Semiconductor device

A semiconductor and conductive type technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of switching characteristics, increase in charge and discharge time, increase in switching loss, etc., to improve the on-voltage, inhibit the The effect of increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

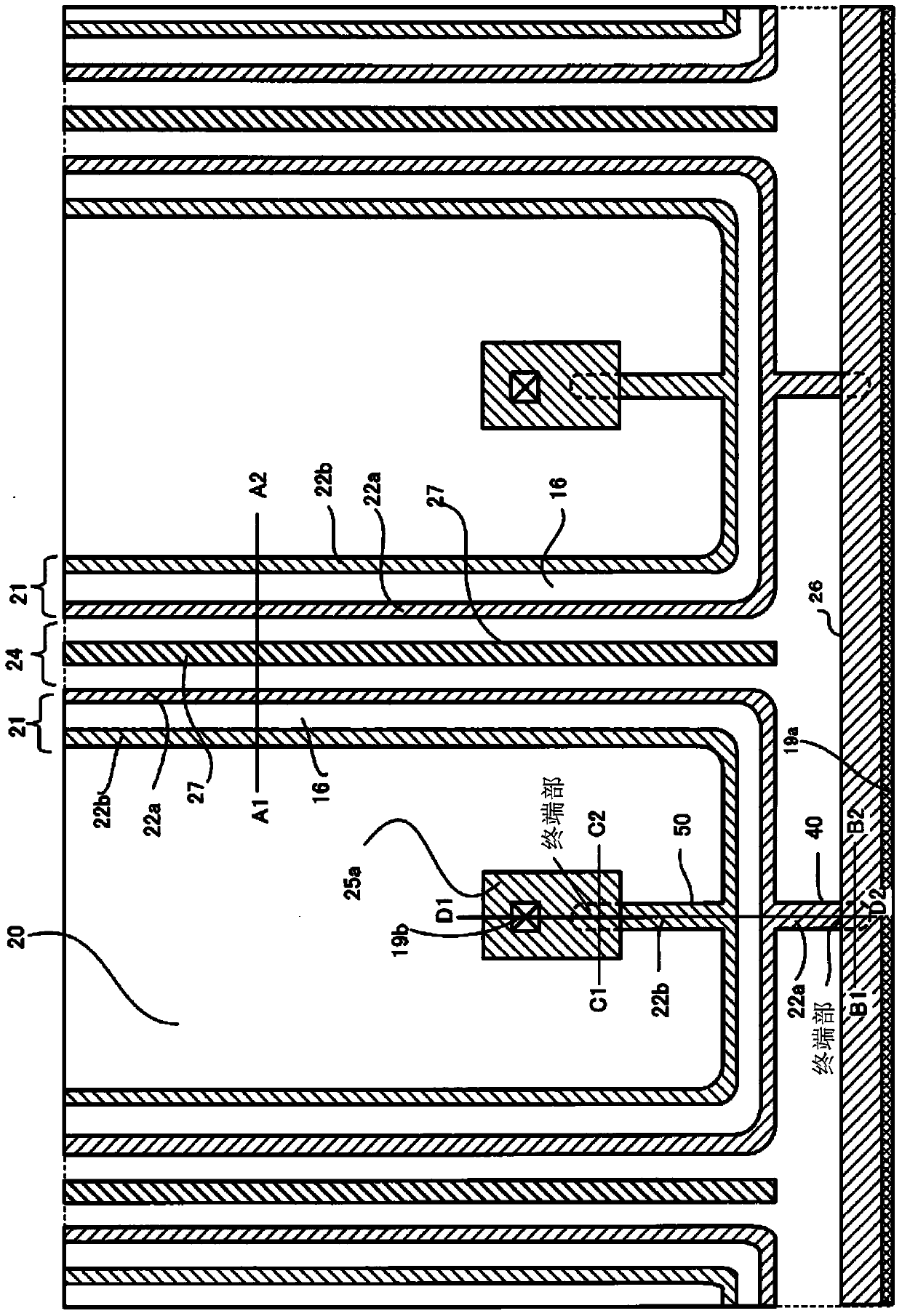

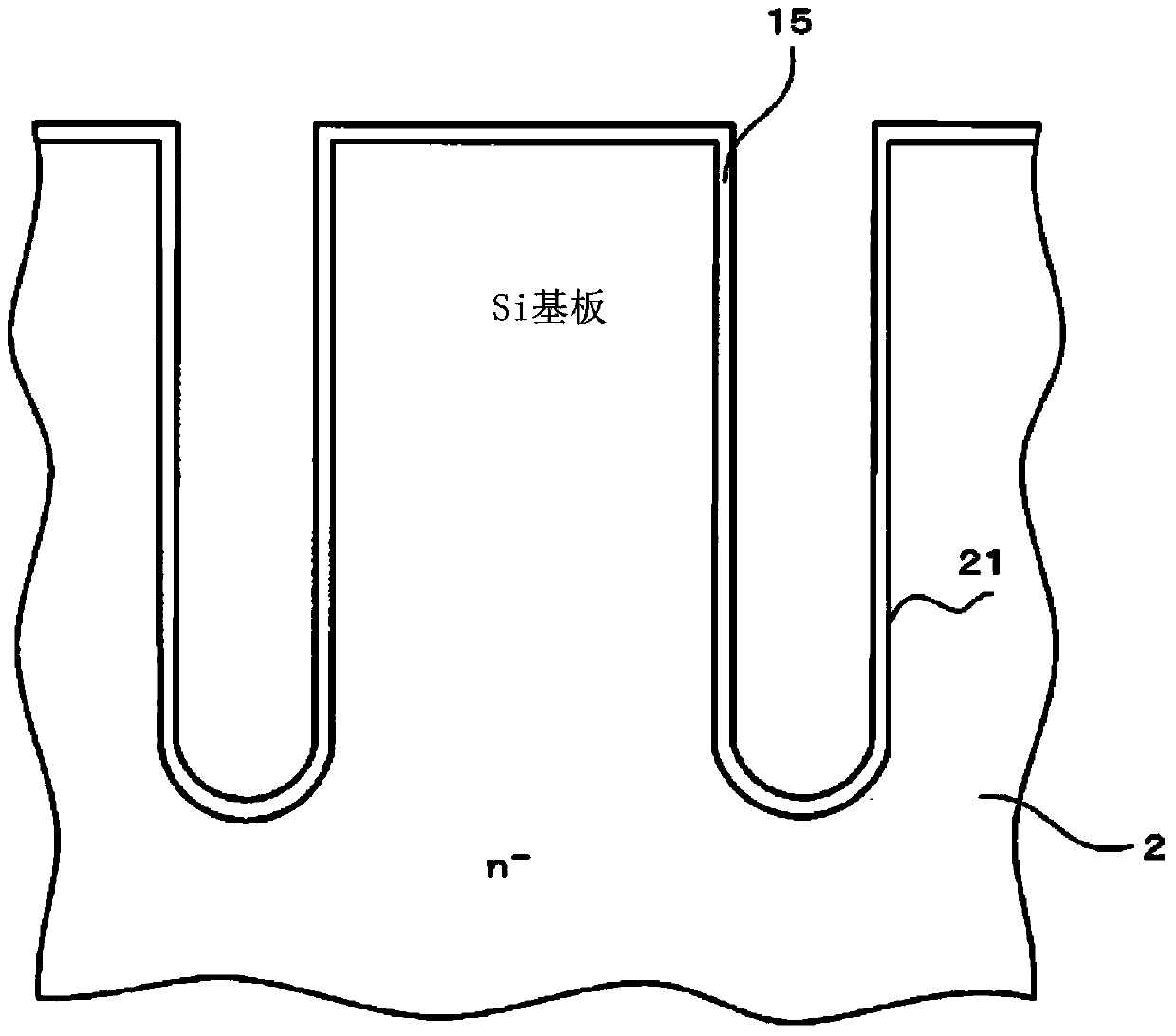

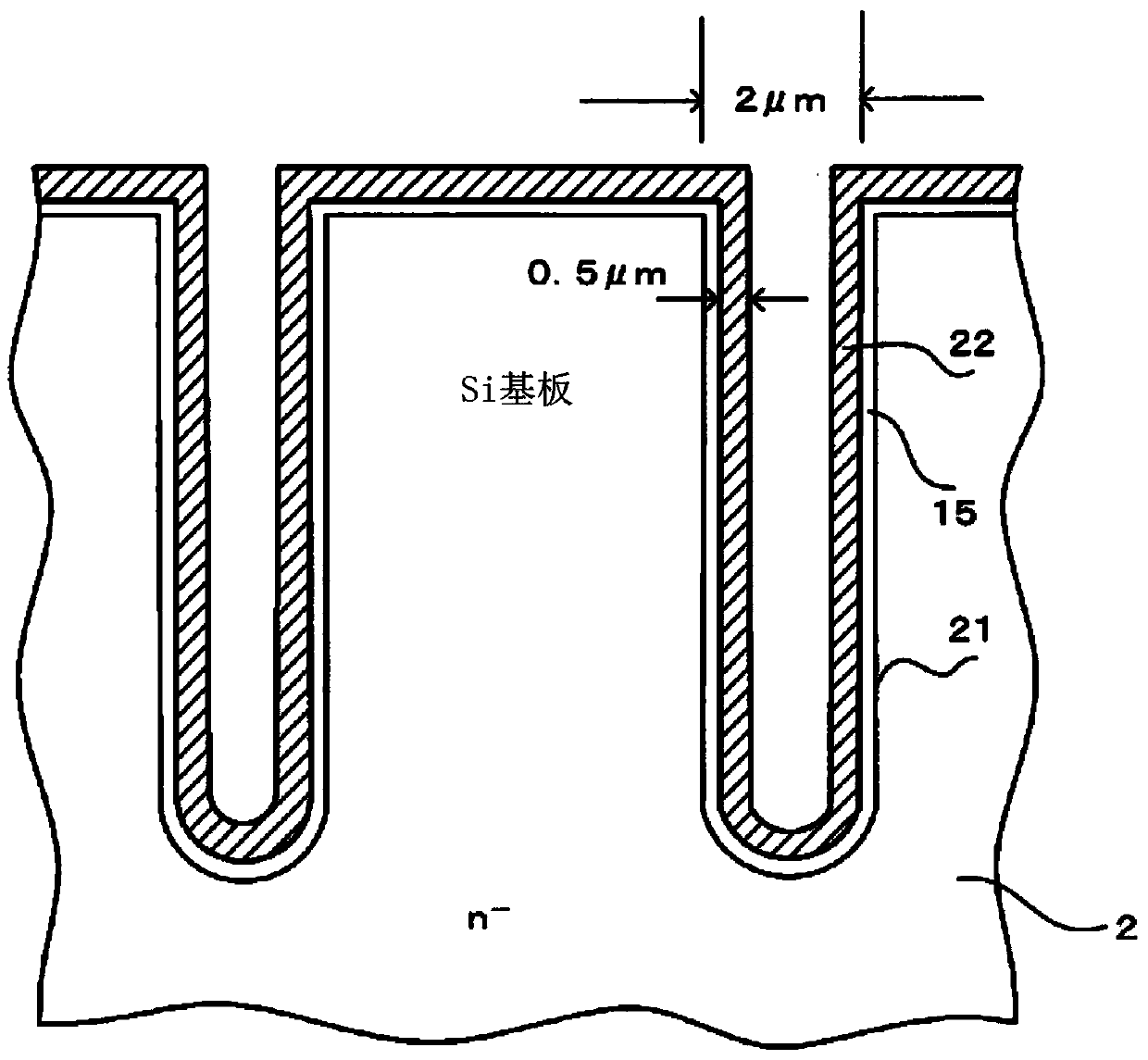

[0087] The configuration of the semiconductor device according to Embodiment 1 will be described. figure 1 It is a plan view showing the planar layout of the main part of the semiconductor device according to the first embodiment. Figure 9 yes means figure 1 A cross-sectional view of the cross-sectional structure at cutting line A1-A2. Figure 10 yes means figure 1 Cross-sectional views of the respective cross-sectional structures at cutting lines B1-B2 and C1-C2. Figure 11 yes means figure 1 A cross-sectional view of the cross-sectional structure at cutting line D1-D2. First, the planar layout of the semiconductor device according to Embodiment 1 will be described. The semiconductor device according to Embodiment 1 includes an active region through which current flows in an on state and a relaxation n - The electric field on the front side of the silicon substrate of the drift layer maintains the withstand voltage region. The voltage-resistant region surrounds th...

Embodiment approach 2

[0124] Next, the configuration of the semiconductor device according to Embodiment 2 will be described. Figure 12 It is a plan view showing the planar layout of the main part of the semiconductor device according to the second embodiment. The semiconductor device according to the second embodiment differs from the semiconductor device according to the first embodiment in the planar shapes of the second trench 40 and the third trench 50 . Specifically, as Figure 12 As shown, the second trench 40 has a substantially U-shaped planar shape, and both ends thereof are connected to the outer sidewalls of the first trench 21 . That is, a substantially rectangular annular planar shape is formed by the second groove 40 and a part of the first groove 21 . The second groove 40 may be formed so that both ends thereof are connected to the outer side walls of the first groove 21 and form a substantially rectangular annular planar shape together with the first groove 21, and is not limite...

Embodiment approach 3

[0131] Figure 14 It is a plan view showing the planar layout of the main part of the semiconductor device according to the third embodiment. The semiconductor device of Embodiment 3 differs from the semiconductor device of Embodiment 1 in the number of second trenches 40 relative to one third trench 50 and the positions where the second trenches 40 are arranged. Specifically, in Embodiment 1, the second groove 40 and the third groove 50 are arranged to face each other with the first groove 21 interposed therebetween. More specifically, the second groove 40 and the third groove 50 are arranged on the same straight line crossing the first groove 21 . In contrast, in Embodiment 3, as Figure 14 As shown, two second grooves 40 are arranged relative to one third groove 50 , and the second groove 40 and the third groove 50 are alternately arranged with the first groove 21 placed in the middle. More specifically, for example, a plurality of second trenches 40 are provided with re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com