Dyeing vat

A dyeing vat and vat technology, which is applied in the field of dyeing vats, can solve the problems of high labor intensity for operators, uneven tension on fabrics, and inconsistent product quality, so as to achieve convenient operation for workers, convenient and labor-saving taking of yarns, and high product quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

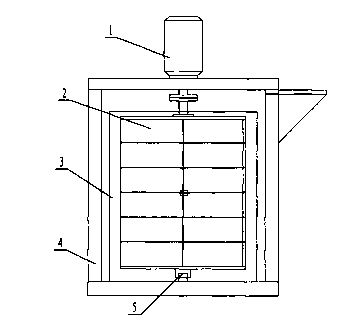

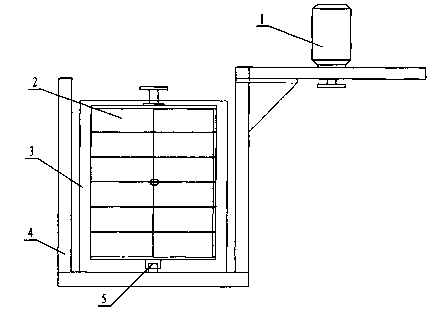

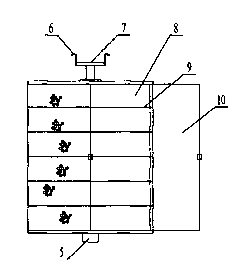

[0022] Such as Figure 1 to Figure 5 Shown, a kind of dye vat includes vat 3 and skeined sarong 2. The skein cage 2 is located in the cylinder body 3 , and the skein cage 2 includes a circular cage body 8 . The outside of the cylinder body 3 is provided with a frame 4 and a power source 1, the power source 1 is fixedly arranged on the frame 4, and the power source 1 is a motor. The upper end of the cage body 8 is provided with a flange 7 , and the upper end of the cage body 8 is also provided with a suspension hook 6 . A positioning shaft 5 is provided at the center of the outer bottom of the cage body 8 . The power source 1 is connected with the cage body 8 through the flange 7 at the upper end of the cage body 8 . One side of the circumference of the cage body 8 is provided with a door 10, and adopts a side door to facilitate taking yarn. The cage body 8 is further provided with at least one layer of horizontal partitions 9 separating the cage body 8 into relatively vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com