Sanding system of sanding machine

A sanding machine and sanding technology are applied in textiles and papermaking, roughening, fabric surface trimming, etc., which can solve problems such as lowering production quality, uneven tension, and increasing motor power, so as to solve uneven tension, assembly and Easy maintenance and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

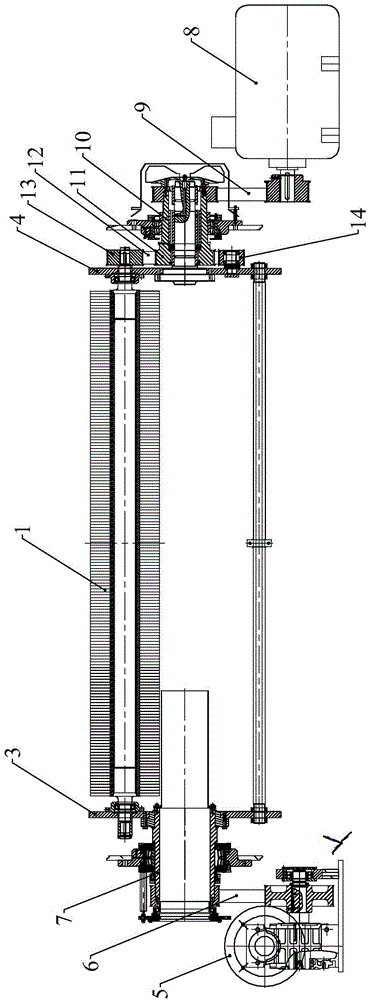

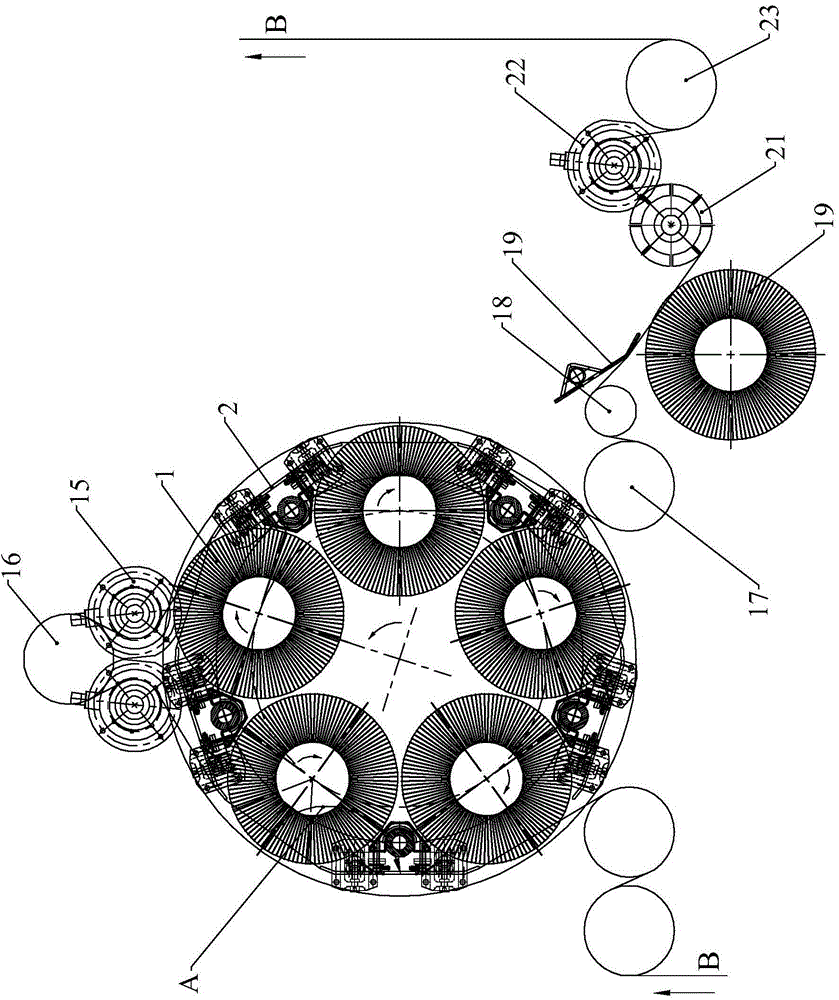

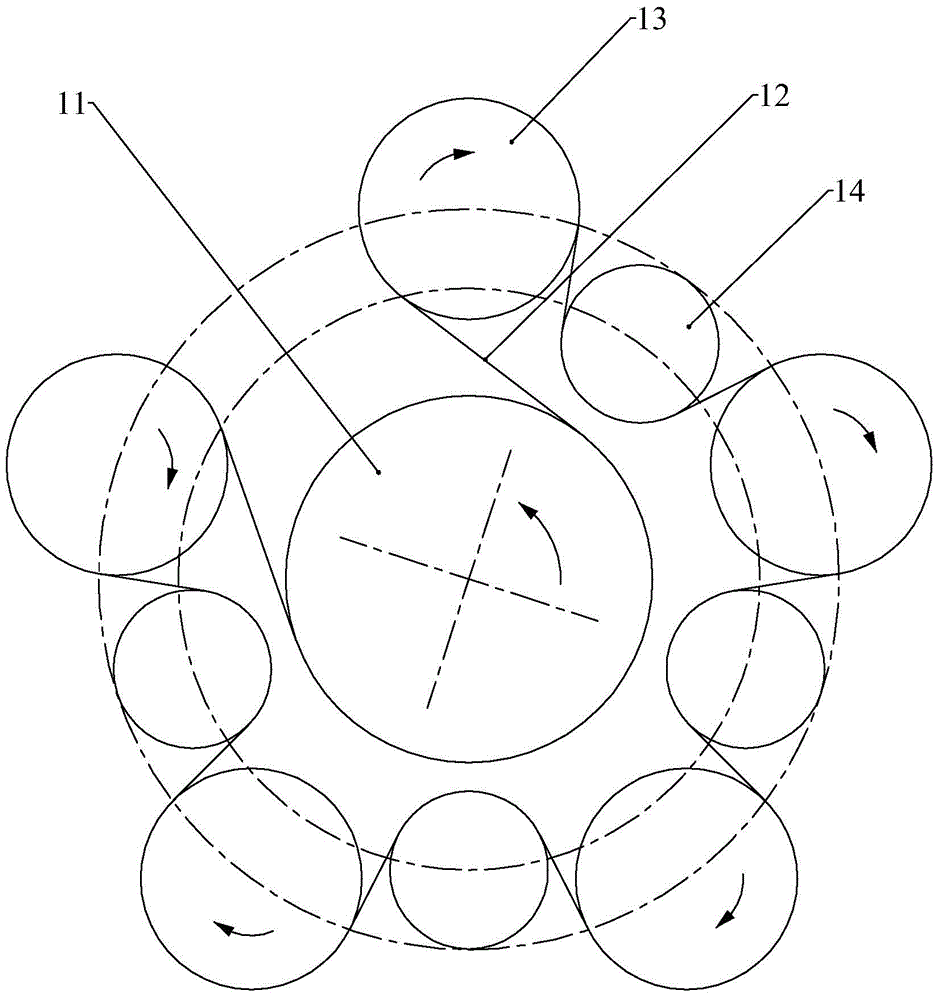

[0022] refer to Figure 1 to Figure 3 , the present embodiment includes a brush drum, a brush drum driving device, a brush roller driving device, a brush roller synchronous rotation device and a brushing finishing device; the brush drum includes five brush rollers 1 and five sets of adjustment plate devices 2 , the five brush rollers are uniformly arranged in a planetary structure and erected horizontally on the left support plate 3 and right support plate 4 of the brush drum, and the adjustment plate device is installed between two adjacent brush rollers; the brush drum driving device Arranged on the left side of the brush drum, the brush drum motor 5 drives the brush drum transmission device 7 through the brush drum synchronous belt 6 to form a brush drum driving device; the brush roller driving device is arranged on the right side of the brush drum, The brush roller driving device includes a brush roller motor 8, a transmission belt 9 and a brush roller transmission device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com