Enhanced foam system based on graphite particle synergistic stability, and preparation method thereof

A graphite particle and foam system technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex and changeable composition, difficult to control the effect, etc., to achieve delayed thinning, easy extraction, and improved recovery Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

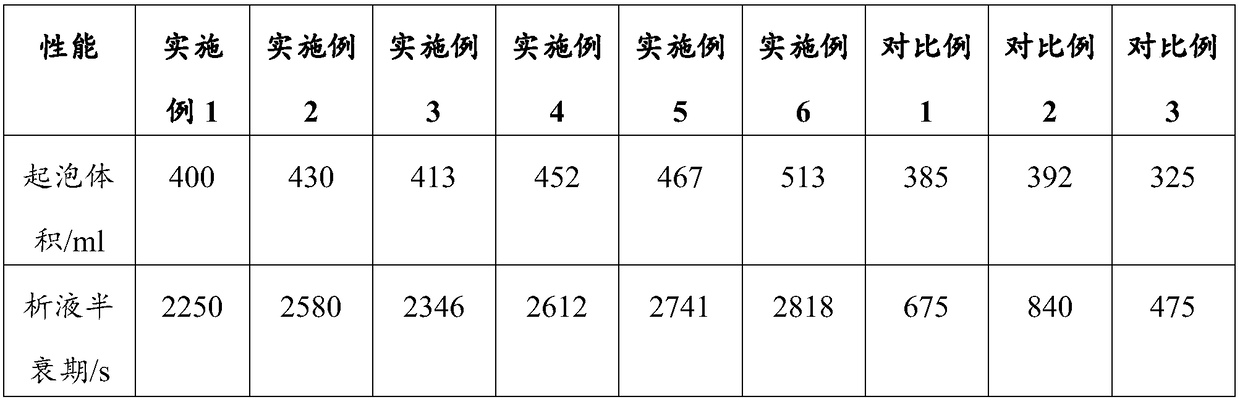

Examples

Embodiment 1

[0029] A reinforced foam system based on synergistic stabilization of graphite particles, made of the following components in mass concentration percentages: sodium lauryl sulfate 0.6%, cetyltrimethylammonium bromide 0.4%, 200 mesh flake graphite particles 1% , make up to 100% with water.

[0030] A method for preparing a strengthened foam system based on the synergistic stabilization of graphite particles, comprising:

[0031] Step 1: Prepare 500ml of sodium lauryl sulfate aqueous solution with a mass concentration of 0.6%, add 5g of 200-mesh flake graphite particles to the solution, and disperse for 2 hours with an ultrasonic power of 500W;

[0032] Step 2: centrifuge the solution obtained in step 1 at 1500 g for 15 min, and take 100 ml of the upper graphite dispersion;

[0033] Step 3: Add 0.4 g of cetyltrimethylammonium bromide to 100 ml of graphite dispersion, stir magnetically for 1 hour, and let stand to obtain a foaming liquid;

[0034] Step 4: Stir at 8000 rpm for 3...

Embodiment 2

[0036] A reinforced foam system based on synergistic stabilization of graphite particles, made of the following components in mass concentration percentages: sodium lauryl sulfate 0.6%, cetyltrimethylammonium bromide 0.4%, 200 mesh flake graphite particles 1% , make up to 100% with water.

[0037] The preparation method of the enhanced foam system based on the synergistic stabilization of graphite particles is the same as that of Example 1 except that nitrogen is used as the gas source during the stirring process using the Waring Blender method.

Embodiment 3

[0039] The reinforced foam system based on the synergistic stability of graphite particles is made of the following components in mass concentration percentages: fatty alcohol ether sodium sulfate 0.7%, cetyltrimethylammonium bromide 0.5%, 200 mesh flake graphite particles 1%, Water topped up to 100%.

[0040] The preparation method of the enhanced foam system based on the synergistic stabilization of graphite particles is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com