Rail transit large-tonnage pre-tensioning method prestressed concrete U type beam and tensioned bed thereof

A technology for rail transit and tensioning pedestals, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as complex construction procedures, overturning risks, and difficulties in the design and manufacture of tension pedestal structures, so as to improve overall stability and stress The effect of clear and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

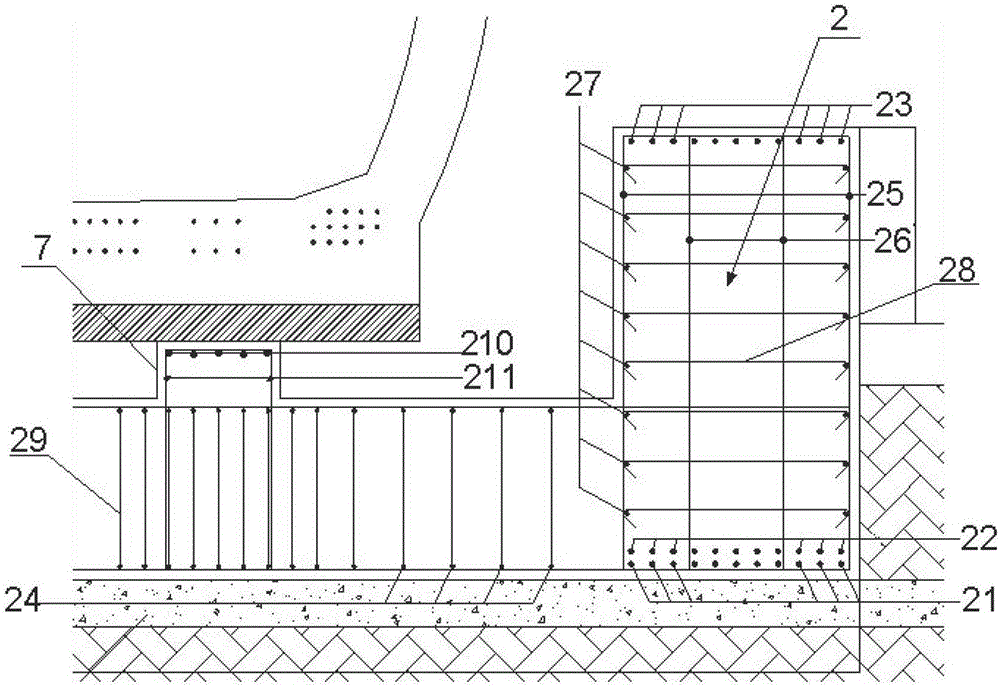

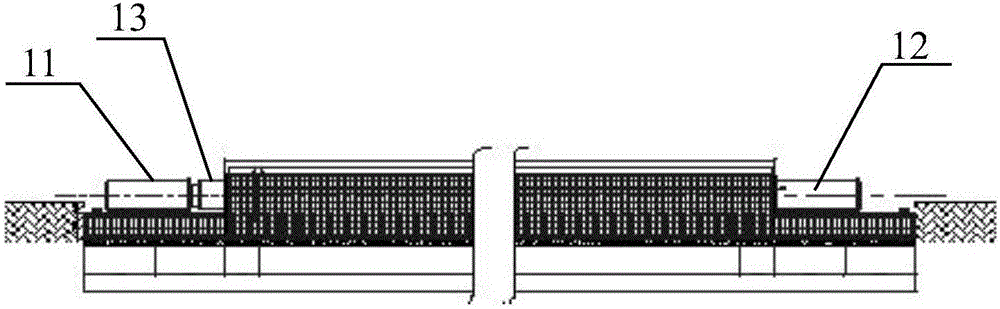

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

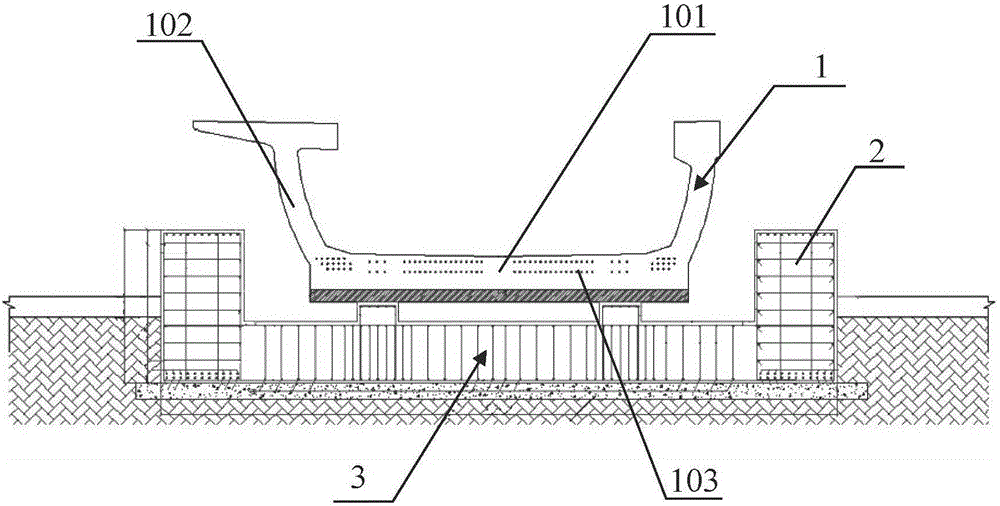

[0025] Such as figure 1 As shown, the large tonnage pre-tensioned prestressed concrete U-shaped beam 1 includes: a bottom plate 101 and a web 102, and the web 102 is arranged on both sides of the bottom plate. There are multiple prestressed steel strands 103 inside the bottom plate 101 . In this embodiment, the bottom plate 101 has a width of 4528mm and a thickness of 400mm, the average thickness of the web 102 is 280mm, and the beam height is 2m.

[0026] The large-tonnage pre-tensioned prestressed concrete U-shaped beam of this embodiment has two kinds of spans, which are 30m and 35m respectively.

[0027] Among them, there are 103 prestressed steel strands for the 30m U-shaped beam floor and 106 strands, with a single tensile force of 17.19 tons and a total tensile tonnage of more than 1,800 tons; the number of prestressed steel strands for the 35m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com