Preparation method of silane crosslinked ethylene-vinyl acetate copolymer adhesive film

A technology of ethylene vinyl acetate copolymer glue and ethylene vinyl acetate, applied in the direction of graft polymer adhesives, adhesives, film/sheet adhesives, etc., can solve the problem of affecting product quality, low production efficiency, and easy production Problems such as rubber materials, to achieve the effect of shortening lamination time, improving production efficiency, and improving lamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

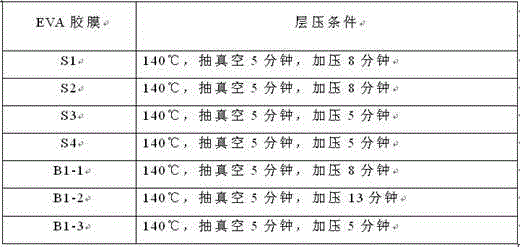

[0044] 100 parts (parts by mass) of EVA copolymer [VA content 28%, melt index (MI) of 25 g / 10 minutes (190°C, 2.16 kg), differential scanning calorimetry (DSC) melting point of 70°C, Vicat The softening point is 42°C, add 1 part of silane coupling agent A: vinyltrimethoxysilane (Dow Corning, 6300), 1 part of silane coupling agent B: γ-methyl Acryloyloxypropyltrimethoxysilane (Dow Corning, 6030), 0.1 parts Organic peroxide: bis(tert-butylperoxyisopropyl)benzene (AkzoNobel, Perkadox 14s-fl), 0.2 parts UV Light absorber: 2-hydroxy-4-n-octyloxybenzophenone (Beijing Institute of Addition Auxiliaries, GW531), 0.1 parts Light stabilizer: bis(2,2,6,6-tetramethyl- 4-piperidinyl) sebacate (Beijing Institute of Addition Auxiliaries, GW480), mix all the raw materials evenly, put them into a single-screw extruder to melt and extrude, the processing temperature is 100 ° C, and then cast, Cooling, traction, coiling and other processes to obtain the EVA film S1, the thickness of the film is ...

Embodiment 2

[0047] Add 2 parts of silane coupling agent A vinyltriethoxysilane (Dow Corning, 6518), 1 part of silane coupling agent B6030, 0.2 parts of organic peroxide to 100 parts of EVA copolymer 2825 (VA content 28%) Bis(tert-butylperoxycumyl)benzene, 0.2 part UV absorber 2-hydroxy-4-n-octyloxybenzophenone, 0.1 part light stabilizer bis(2,2,6,6-tetra Methyl-4-piperidinyl) sebacate, mix all raw materials evenly, put them into a single-screw extruder to melt and extrude, the processing temperature is 100°C, and then go through casting, cooling, pulling, coiling and other processes , to obtain the EVA film S2, the film thickness is 0.5mm.

[0048] The obtained EVA film is used as an encapsulation film to prepare a solar cell module. The upper layer is a glass substrate with a thickness of 3mm, the middle layer is a battery sheet, the lower layer is a fluorine-containing material backsheet with a thickness of 0.33mm, and an EVA film is placed between the glass and the battery sheet. , Th...

Embodiment 3

[0050] 100 parts of EVA copolymer [VA content 18%, melt index (MI) is 2.5 g / 10 minutes (190 ° C, 2.16 kg), differential scanning calorimetry (DSC) melting point is 88 ° C, Vicat softening point is 64 ℃, American DuPont Company, 460], add 1 part of silane coupling agent A vinyltrimethoxysilane 6300, 1 part of silane coupling agent Bγ-methacryloxypropyl trimethoxysilane 6030, 0.1 part of organic peroxide Oxide 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (AkzoNobel, TRIGONOX 101), 0.2 parts UV absorber 2-hydroxy-4-n-octyloxydi Benzophenone, 0.1 part of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, mix all raw materials evenly, add to single-screw extruder to melt and extrude , the processing temperature is 150°C, and then through the processes of casting, cooling, pulling, coiling, etc., the EVA film S3 is obtained, and the thickness of the film is 0.5mm.

[0051] The obtained EVA film is used as an encapsulation film to prepare a solar cell module. The uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com