Ink cartridge for inkjet printers

An inkjet printer, printer technology, applied in printing and other directions, to achieve the effect of eliminating the environment and simple measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

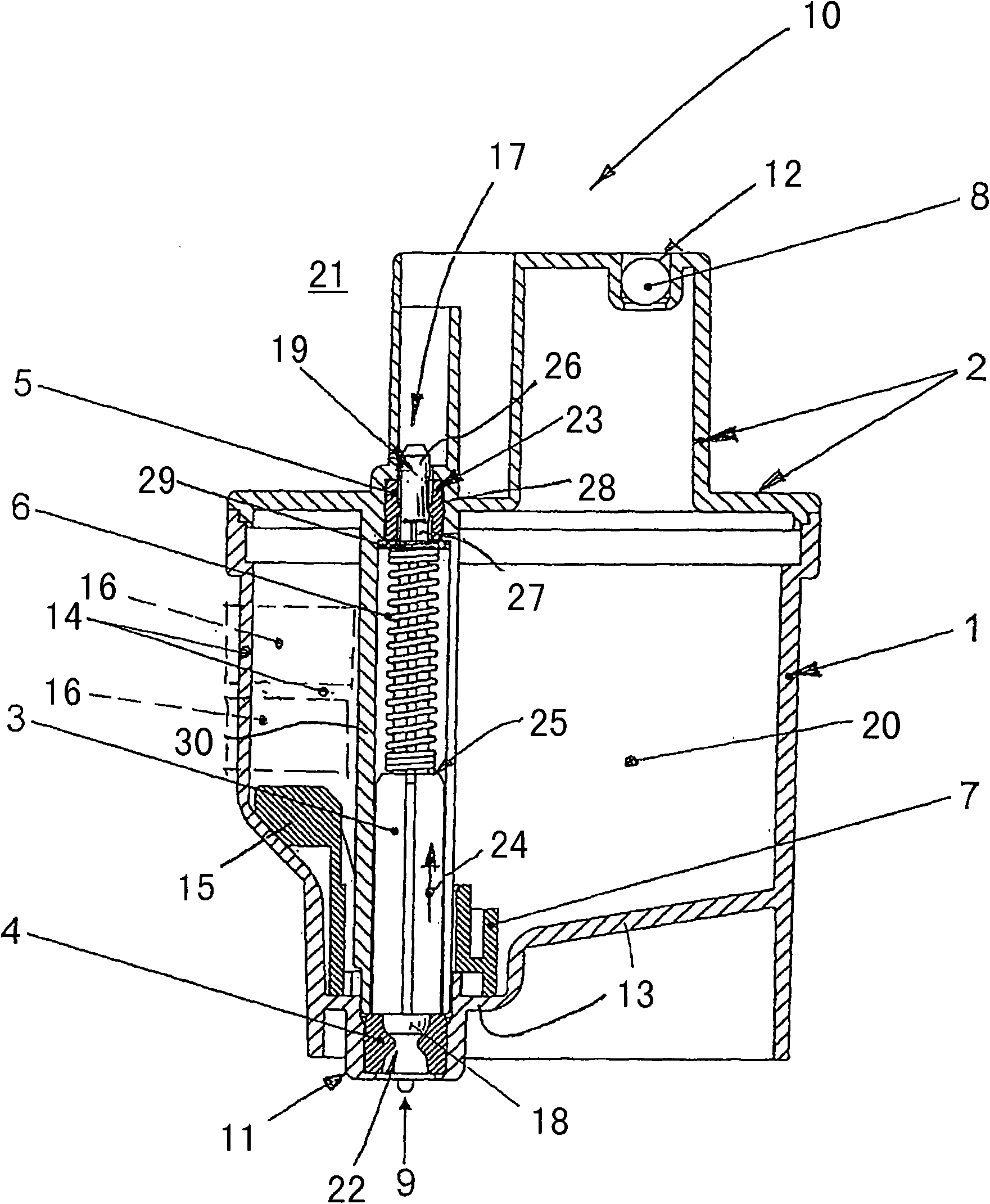

[0020] The drawing shows an ink cartridge 10 for an otherwise not described inkjet printer comprising a ventilation opening 17 between the ink storage chamber 20 and the environment 21 and an ink cartridge arranged in the bottom 13 of the housing 1 of the ink cartridge 10 The valve 22 of the discharge port 11, which, when installed in the printer, can be brought from the closed position depicted in the figures into the open position and vice versa against the action of the elastic element (here the helical compression spring 6) . According to the present invention, the valve 12 arranged at the ink outlet 11 is connected with the valve 23 arranged at the ventilation opening 17 so that when the ink cartridge is installed in the printer, the ink outlet 11 and the ventilation opening 17 are opened, or when the ink cartridge is released from the printer. The opposite is true when taking it out. The coupling already mentioned is produced in such a way that when the ink cartridge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com