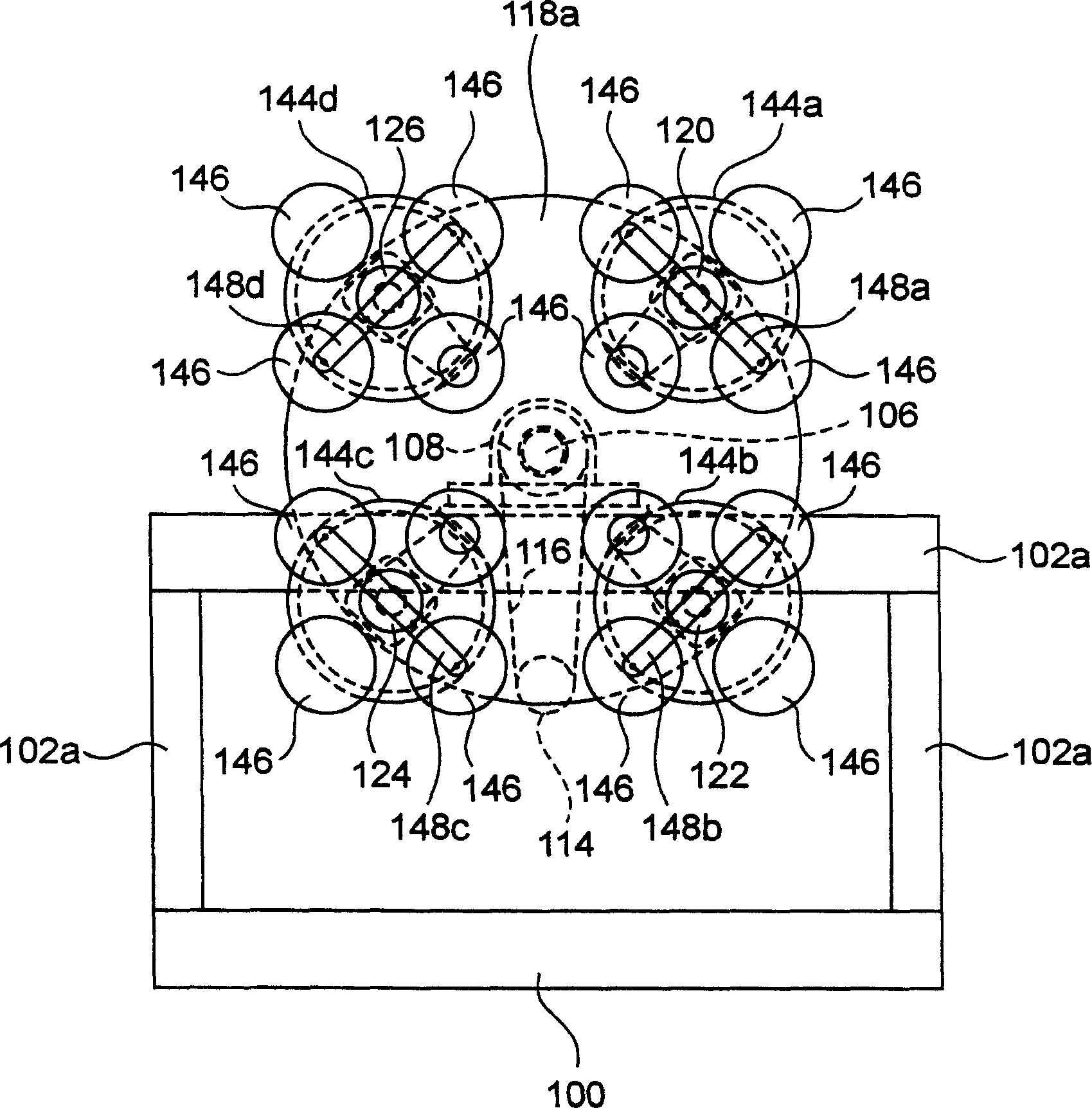

[0040] exist figure 1 Among them, the sampling warping machine 200 of the present invention has: a warping cylinder 202, and can be flexibly rotatably arranged on the side of the warping cylinder 202 and wind yarn 22 on the warping cylinder 202 with multiple branches (in the figure 8 are shown, but actually use the same number of yarn guides as all bobbins, for example, if the number of bobbins is 16, use 16 yarn guides.) Yarn guides 6a~6h, and setting One end of the base 204 supporting the warping cylinder 202 is provided corresponding to the yarn guides 6a to 6h, and is rotated to protrude toward the yarn changing position during yarn changing, and is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com