Blade pitch changing device of wind power generation device

A wind power generation device and pitch pitch technology, applied in wind power generation, wind turbine, wind turbine control, etc., can solve the problems of difficulty in maintaining the consistency of reliability and synchronization accuracy, many moving parts, and high probability of failure, etc. Achieve the effects of quickly adapting to complex wind changes, simplifying the blade pitch device, and reducing the cumulative error of node gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

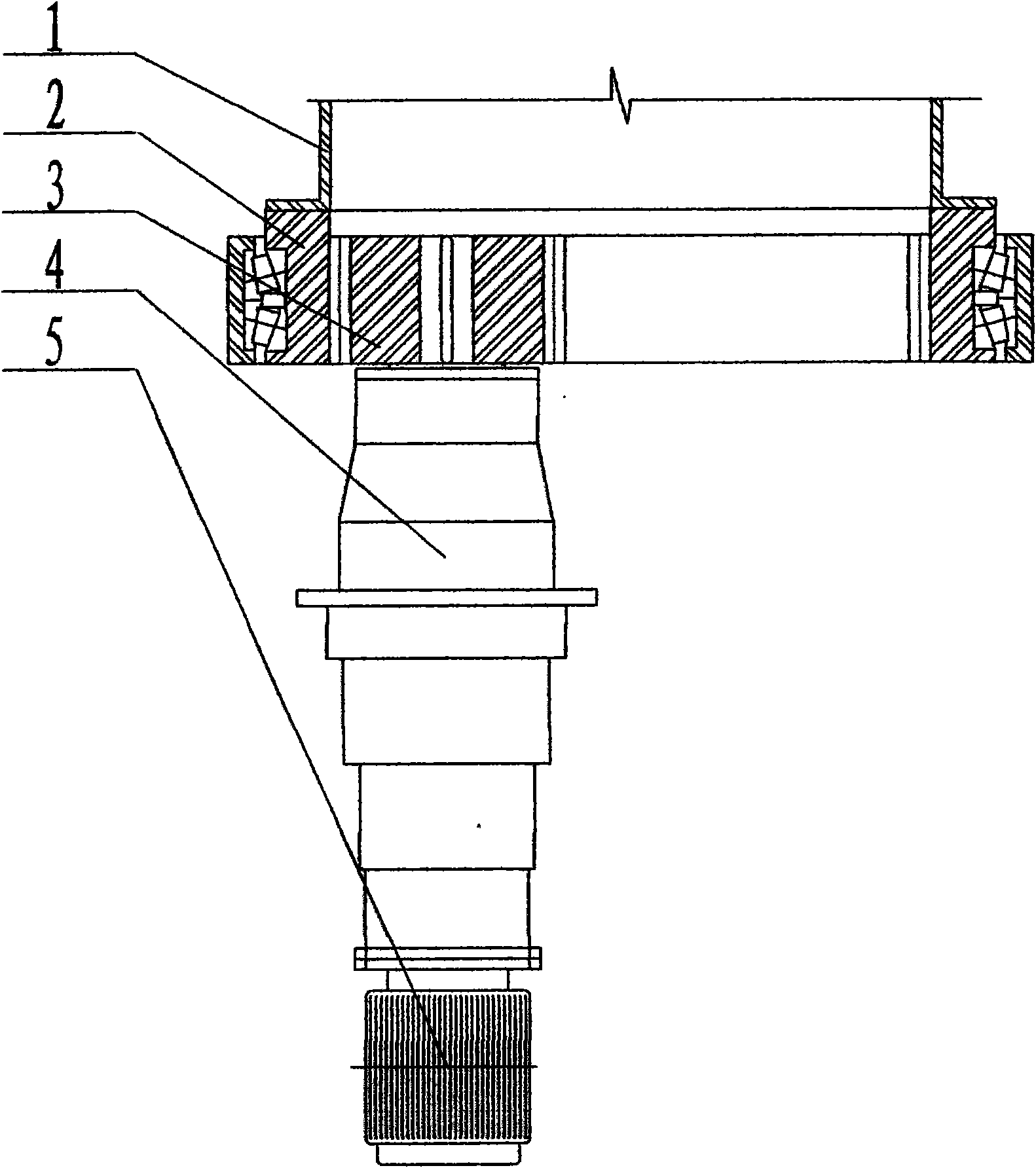

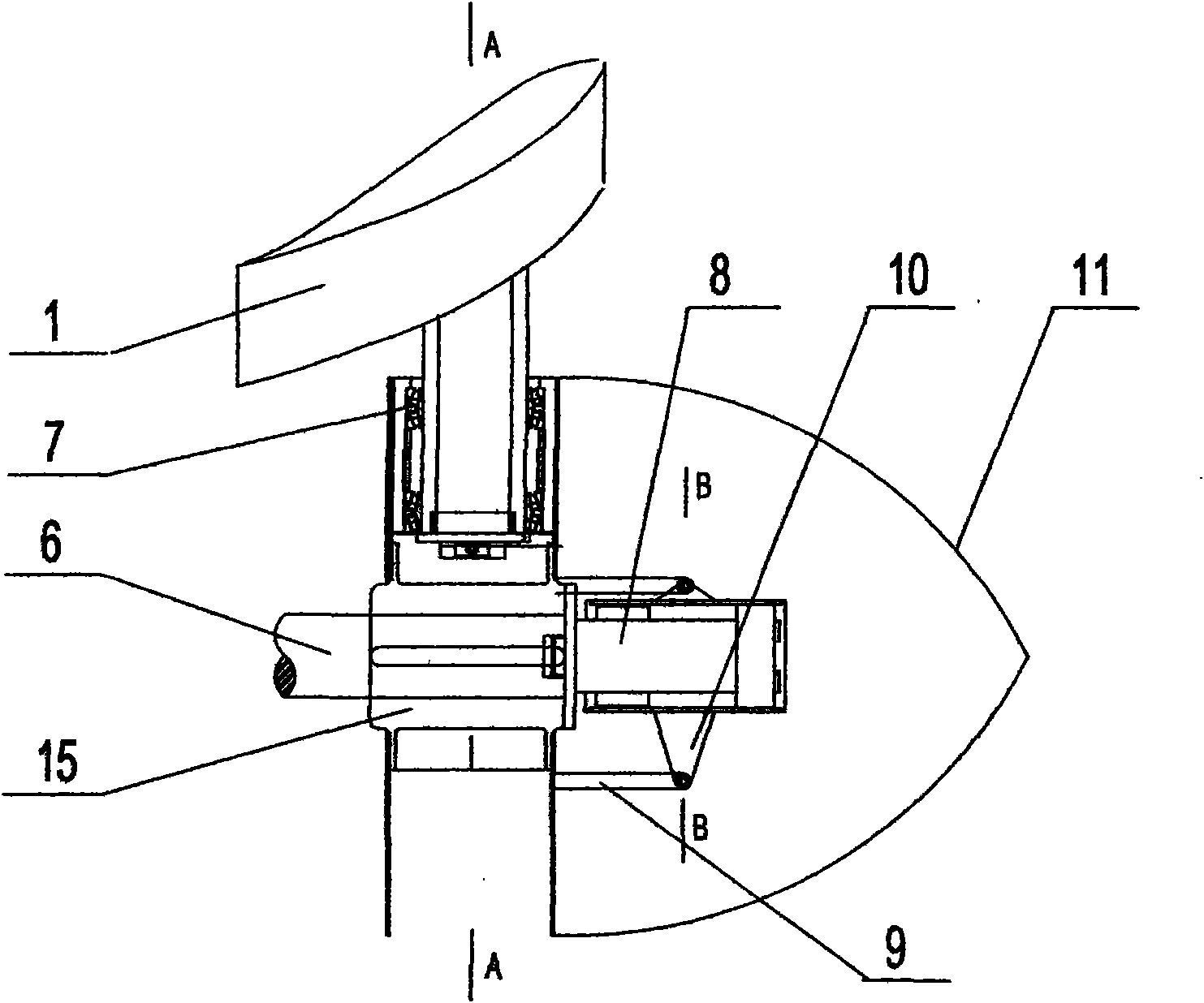

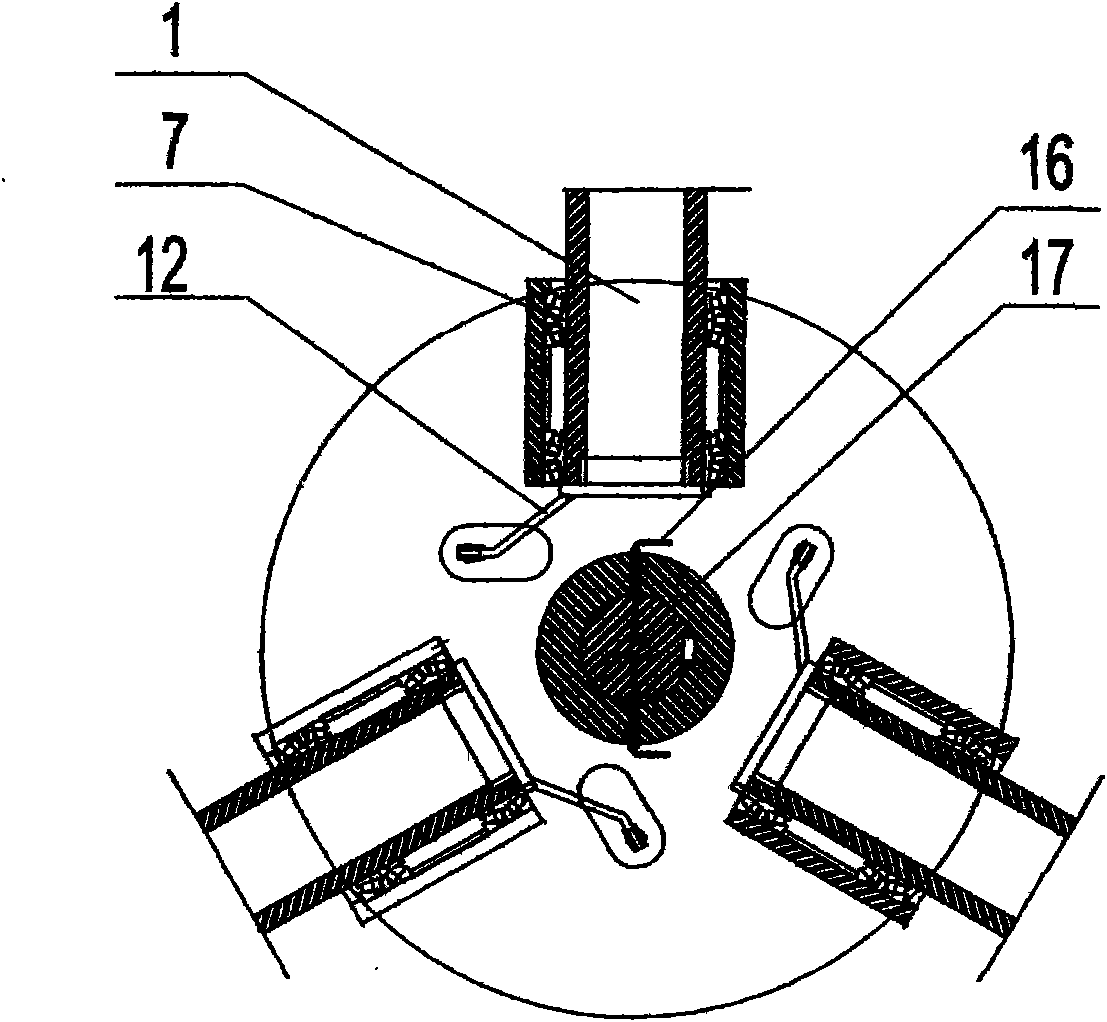

[0029] Embodiment 1: see Figure 2-6 , the piston rod of the oil cylinder 8 is fixed on the main shaft 6, so that the oil cylinder rotates with the main shaft. Each paddle 1 petiole root is fixed with a rocker bar 12, and the other end of the rocker bar is movably connected with a pull bar 9 parallel to the main shaft, and the two form a two-force bar link mechanism that drives the blade to rotate. There are left and right threaded joint bearings 13.1 and 13.2 at both ends of the tie rod 9, so that the axial length of the tie rod can be adjusted. After adjusting the length, use the nut and tighten it so that the axial length does not change again. The two joint bearings are respectively connected with the rocker arm rod 12 is flexibly connected with cylinder liner radially stretching out support arm 10. A shaft sleeve 15 is radially positioned on the main shaft 6 through a key, flange rings are provided at both ends of the shaft sleeve, on which are fixed parallel paddle moun...

Embodiment 2

[0031] Embodiment 2: As in Embodiment 1, a displacement sensor is provided on the hydraulic cylinder to detect and respond to the axial telescopic movement distance of the cylinder, and the detection data signal of the displacement sensor is output through the electric ring / brush.

Embodiment 3

[0032] Embodiment 3: see Figure 7 , as in embodiment 1, the paddle blade 1 wind wheel is arranged on the hollow shaft section 22, and the front section of the hollow shaft section 22 has an axially slidable sleeve 20 which is radially positioned by a linear bearing and a key. The radially extending support arms 18 (the embodiment is three) with the same distribution angle, between the radially extending supporting arms and the fixed rocker arm member 12 at the root of the paddle petiole, there are two ends that are movably connected (such as joint bearings) The pull rod 19, when the sleeve 20 moves axially, pulls the blade to deflect to adjust the angle of the blade. The axially moving telescopic power mechanism (for example, hydraulic cylinder 8) that drives the slurry adjustment is arranged at the rear of the wind wheel, fixed on the wind turbine support platform (fixed positioning), and the inner core (piston rod) extension rod 23 passes through The hollow shaft section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com