Drawing method for aluminum plate part

A technology for parts and aluminum plates, which is applied in the field of stamping dies for automotive panels, can solve problems such as prolonging the time for customer negotiation and communication, and achieve the effects of avoiding wrinkling and cracking, improving the pass rate, and reducing thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

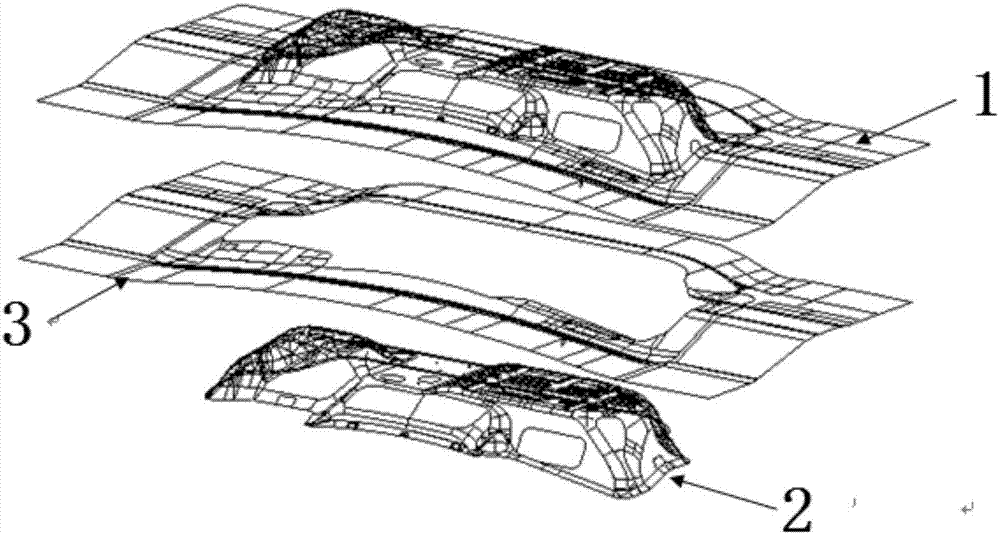

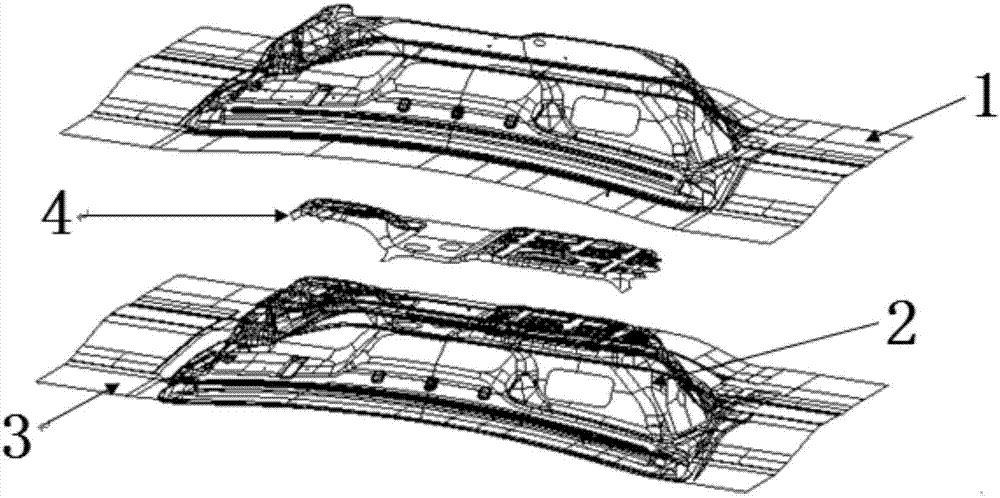

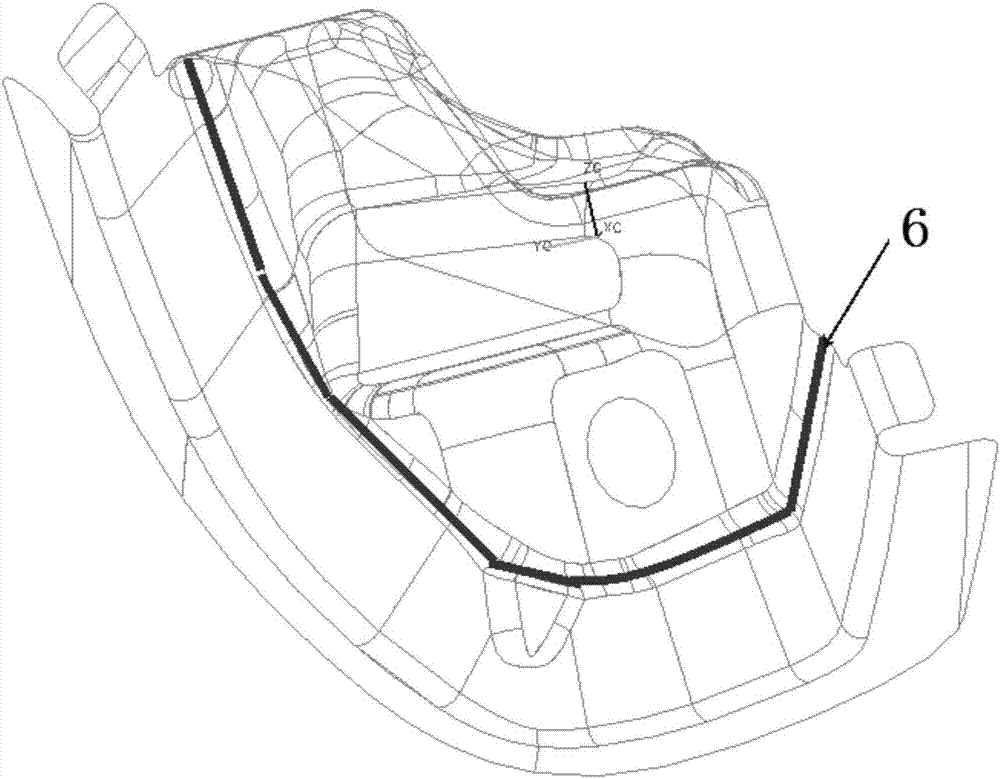

[0041] Embodiment 1: as Figure 5 As shown, the area within the first-order drawing boundary line 5 of the part 1 is the first-order drawing area, and the area between the second-order drawing boundary line 7 of the part 1 and the first-order drawing boundary line 5 of the part 1 is the area of the part 1 In the second-order drawing area, the thinning of the first-order drawing is set to 15%, the wrinkle coefficient is 2, the thinning rate of the second-order drawing is set to 13%, the wrinkle coefficient is 2, and the qualified rate of the product after forming is 98%. Above, the pass rate of the previous drawing was about 75%, which increased the pass rate by more than 20%.

Embodiment 2

[0042] Embodiment 2: as Figure 6 As shown, the area within the first-order drawing boundary line 8 of the part 2 is the first-order drawing area, and the area between the second-order drawing boundary line 9 of the part 2 and the first-order drawing boundary line 8 of the part 2 is the area of the part 2 In the second-order drawing area, the thinning of the first-order drawing is set to 14%, the wrinkle rate is set to 2.8, the thinning rate of the second-order drawing is set to 13%, the wrinkle coefficient is 3, and the pass rate of the product after forming is 98. % or more, the pass rate of the previous sequence drawing was about 75%, which increased the pass rate by more than 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com