Unilateral wire loosening elimination method of cutting wire electrodes through reciprocating wire moving electrical discharge wires

A technology of EDM wire and reciprocating wire travel, which is used in electric processing equipment, electrode manufacturing, metal processing equipment, etc., to simplify the wire travel structure, improve the cutting speed, and increase the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Such as Figure 4 , 5 shown.

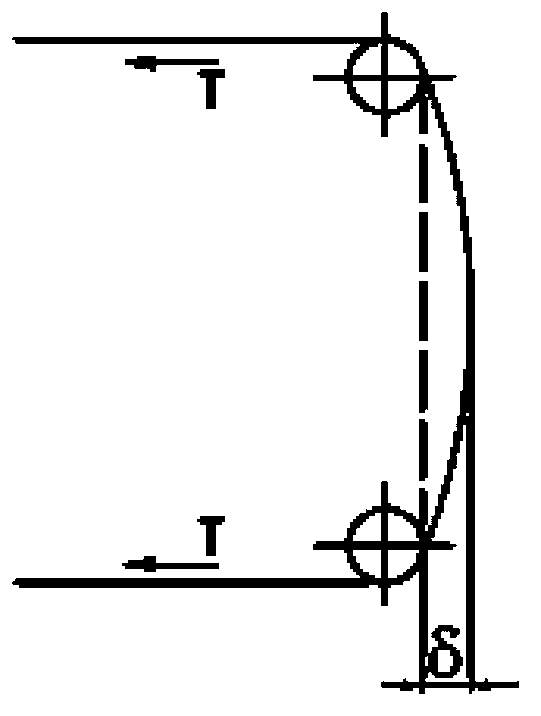

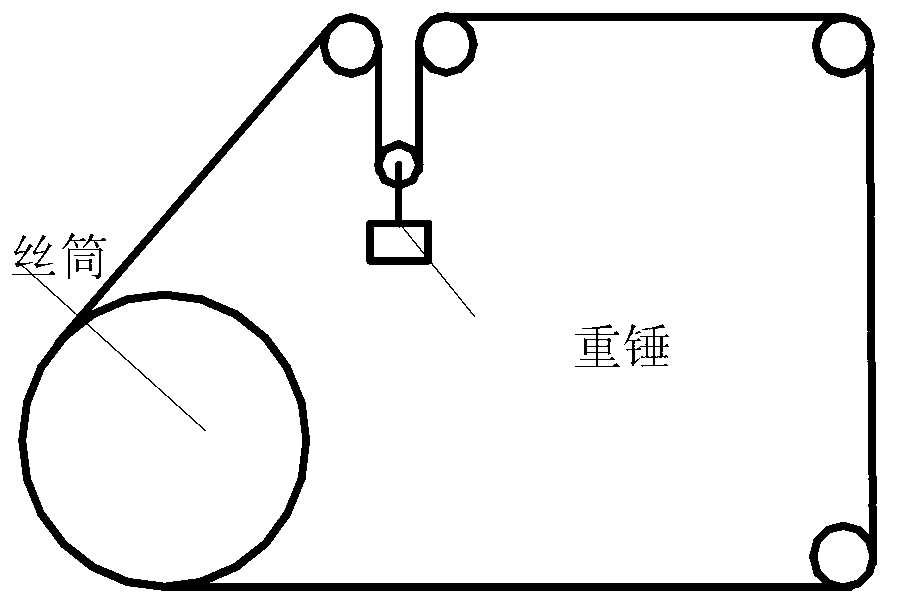

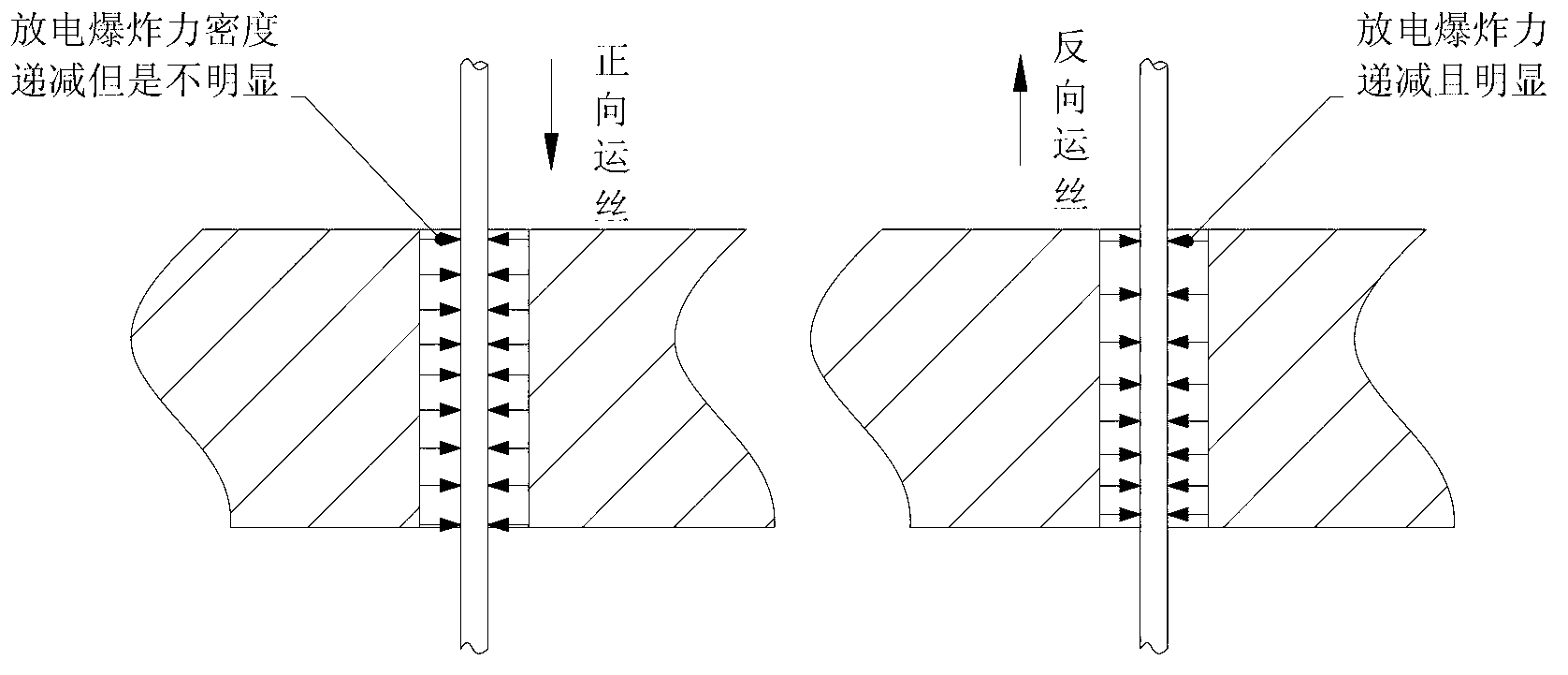

[0023] A method for eliminating loose wires on one side of a reciprocating wire electric discharge wire cutting machining electrode, which is applied to such as Figure 4 In the system shown, the forward and reverse rotation speed of the wire storage drum is controlled by the frequency conversion speed regulating device, and the positive and negative differential speed rotation of the wire storage drum is realized to eliminate the tension difference between the forward and reverse direction of the high-speed reciprocating wire EDM electrode wire. Value, eliminate the phenomenon of "unilateral loose wire", and then improve the processing accuracy, surface roughness, and prolong the service life of the electrode wire. The wire speed of the electrode wire from top to bottom (forward wire) can be lower than that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com