Drive train for a motor vehicle, and motor vehicle

A technology for power trains and motor vehicles, applied in the field of power trains, can solve the problems of reducing the exhaust gas volume, the power trains no longer meeting environmental regulations, etc., and achieve the effects of improving exhaust gas heating, improving cold start characteristics, and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

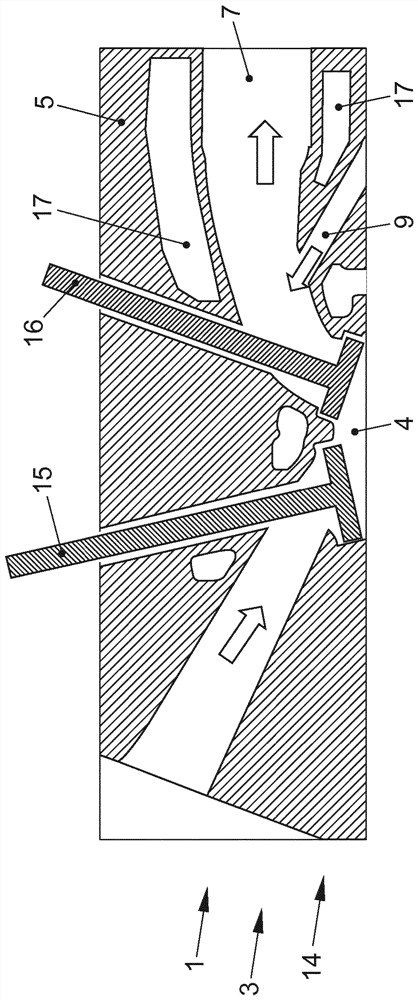

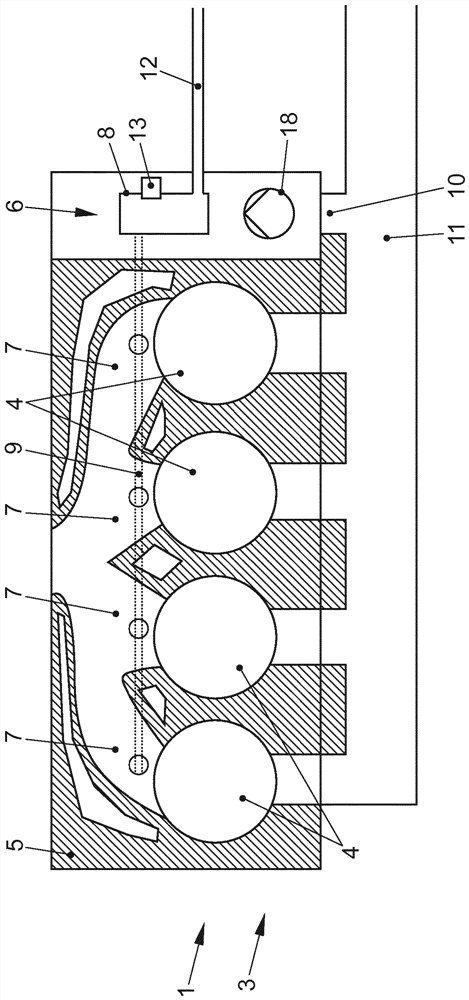

[0029] exist figure 1 A detail of a preferred embodiment of the drive train 1 according to the invention is depicted schematically in a sectional illustration in . The drive train 1 has an internal combustion engine 3 , the cylinder head 14 of which is depicted with an exhaust manifold 5 in this illustration. Arranged in the cylinder head 14 are an intake valve 15 for introducing fresh air into the cylinder 4 of the internal combustion engine 3 and an exhaust valve 16 for exhausting exhaust gas from the cylinder 4 . A plurality of cooling channels 17 are formed in the cylinder head 14 . Furthermore, an exhaust gas outlet 9 of the burner arrangement 6 , which is only partially visible, is formed in the cylinder head 14 . The exhaust outlet 9 opens into the exhaust channel 7 of the exhaust manifold 5 in the region of the exhaust valve 16 and leads to the exhaust valve 16 . The exhaust gas outlet 9 is thus directed opposite to the flow direction of the exhaust gas exiting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com