Layered composite hard metal stretching die

A cemented carbide, layered composite technology, applied in wire drawing dies, metal processing equipment, forming tools, etc., can solve the problems of easy cracking of mold cores, low efficiency, and difficult implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

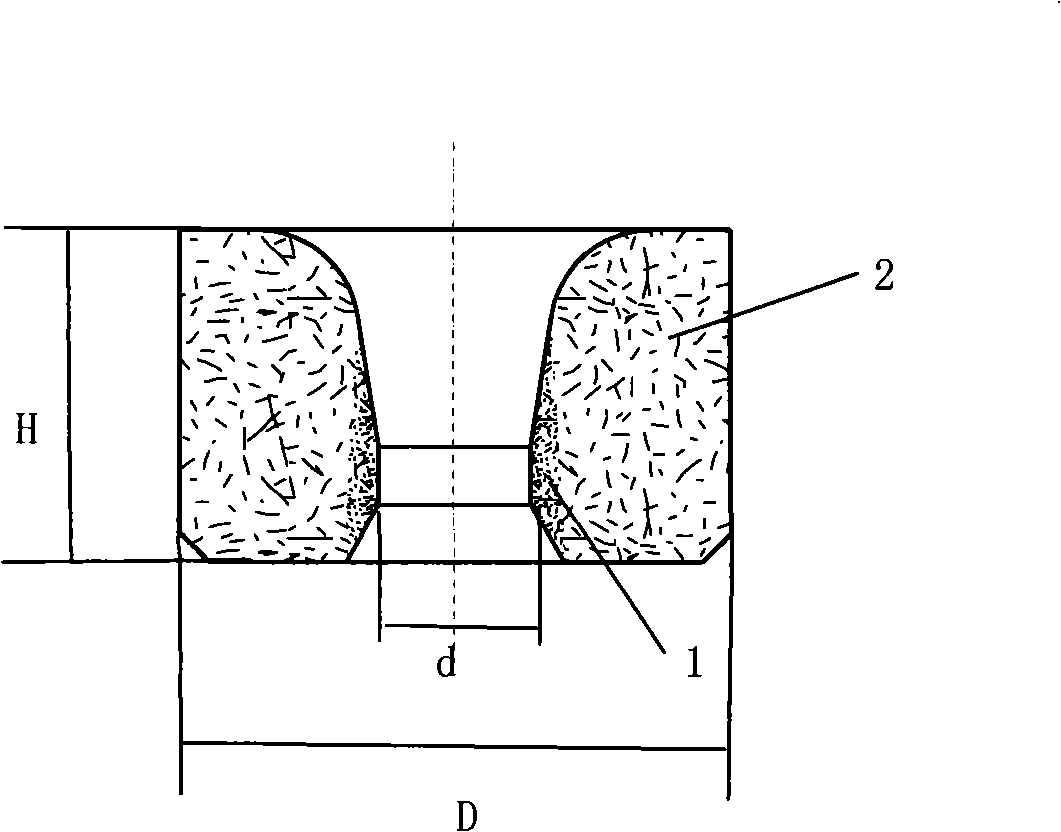

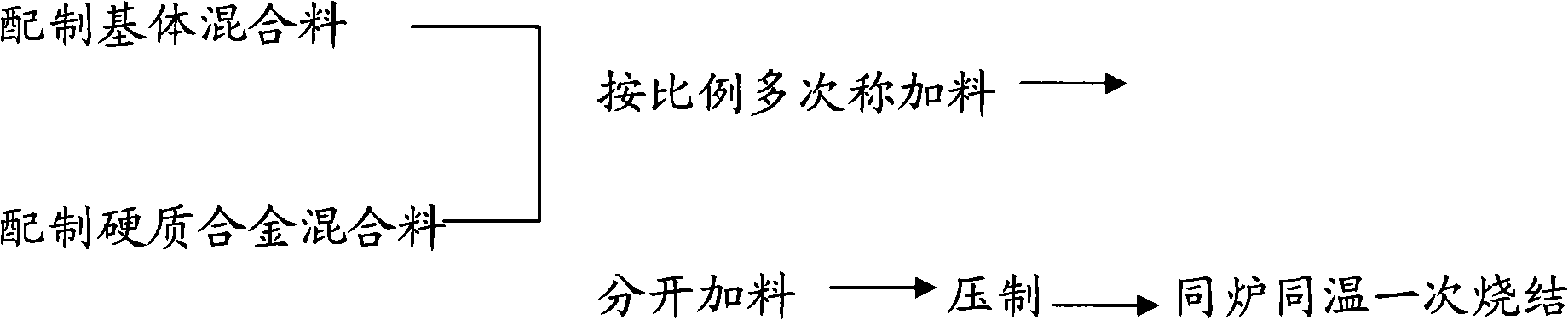

[0015] The implementation method takes the production of the cemented carbide part with the grade YG8 and the specification of 11-5.6-28 layered composite cemented carbide drawing die as an example:

[0016] A. Preparation of mixture: take a: TiC-WC / Ni composite: 75% / 25%; b: TiC / WC: 60% / 40%; c: Ni+Co / Mo: 85% / 15% as The basic composition of the layered composite cemented carbide drawing die is prepared, ball milled for 24 hours, and then unloaded, dried, mixed with glue according to the conventional cemented carbide production method, and the matrix mixture is prepared for use, while the working area and the sizing area The cemented carbide mixture used is prepared according to the corresponding YG8 brand process.

[0017] B. Determine the volume (or size) ratio and pressing conditions of the two-layer materials: the volume ratio of the substrate and the YG8 cemented carbide two-layer material is 15%, and the pressure test conditions are: substrate unit weight / YG8 cemented carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com