Edge drop control method of cold-rolled non-oriented silicon steel

A control method and technology for oriented silicon steel, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of low control accuracy of strip transverse thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

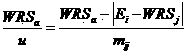

[0058] Such as figure 1 As shown, the position of the existing specific point is selected at 15mm from the edge, and the position of the reference point is selected at 115mm from the edge. Taking electrical steel with a thickness of 0.5mm rolled by a 1500mm UCMW rolling mill in a cold-rolled silicon steel plant as an example, the strip width is 1250mm, and the edge drop value is known EH =125μm, the distance from the edge drop start point to the strip edge is 40mm. Single side taper roller taper design such as image 3 As shown, the difference between the roll flattening amount of the taper part and the roll flattening amount of the roll body part PV =0-20μm, the taper of the Taper roller can be calculated according to the formula:

[0059]

[0060] According to the strip width SW=1250mm, the distance TSP=[1500-1250+2(EW+10)] / 2=175mm from the taper starting position to the edge of the roll can be determined.

[0061] In order to effectively evaluate the effect of edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com