Conveying belt of aramid fiber high in wear resistance and high in bond strength

A conveyor belt, high wear-resistant technology, applied in the direction of non-polymer adhesive additives, conveyors, adhesive types, etc., can solve the problems of poor flex life, short service life, delamination, etc., and achieve grooving Good performance, good wear resistance, good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 A high wear-resistant and high-adhesion aramid conveyor belt and its preparation method

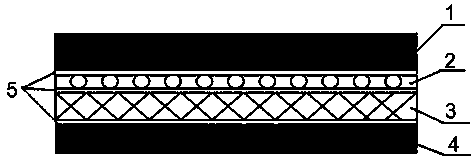

[0035] Such as figure 1 As shown, a high wear-resistant and high-adhesive aramid conveyor belt includes an aramid skeleton layer 3, a buffer layer 2, an upper cover rubber 1 and a lower cover rubber 4, and the upper cover rubber 1 and the lower cover rubber 4 are both high-resistant Grinding the cover rubber, the buffer layer 2 is between the upper cover rubber 1 and the aramid skeleton layer 3, the upper cover glue 1 and the buffer layer 2, the aramid skeleton layer 3 and the buffer layer 2, the aramid skeleton layer 3 and the lower cover rubber 4 All are bonded together by high adhesive core 5 glue.

[0036] in,

[0037] Cover rubber: 80 parts of natural rubber, 25 parts of butadiene rubber, 0.7 parts of vulcanizing agent, 6 parts of activator, 2 parts of stearic acid, 3 parts of accelerator, 4 parts of anti-aging agent, 53 parts of reinforcing agent carbon black, s...

Embodiment 2

[0048] Example 2 A high wear-resistant and high-adhesion aramid conveyor belt and its preparation method

[0049] Such as figure 1 As shown, a high wear-resistant and high-adhesive aramid conveyor belt includes an aramid skeleton layer 3, a buffer layer 2, an upper cover rubber 1 and a lower cover rubber 4, and the upper cover rubber 1 and the lower cover rubber 4 are both high-resistant Grinding the cover rubber, the buffer layer 2 is between the upper cover rubber 1 and the aramid skeleton layer 3, the upper cover glue 1 and the buffer layer 2, the aramid skeleton layer 3 and the buffer layer 2, the aramid skeleton layer 3 and the lower cover rubber 4 They are all bonded together by high adhesive core glue 5.

[0050] in,

[0051] Cover rubber: 60 parts of natural rubber, 3 parts of butadiene rubber, 0.5 parts of vulcanizing agent, 6 parts of activator, 1 part of stearic acid, 2.1 parts of accelerator, 3 parts of anti-aging agent, 46 parts of reinforcing agent carbon bla...

Embodiment 3

[0054] Example 3 A high wear-resistant and high-adhesion aramid conveyor belt and its preparation method

[0055] Such as figure 1 As shown, a high wear-resistant and high-adhesive aramid conveyor belt includes an aramid skeleton layer 3, a buffer layer 2, an upper cover rubber 1 and a lower cover rubber 4, and the upper cover rubber 1 and the lower cover rubber 4 are both high-resistant Grinding the cover rubber, the buffer layer 2 is between the upper cover rubber 1 and the aramid skeleton layer 3, the upper cover glue 1 and the buffer layer 2, the aramid skeleton layer 3 and the buffer layer 2, the aramid skeleton layer 3 and the lower cover rubber 4 They are all bonded together by high adhesive core glue 5.

[0056] in,

[0057] Cover rubber: 95 parts of natural rubber, 20 parts of butadiene rubber, 0.8 parts of sulfur, 9 parts of zinc oxide, 3 parts of stearic acid, 3 parts of Qiulan mother accelerator, and the mass composition ratio of 1:1 anti-aging agent 4010NA and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com