Steel pipe screw anchor pile group foundation

A technology of group pile foundation and screw anchor, applied in the direction of foundation structure engineering, construction, etc., can solve the problems of low bearing capacity and high cost of steel pipe piles, and achieve the effect of improving bearing capacity and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

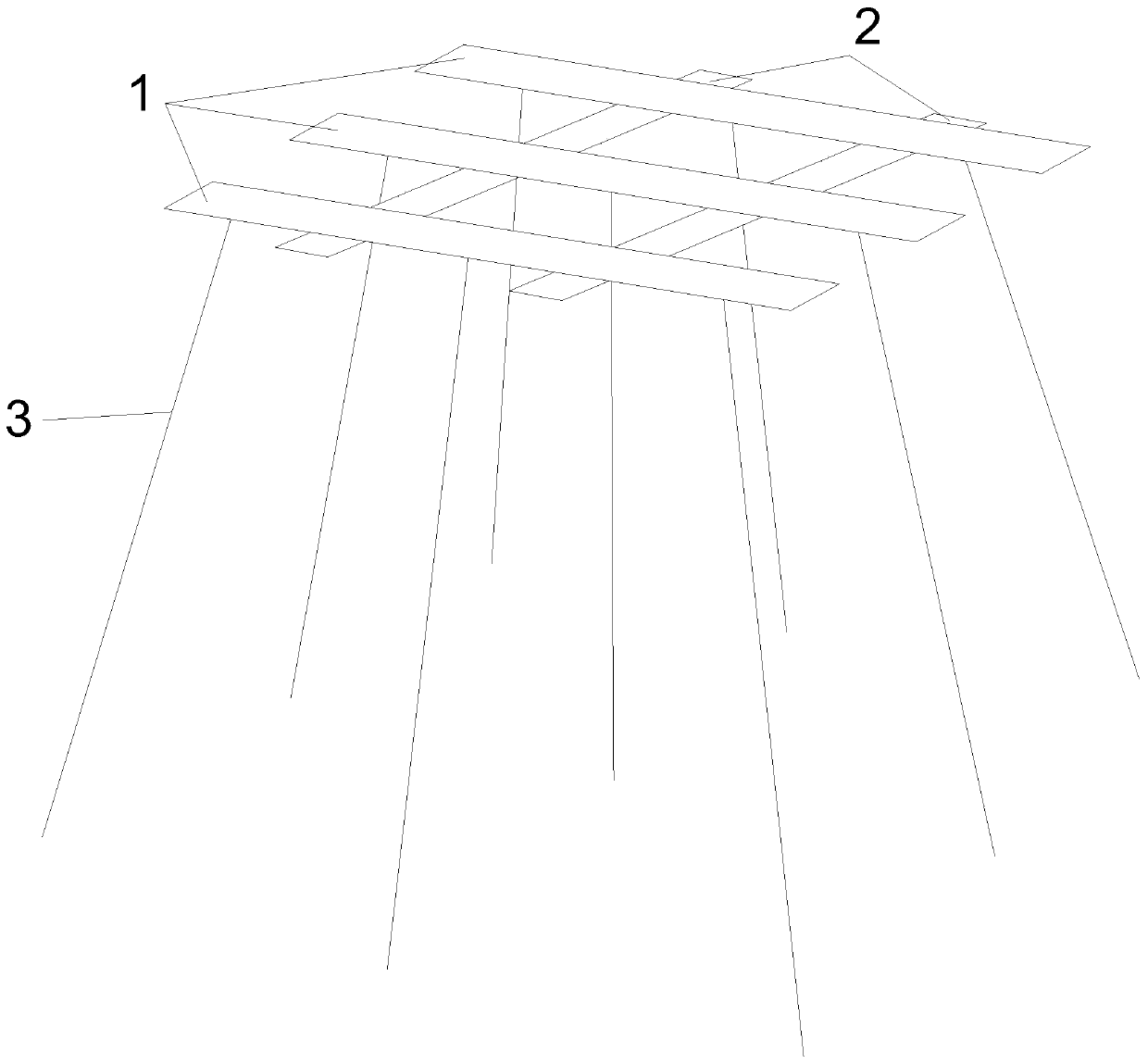

[0020] The present invention proposes a steel pipe spiral anchor pile group foundation, referring to figure 1 , including a base, the base includes 3 parallel mounting blocks 1 and two connecting blocks 2 vertically placed with the mounting block 1, the connecting block 2 is fixedly connected with the mounting block 1, and the mounting block 1 is fixedly connected with the steel pipe spiral anchor.

[0021] A steel pipe spiral anchor of a vertical base is fixed in the middle of the bottom of the base, and 8 steel pipe spiral anchors 3 at a certain angle with the steel pipe spiral anchors of the vertical base are fixed around the bottom of the base, and the angle range is 2° to 15°. The pile body is arranged with a slight inclination, which can withstand large longitudinal and horizontal forces.

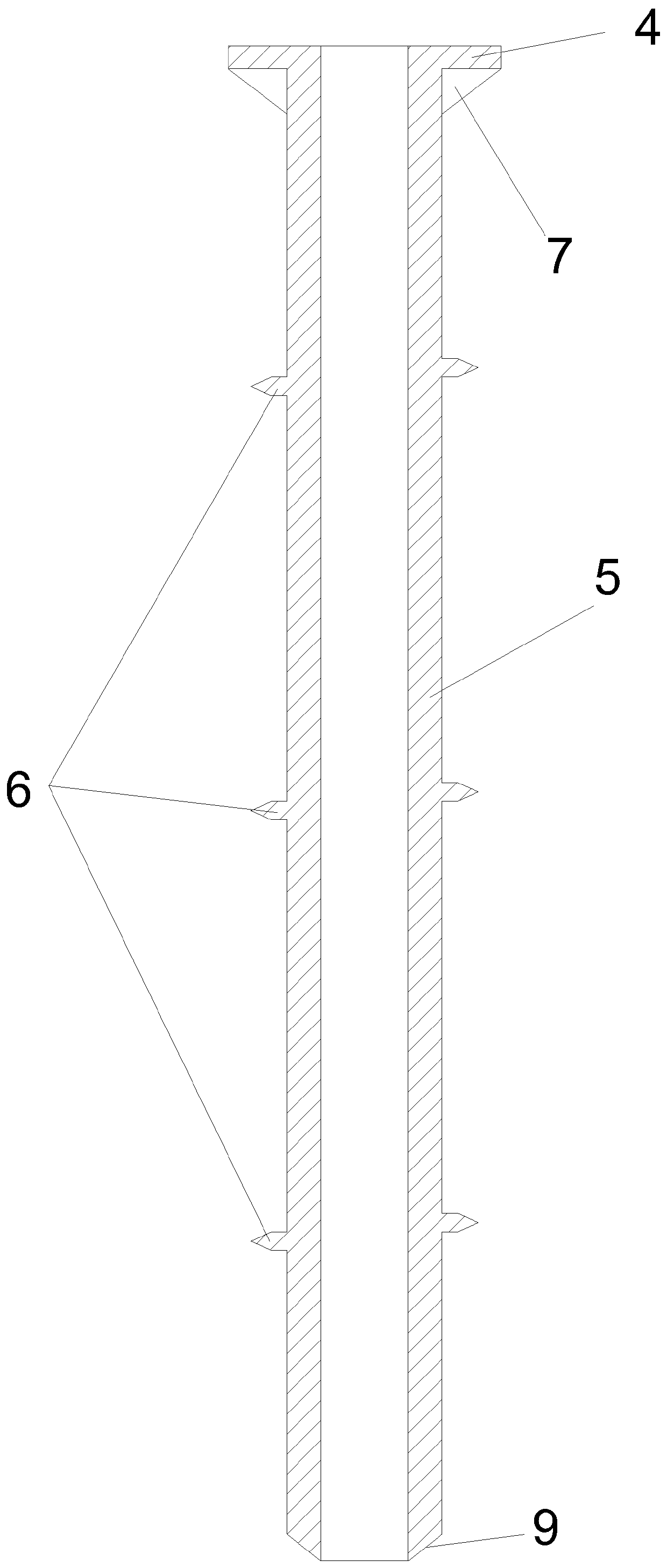

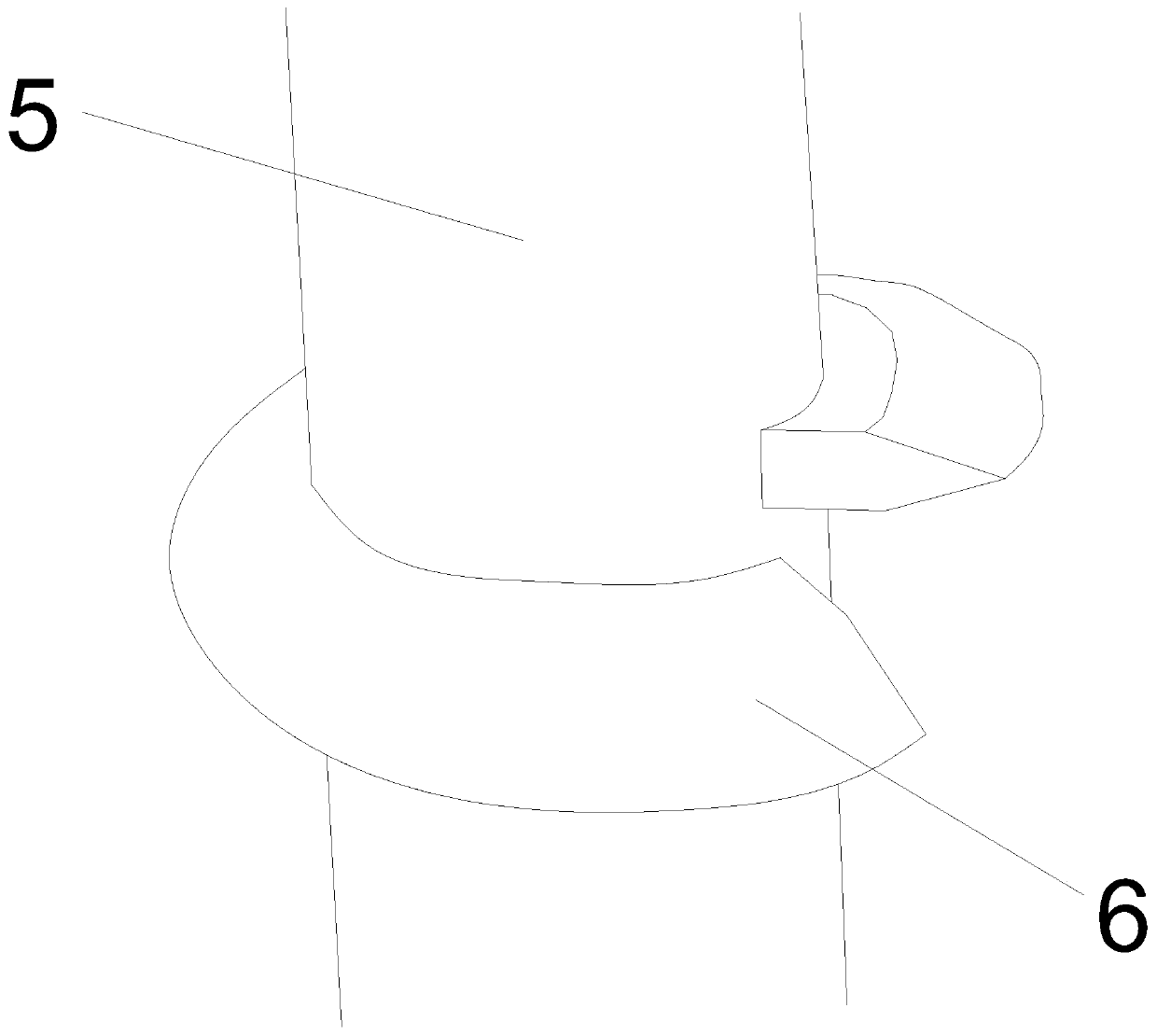

[0022] refer to figure 2 and image 3 The steel pipe spiral anchor 3 includes a steel pipe seat 4 and a steel pipe 5 fixed on the steel pipe seat 4, the steel pipe seat 4 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com