Assembled steel girder and power-transmission steel pipe pole structure assembly provided with same

An assembled, power transmission steel technology, which is applied in the testing of machines/structural components, measuring devices, testing of mechanical components, etc., can solve the problems of fixed bending resistance, non-reusable, and large limitations, and achieve the appearance Beautiful appearance, reduced single weight, and stable frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

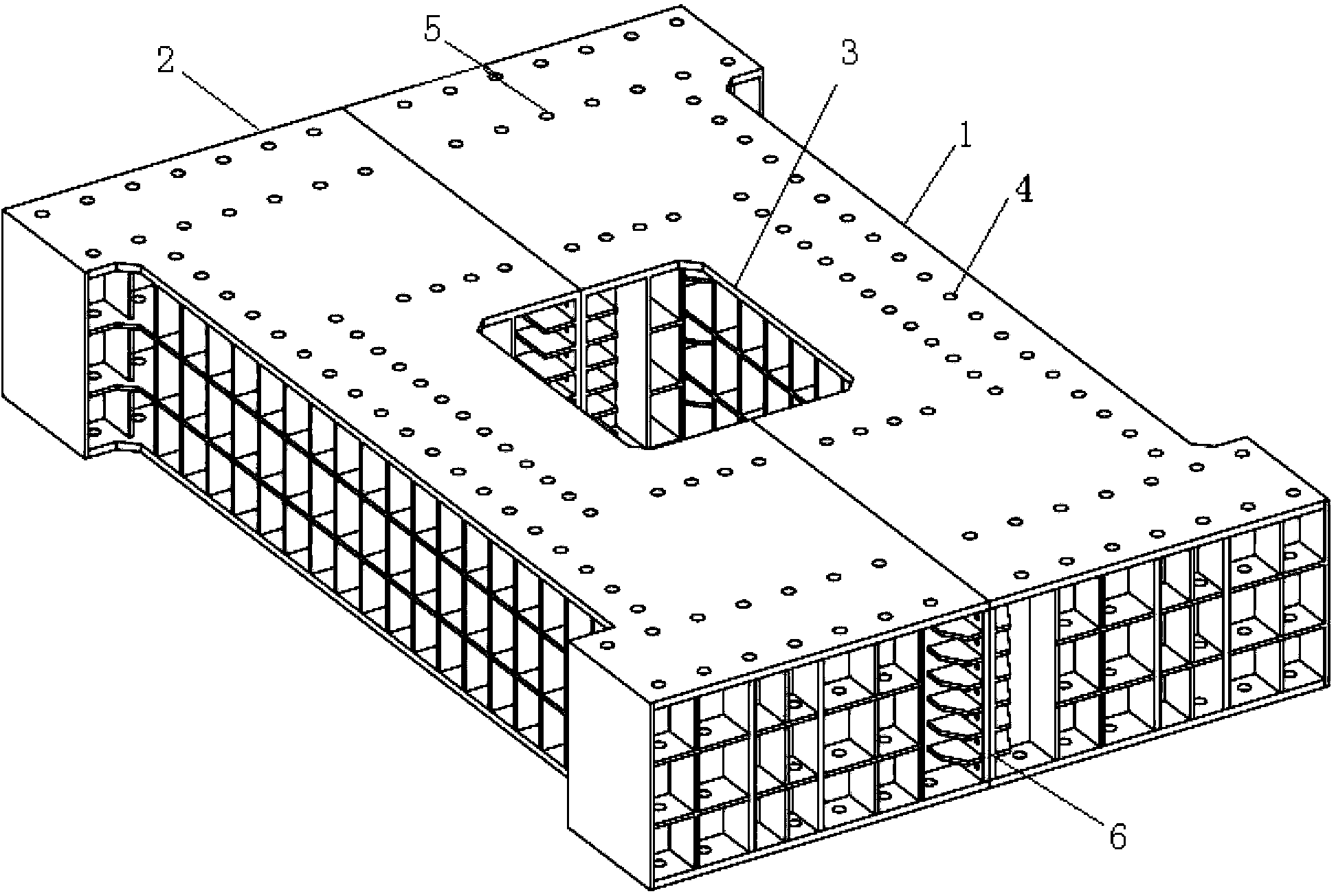

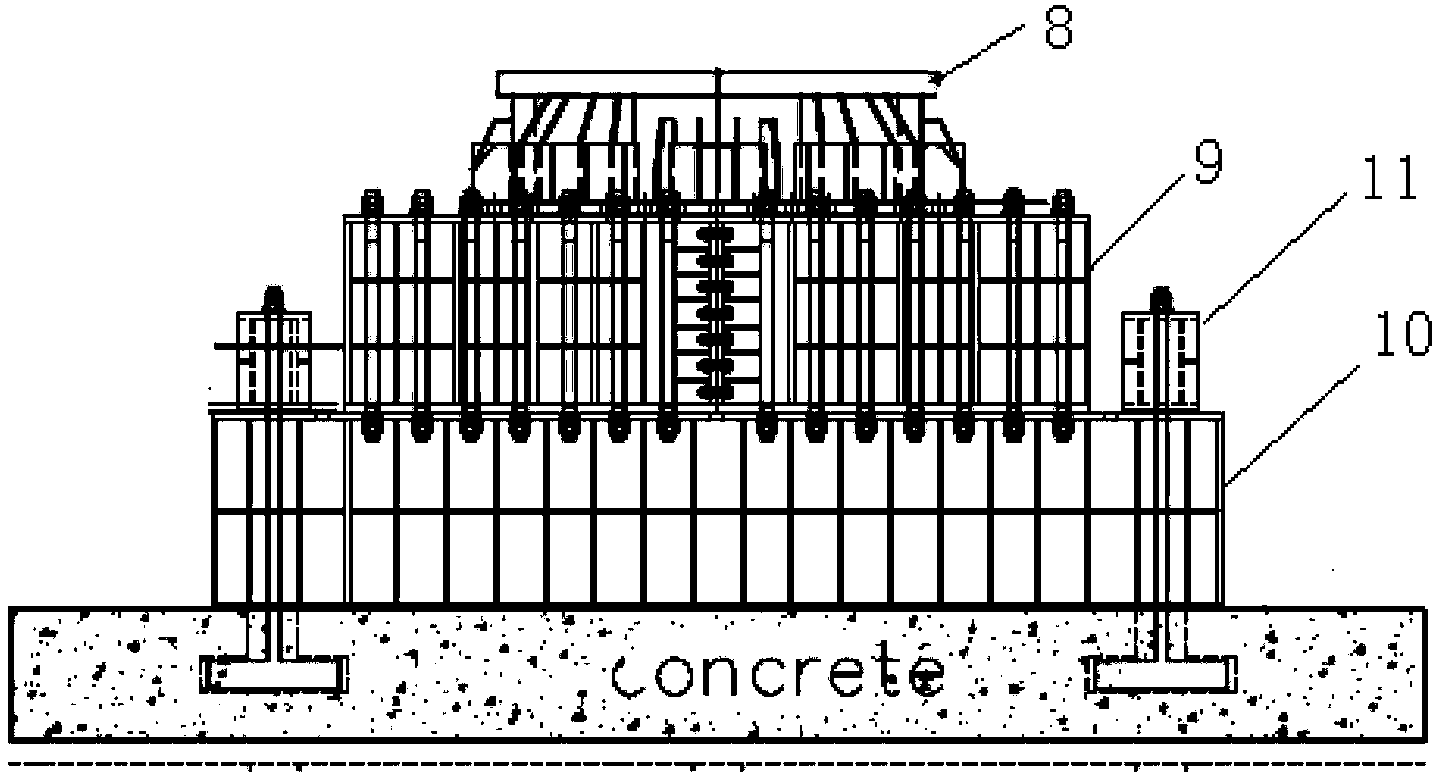

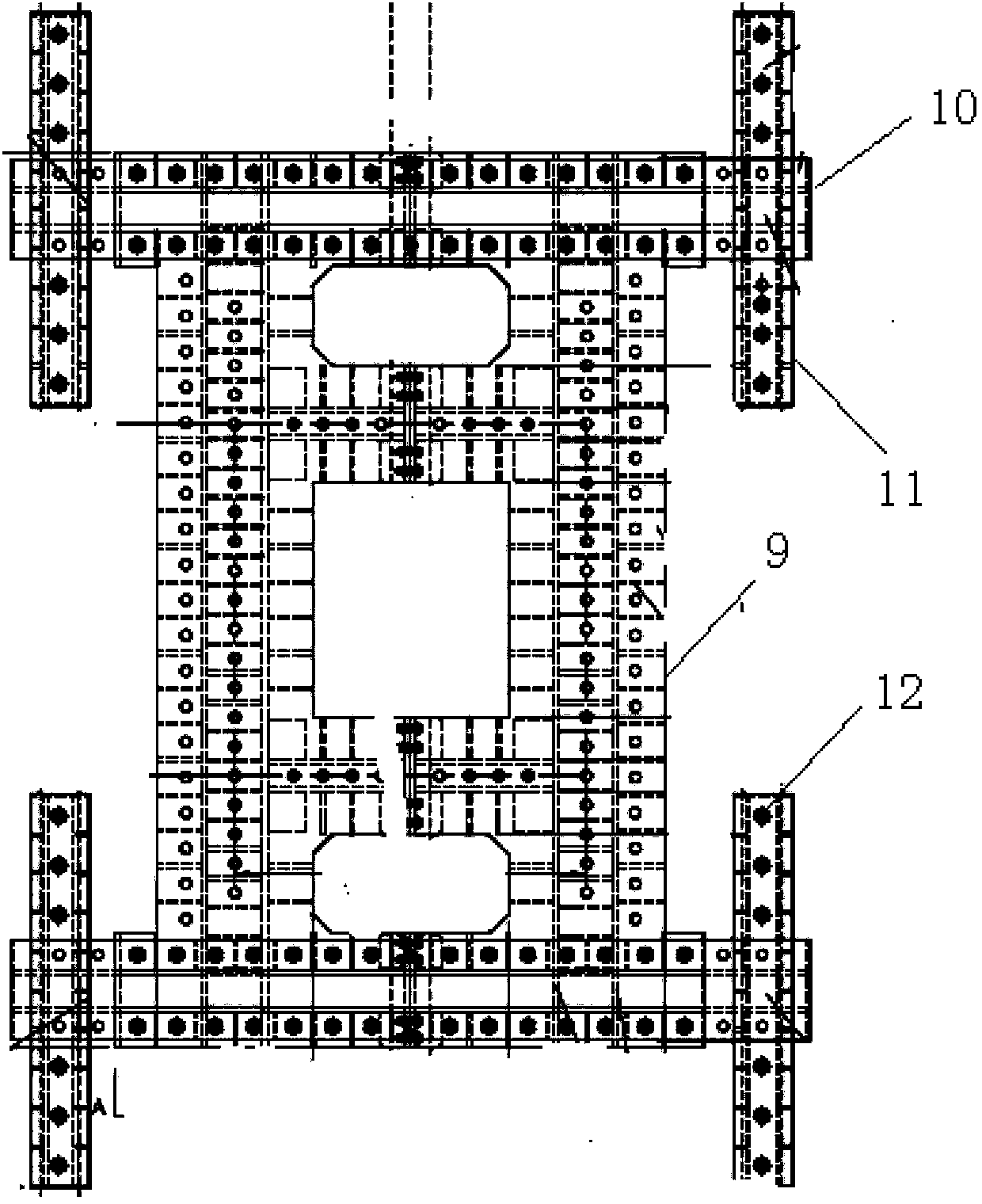

[0025] Such as figure 1 The embodiment shown is an assembled steel beam, including a steel beam body 1, the steel beam body 1 is 6870mm long, 4520mm wide, 1200mm high, and has a total weight of 56t; the steel beam body 1 consists of two mirrored frames on the left and right Frame body 2, which is divided into two along the midpoint of the length direction of the steel beam body 1. The frame body 2 weighs 28t, and baffle plates 6 are provided at both ends of the contact surfaces of the left and right frame body 2, and the baffle plate 6 is provided with bolt holes. , the bolts pass through the bolt holes to connect the left and right frames 2 into one body. When the steel beam is used, it can be hoisted to a predetermined position in blocks, and then connected with bolts; 2 is a frame surrounded by welded steel plates. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com