Composition capable of improving stability of hydrate and storage and transportation method based on solid hydrate

A composition and hydrate technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of limited decomposition inhibition effect and inability to meet the long-term atmospheric pressure storage and transportation requirements, so as to increase the formation rate and improve mechanical stability sex, the effect of inhibiting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] The formulation of the composite phase change material is: the PEG400 (6.0 ° C melting point), the nanometer graphite and bentonite are compared to the mass ratio of 1: 5: 0.05.

[0098] The preparation method of composite phase change materials is as follows:

[0099] (1) The PEG400 is accurately weighed, and it is configured with ethanol (75% by volume) to a PEG400 alcohol solution having a mass concentration of 5%;

[0100] (2) Dry nanometer graphite under 120 ° C, remove impurities inside the material to prepare nano graphite;

[0101] (3) Accurate weighing pretreatment nano graphite, bentonite is added to the alcohol solution obtained in step (1) in a stirred state, and after impregnating 8 h, drying 8 h is dried under 8 h to obtain a composite phase change material.

[0102] The formulation of the hydrate accelerator is that the hydrate promoter is configured by tetrabutylammonium bromide and leucine according to the mass ratio 2: 1.

[0103] A composition capable of ...

Embodiment 2

[0119] Method based on solid hydrate storage:

[0120] (1) Hydrate production process:

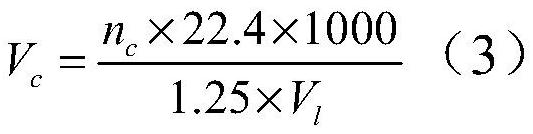

[0121] The total amount of the hydrate accelerator, the composite phase change material, and the rats, and the rats of the rats are 1.5% of the water content (i.e., the mass ratio of the aqueous phase and the support material is 2.6: 1), and the present embodiment is obtained. A composition capable of improving hydrate stability is added to a high pressure reactor containing water, and evacuates the remaining impurity gas in the kettle; set the hydrate to prepare the temperature of 278.65K to reach the reaction temperature and remain stable for 2h. The pre-treated gas passes into the high pressure reactor to the experimental pressure 8.0 MPa, and the reaction process is enhanced by magnetic stirring, and the stirring rate is set to 60R / min;

[0122] When the hydrate production in the high pressure reactor is monitored. When the white hydrate particles are present in the system, the time to b...

Embodiment 3

[0132] Method based on solid hydrate storage:

[0133] (1) Hydrate production process:

[0134] The total amount of the hydrate accelerator, the composite phase change material, and the rats, and the rats of the rats are 1.5% of the water content (i.e., the mass ratio of the aqueous phase and the support material is 2.6: 1), and the present embodiment is obtained. A composition capable of improving hydrate stability is added to a high pressure reactor containing water, and evacuates the remaining impurity gas in the kettle; set the hydrate to prepare the temperature of 278.65K to reach the reaction temperature and remain stable for 2h. The pre-treated gas passes into the high pressure reactor to the experimental pressure 8.0 MPa, and the reaction process is enhanced by magnetic stirring, and the stirring rate is set to 60R / min;

[0135] When the hydrate production in the high pressure reactor is monitored. When the white hydrate particles are present in the system, the time to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Cell diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com