Feeding device of aluminum foil slitting machine

A technology of slitting machine and aluminum foil, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of affecting the slitting process, inconvenient shaft rotation, larger outer diameter, etc., to achieve operation and control. Convenience, stable fixation of raw materials, and uniform tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

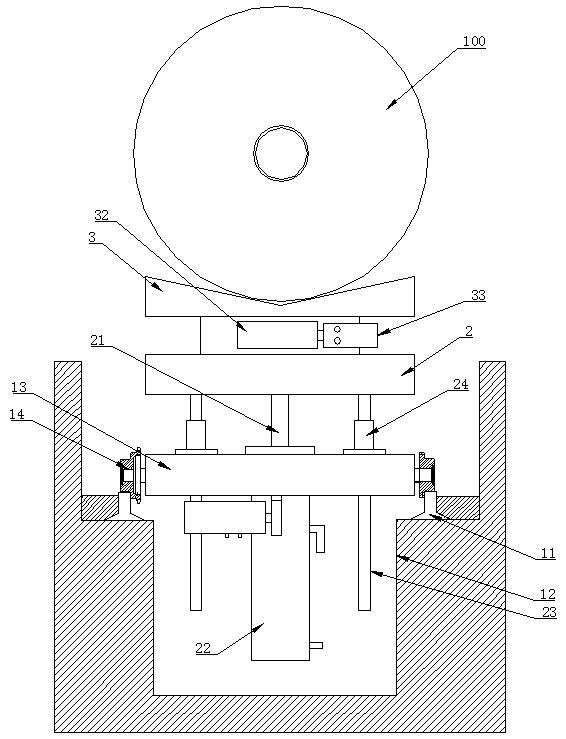

[0042] like Figure 1 to Figure 5 Shown, a kind of aluminum foil slitting machine feeding device comprises:

[0043] The rotary trolley and its walking guide rail 11 used for transporting raw materials, the walking guide rail 11 is installed in the traveling groove 12, the traveling groove 12 is a groove opened on the ground, and the traveling groove is formed by masonry building or concrete pouring in the groove. Groove 12, the top surface of travel groove 12 is flush with ground.

[0044] For the feeding machine for loading raw materials 100, the end point of the walking guide rail 11 extends to one side of the feeding machine.

[0045] Rotary trolley includes:

[0046] The traveling mechanism includes a traveling base 13 and traveling wheels 14, and the traveling wheels 14 are driven by a power mechanism to move along the traveling guide rail 11.

[0047] The lifting platform 2 and the lifting mechanism driving the lifting platform 2 to lift, the lifting platform 2 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com